rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

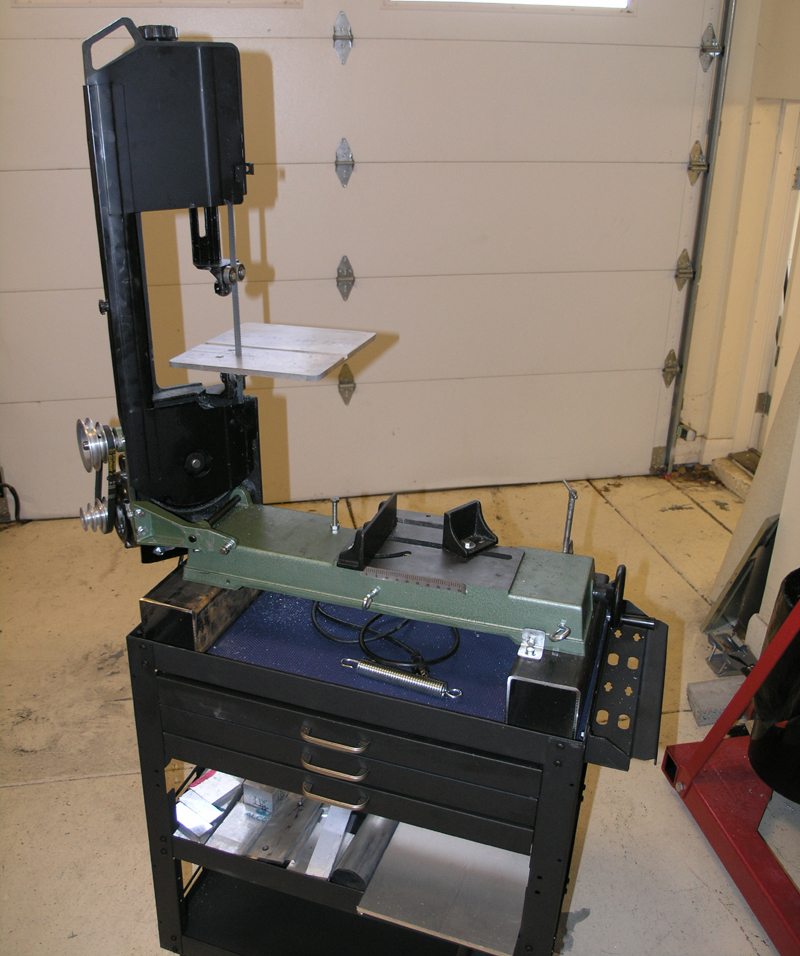

They are tough little saws for the cost.

This was my first one.

It was 20 years old when I bought it 2ed hand for $25 from a

classified ad. I bought a new one last year and gave the old one

to my brother-in-law. He's still using it.

Rick

This was my first one.

It was 20 years old when I bought it 2ed hand for $25 from a

classified ad. I bought a new one last year and gave the old one

to my brother-in-law. He's still using it.

Rick