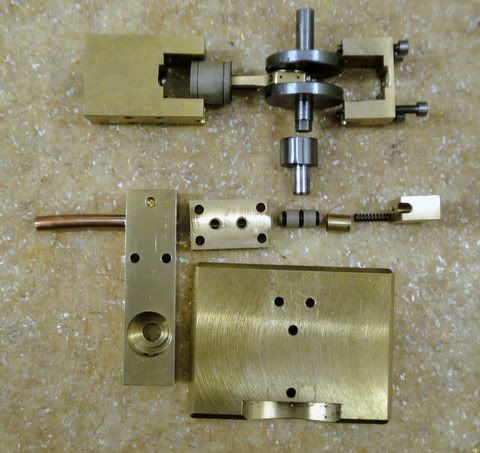

Dug out the little single cylinder engine, here, for those who havent seen it.

[ame="http://www.youtube.com/watch?v=04RBvolzaiA&feature=plcp"]

http://www.youtube.com/watch?v=04RBvolzaiA&feature=plcp[/ame]

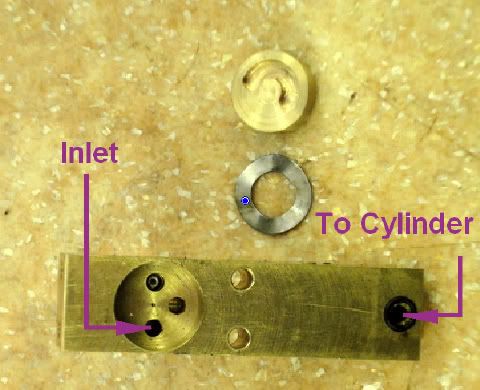

This is how it works.

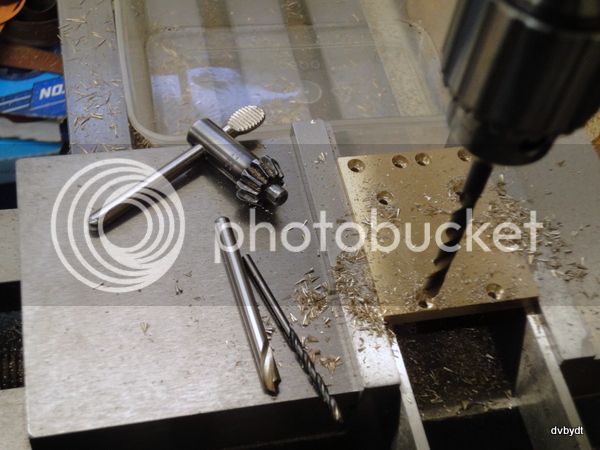

(Photobucket is playing up, had to use imageshack .)

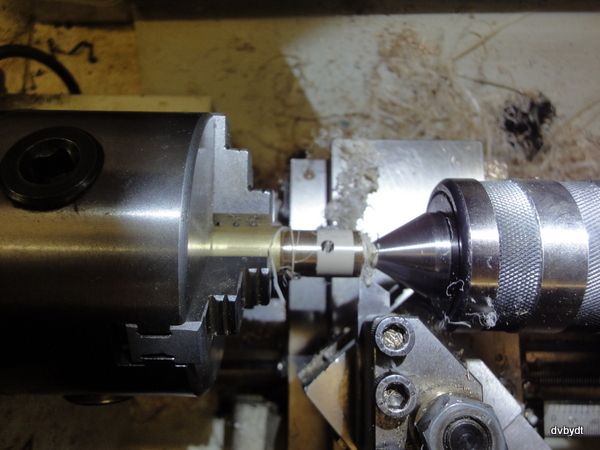

This is the set up for measuring the RPM.

These are the results of gradually making the cam duration smaller but keeping it opening at TDC.

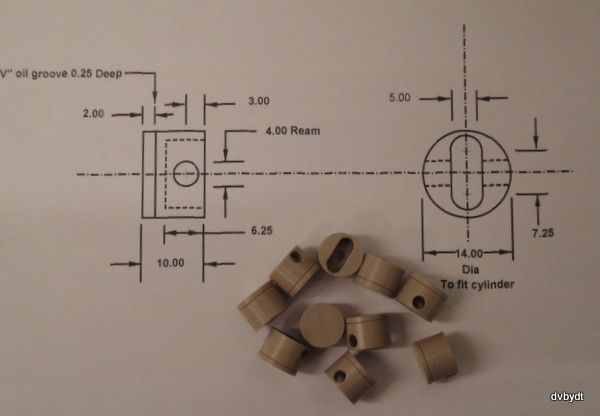

Having got to a 70 Degree cam

It looks smaller than 70 degrees but the pusher lifts the ball and admits air long before the full stroke of the cam. The cam has a hex (Allen key made) broached hole to connect to the hex on the end of the crankshaft and I was able to retard the air admission by 60 degrees for the final test.

So what did I learn from all this, bearing in mind that this is an odd type of single cylinder set up?

1. Cut-off works on air as well as steam and, in this engine configuration, can give higher RPM.

2. Torque goes down as cut-off increases - I did not have any way to measure this but in between altering the air pressure I stopped the fly wheel by hand, well, fingers, so got an impression of the torque.

3. Retarding the air admission in the last test reduced top speed but seemed to increase torque over the top dead centre air admission, presumably because the air pressure was acting at a better mechanical advantage on the piston. In this, the last of my tests, air consumption was much reduced, judged by how often the air compressor kicked in.

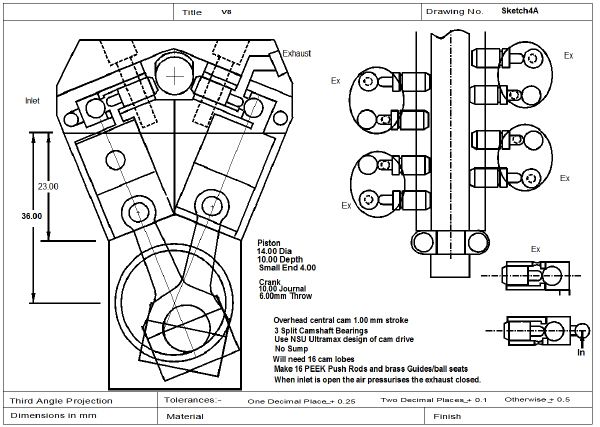

Conclusions - I will be able to run the V8 at 70 degree cut-off and retarded air entry for more economic use of air and that this little engine

deserves to be made into a proper project of it's own with full drawings and a bit of bling!

Final cam timing will need more experiments on the V8 engine with only one piston installed, but I now have a few guidelines from the above.

Ian