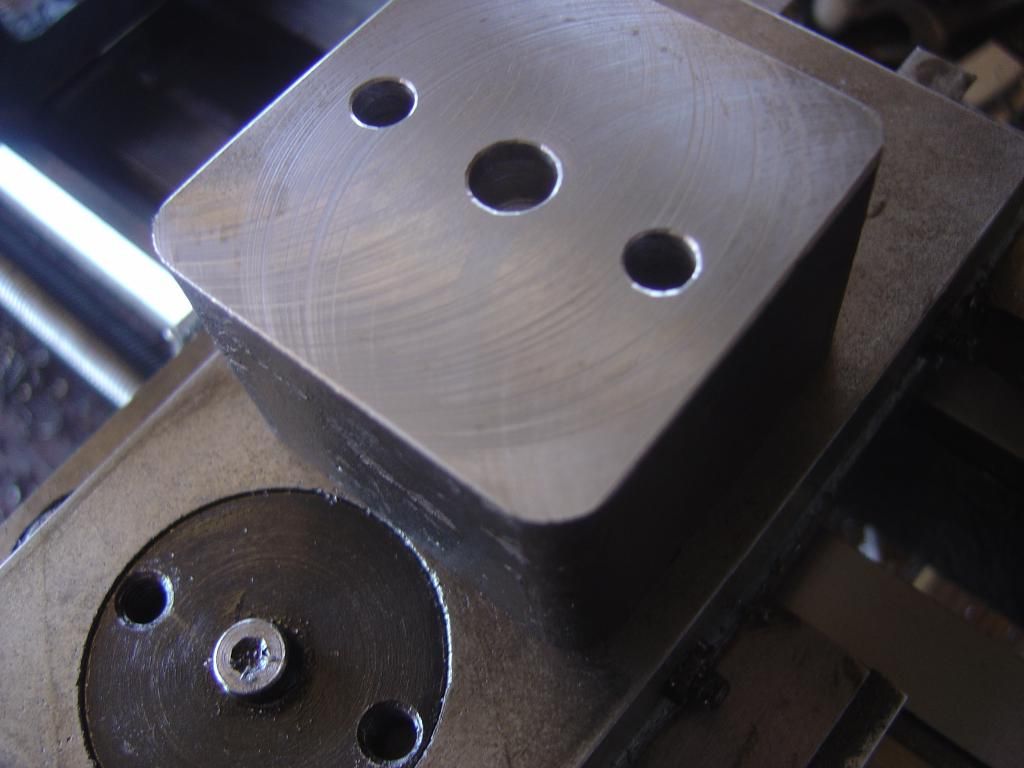

here is a block i made that bolts in place of the compound rest.

it greatly improves the rigidity of the lathe. i made it exactly the same thickness as the compound so i can switch them out and still have my tools on center.

[URL=http://s758.photobucket.com/user/MCRIPPPer/media/DSC00570_zpsdb5b0e7c.jpg.html]

it greatly improves the rigidity of the lathe. i made it exactly the same thickness as the compound so i can switch them out and still have my tools on center.

[URL=http://s758.photobucket.com/user/MCRIPPPer/media/DSC00570_zpsdb5b0e7c.jpg.html]