Hi All,

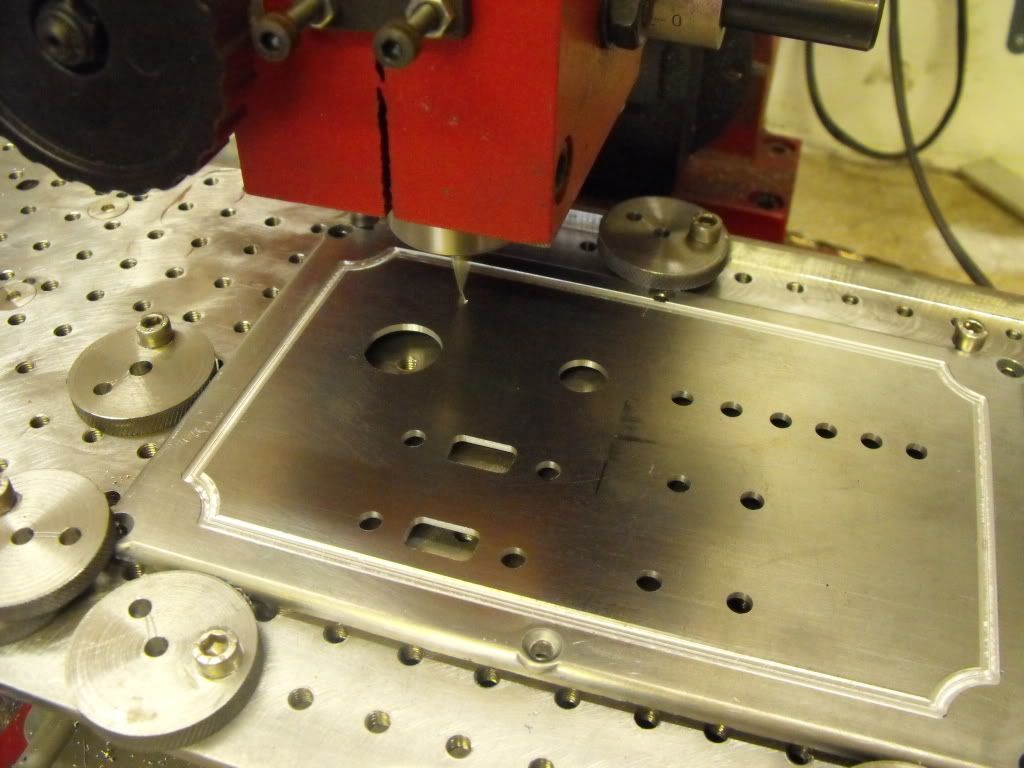

I have converted my Seig X1 mill to complete cnc running on Mach 3. All drives are steppers with oldham links and home-built lead-screw systems with virtually no backlash. They are not ballscrews but have a slight tolerance. My accuracy is out by three steps per shaft rotation but I am microstepping at 1600 steps per rev so not too shabby. Did an electronics project last week and needed to mark and drill the lid of the ali box so decided to let cnc do it while I did something else. Thought you might like a couple of pics:-

Machining.

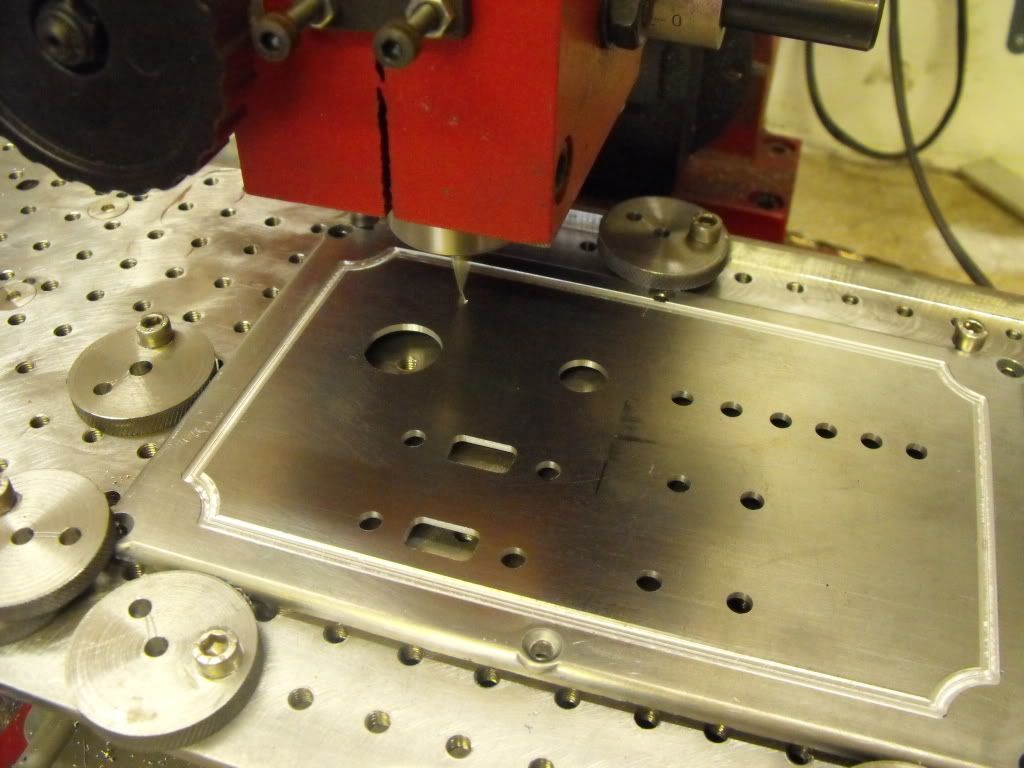

Finished after two passes one with 5mm cutter and one with engraving bit.

Regards

Julian.

I have converted my Seig X1 mill to complete cnc running on Mach 3. All drives are steppers with oldham links and home-built lead-screw systems with virtually no backlash. They are not ballscrews but have a slight tolerance. My accuracy is out by three steps per shaft rotation but I am microstepping at 1600 steps per rev so not too shabby. Did an electronics project last week and needed to mark and drill the lid of the ali box so decided to let cnc do it while I did something else. Thought you might like a couple of pics:-

Machining.

Finished after two passes one with 5mm cutter and one with engraving bit.

Regards

Julian.