drysdam

Well-Known Member

- Joined

- Feb 10, 2012

- Messages

- 87

- Reaction score

- 7

Some background.

tldr: I want to make a manually operated, 100% mechanical water pump for my cat who will only drink running water. The goal is about equal parts hilarity and shop-time, with a distant third of making an actual working device to be operated by a cat.

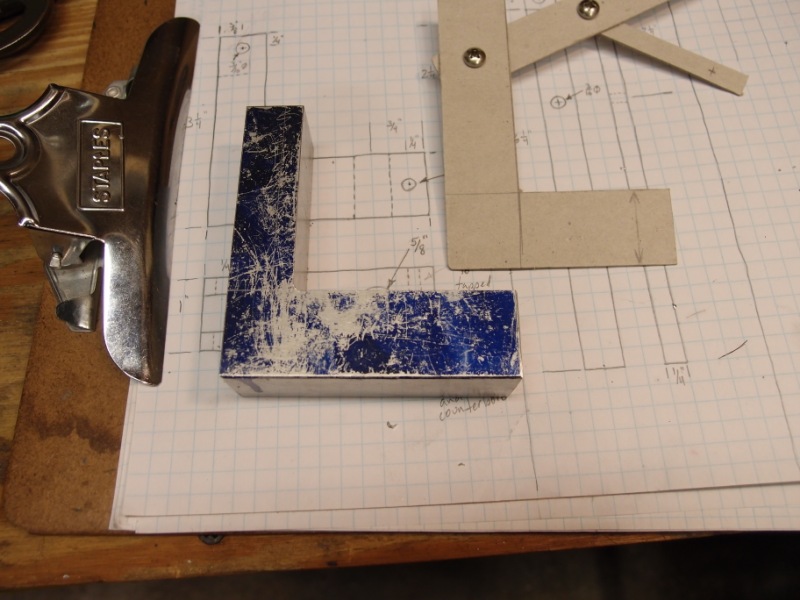

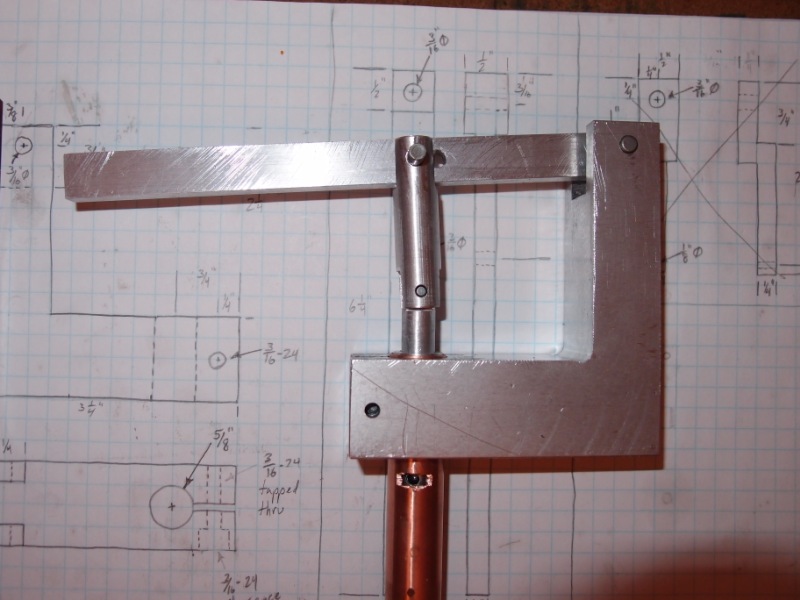

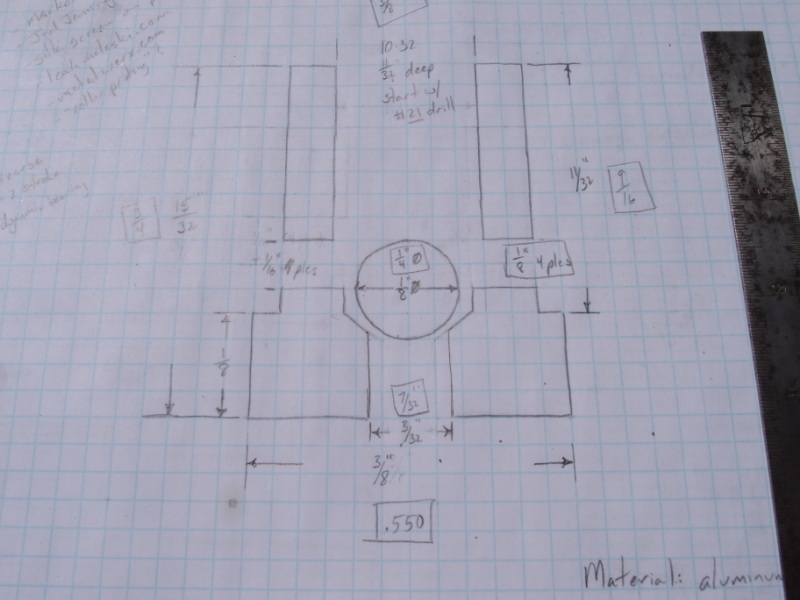

Step 1: A check valve

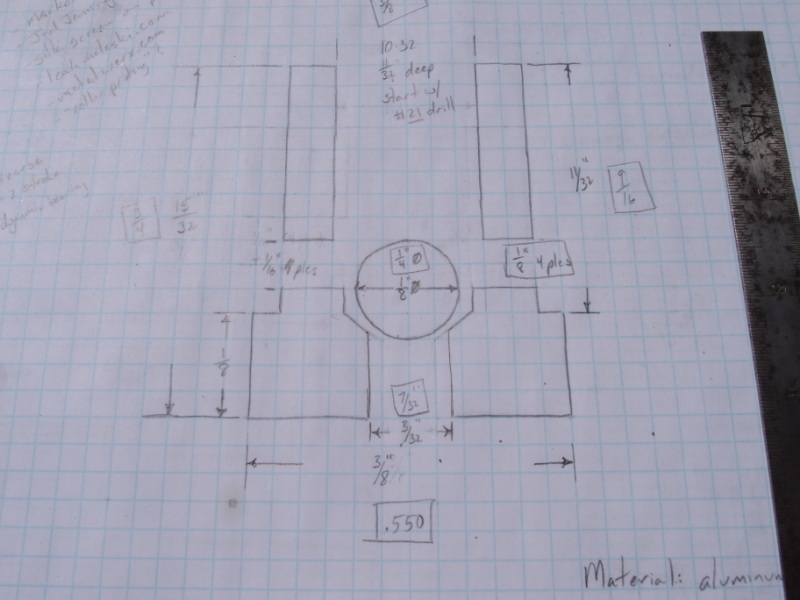

(The circled dimensions are embodied below, the others are an even-more-prototypical set I made some of last week.)

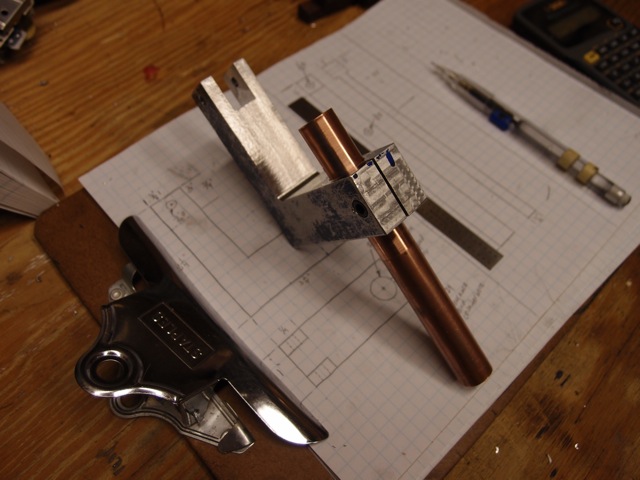

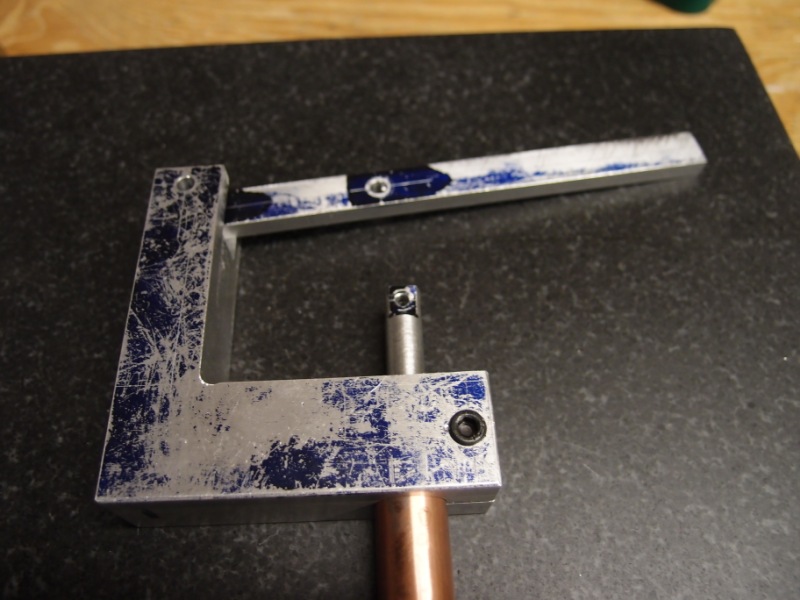

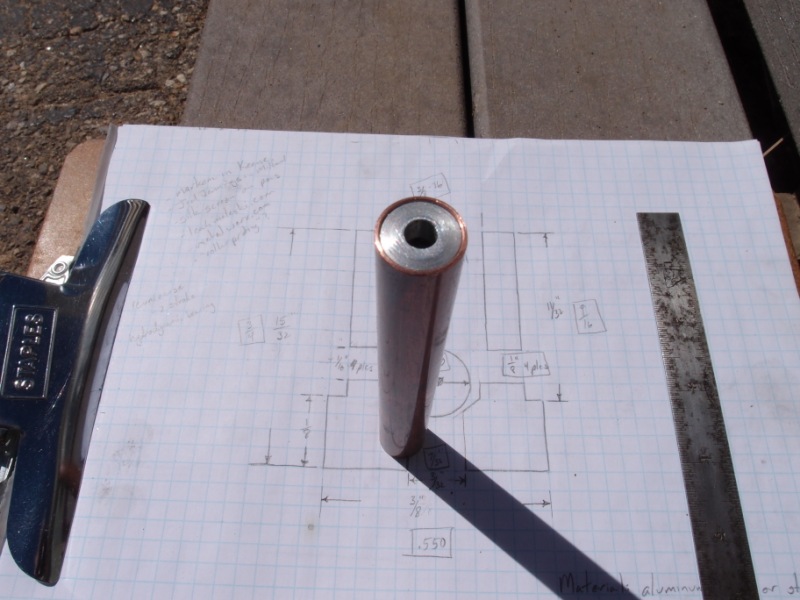

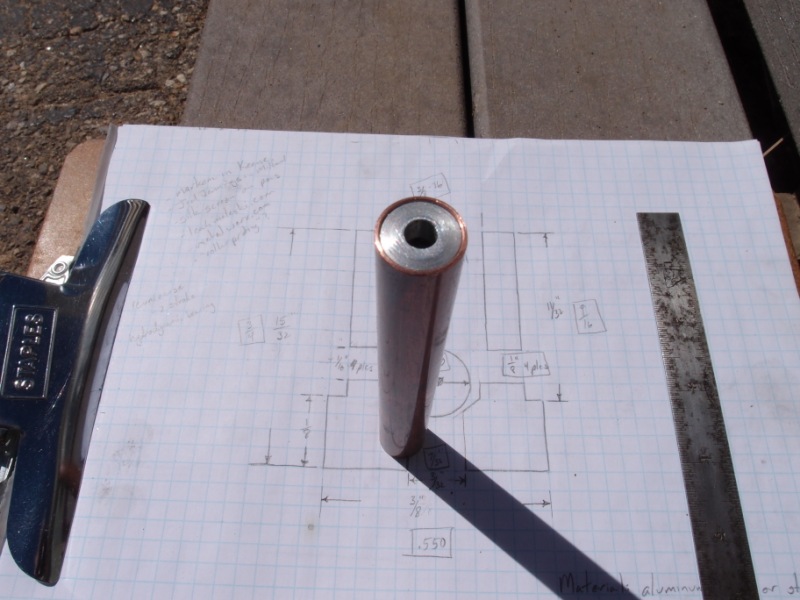

I need two of these. One pressed into the base of the cylinder (ordinary copper pipe--hints on machining this material, btw?):

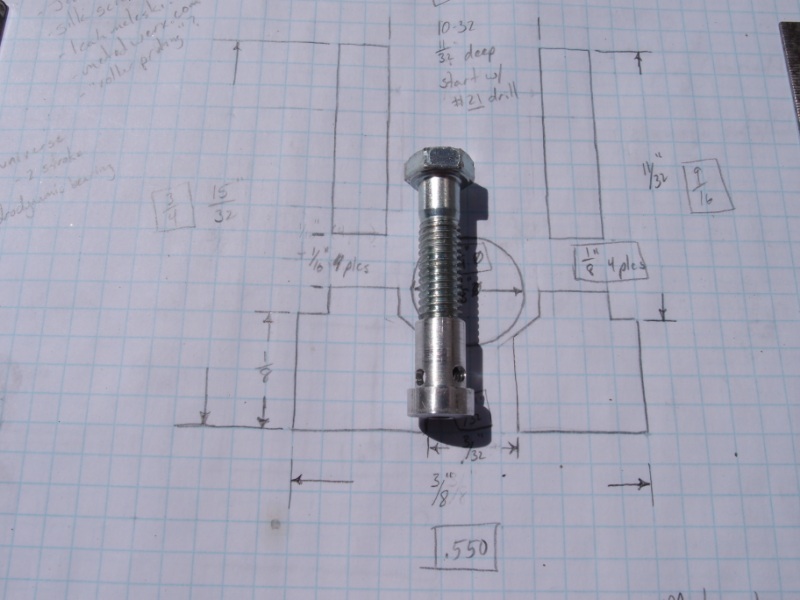

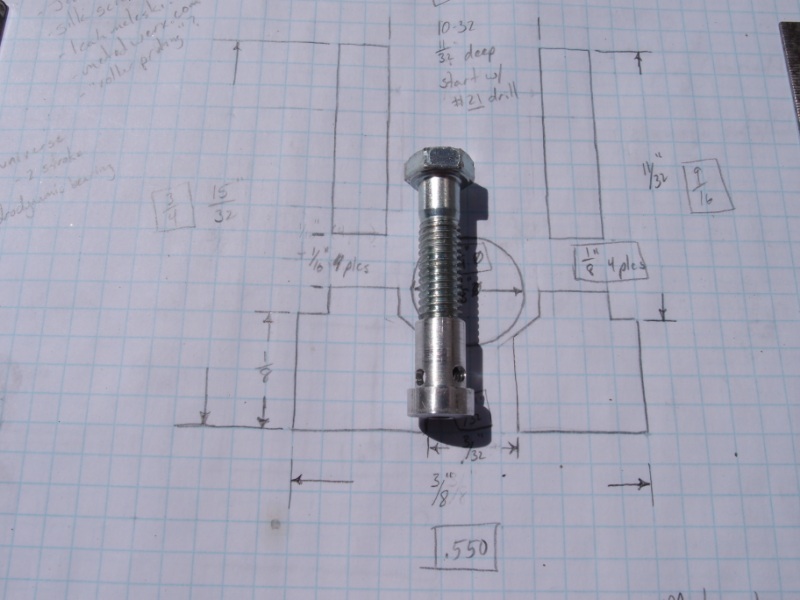

and one in a movable piston (bolt is temporary to hold the ball in place and for testing)

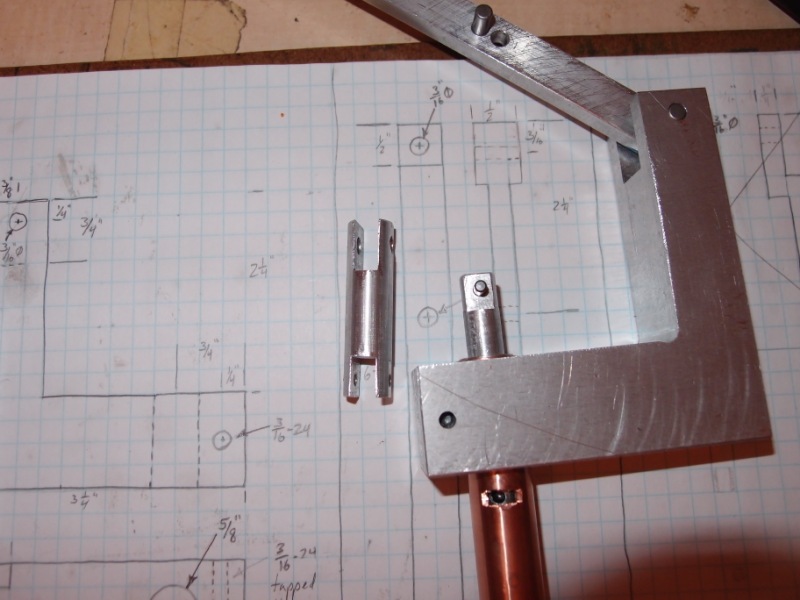

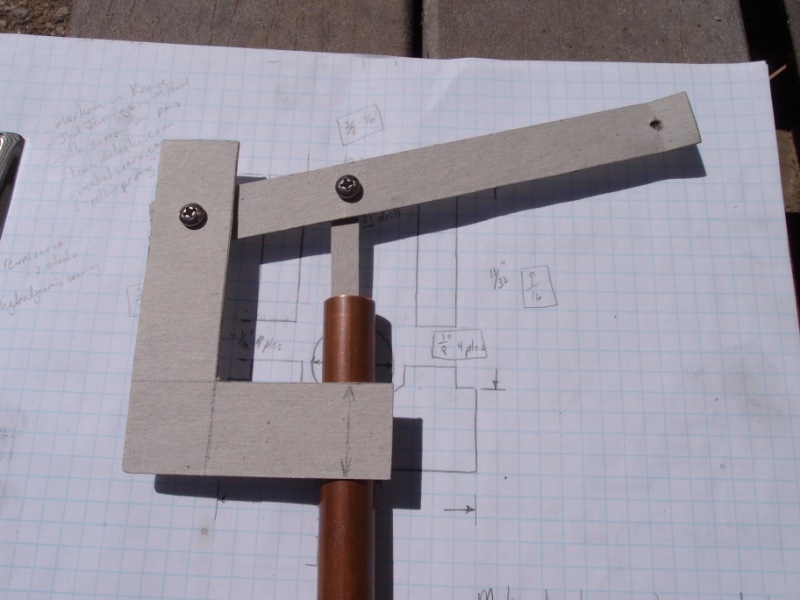

Next up is some kind of handle arrangement. I did some math to compute a few angles and distance ratios. I'm not sure if I'll need a cross head or not. I'm going to start without one and see if I can avoid it. My rain barrel water pump doesn't have one, but it may be more forgiving of a cocked piston.

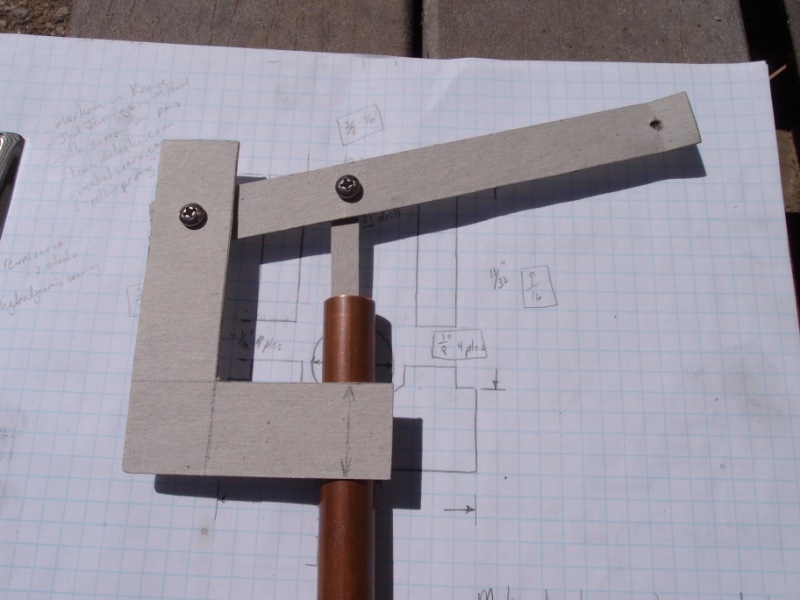

Anyway, I also mocked it up in cardboard to see if I had my math right:

(I'm working on two other projects at the same time, along with normal life, so who knows when the next update will be.)

tldr: I want to make a manually operated, 100% mechanical water pump for my cat who will only drink running water. The goal is about equal parts hilarity and shop-time, with a distant third of making an actual working device to be operated by a cat.

Step 1: A check valve

(The circled dimensions are embodied below, the others are an even-more-prototypical set I made some of last week.)

I need two of these. One pressed into the base of the cylinder (ordinary copper pipe--hints on machining this material, btw?):

and one in a movable piston (bolt is temporary to hold the ball in place and for testing)

Next up is some kind of handle arrangement. I did some math to compute a few angles and distance ratios. I'm not sure if I'll need a cross head or not. I'm going to start without one and see if I can avoid it. My rain barrel water pump doesn't have one, but it may be more forgiving of a cocked piston.

Anyway, I also mocked it up in cardboard to see if I had my math right:

(I'm working on two other projects at the same time, along with normal life, so who knows when the next update will be.)