Twinsquirrel

Well-Known Member

- Joined

- Jun 8, 2008

- Messages

- 227

- Reaction score

- 0

oooh that's a mean looking beastie!! Nice work.

Have a safe trip home

David

Have a safe trip home

David

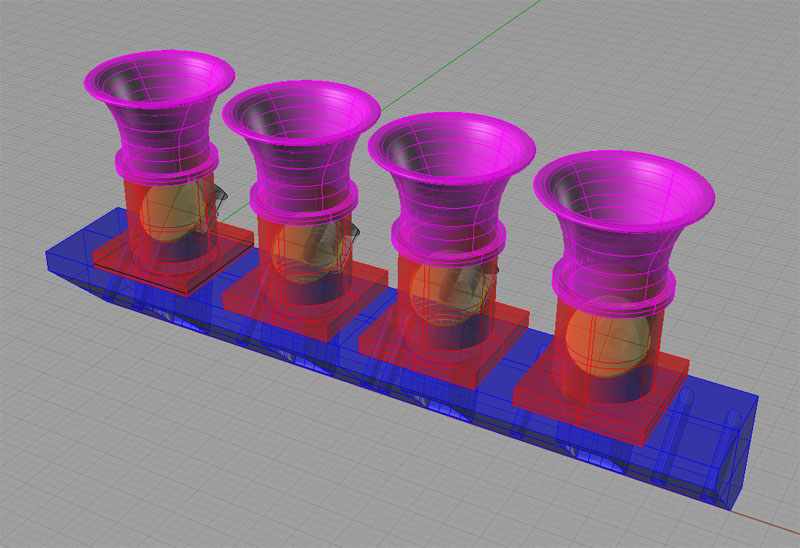

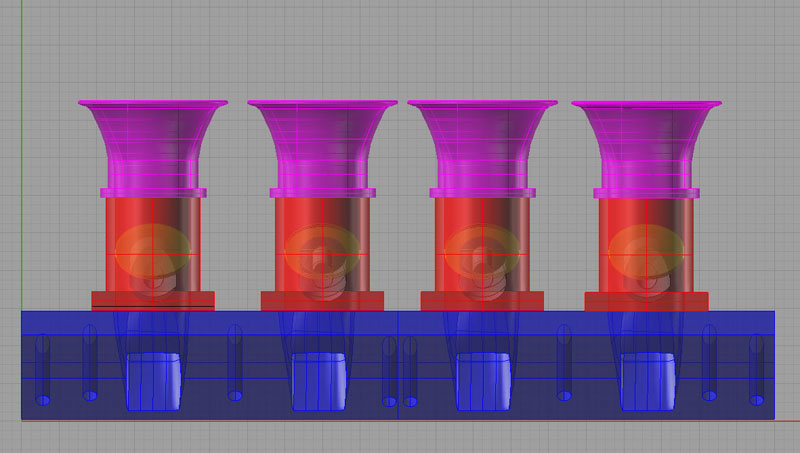

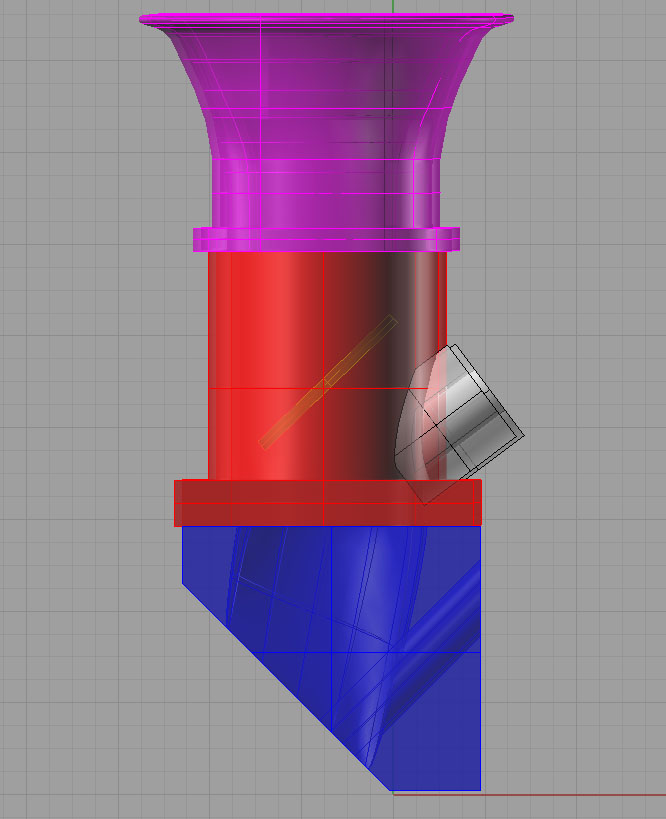

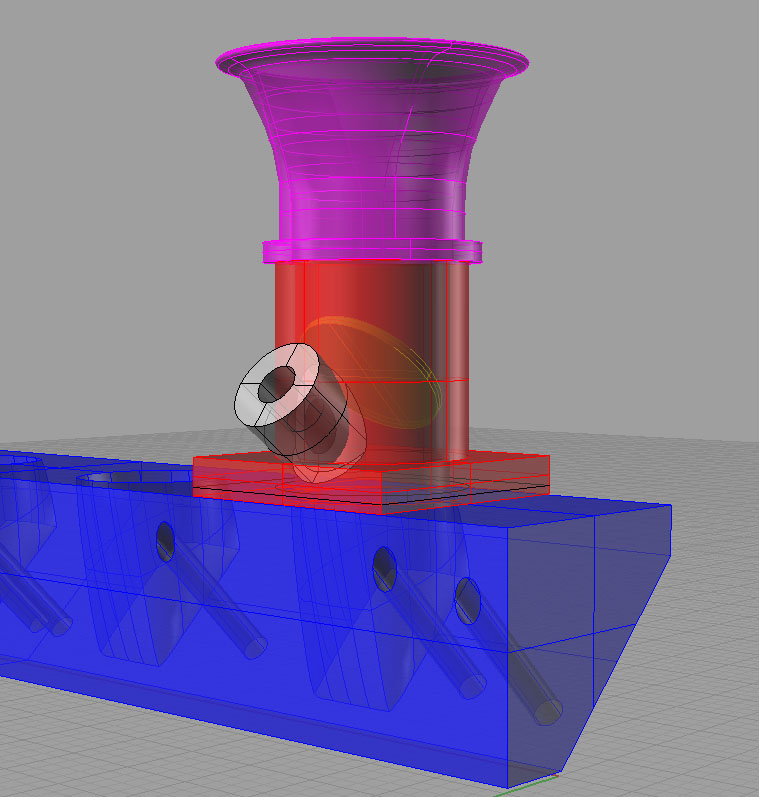

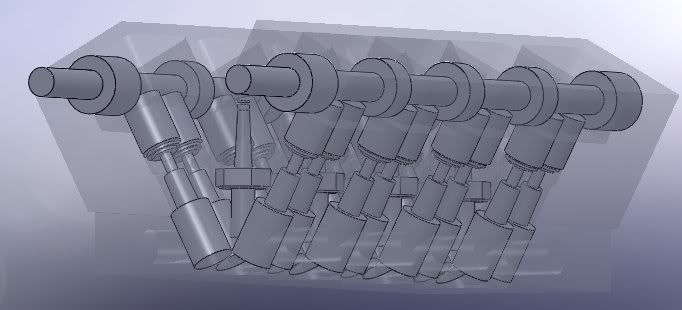

Brian Rupnow said:And this is typical of what I do at my real job!!! This is an industrial centrifuge, about 400 individual parts---72 engineering drawings---3 weeks work.

John Stevenson said:Bob,

Got the specs and drawings of the D1-3 studs but not the D1-4 as i don't have anything on D1-4

Enter your email address to join: