deere_x475guy

Well-Known Member

Hi gang, I started Mcgyver's tube bender this weekend. Here are some pics to date of the build.

I didn't take step by step pictures. I am just posting a few to show some the steps.

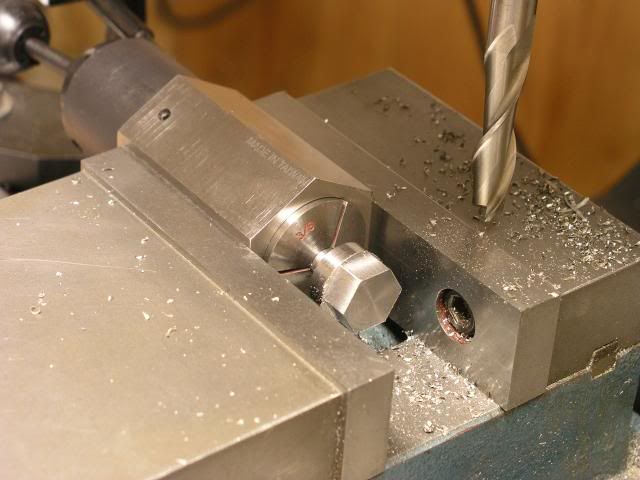

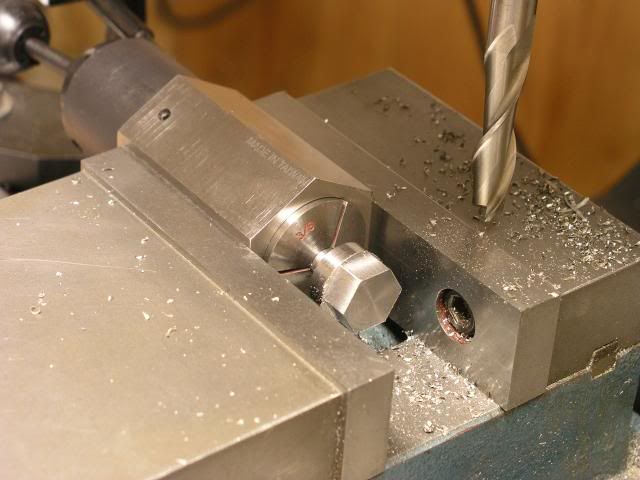

There are several bolts that I made up and I used my 6 sided 5C block to help this along.

This set up allowed me to hold the part so I could drill, ream, counter bore and tap. And the DRO guided me to my hole locations.

I needed to reduce the size of the head on my 10-32 screws so I used a collet set up in the lathe.

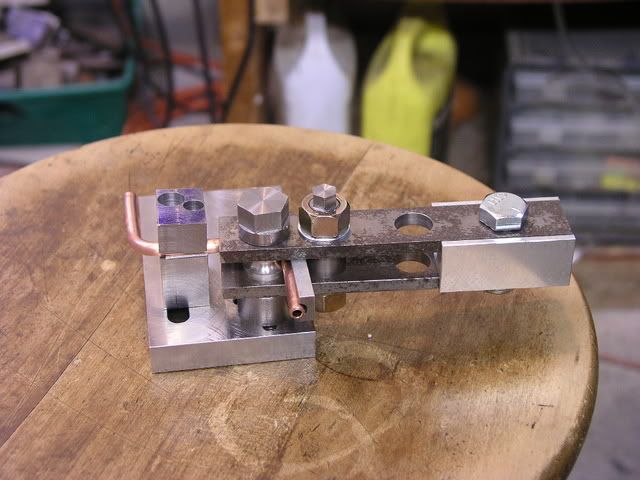

Here is a shot of some of the parts laid out.

and here is where I ended up for the weekend. There are still a lot of parts and I hope to finish this up by the end of next weekend so I can at least bend the 1/4" tubing.

Many thanks to Mcgyver!!!

I didn't take step by step pictures. I am just posting a few to show some the steps.

There are several bolts that I made up and I used my 6 sided 5C block to help this along.

This set up allowed me to hold the part so I could drill, ream, counter bore and tap. And the DRO guided me to my hole locations.

I needed to reduce the size of the head on my 10-32 screws so I used a collet set up in the lathe.

Here is a shot of some of the parts laid out.

and here is where I ended up for the weekend. There are still a lot of parts and I hope to finish this up by the end of next weekend so I can at least bend the 1/4" tubing.

Many thanks to Mcgyver!!!