arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

Thanks Dave, I'll pop Rudy a mail  - Must be the air here, or some psychological remnants from previous years where we were all very limited to imports into these part of Southern Africa :big: (and that's enough said

- Must be the air here, or some psychological remnants from previous years where we were all very limited to imports into these part of Southern Africa :big: (and that's enough said  )

)

Well, new start today...

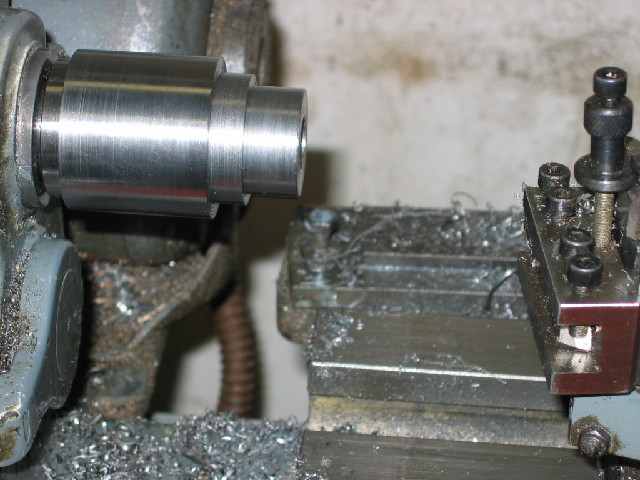

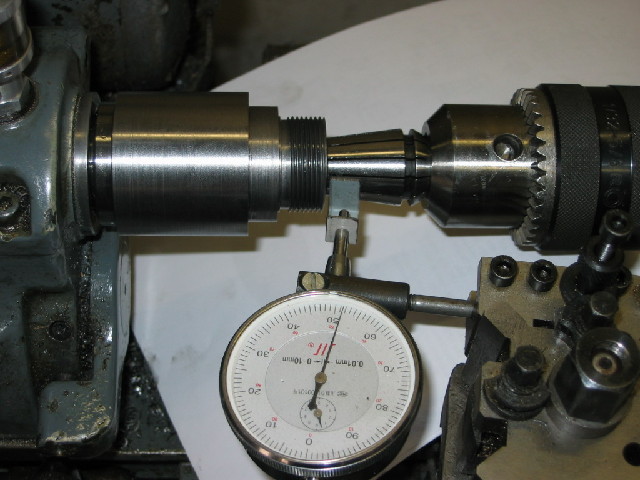

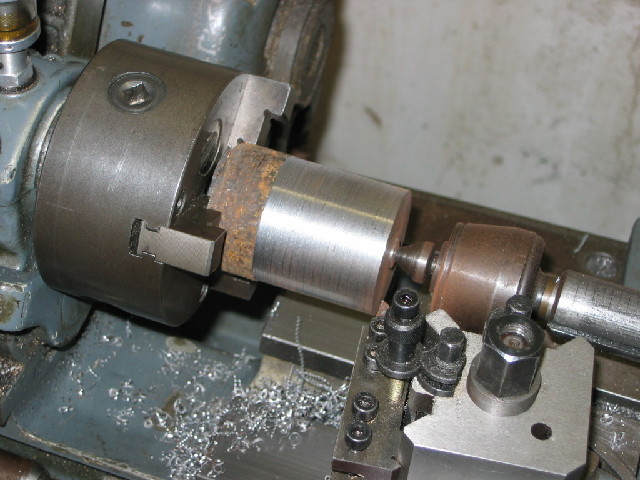

Cleaned up the new chuck body:

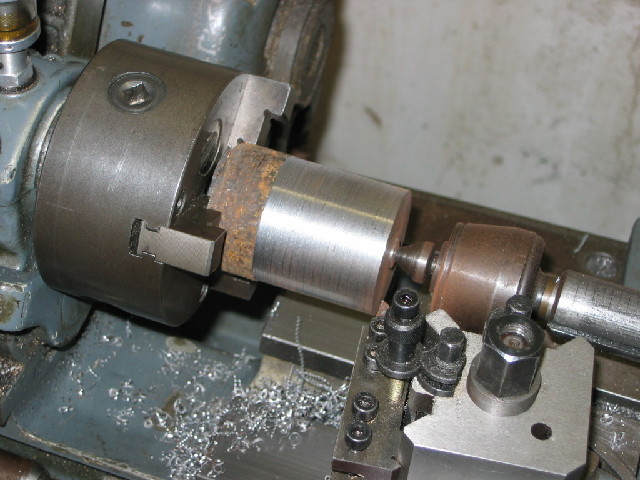

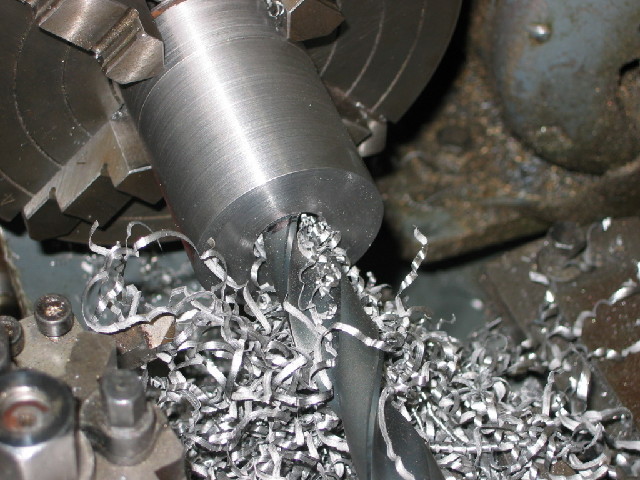

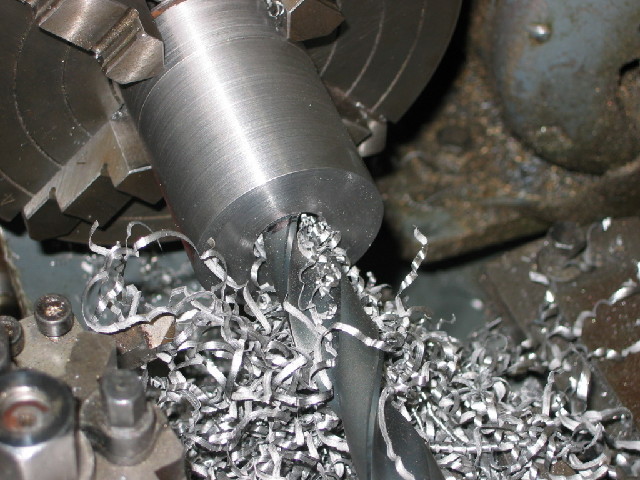

Then switched to the 4-jaw and drilled consecutive through-holes to 16mm, and tried my hand at an action shot while drilling on fast back-gear to 19mm (my biggest drill) to spindle-depth:

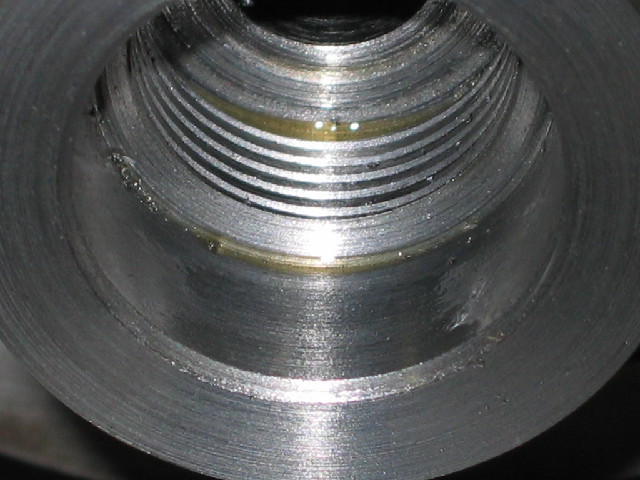

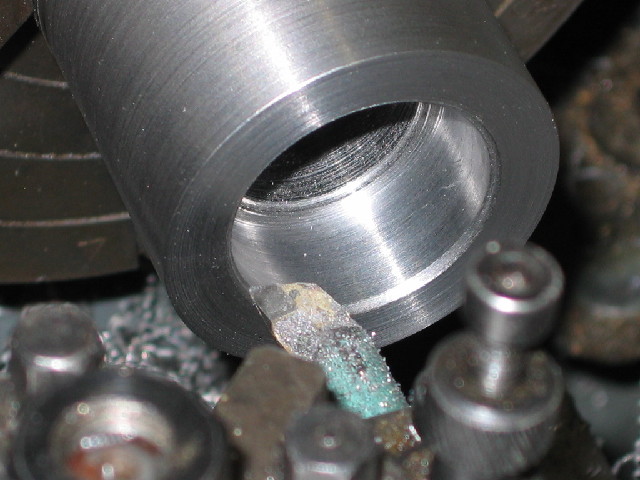

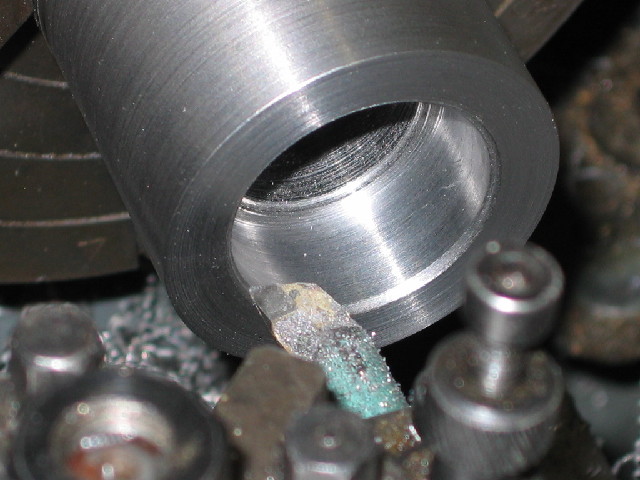

And bored the register to size using a carbide tipped bit that I honed on a bit of emery:

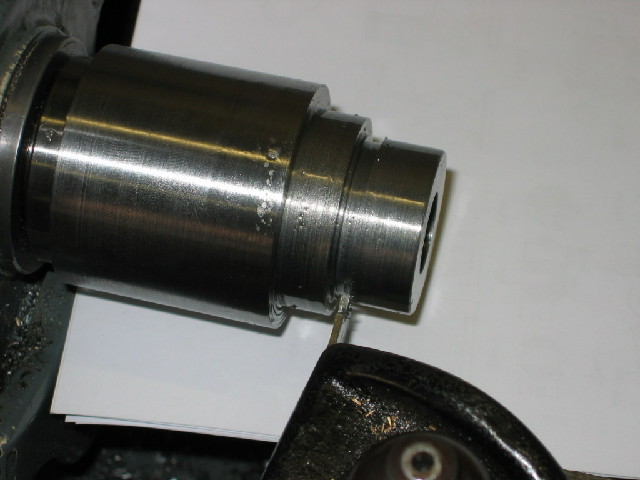

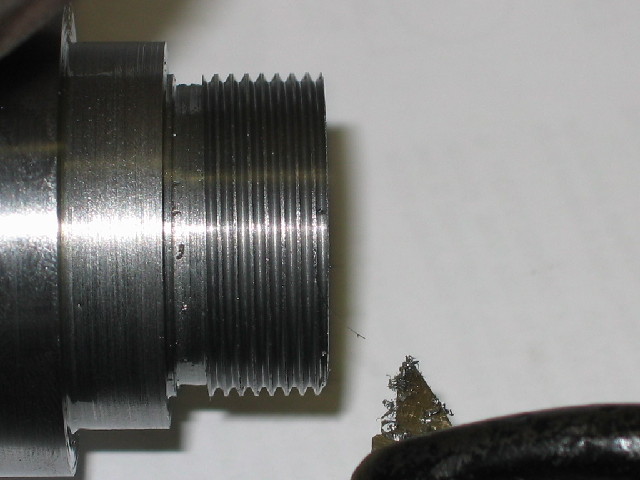

After this I bored out for thread run-out in the back; slowest back-gear speed & PLENTY of lube with frequent stops to clean out the swarf ribbon. Thought it might be more difficult, but came out well. Then I set up the change wheels for the internal thread, and set up for the single-pointing. Decided to stop there, and do the thread tomorrow when I'm fresh.

Regards, Arnold

Well, new start today...

Cleaned up the new chuck body:

Then switched to the 4-jaw and drilled consecutive through-holes to 16mm, and tried my hand at an action shot while drilling on fast back-gear to 19mm (my biggest drill) to spindle-depth:

And bored the register to size using a carbide tipped bit that I honed on a bit of emery:

After this I bored out for thread run-out in the back; slowest back-gear speed & PLENTY of lube with frequent stops to clean out the swarf ribbon. Thought it might be more difficult, but came out well. Then I set up the change wheels for the internal thread, and set up for the single-pointing. Decided to stop there, and do the thread tomorrow when I'm fresh.

Regards, Arnold