Nice engine! Where did you find the plans? It looks like the Stuart Beam engine, which I know was modeled off of an old engine.

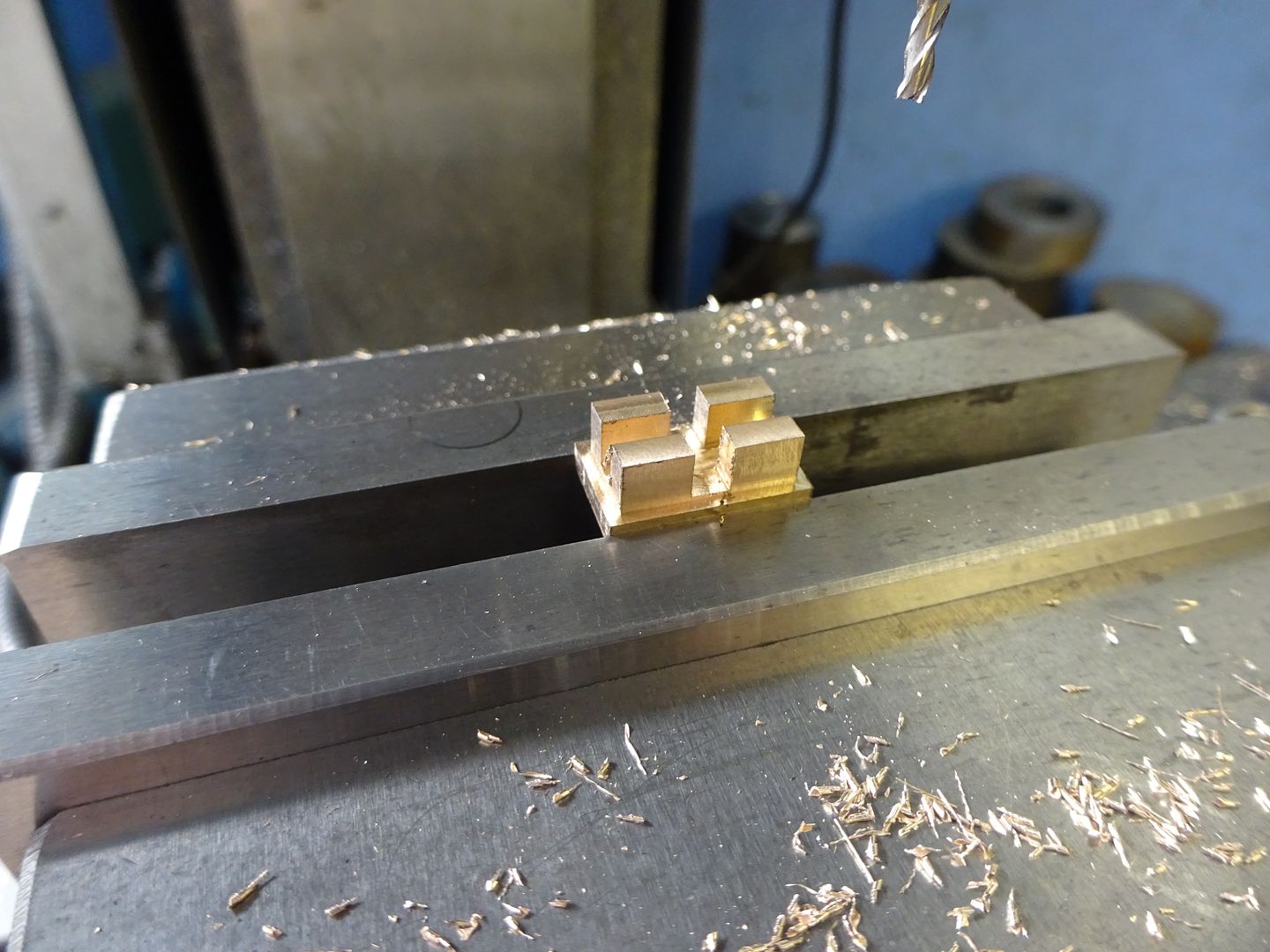

About ten years ago I designed and build a much smaller version of the beam engine, similar to the Stuart on my CNC'd Sherline mill.

I'd like very much to compare designs.

Alan

About ten years ago I designed and build a much smaller version of the beam engine, similar to the Stuart on my CNC'd Sherline mill.

I'd like very much to compare designs.

Alan