Well my gut said to just start again so that's what happened - I am not where I would like to be but I did more than I expected today. Apologies if some of this feels like Top Gear on Dave.

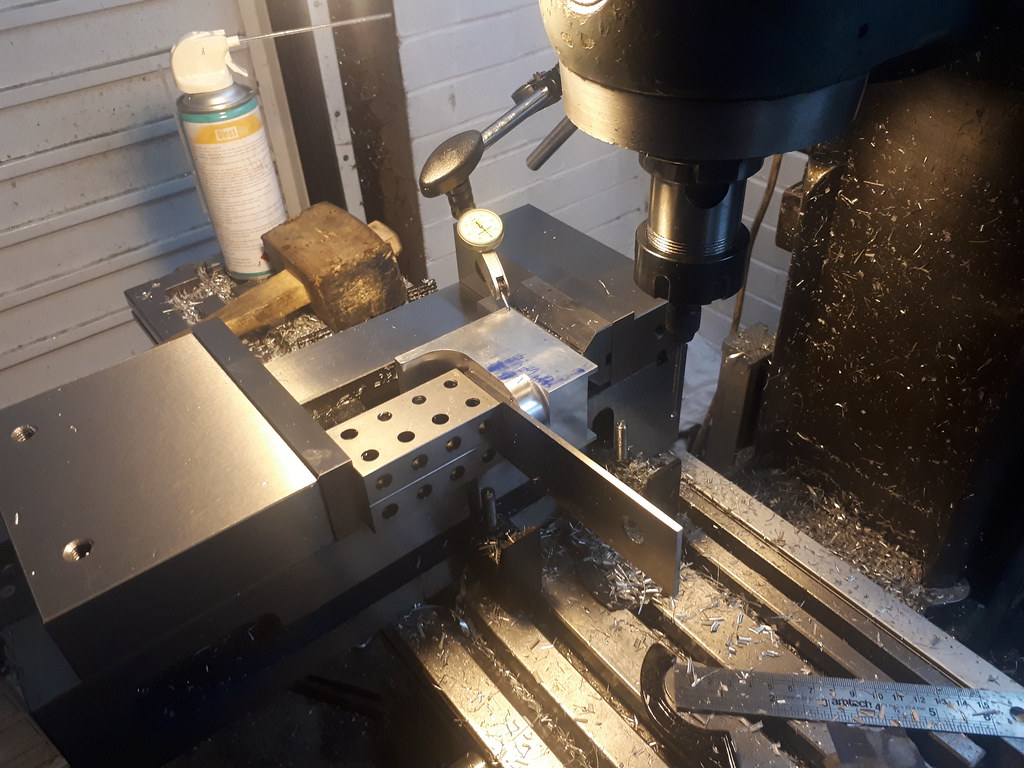

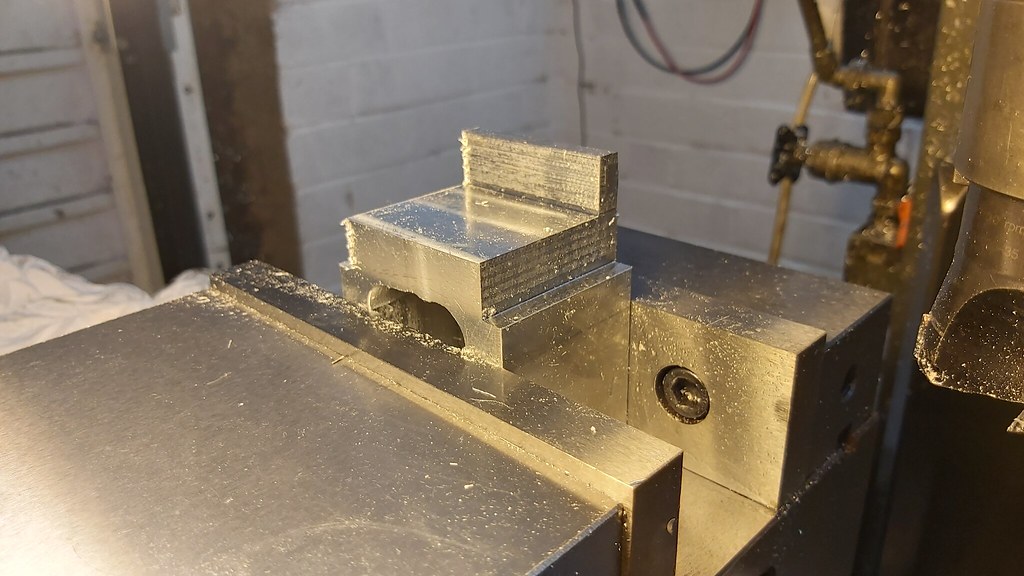

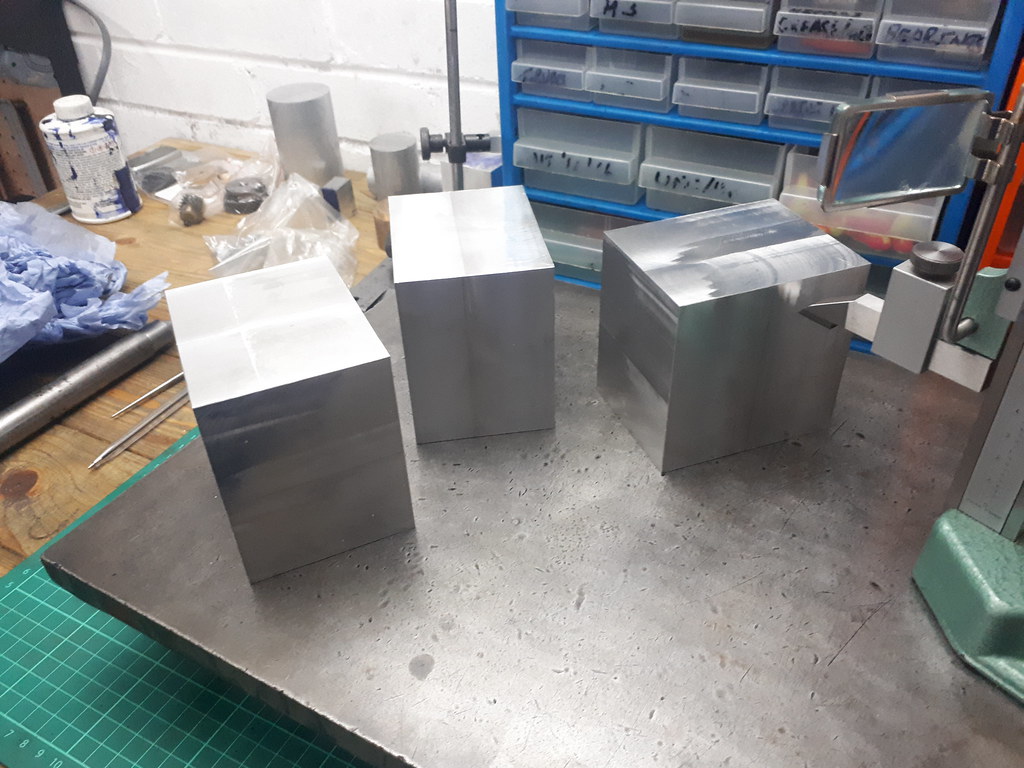

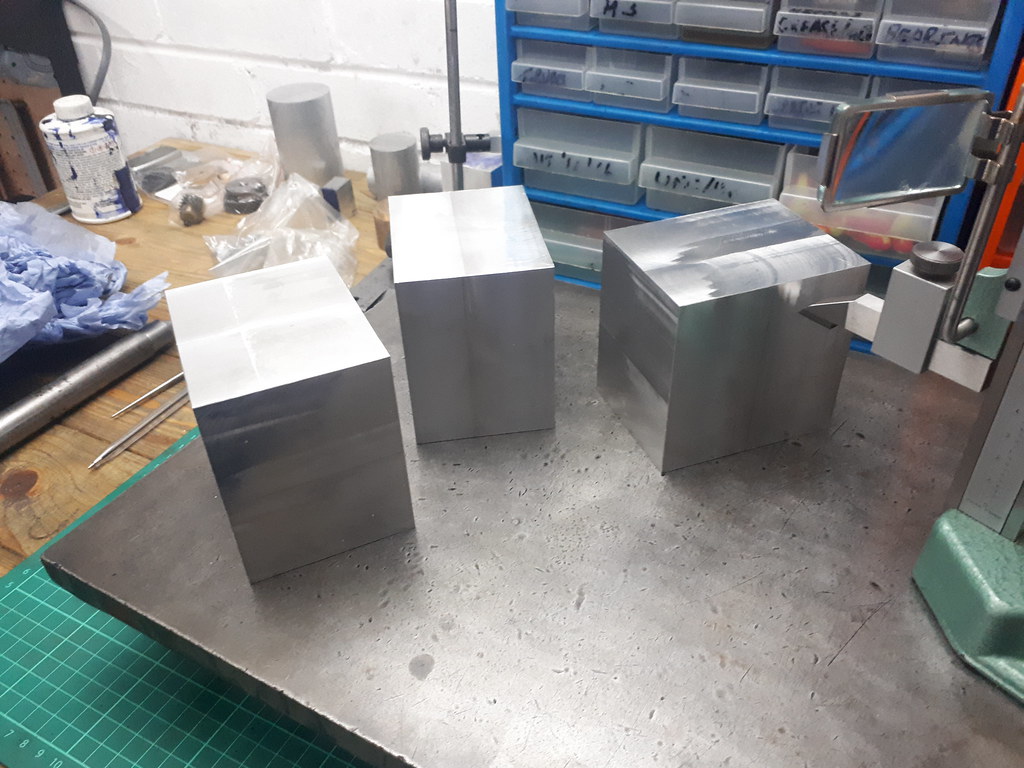

Whilst I was starting again squaring off the stock, I decided to square off 3 sides of the remaining chunks which will later become the frame rear and water hopper.

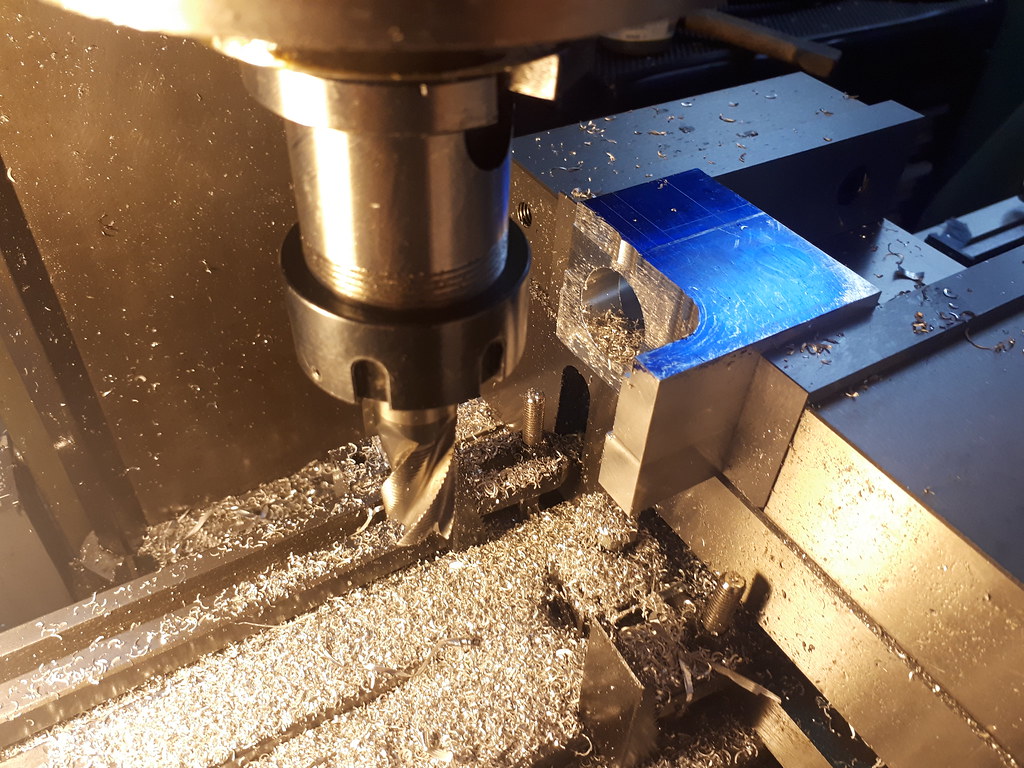

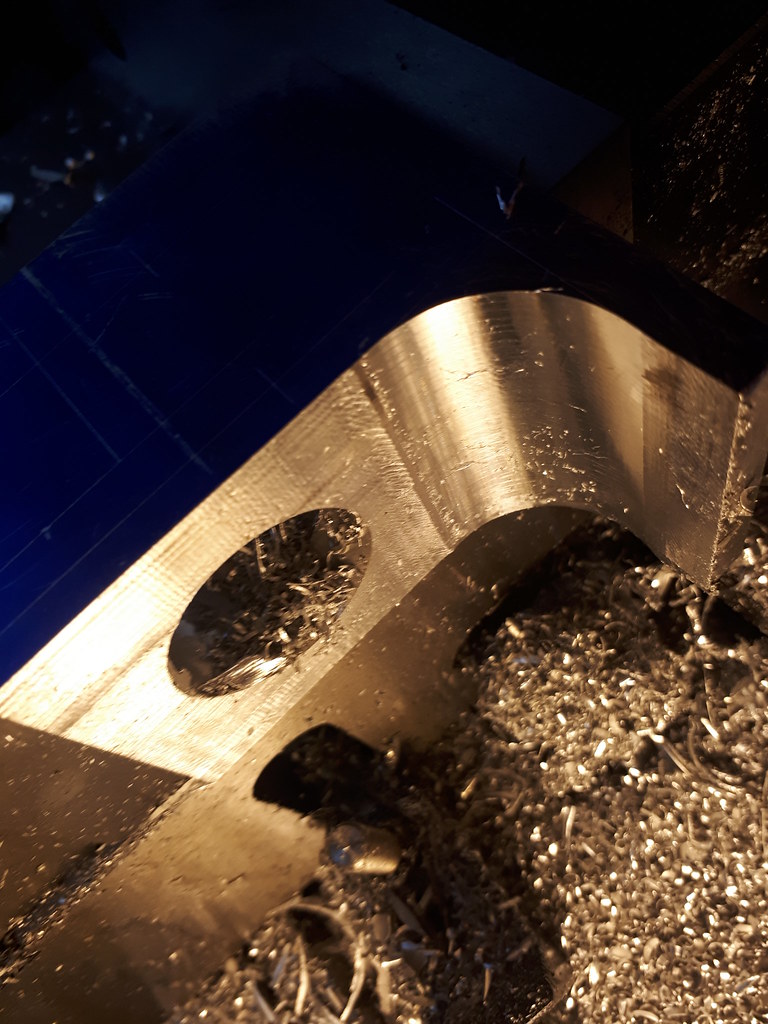

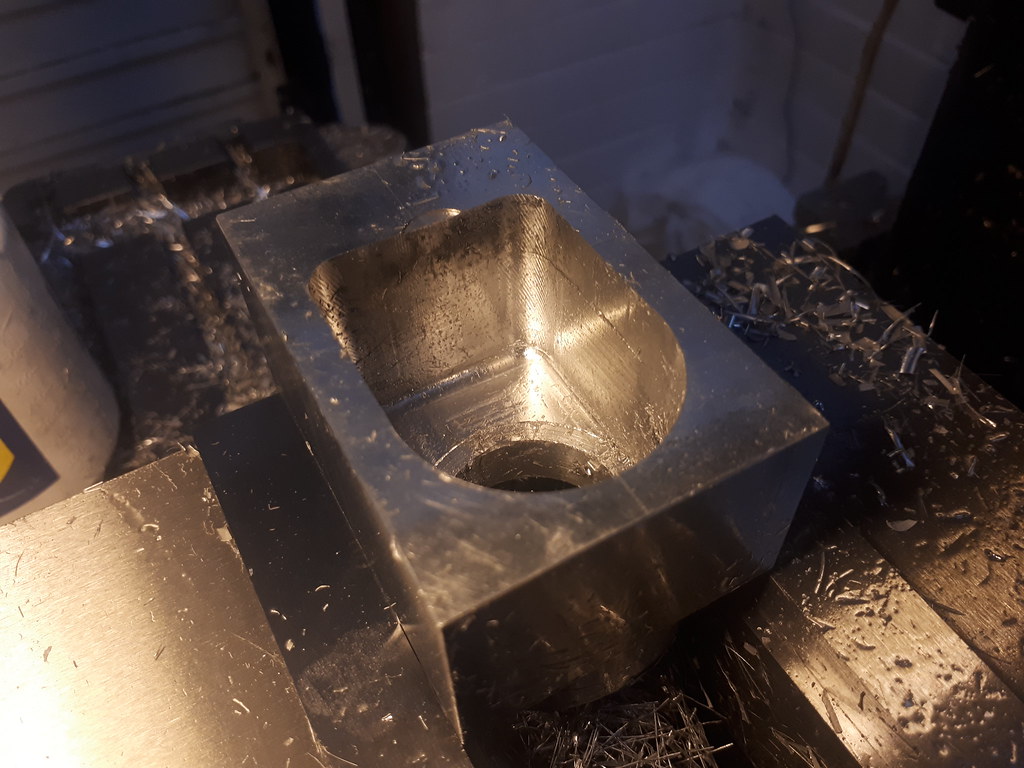

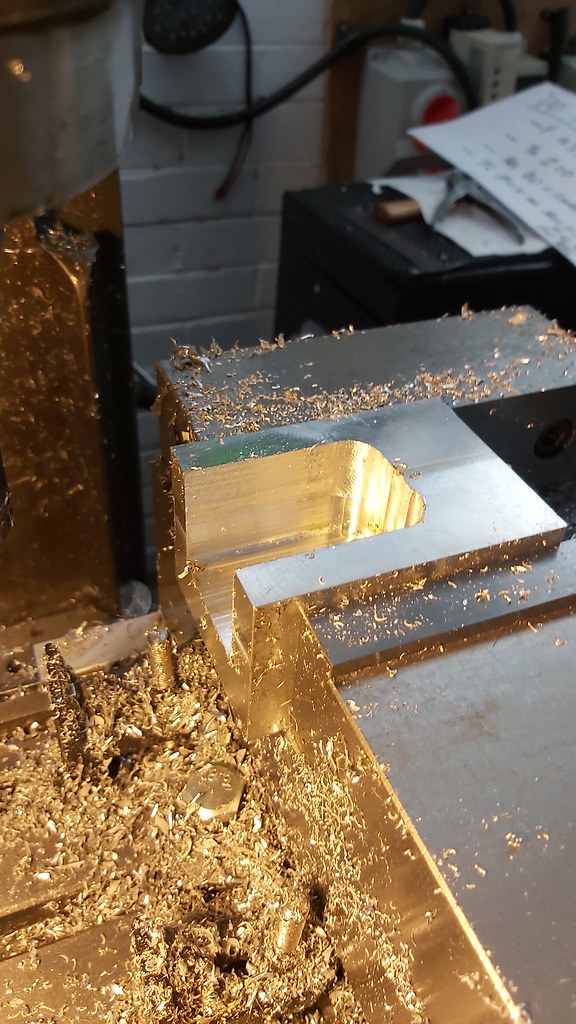

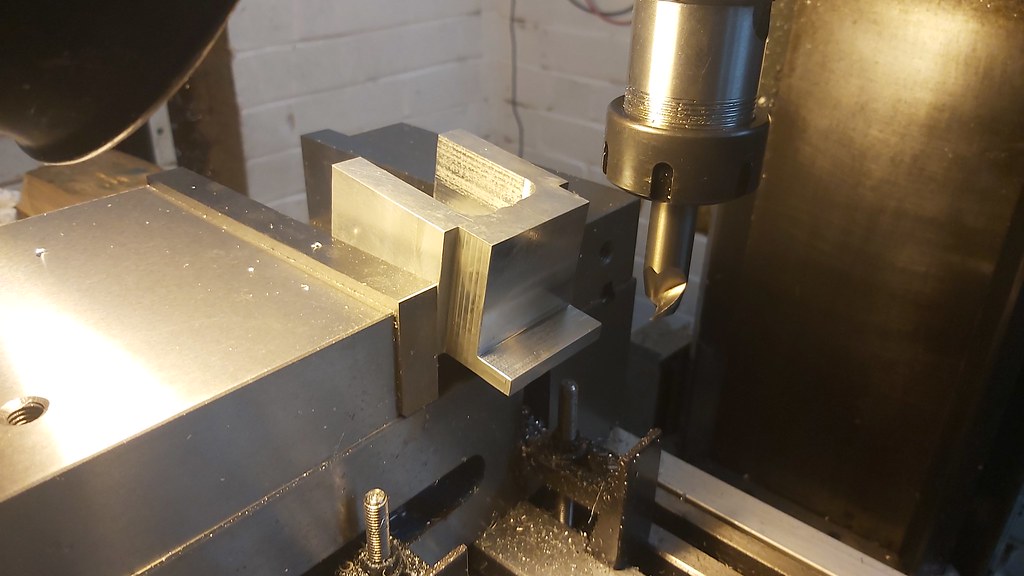

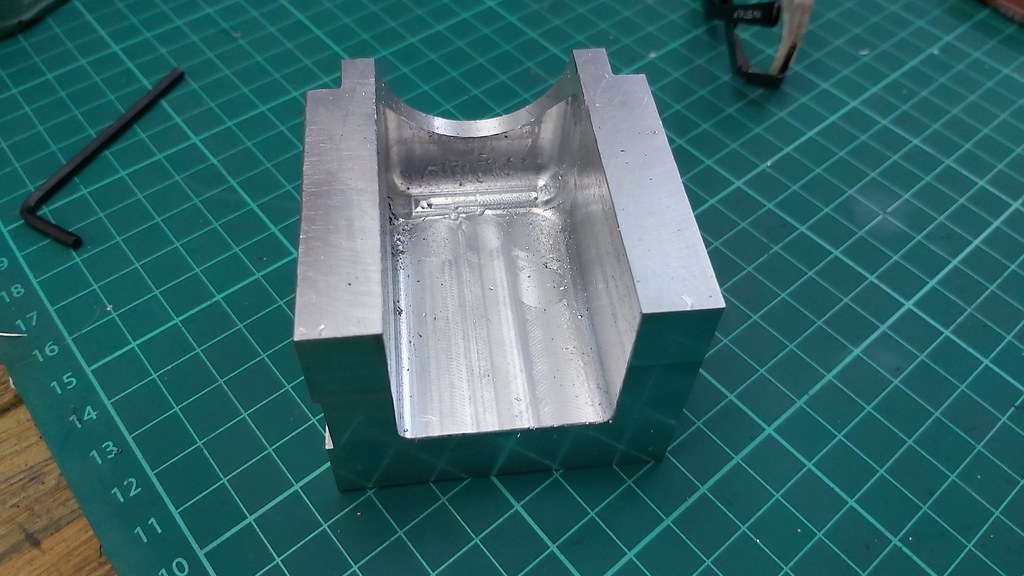

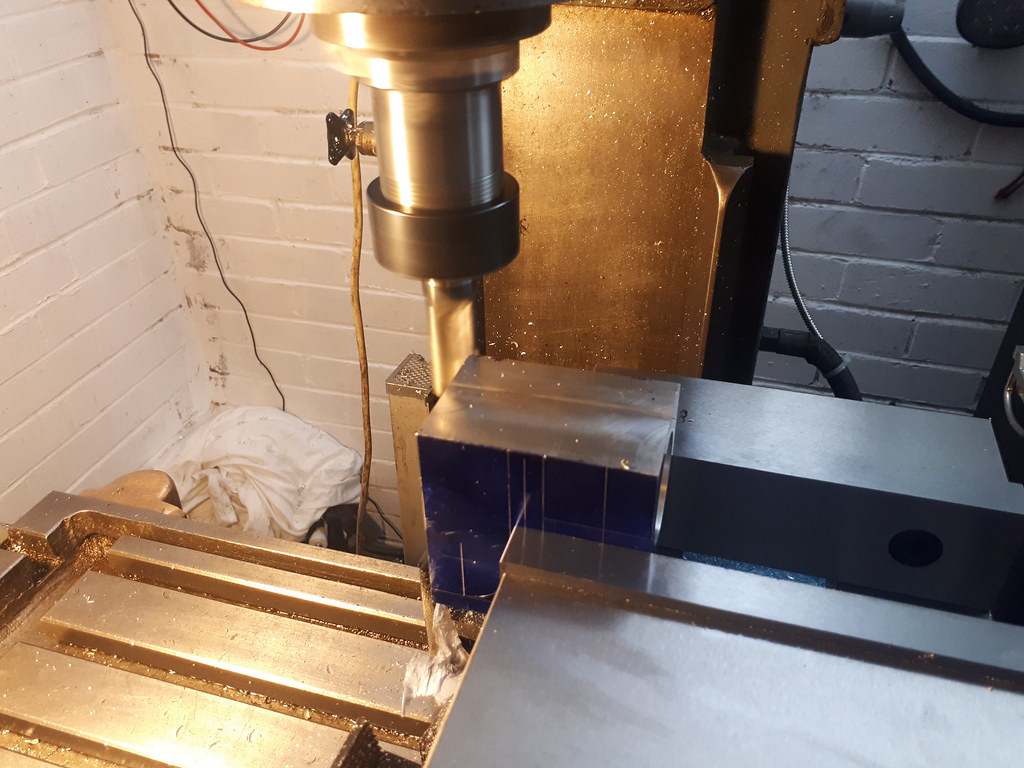

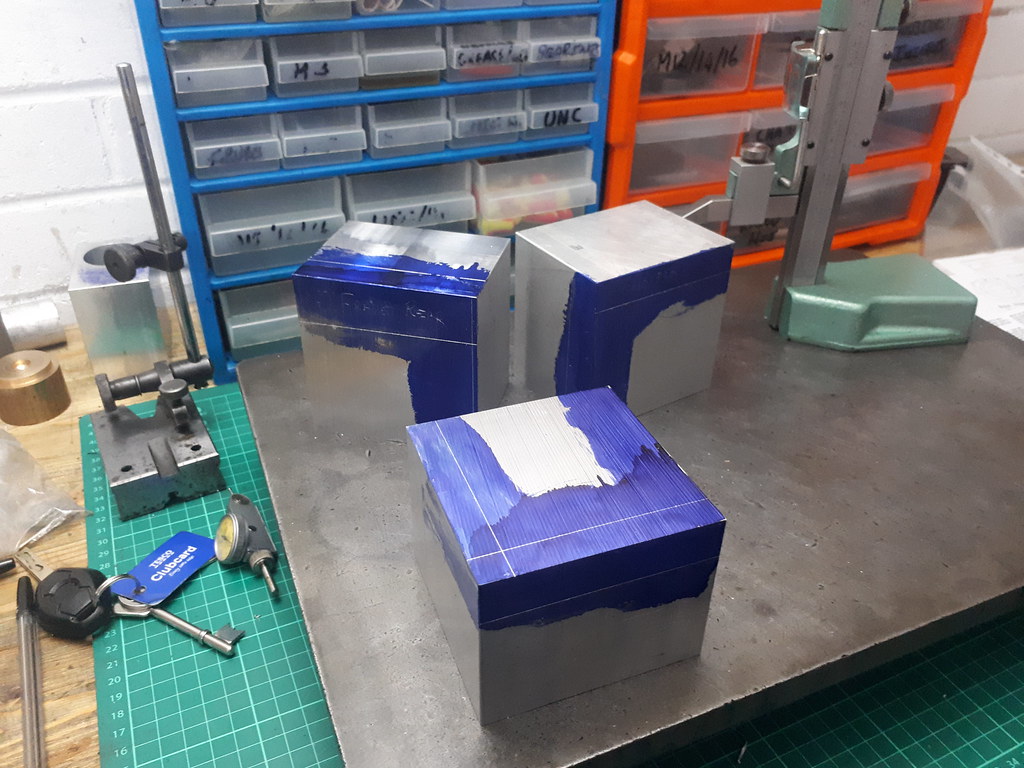

In the interest of saving money by buying the stock at one size, it shows just how much needs to be removed!

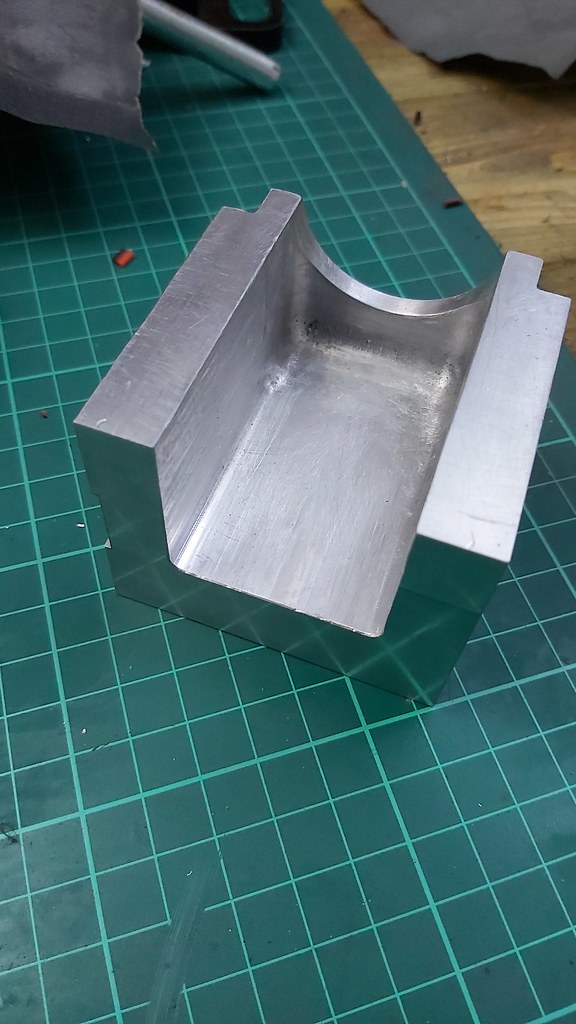

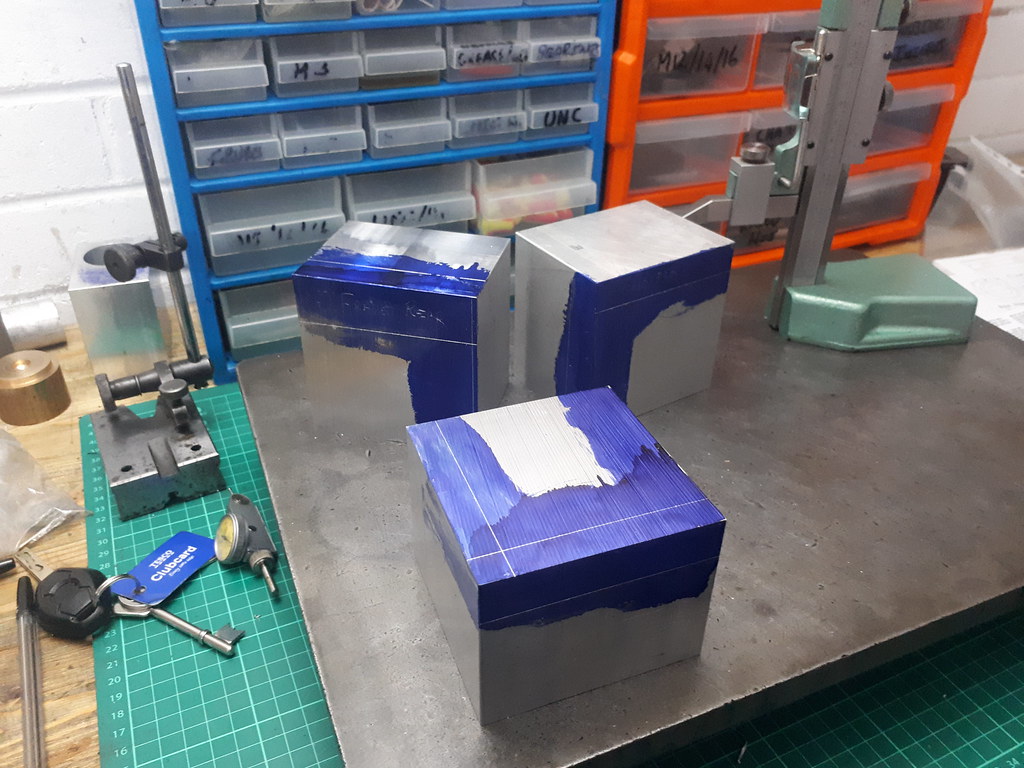

Placed next to the scrap piece you can get a sense of what about needs to be taken off

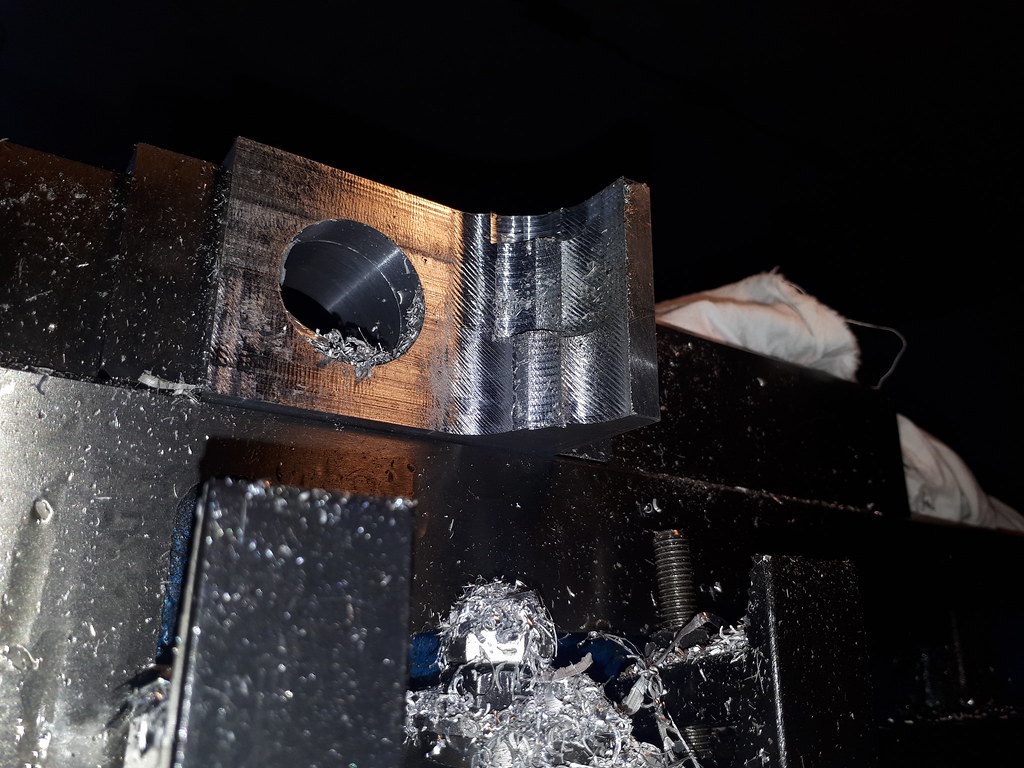

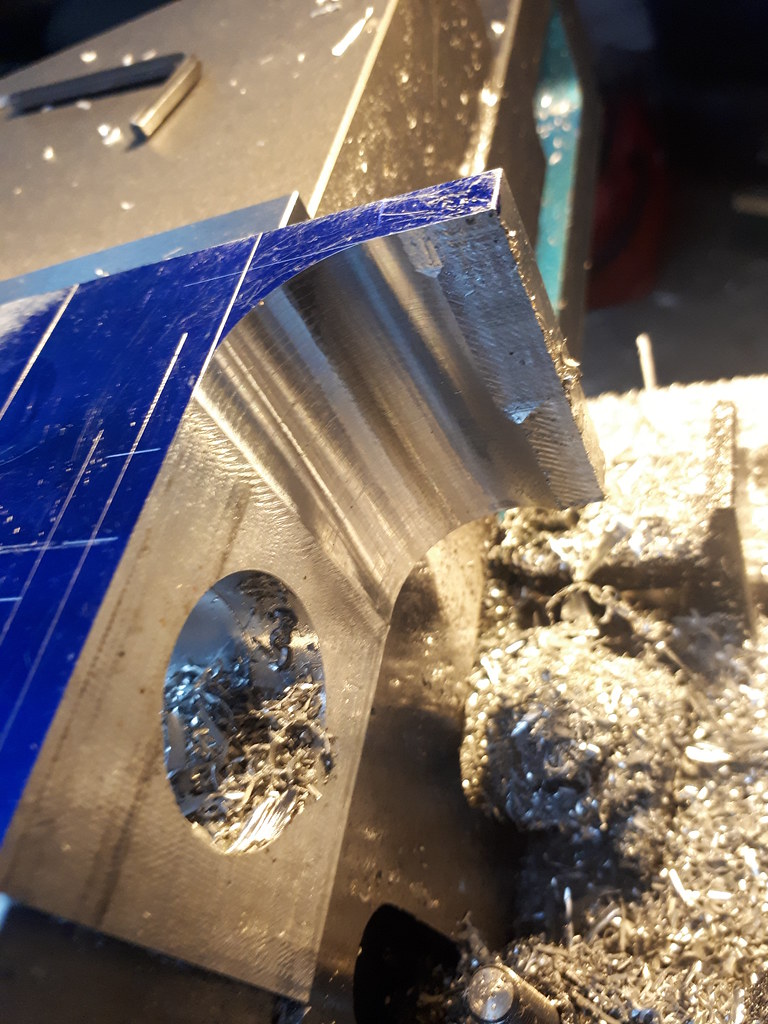

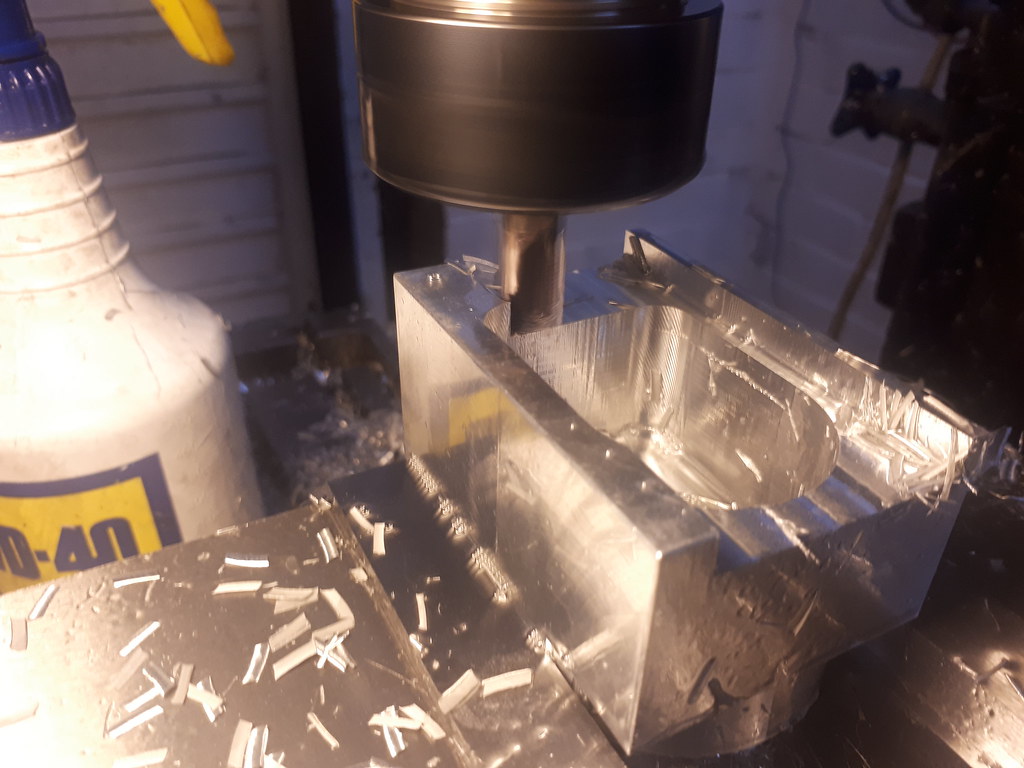

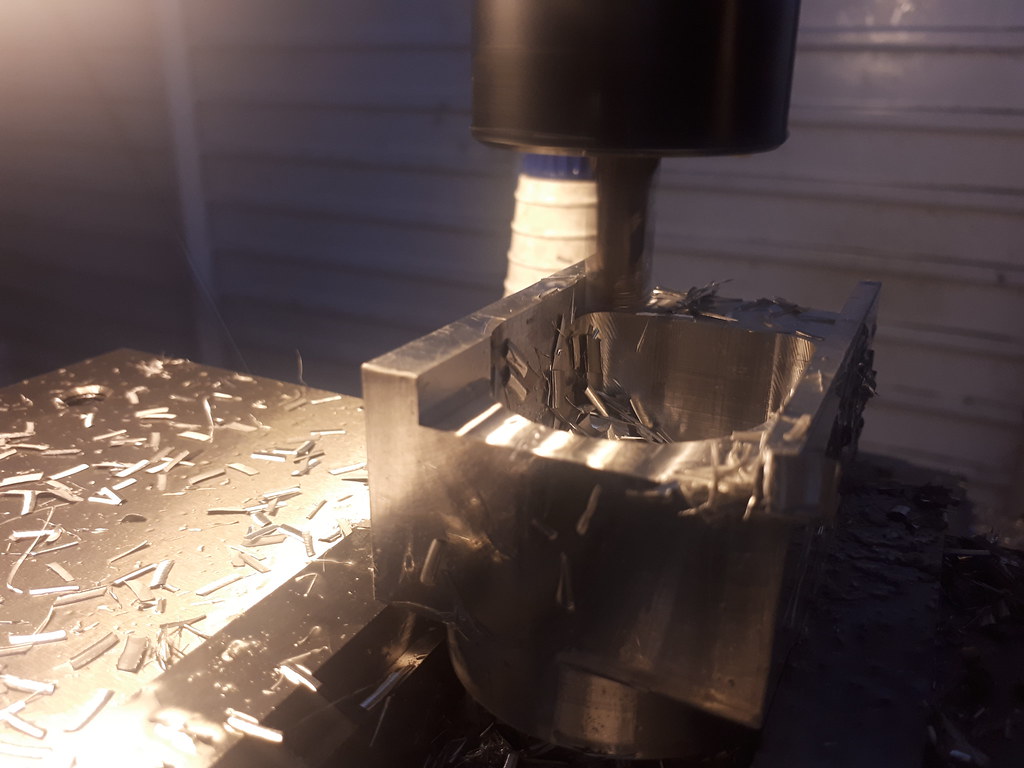

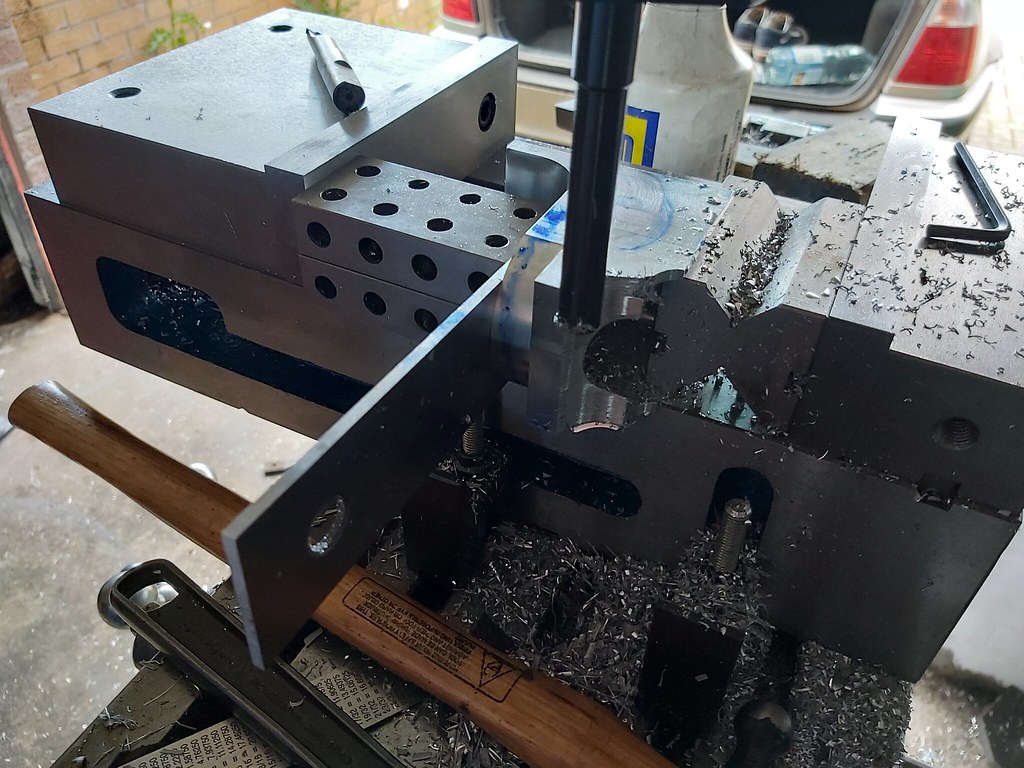

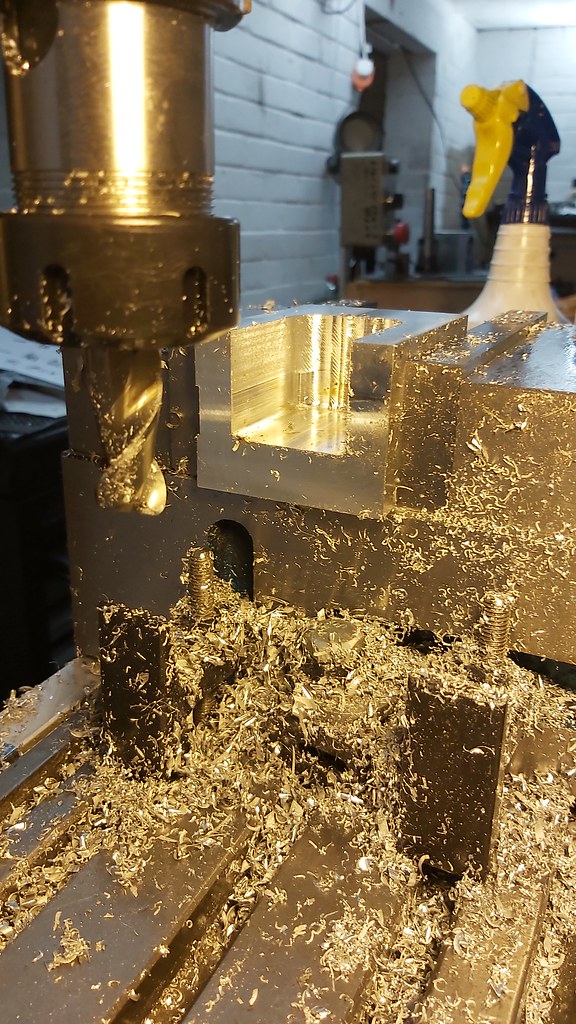

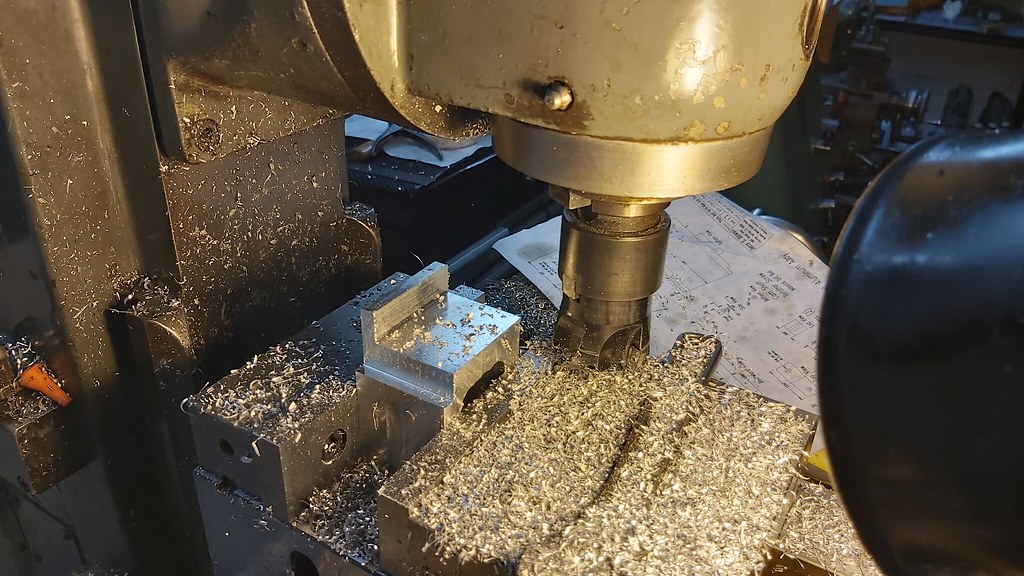

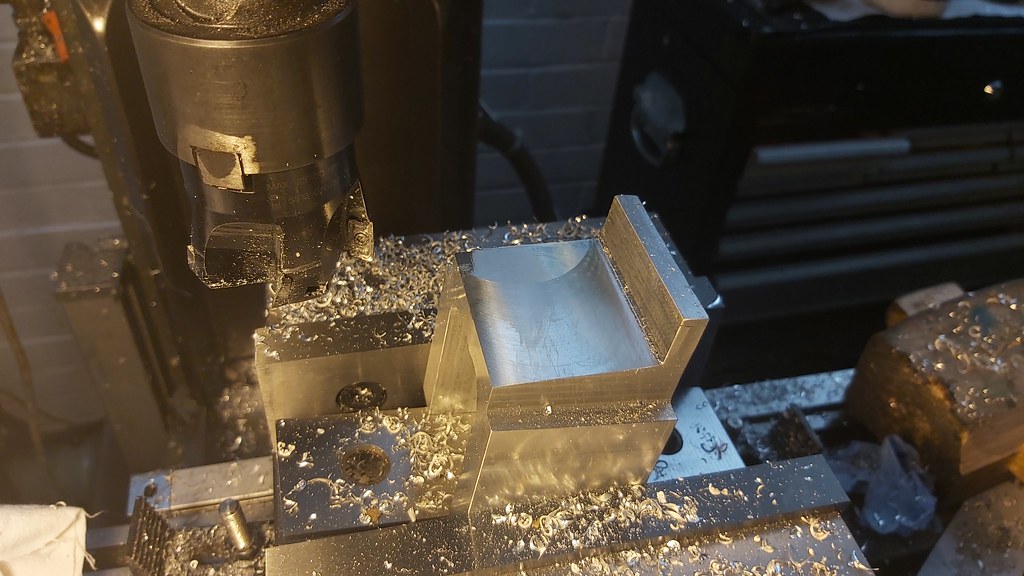

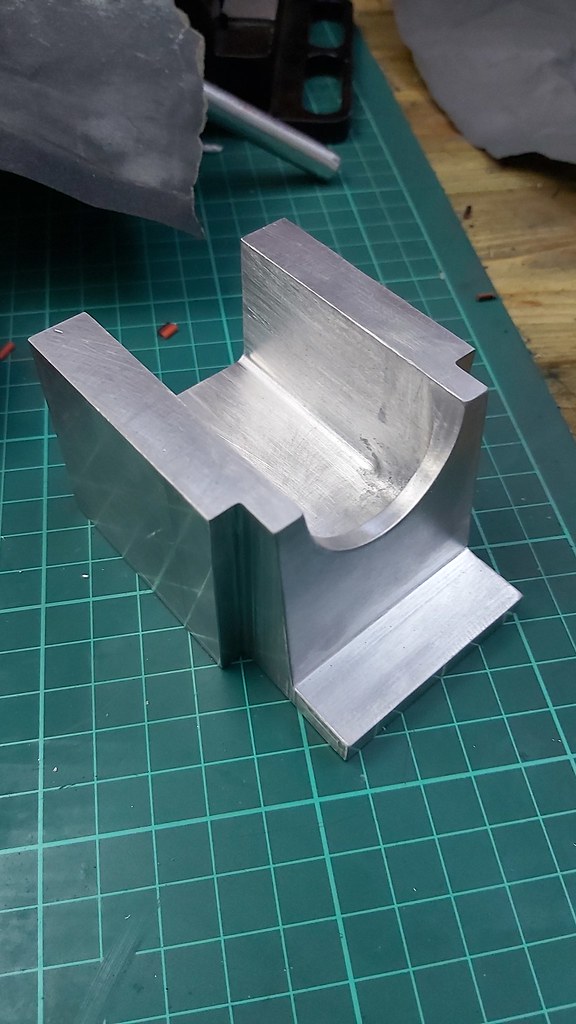

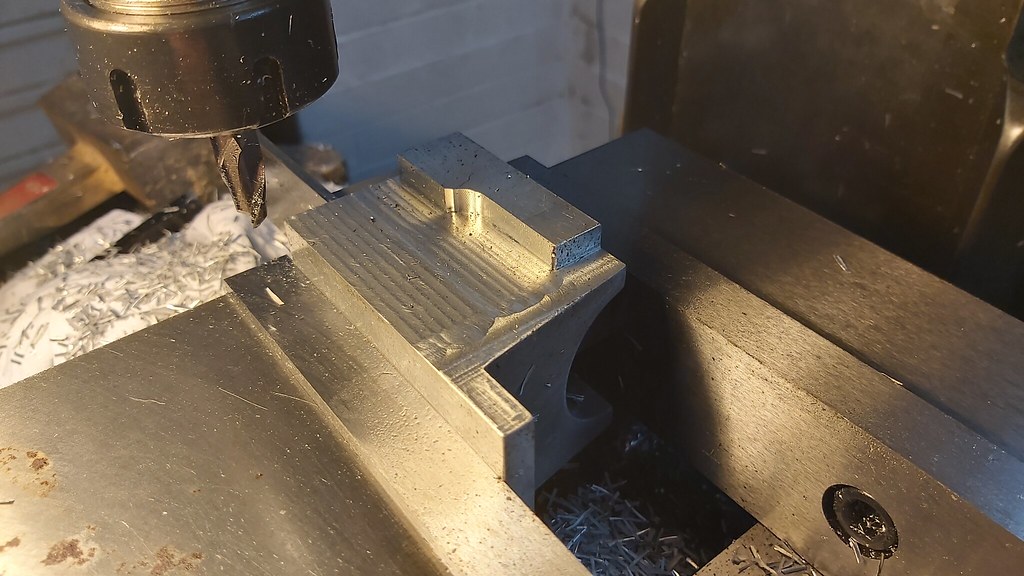

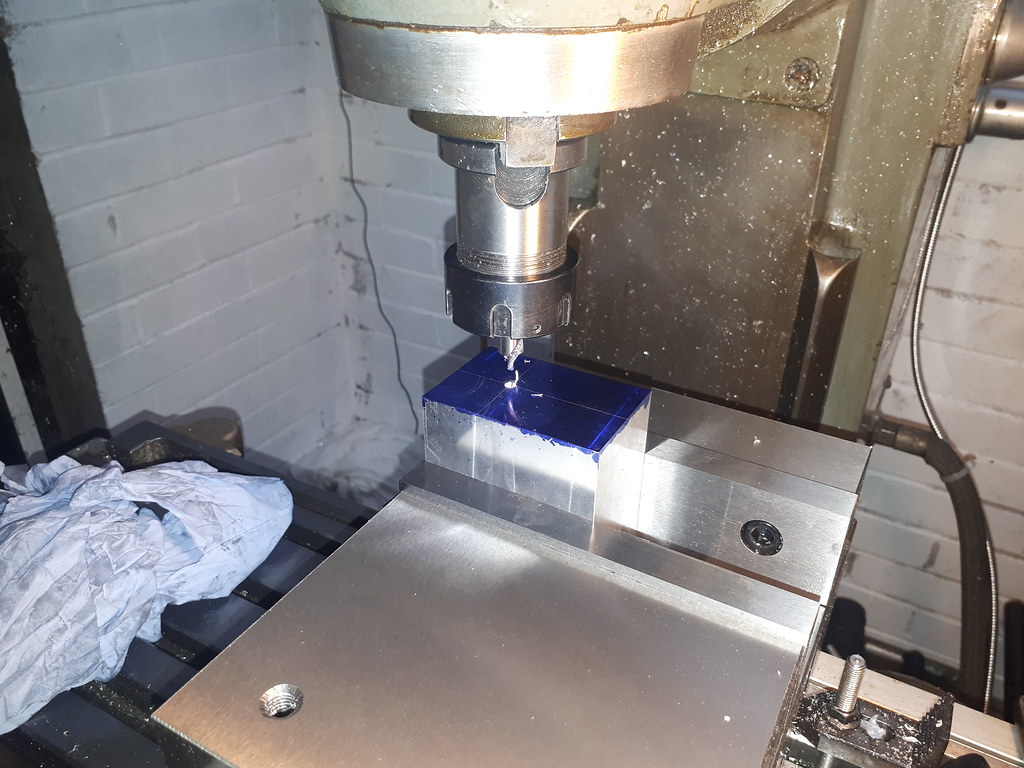

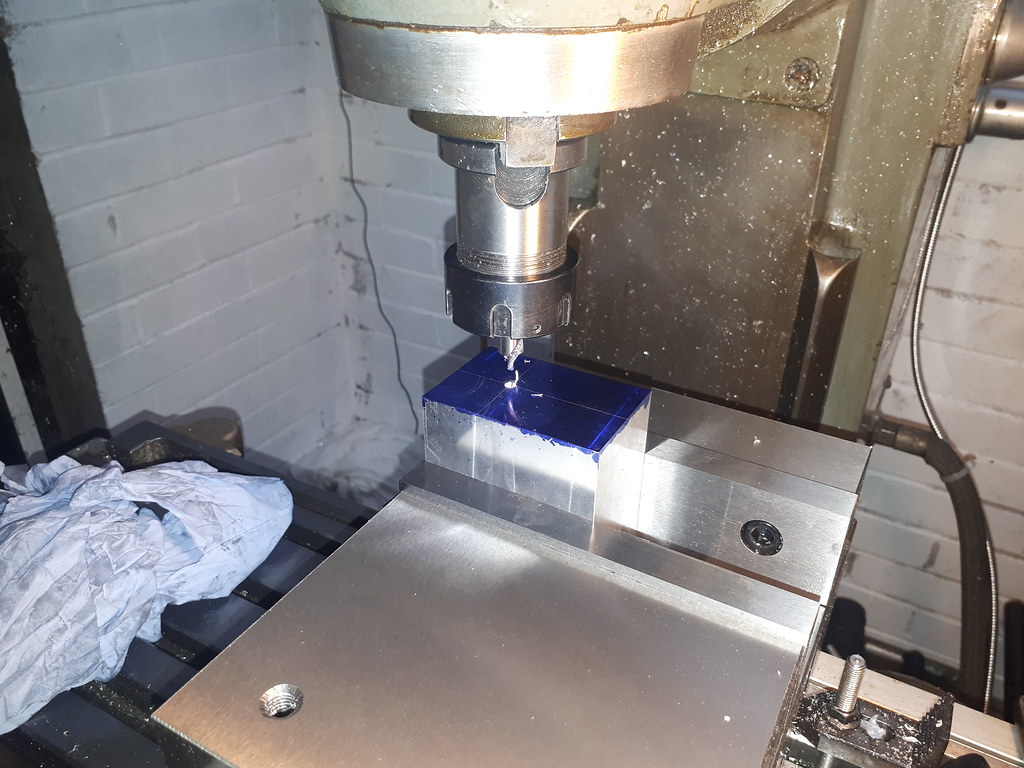

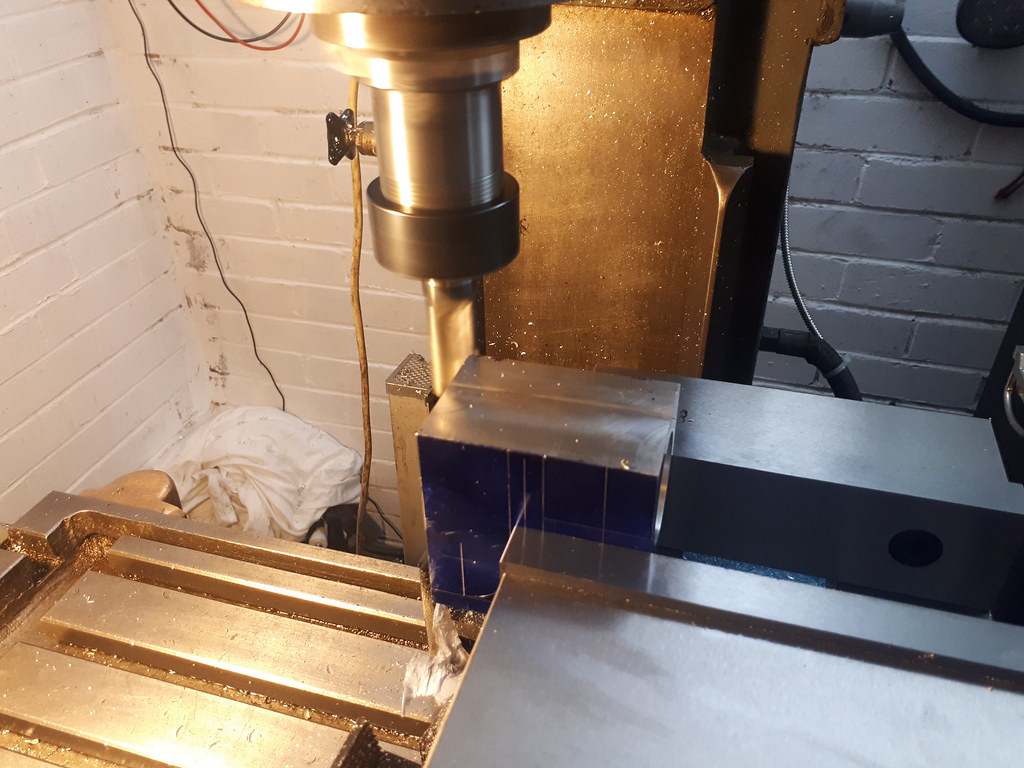

After my first cut, measured and the DRO set so it's simply a case of working toward the 3.0000" mark - double checked on final cut and it came in perfectly. Rotated 90 degrees on the Y axis and did the same. Then rotated 90 degrees along X axis and worked to 2". Came in a hair under at 1.998" I am very surprised at the finish this facemill is giving, and the linear patterns to bother me and most of this will end up in a rubble sack as chips...

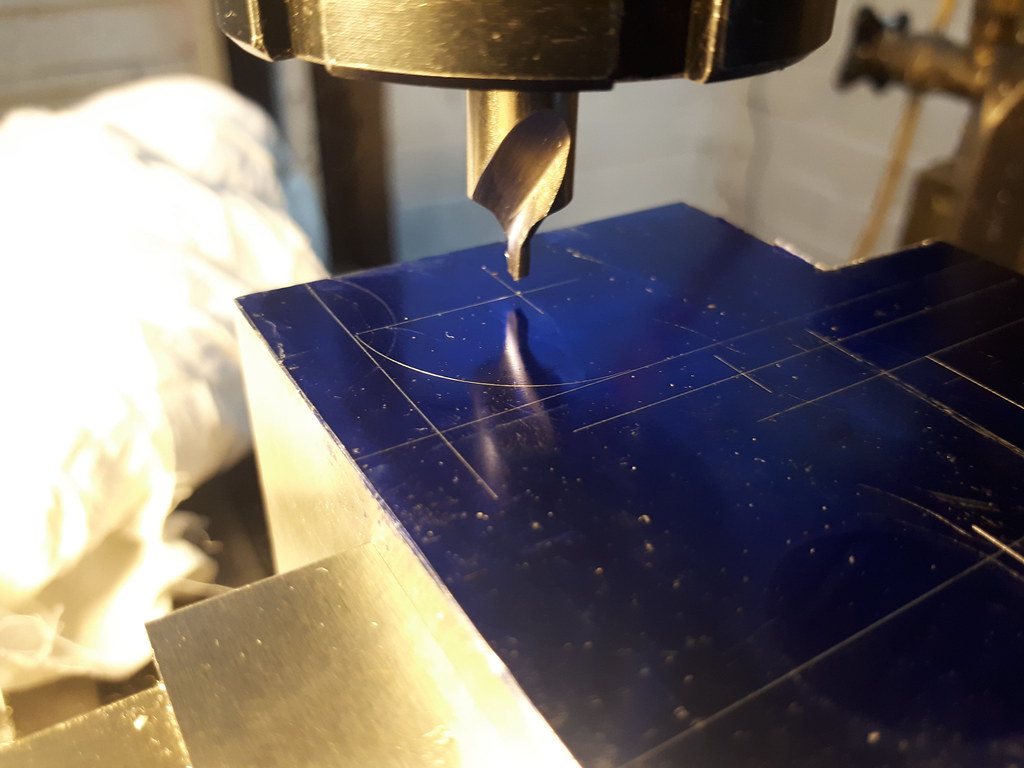

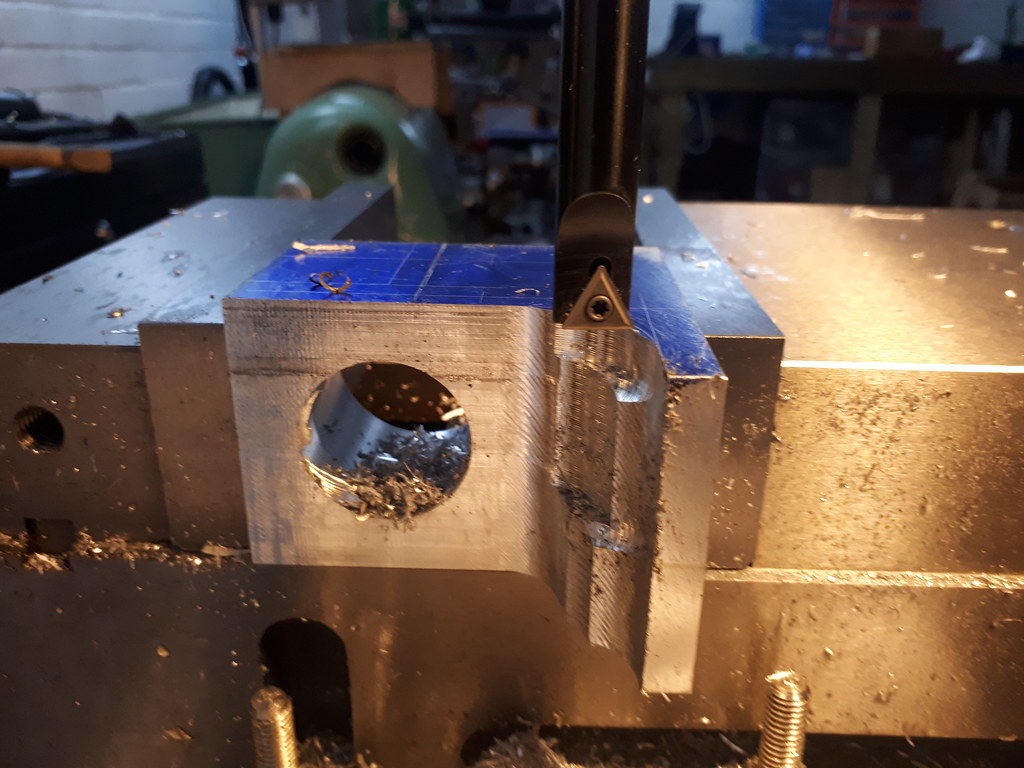

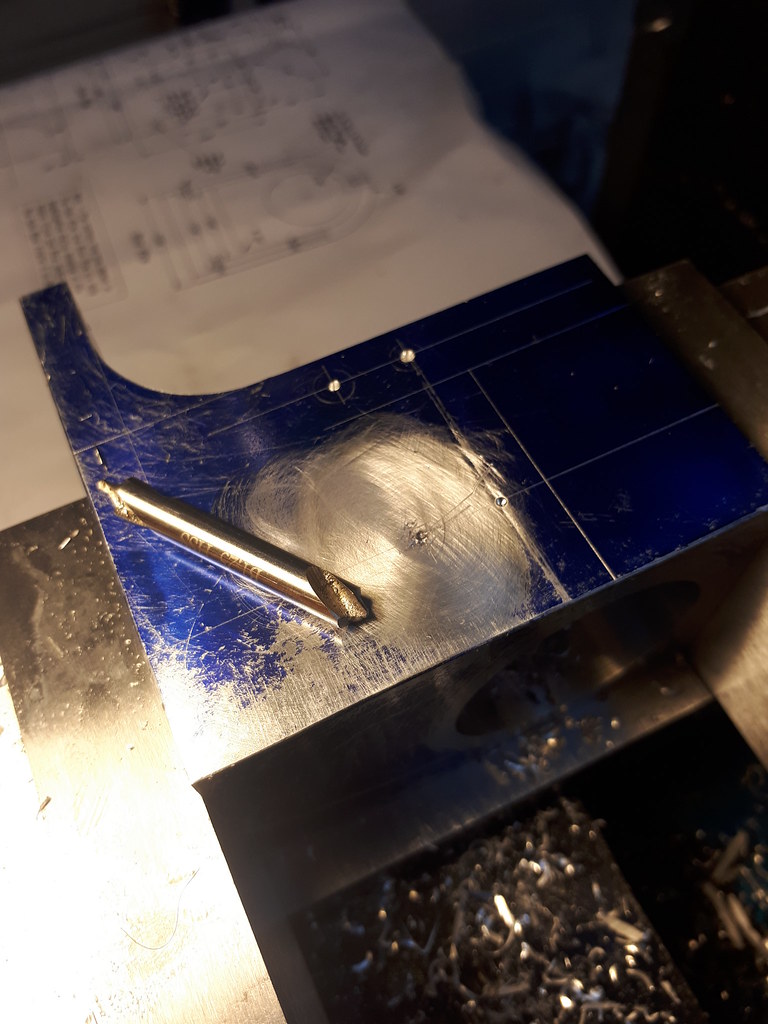

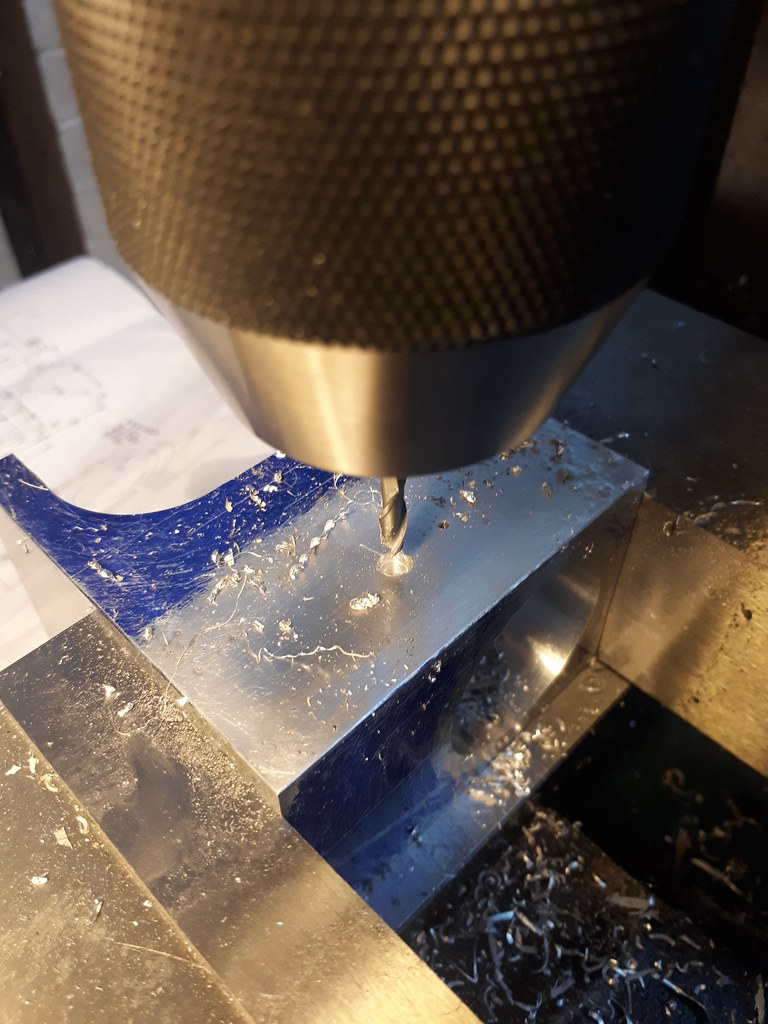

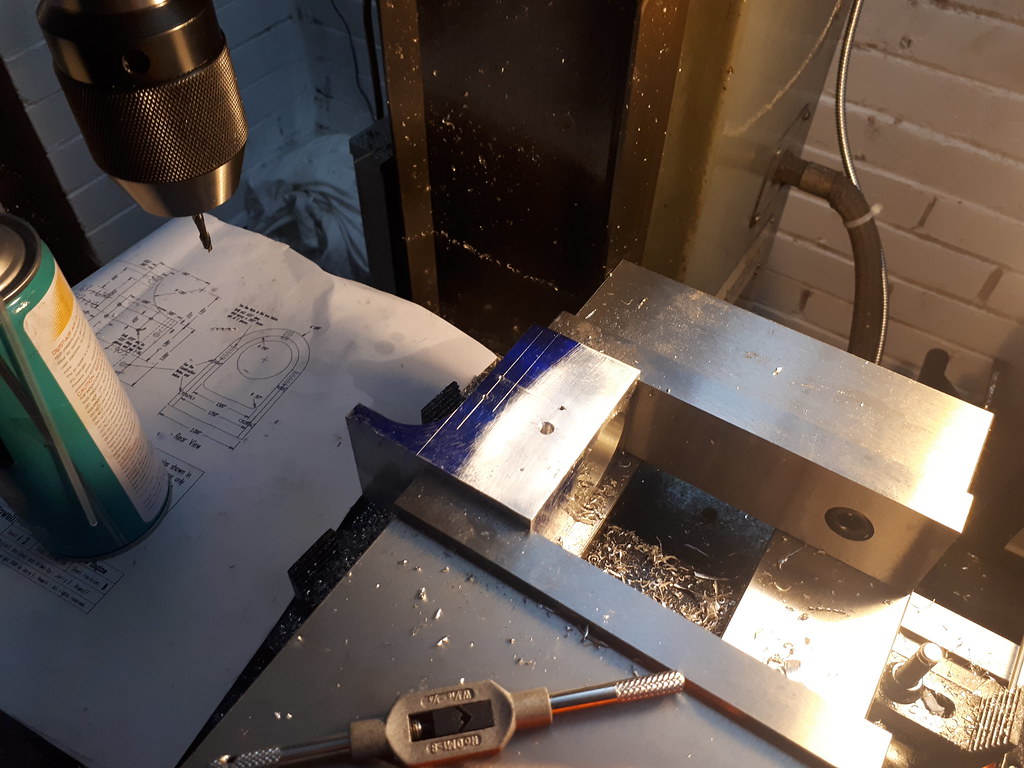

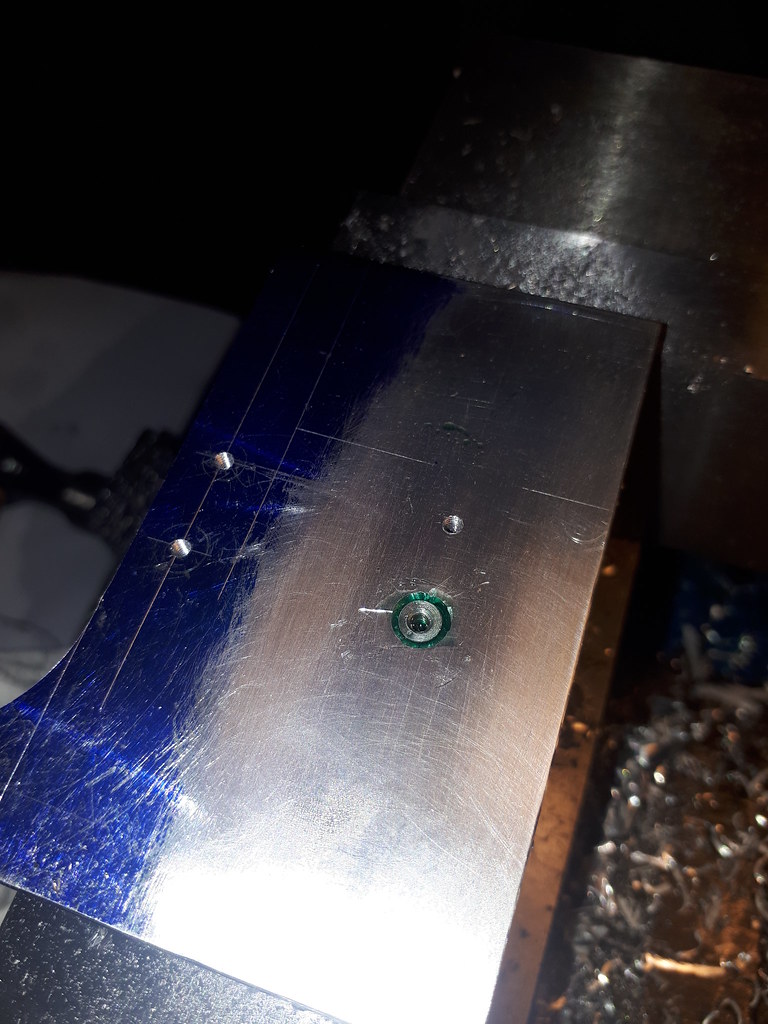

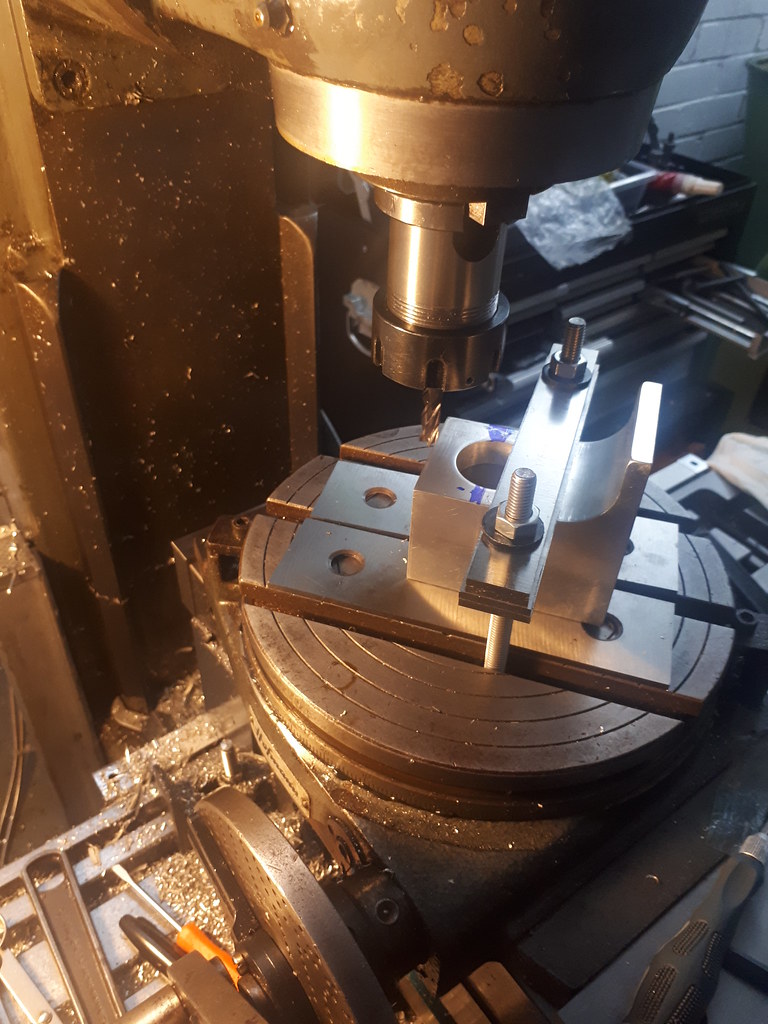

This time marking out the centre point before drilling:

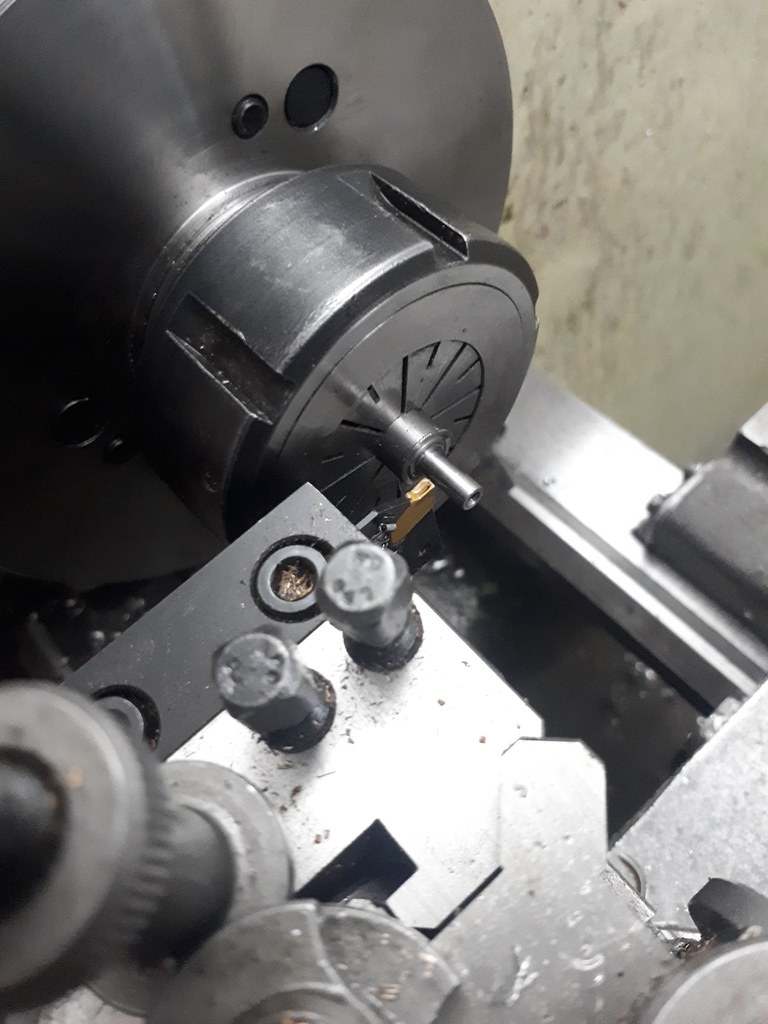

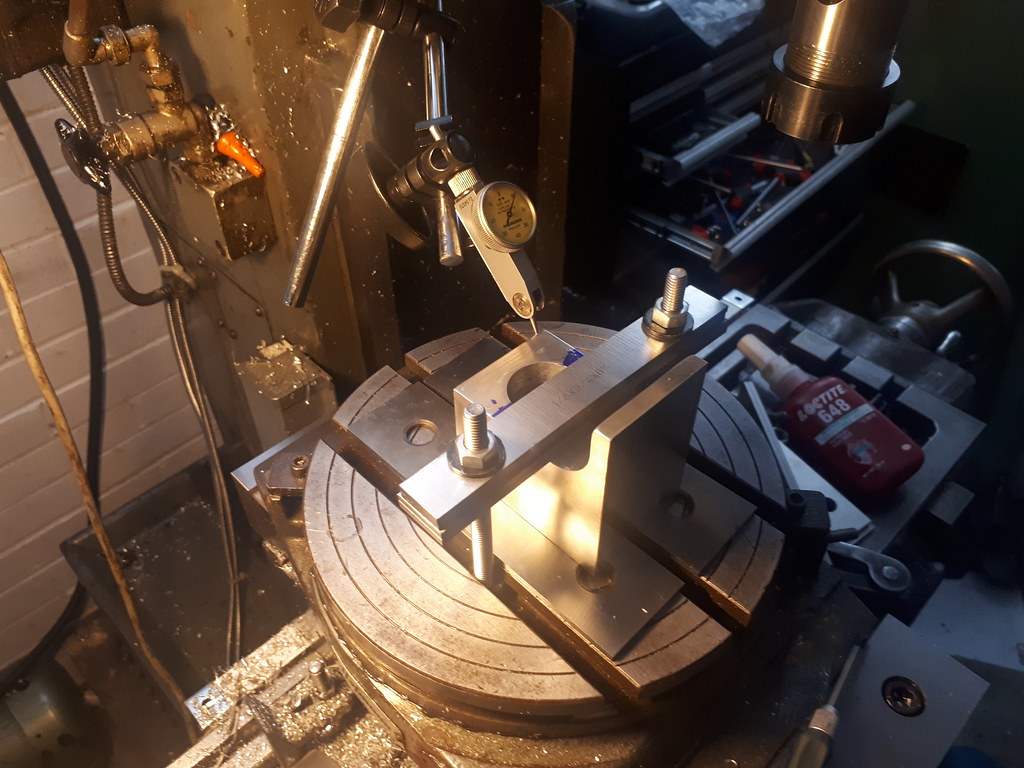

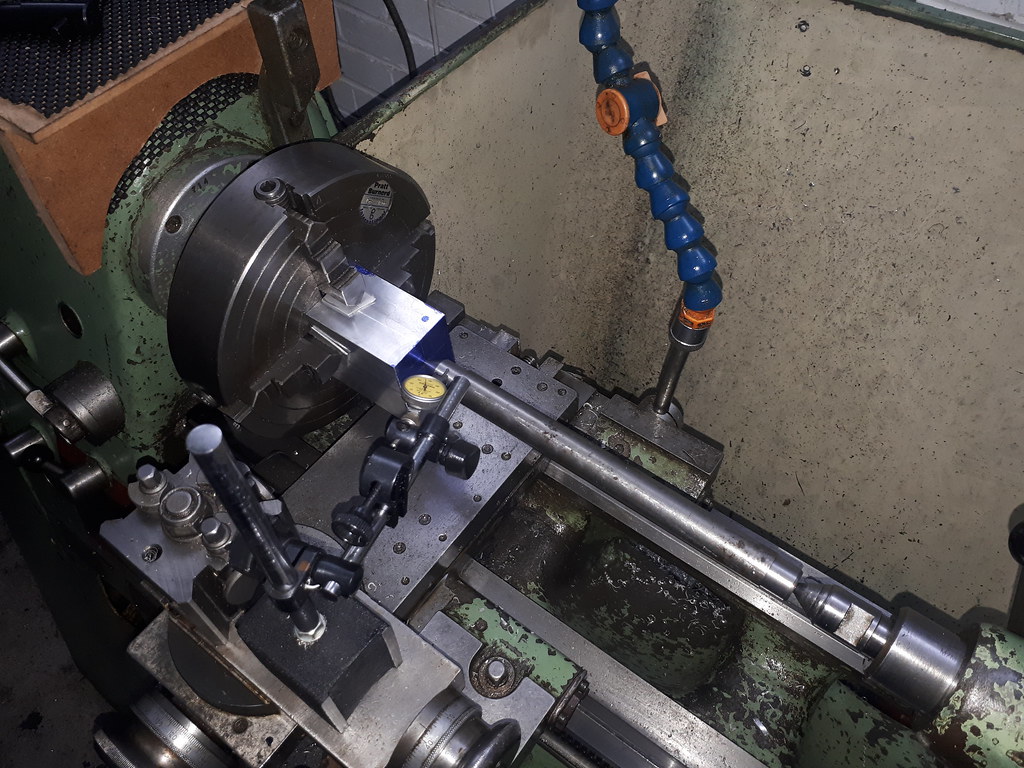

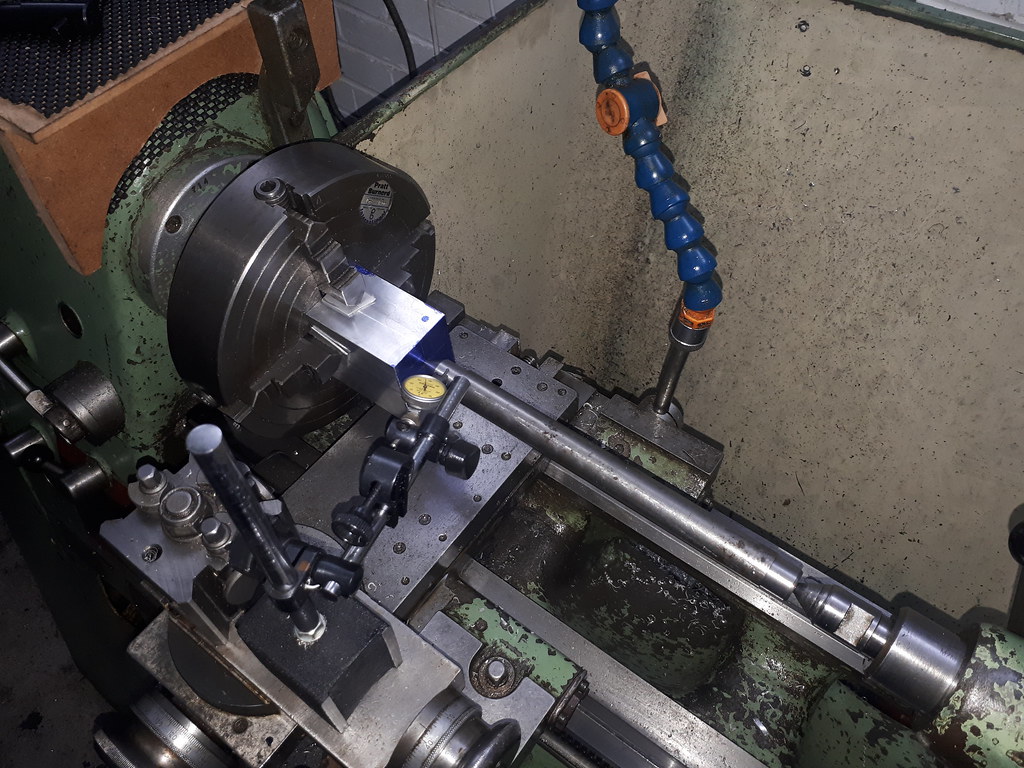

Indicating it in on the 4 jaw - using my "premade" test bar.

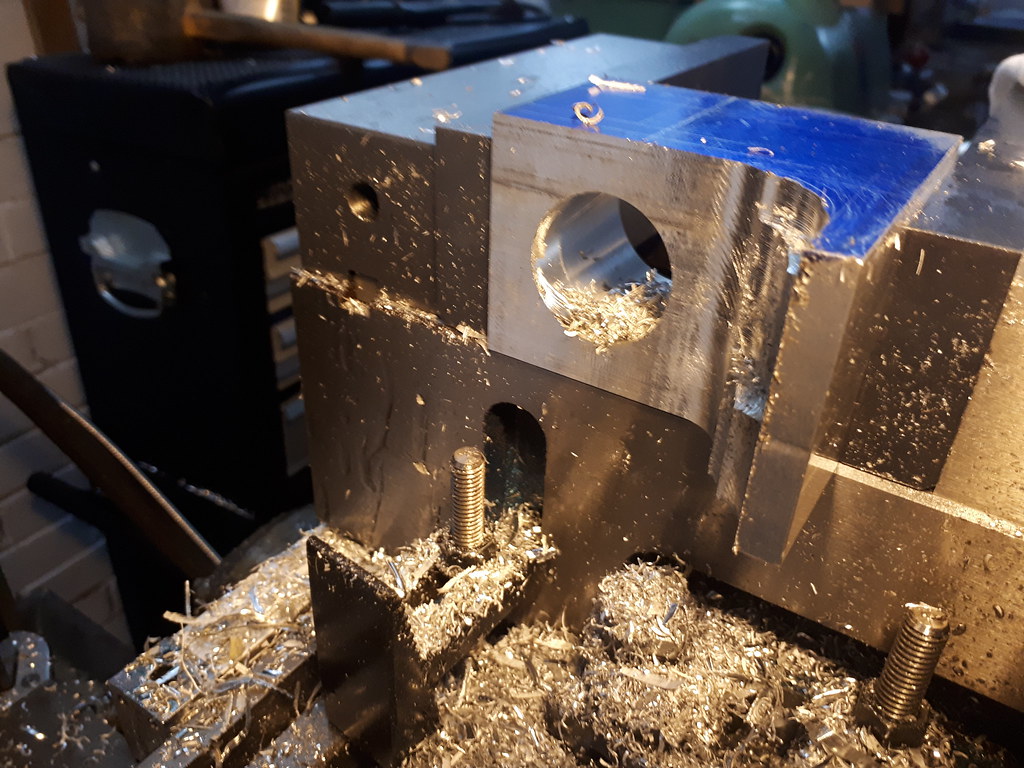

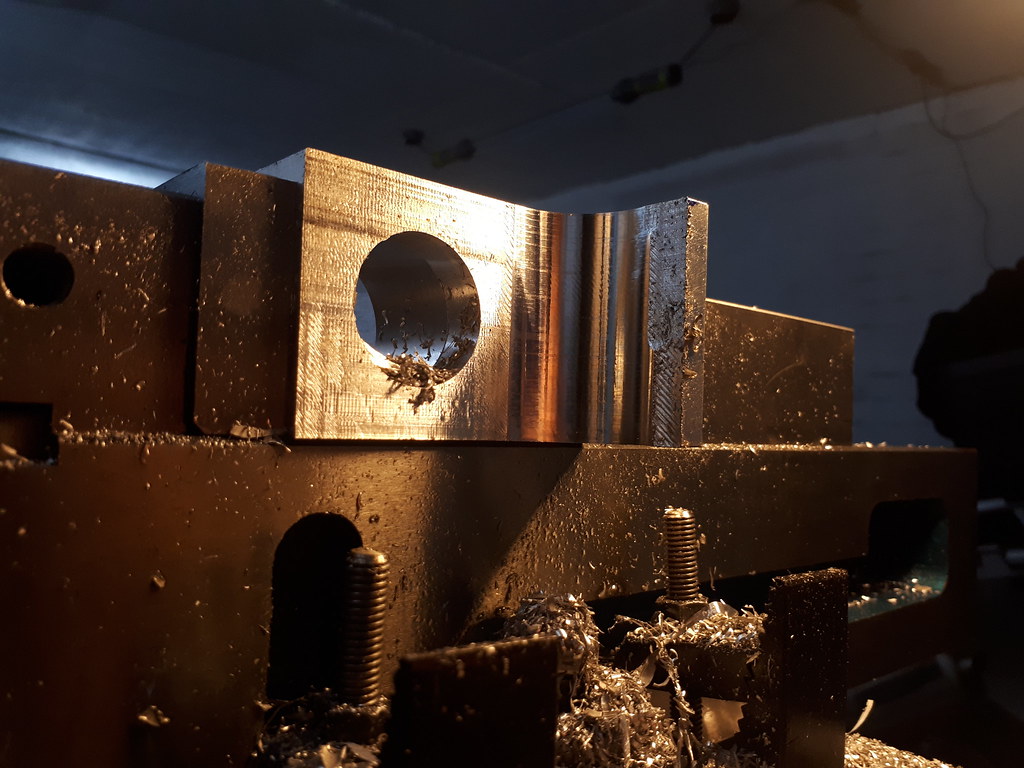

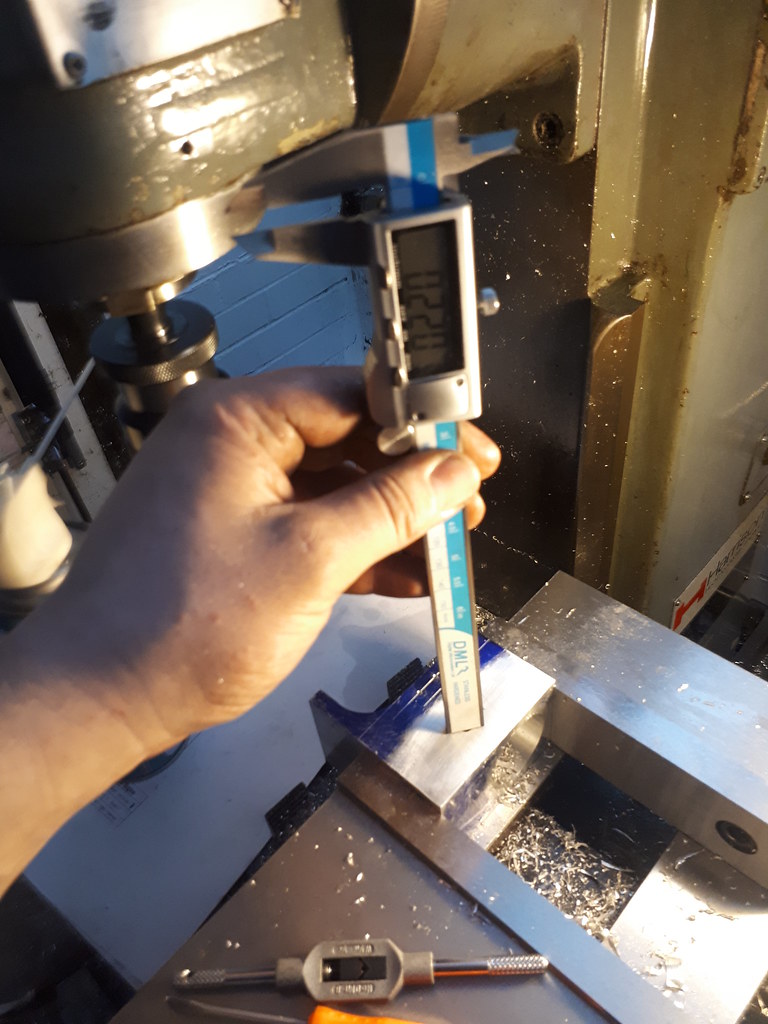

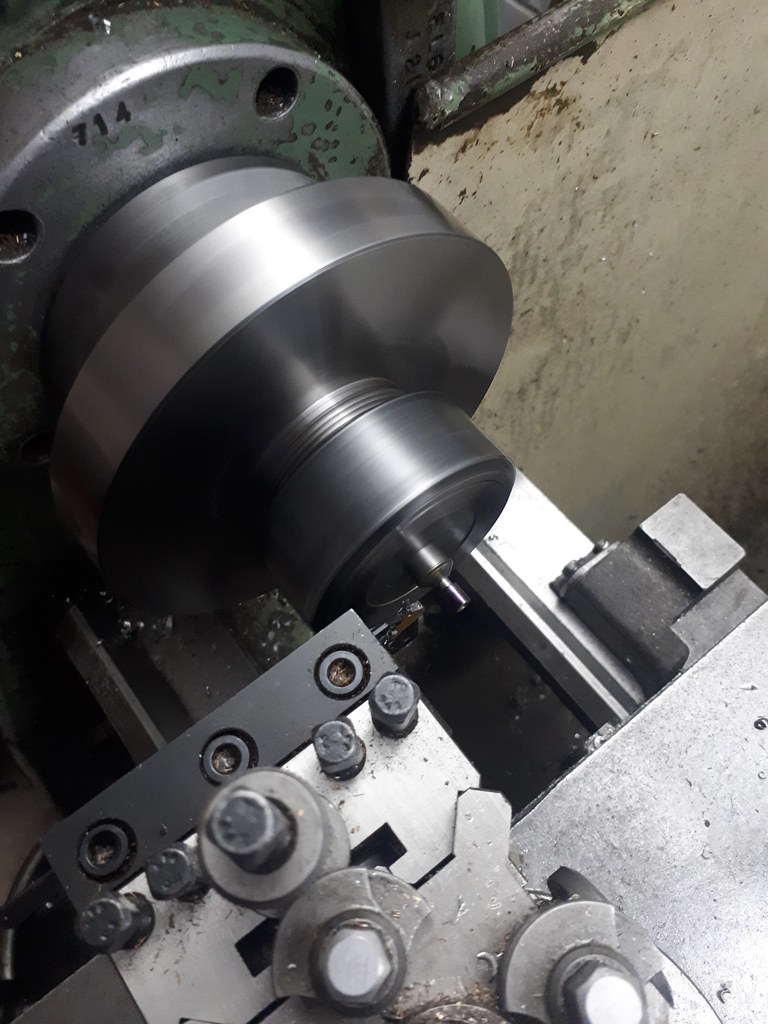

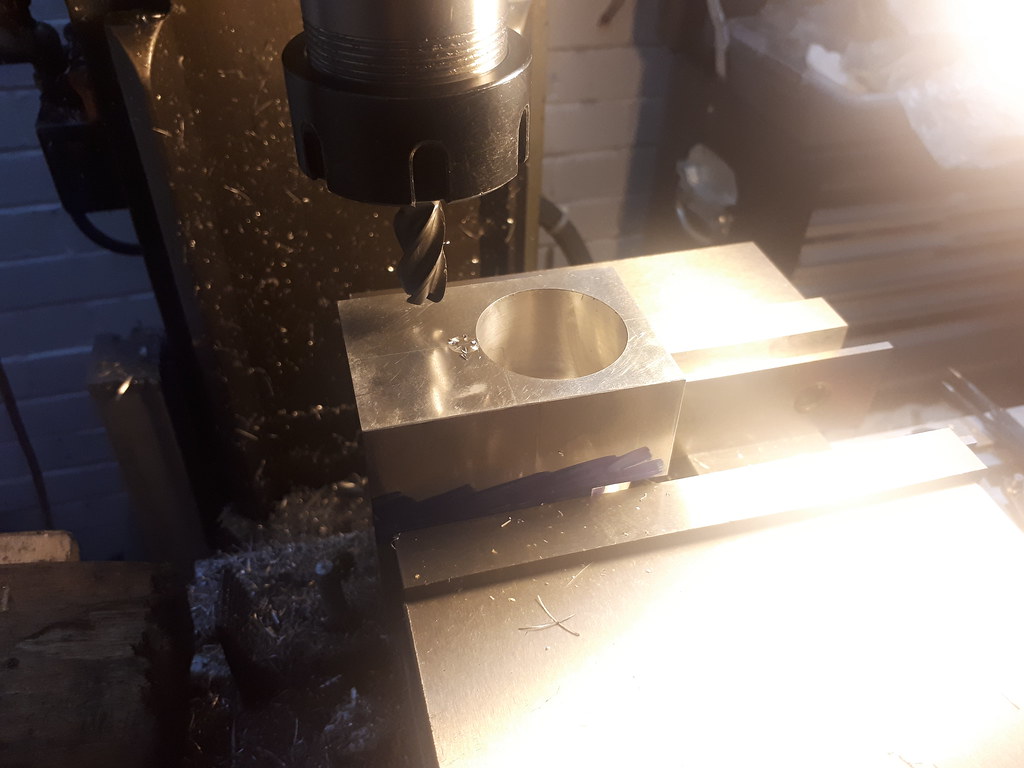

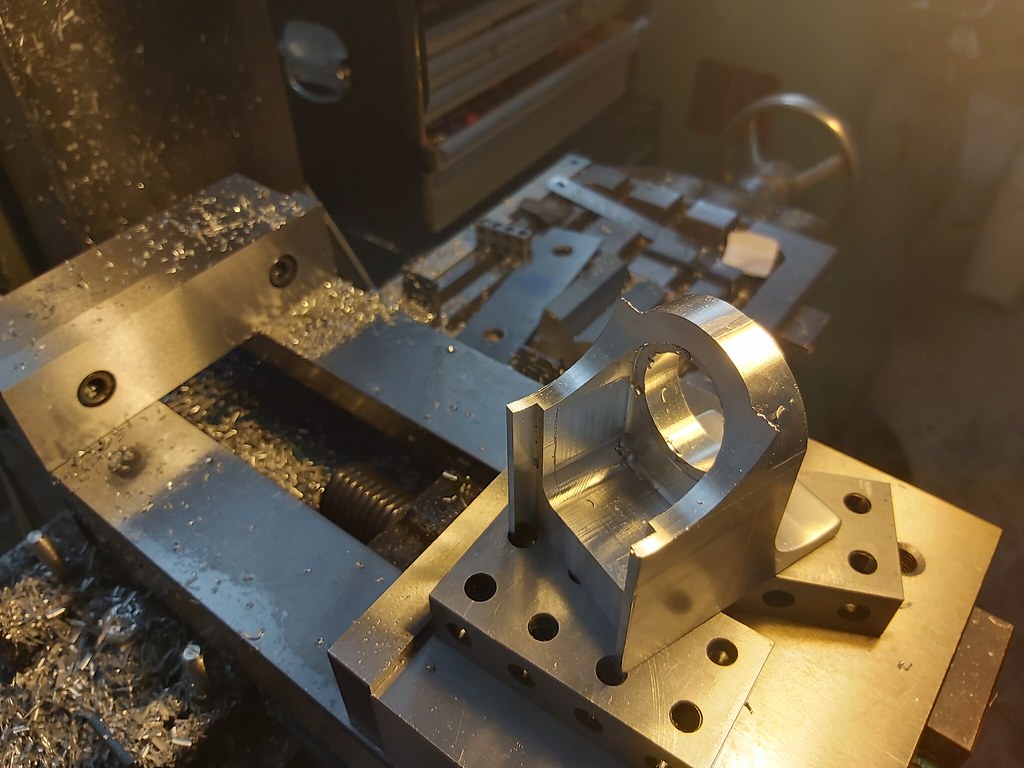

Halleluyah the dimensions are spot on this time. The scrap in the background there...

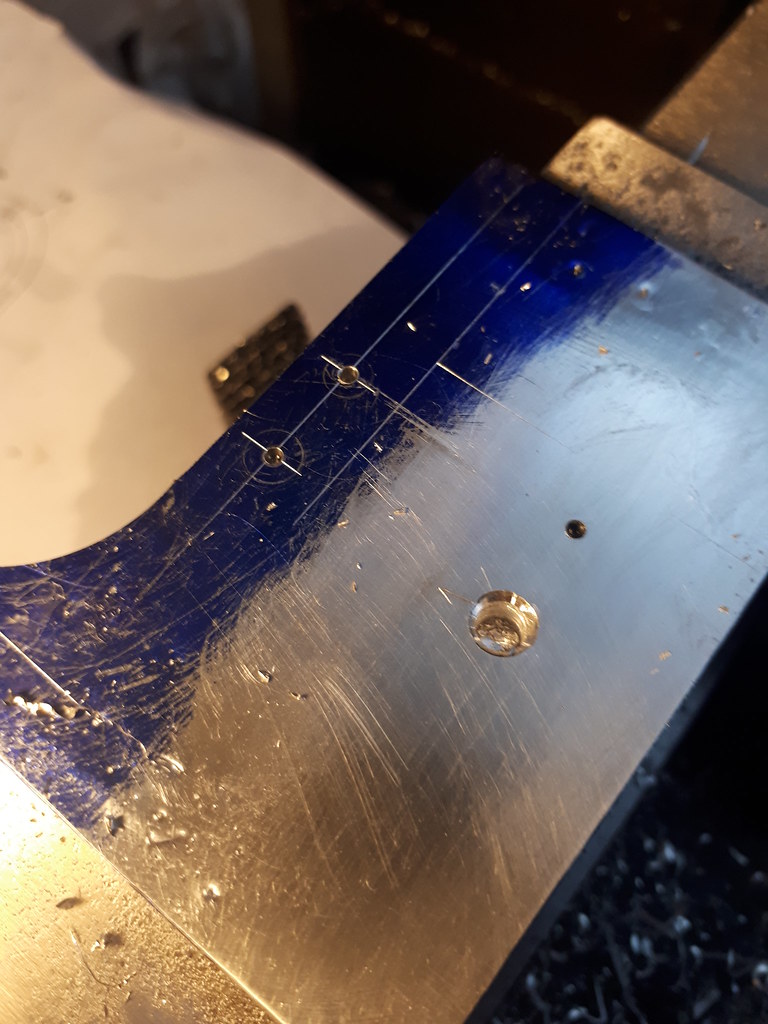

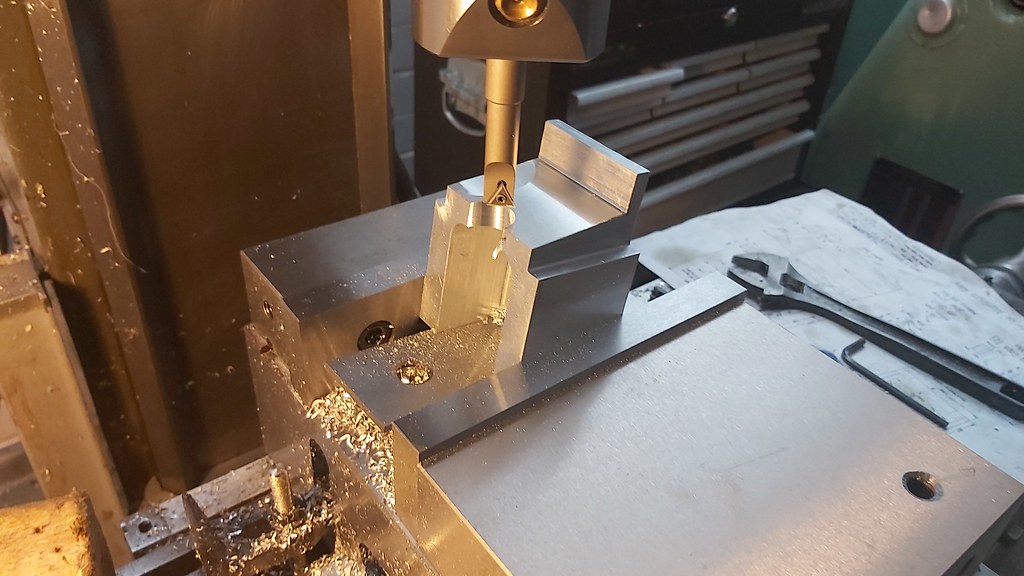

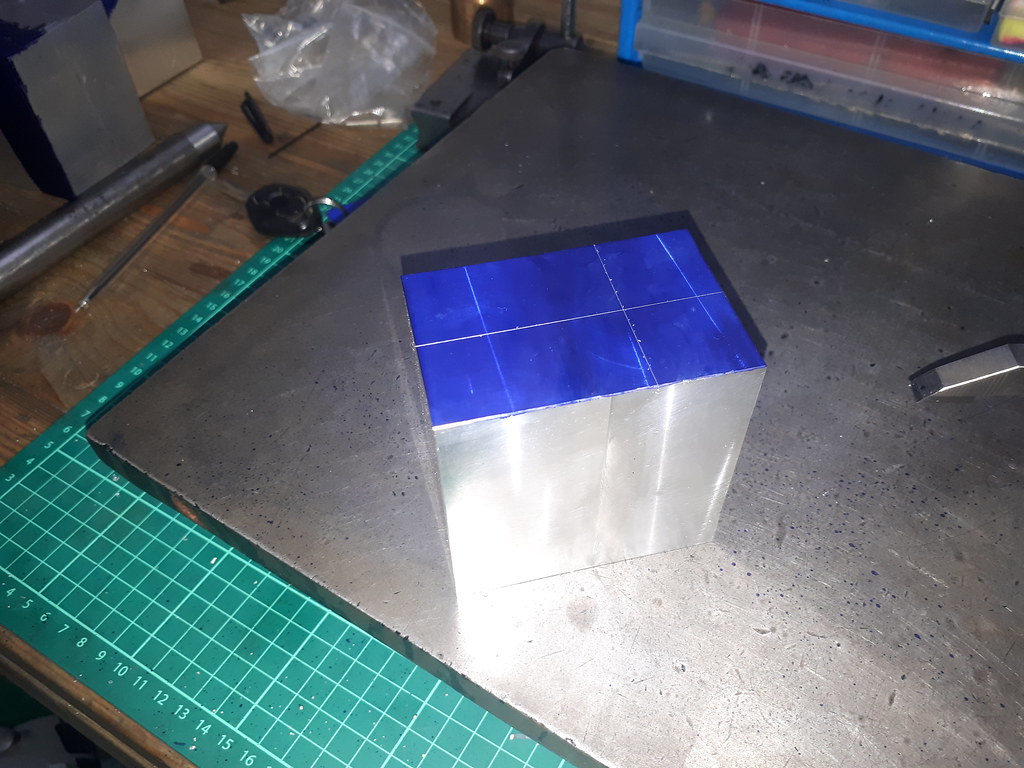

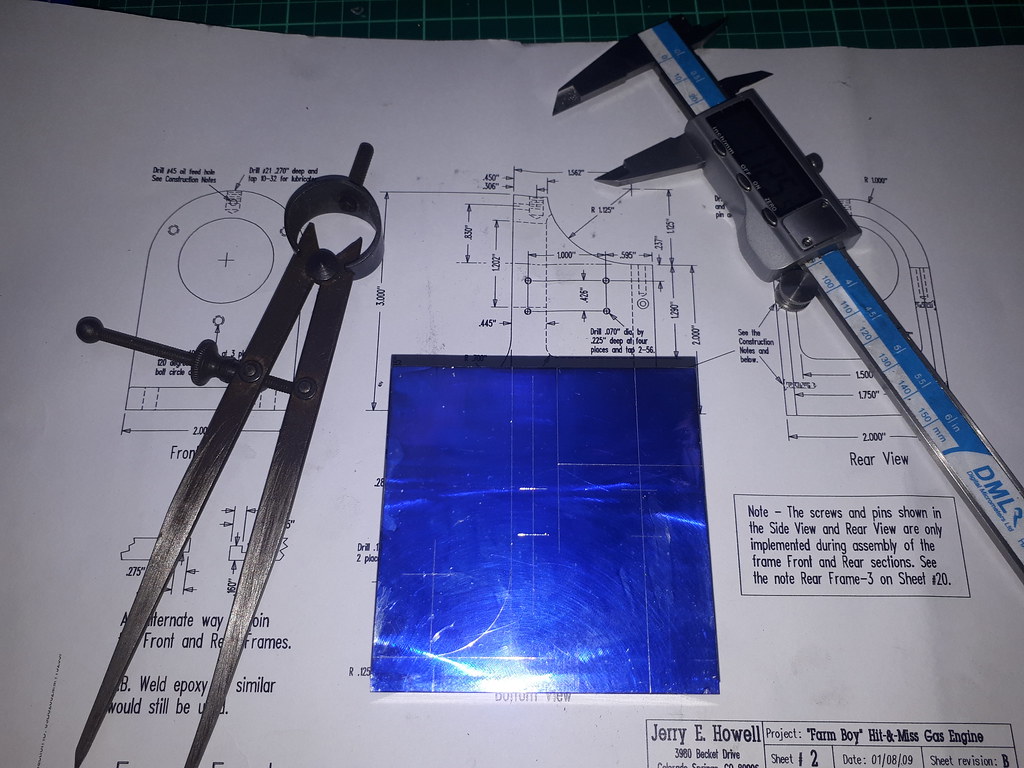

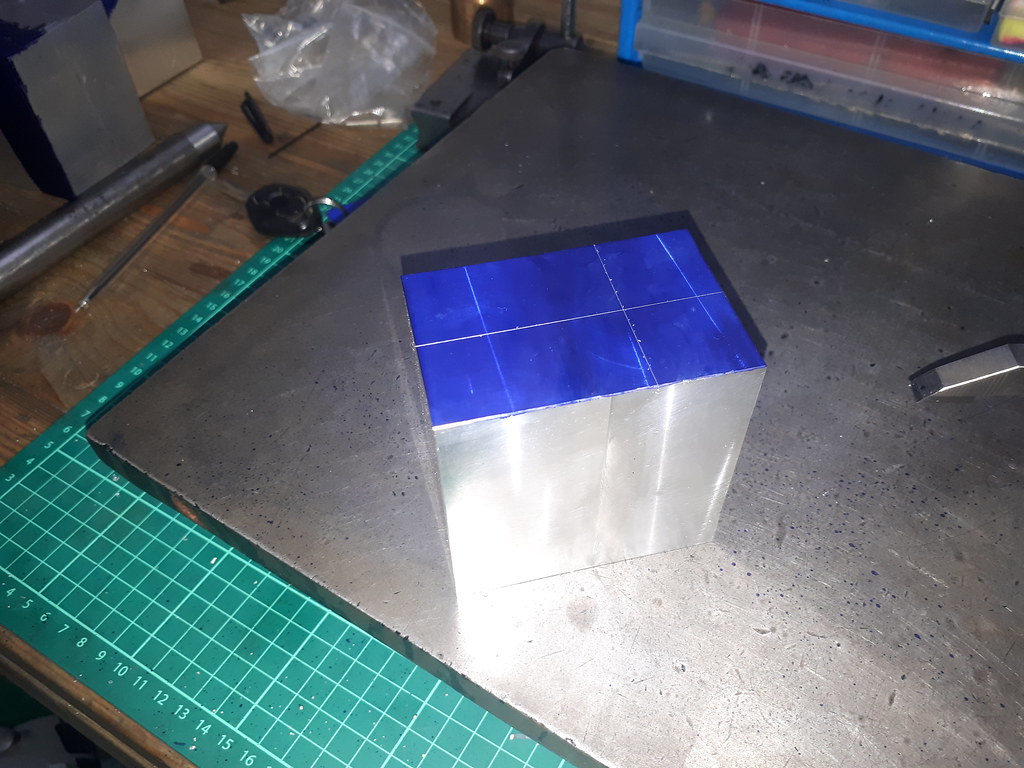

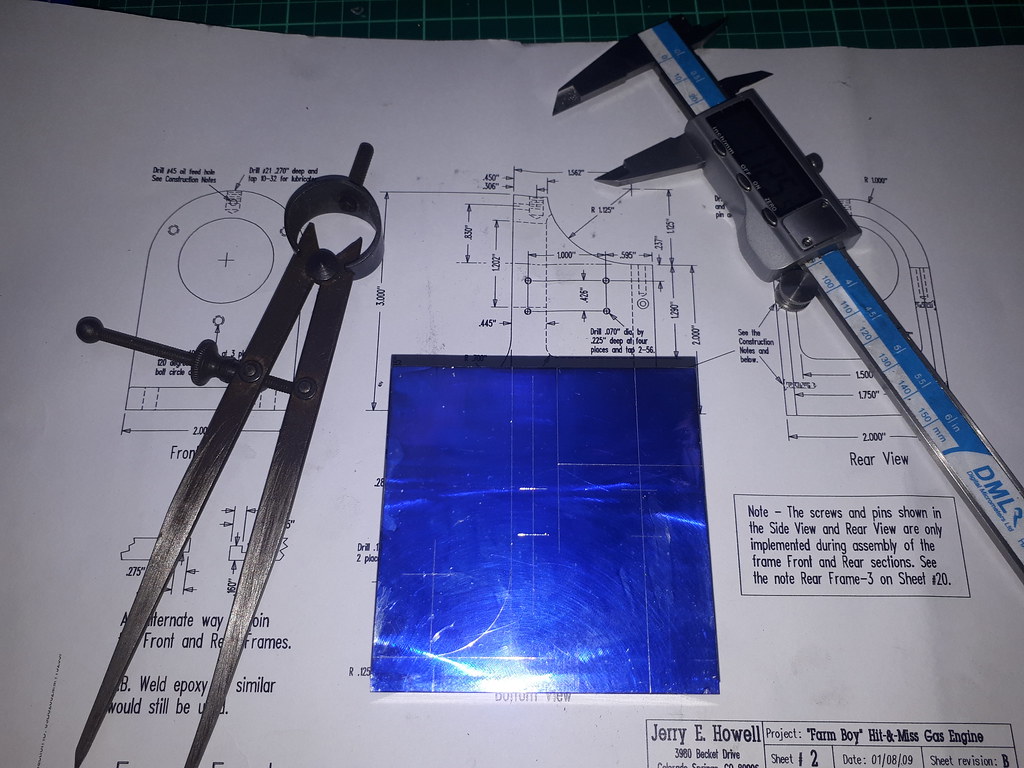

I have to say I am very pleased with this marking out. I just recently got the height gauge for a very reasonable £39 and it looks brand new! Few important lines marked up. And then on wards with more chip making!

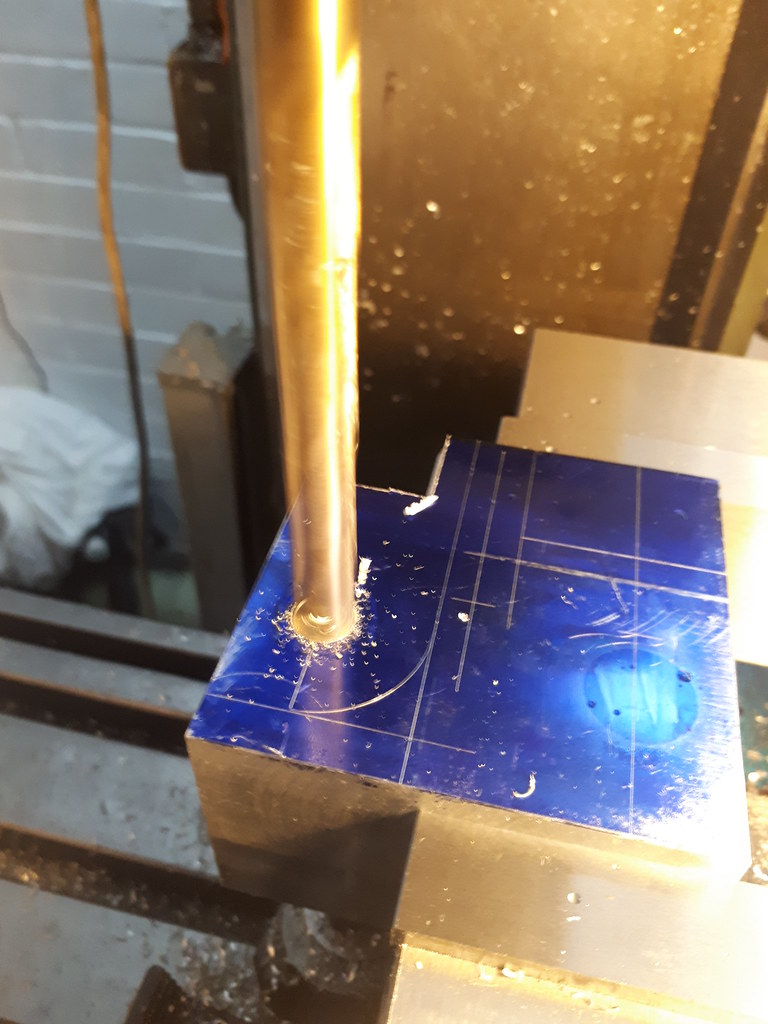

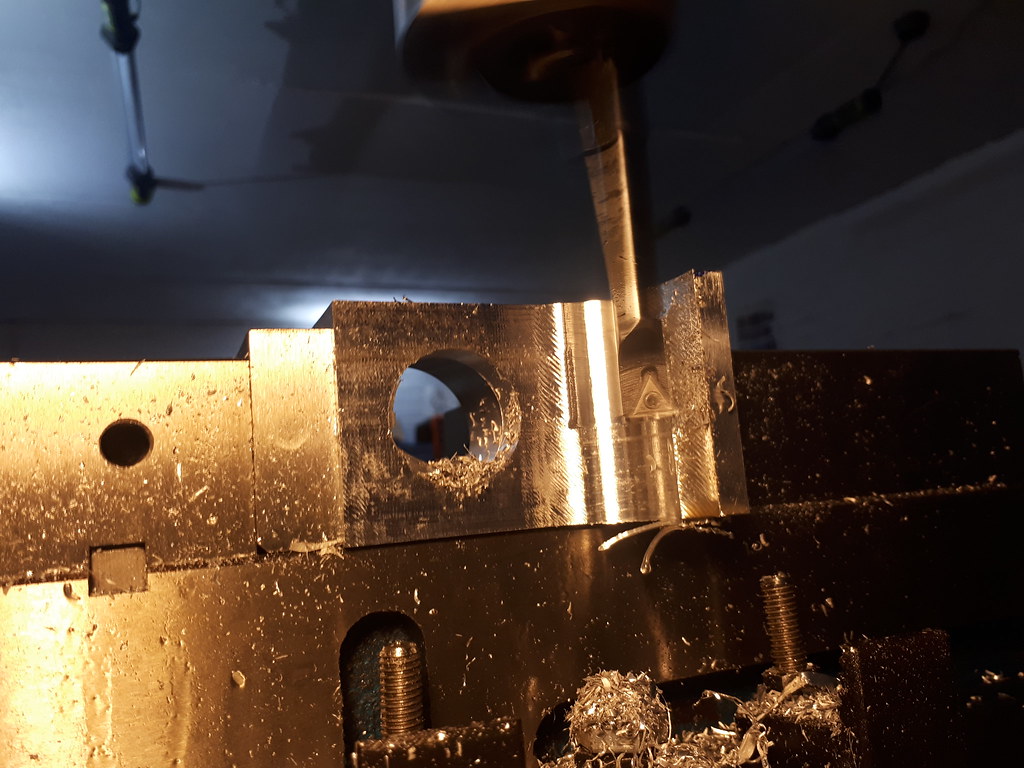

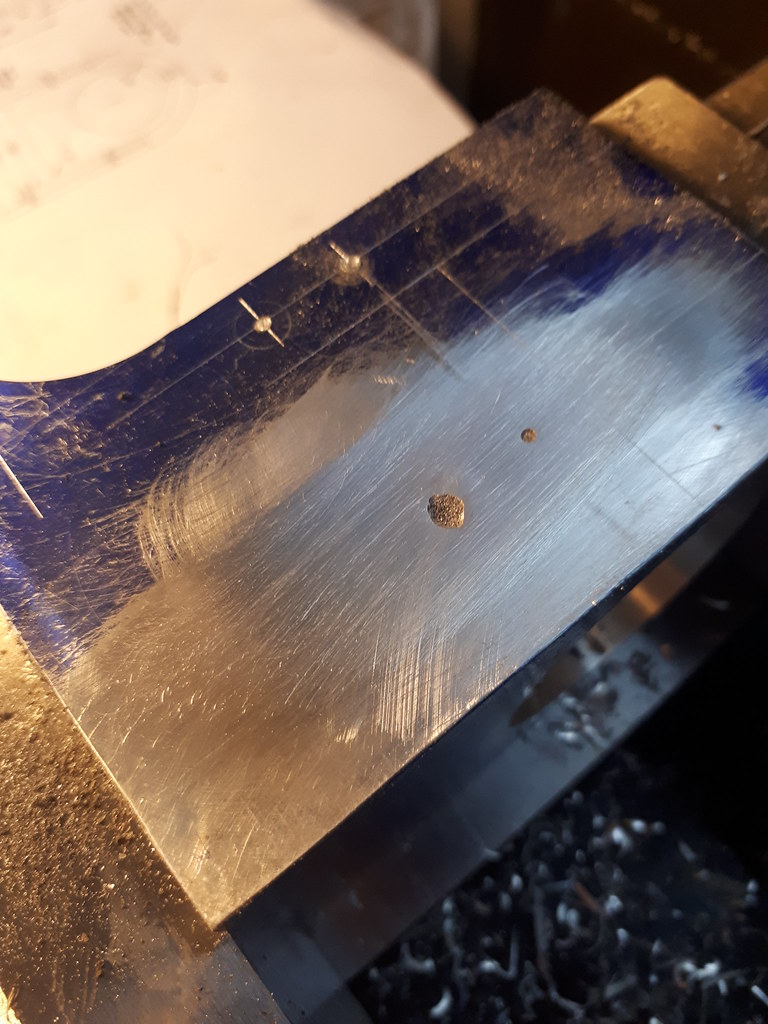

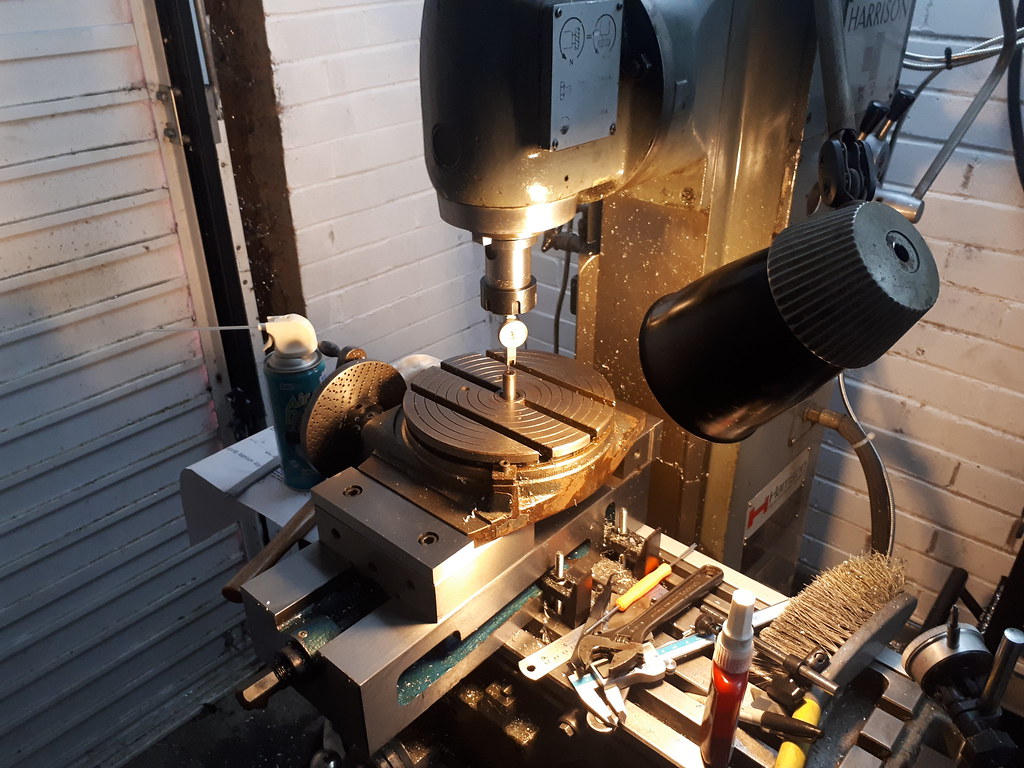

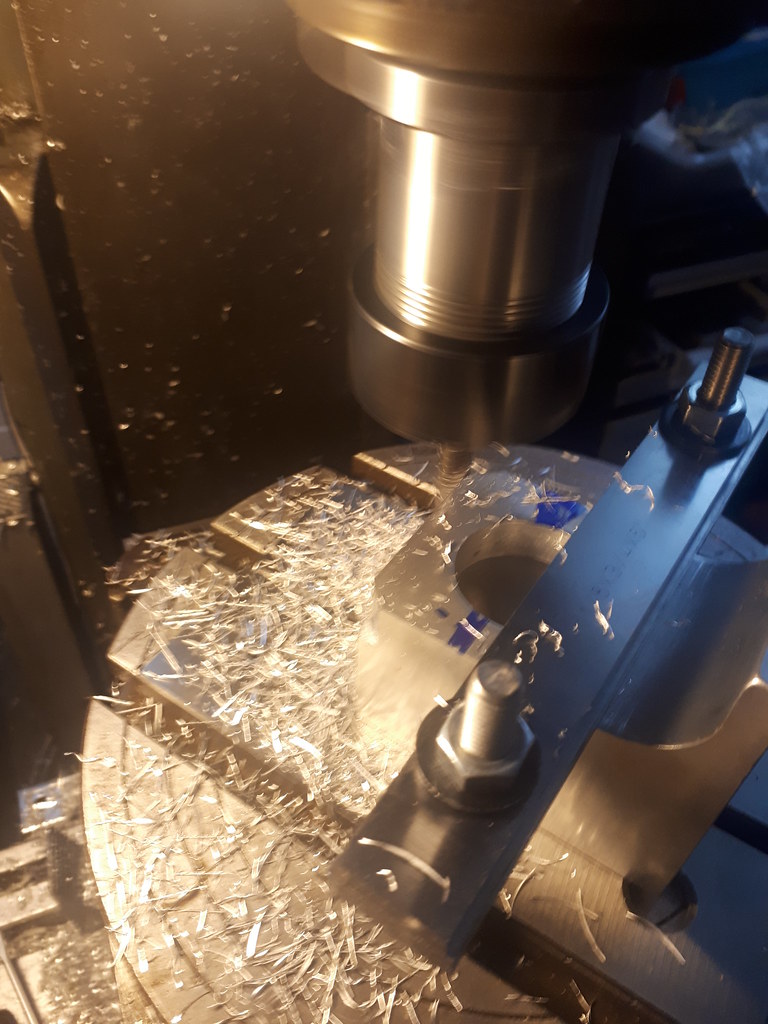

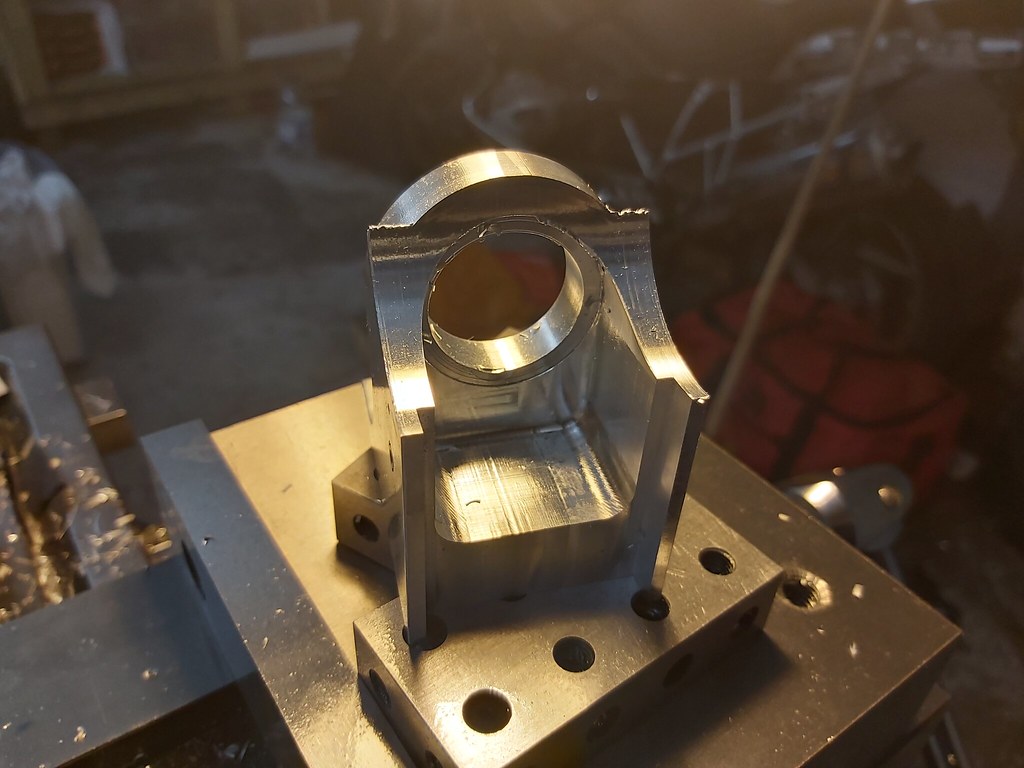

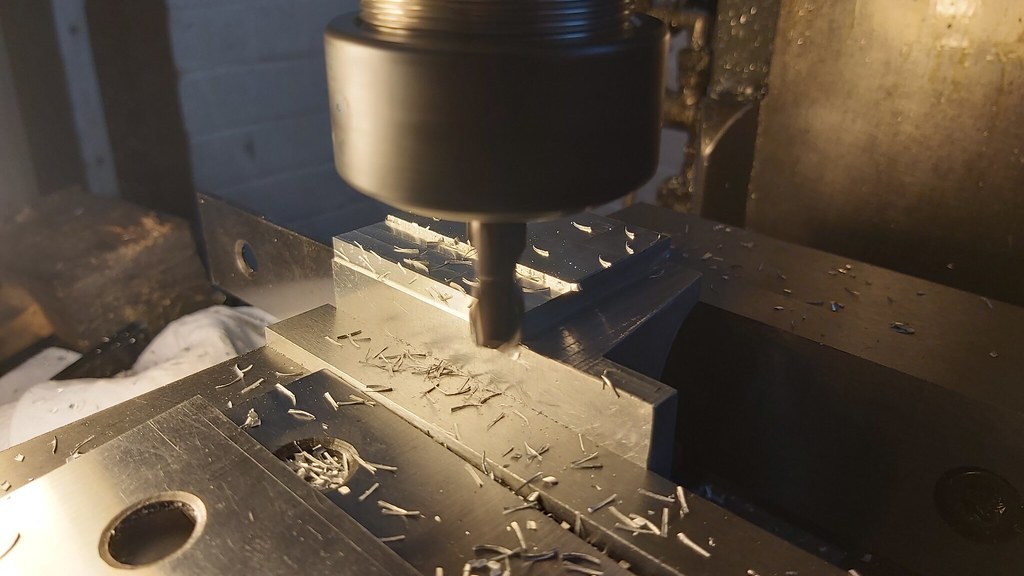

Auld ripper.

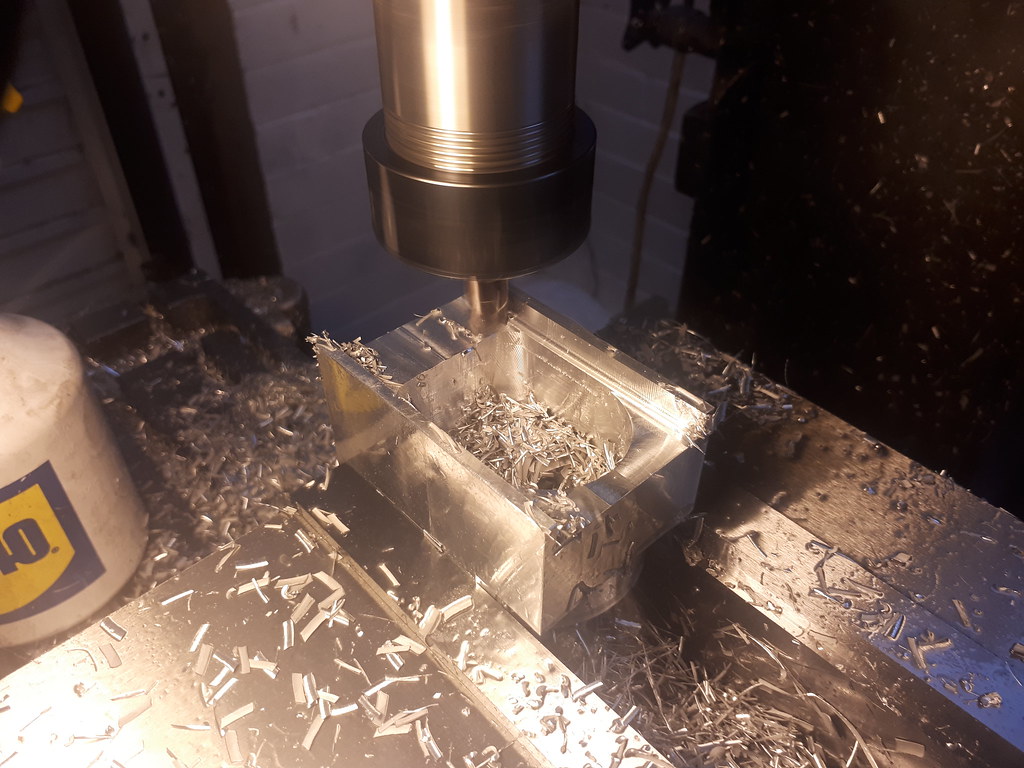

And unfortunately, on that last photograph is exactly where it got left. I had given the battery some abuse almost continually today for around 6 hours. At one point I was drawing around 250A when face milling - the terminals on the cells themselves were cooking! I think we are looking at a good 21hr recharge on it but hopefully be ready for a go on Sunday! And with much less of a tough day I might get more than 6 hours out of them - I couldn't even finish hoovering today!

Thanks again for reading

Earl

Whilst I was starting again squaring off the stock, I decided to square off 3 sides of the remaining chunks which will later become the frame rear and water hopper.

In the interest of saving money by buying the stock at one size, it shows just how much needs to be removed!

Placed next to the scrap piece you can get a sense of what about needs to be taken off

After my first cut, measured and the DRO set so it's simply a case of working toward the 3.0000" mark - double checked on final cut and it came in perfectly. Rotated 90 degrees on the Y axis and did the same. Then rotated 90 degrees along X axis and worked to 2". Came in a hair under at 1.998" I am very surprised at the finish this facemill is giving, and the linear patterns to bother me and most of this will end up in a rubble sack as chips...

This time marking out the centre point before drilling:

Indicating it in on the 4 jaw - using my "premade" test bar.

Halleluyah the dimensions are spot on this time. The scrap in the background there...

I have to say I am very pleased with this marking out. I just recently got the height gauge for a very reasonable £39 and it looks brand new! Few important lines marked up. And then on wards with more chip making!

Auld ripper.

And unfortunately, on that last photograph is exactly where it got left. I had given the battery some abuse almost continually today for around 6 hours. At one point I was drawing around 250A when face milling - the terminals on the cells themselves were cooking! I think we are looking at a good 21hr recharge on it but hopefully be ready for a go on Sunday! And with much less of a tough day I might get more than 6 hours out of them - I couldn't even finish hoovering today!

Thanks again for reading

Earl