JMI

Well-Known Member

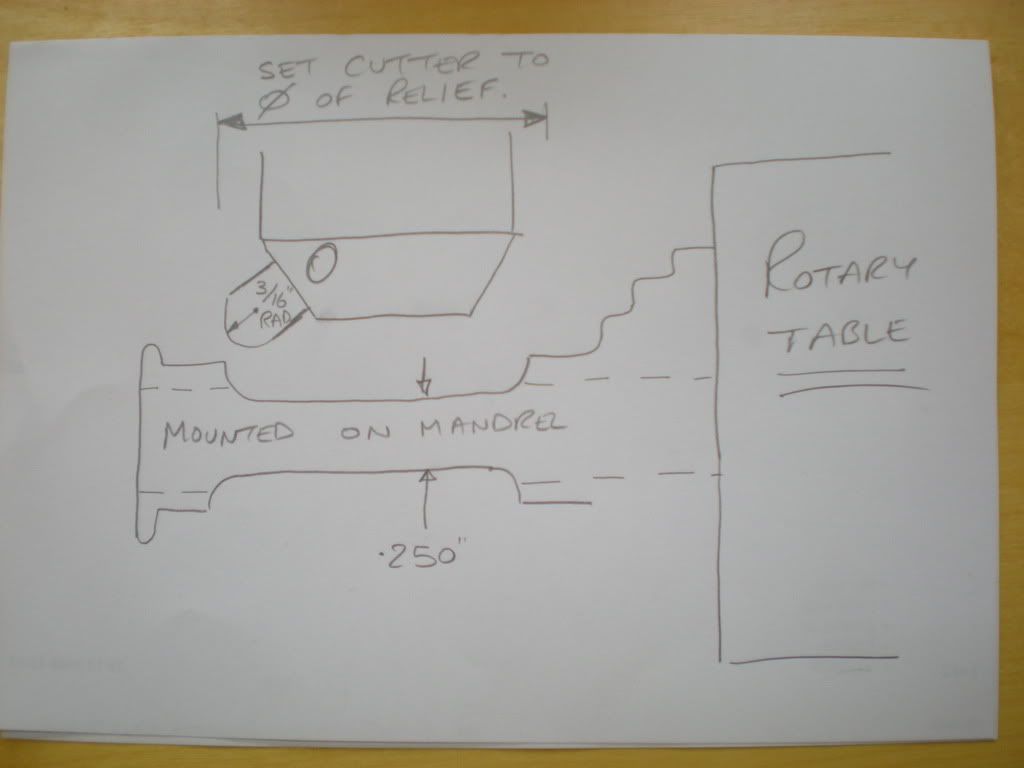

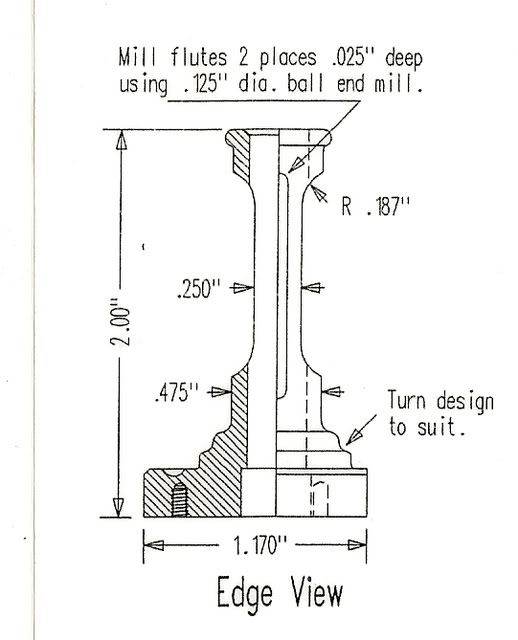

Have made this piece in 303 stainless up to the point where the next step is to cut the reliefs on both sides with the .187 radius also.

So I can use a 3/8" end mill and use the side of the cutter to achieve the approximately .112 depth and also the .187 radius on the end of the cut.

Is there a better/different way. Say using the end of a regular/flat end mill to remove the bulk of metal and than use the end of a different cutter (ball type? 3/8"?) to get the .187 radius?

Is this sounding as clear as mud?

TIA

Jim

So I can use a 3/8" end mill and use the side of the cutter to achieve the approximately .112 depth and also the .187 radius on the end of the cut.

Is there a better/different way. Say using the end of a regular/flat end mill to remove the bulk of metal and than use the end of a different cutter (ball type? 3/8"?) to get the .187 radius?

Is this sounding as clear as mud?

TIA

Jim