Flywheel (continued)

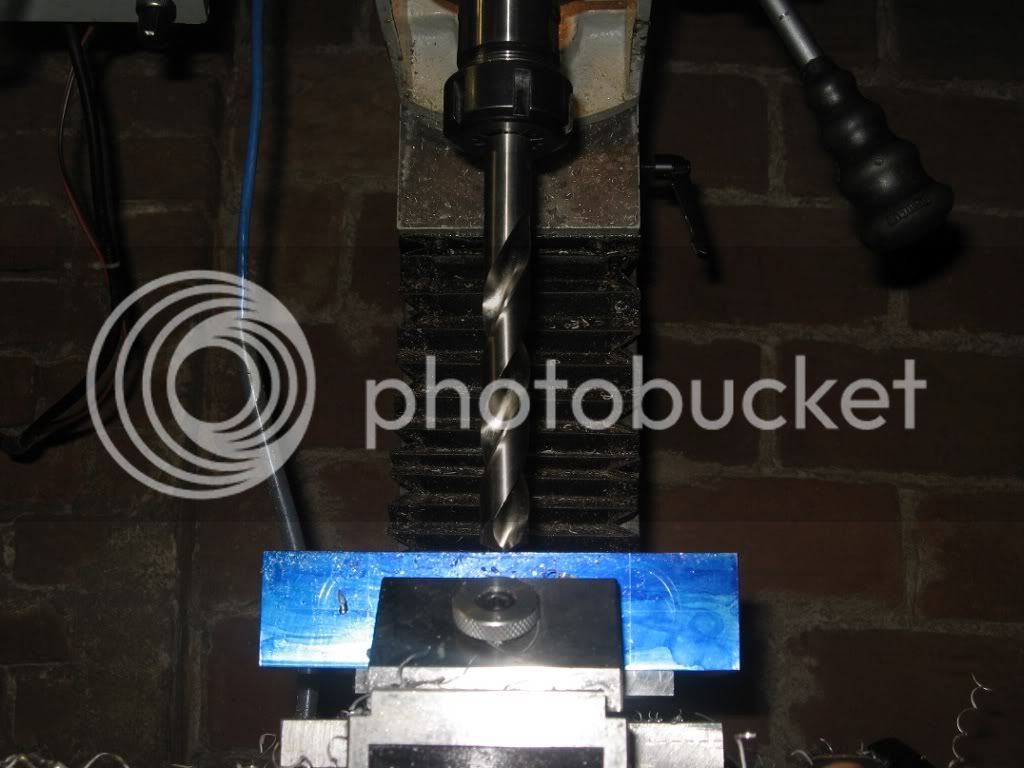

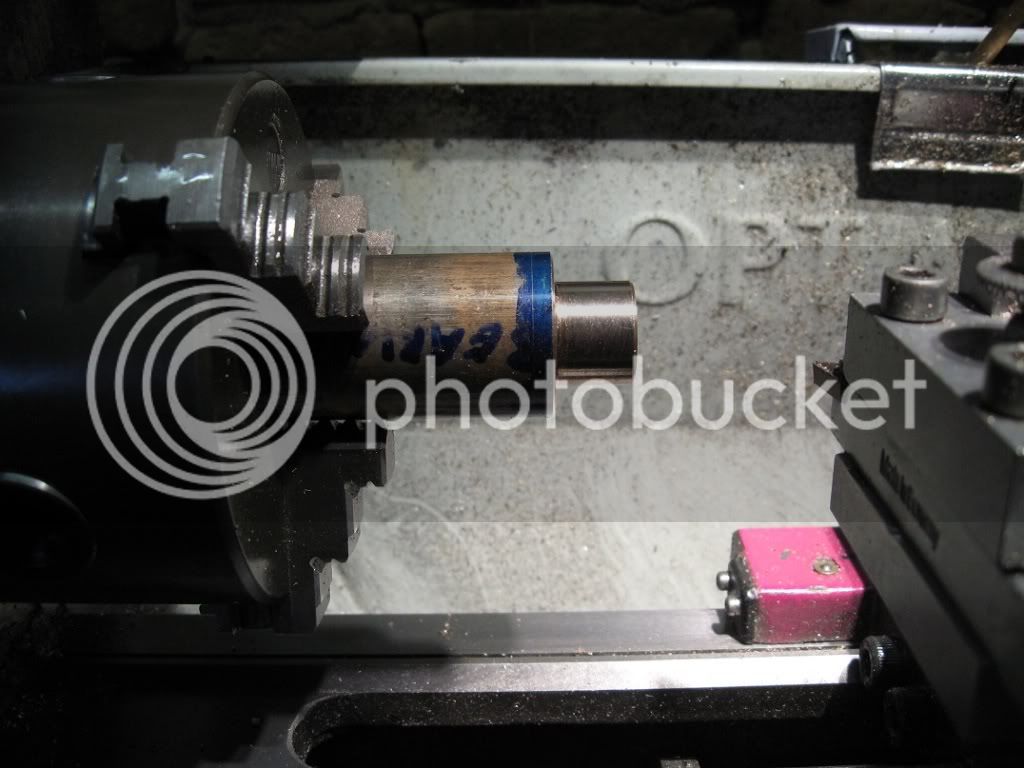

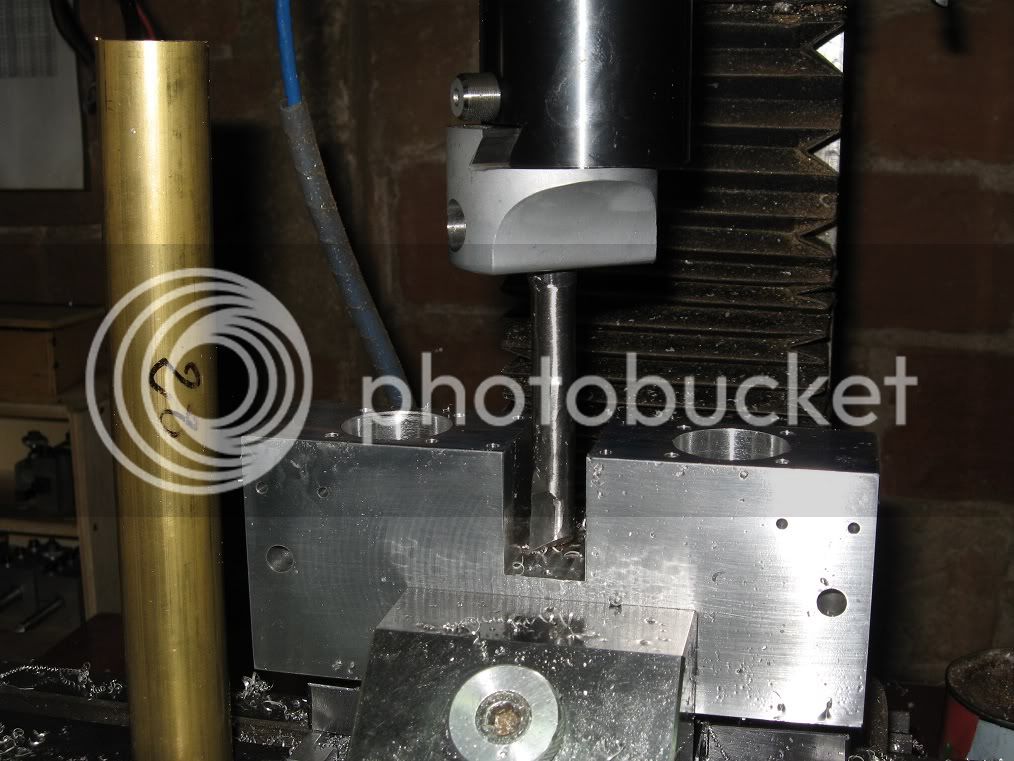

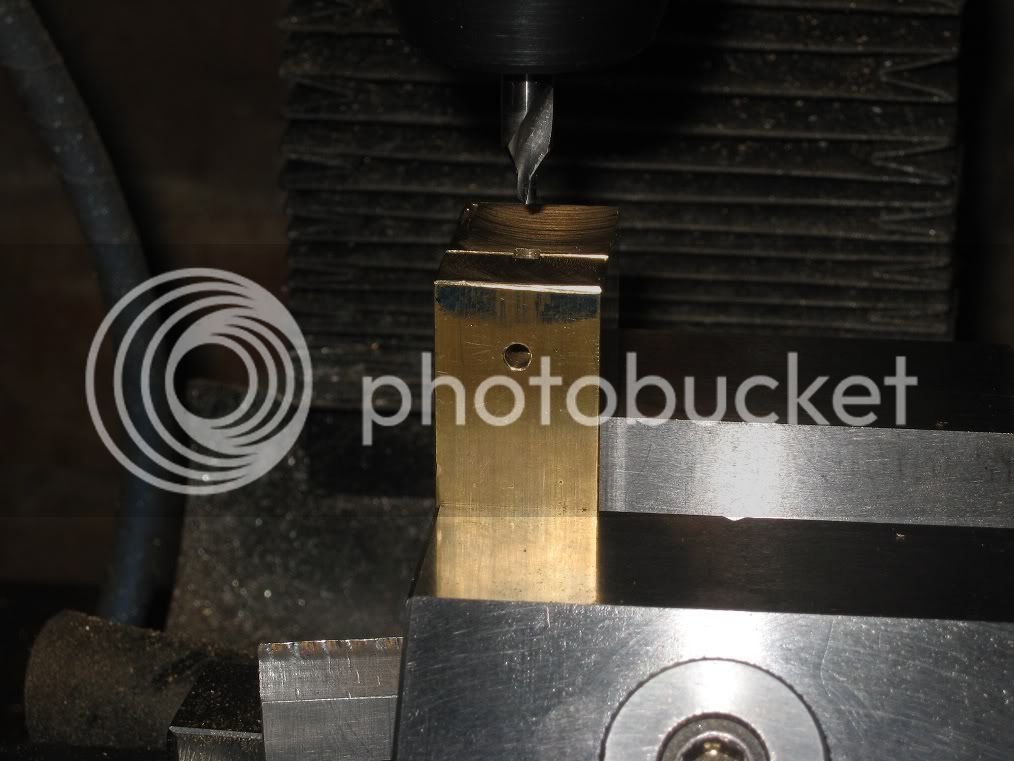

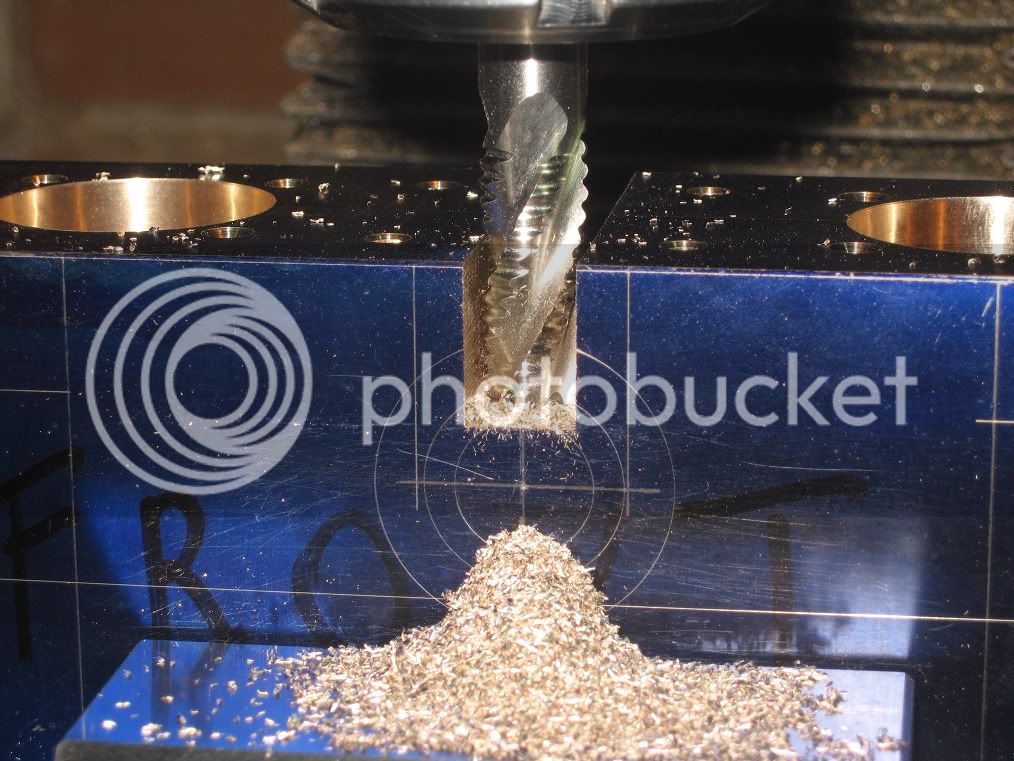

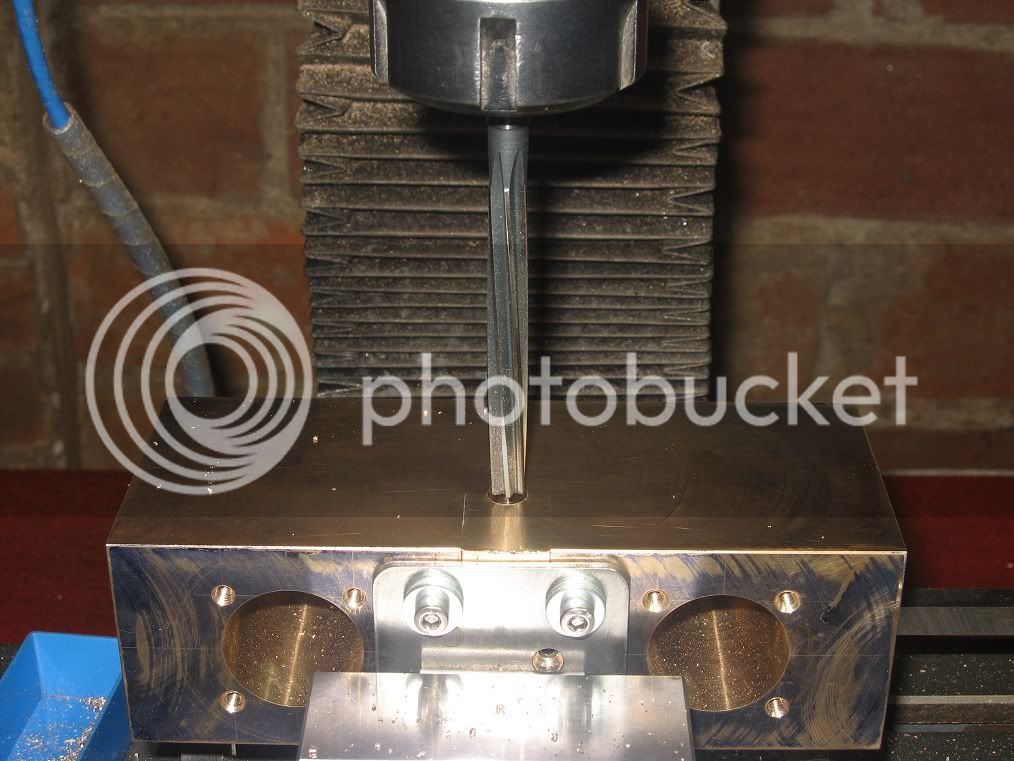

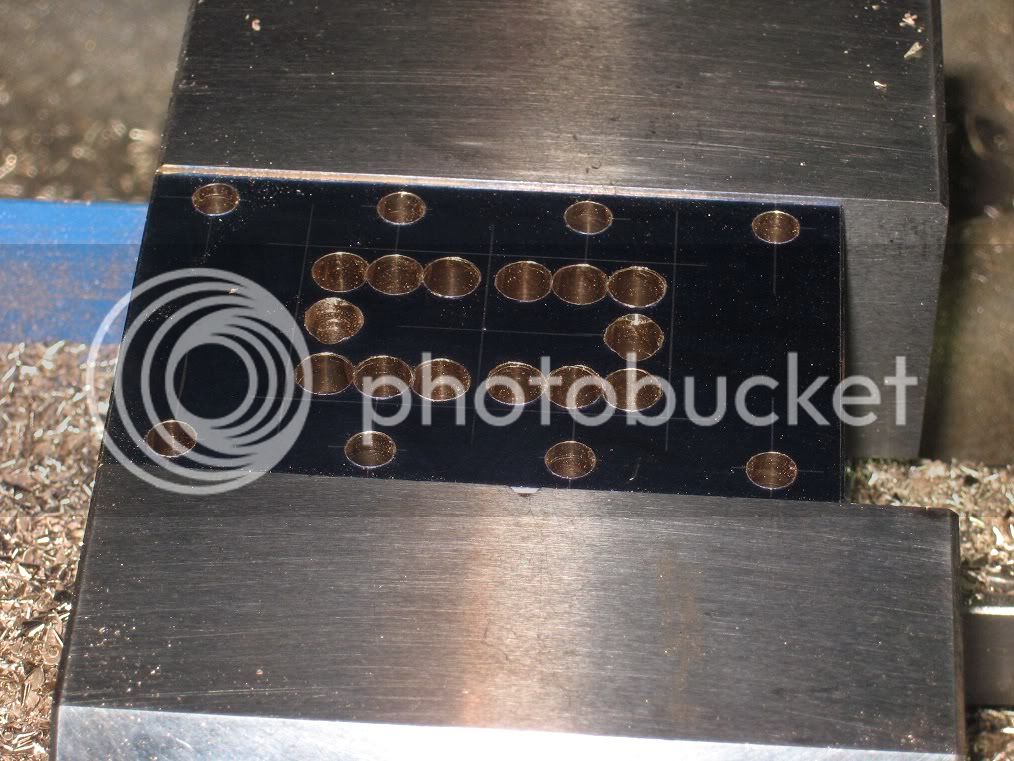

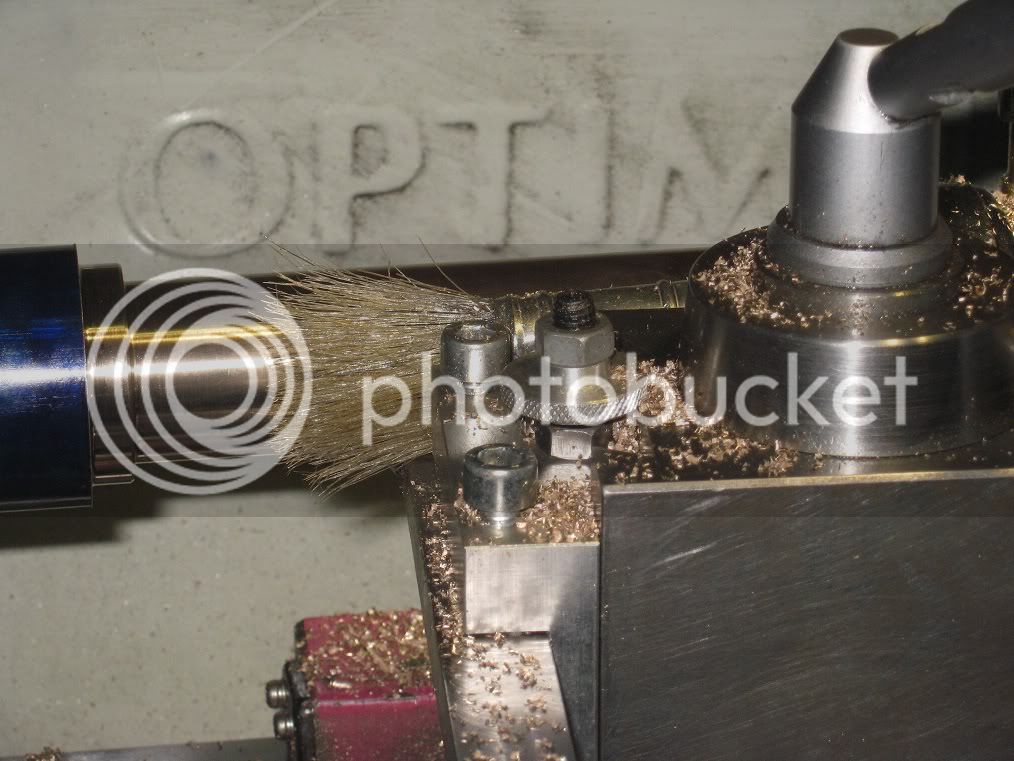

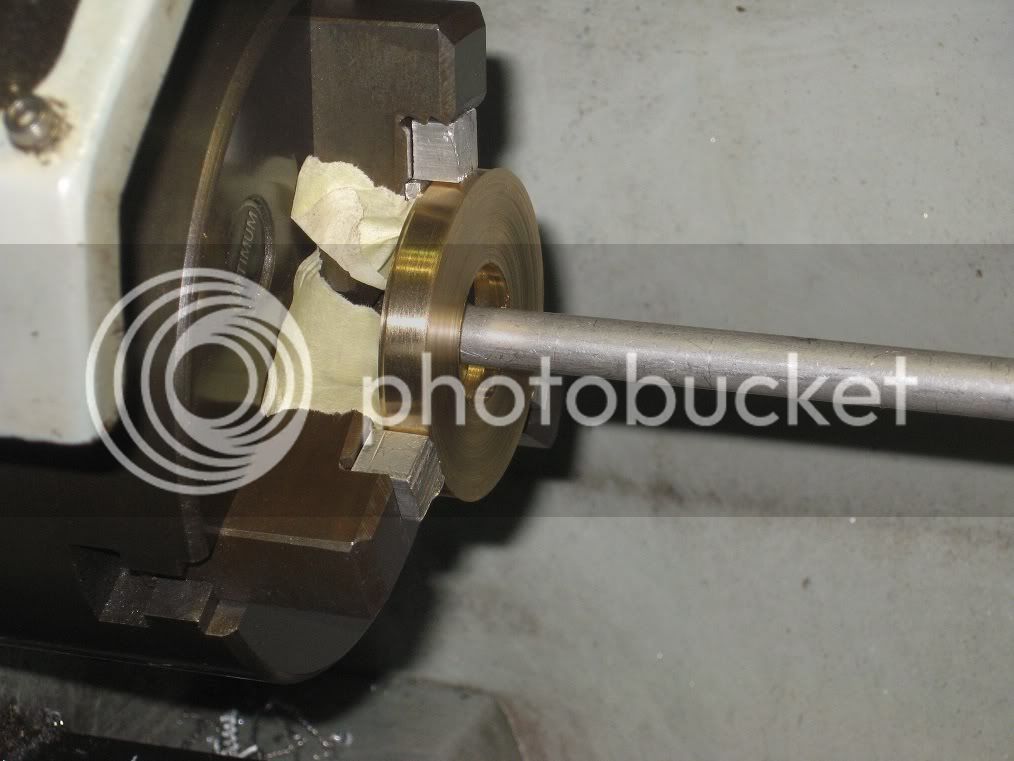

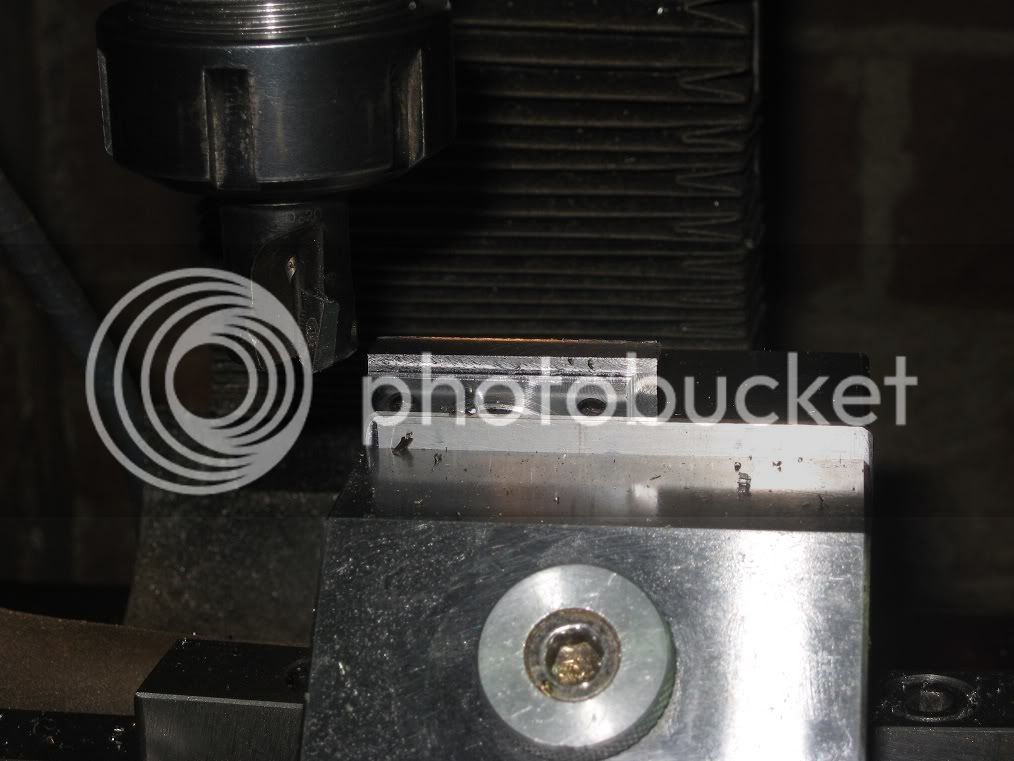

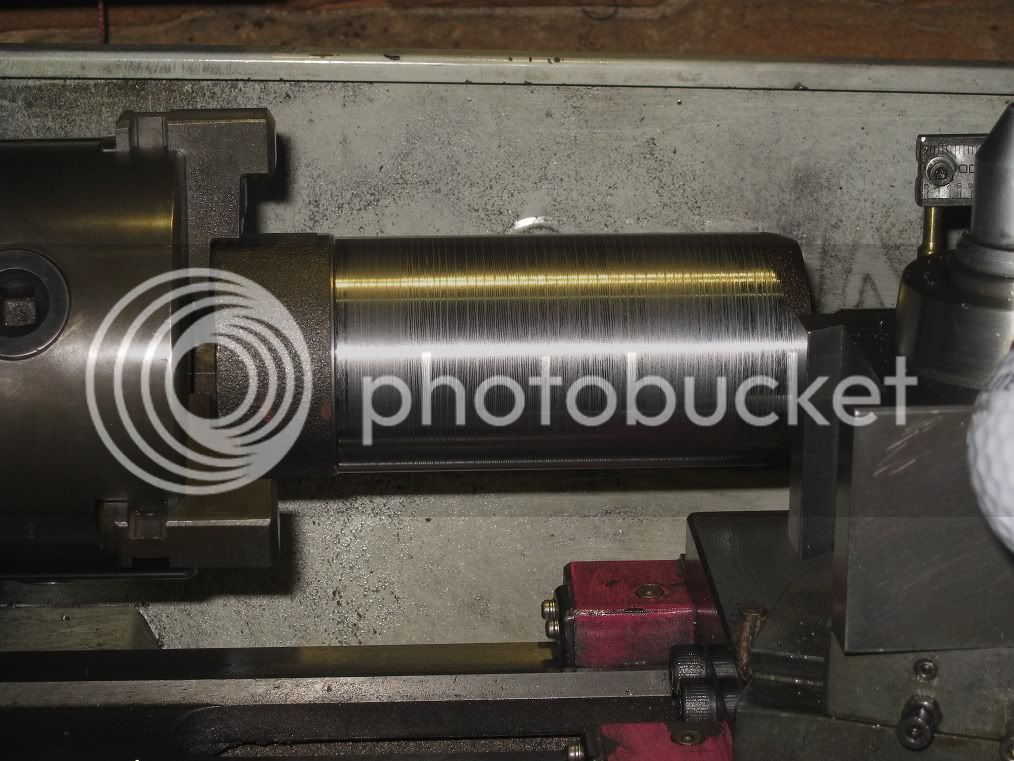

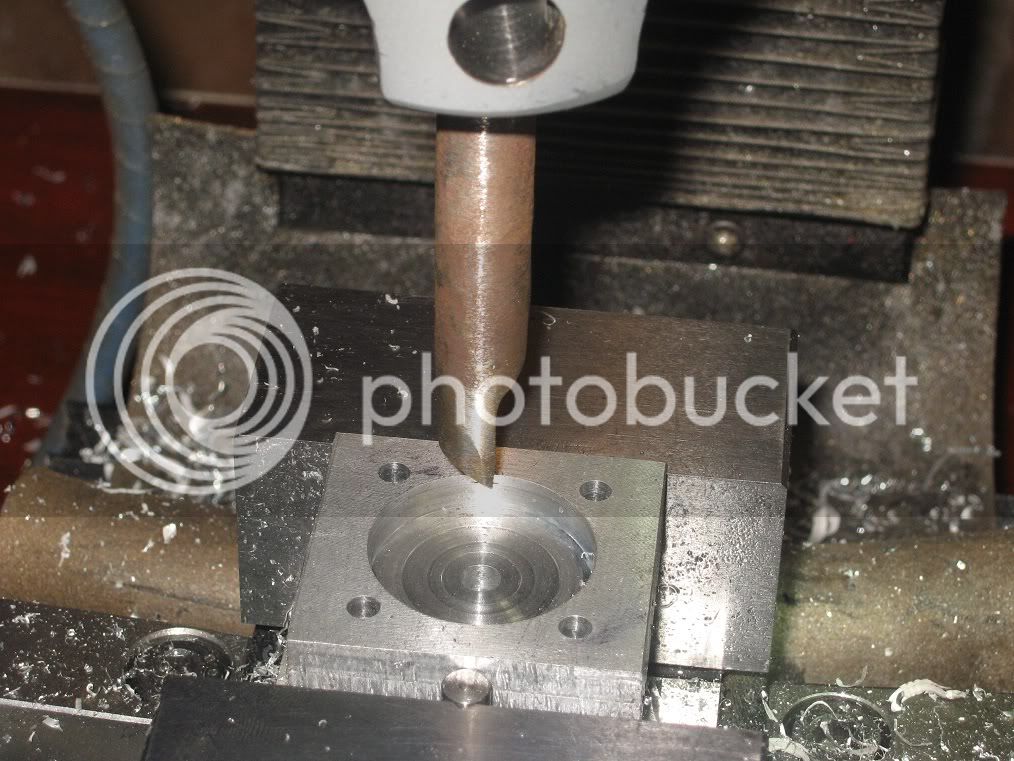

Drilling the hub to 10mm. then it will be bored to 11.85 and reamed to 12.

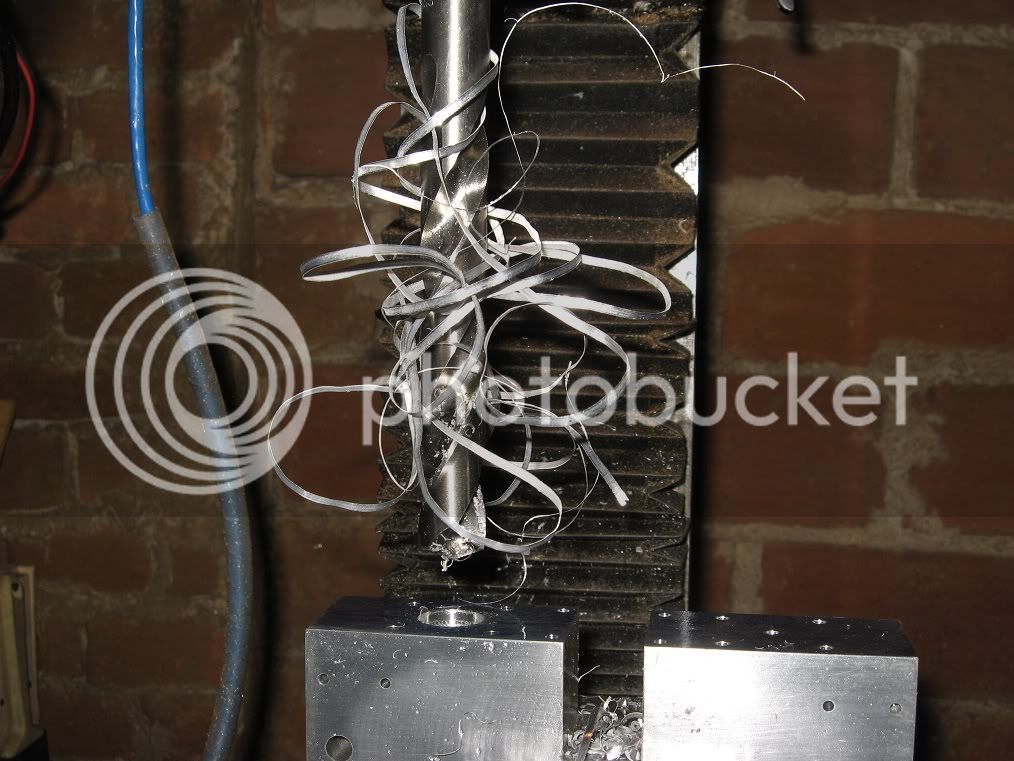

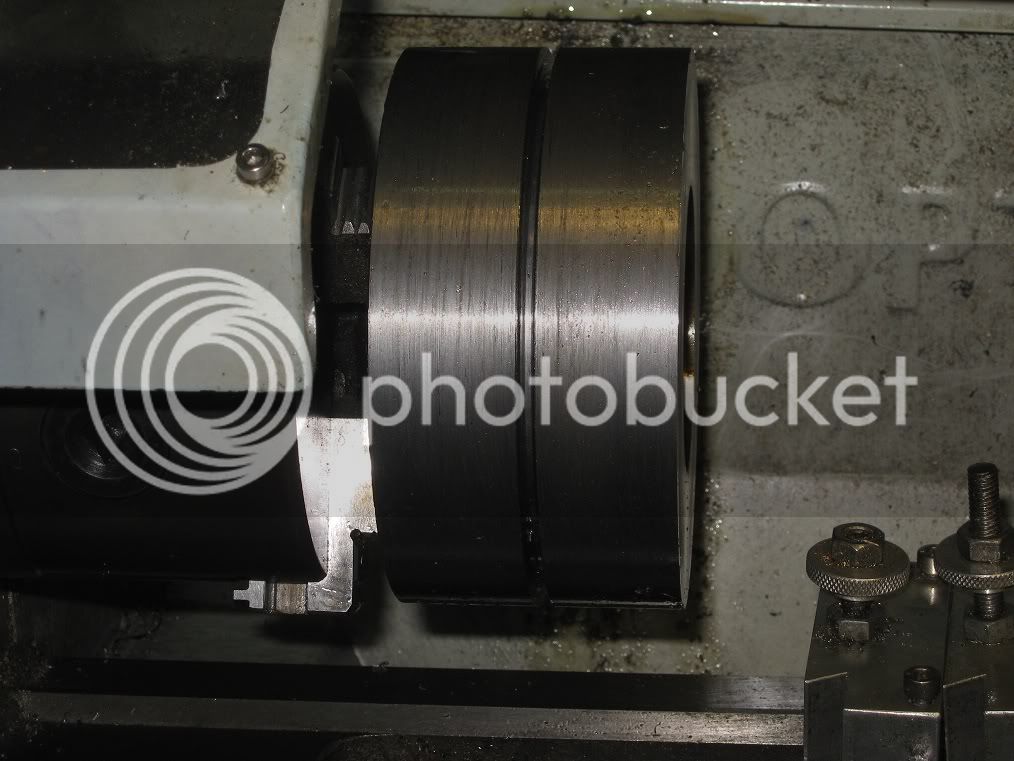

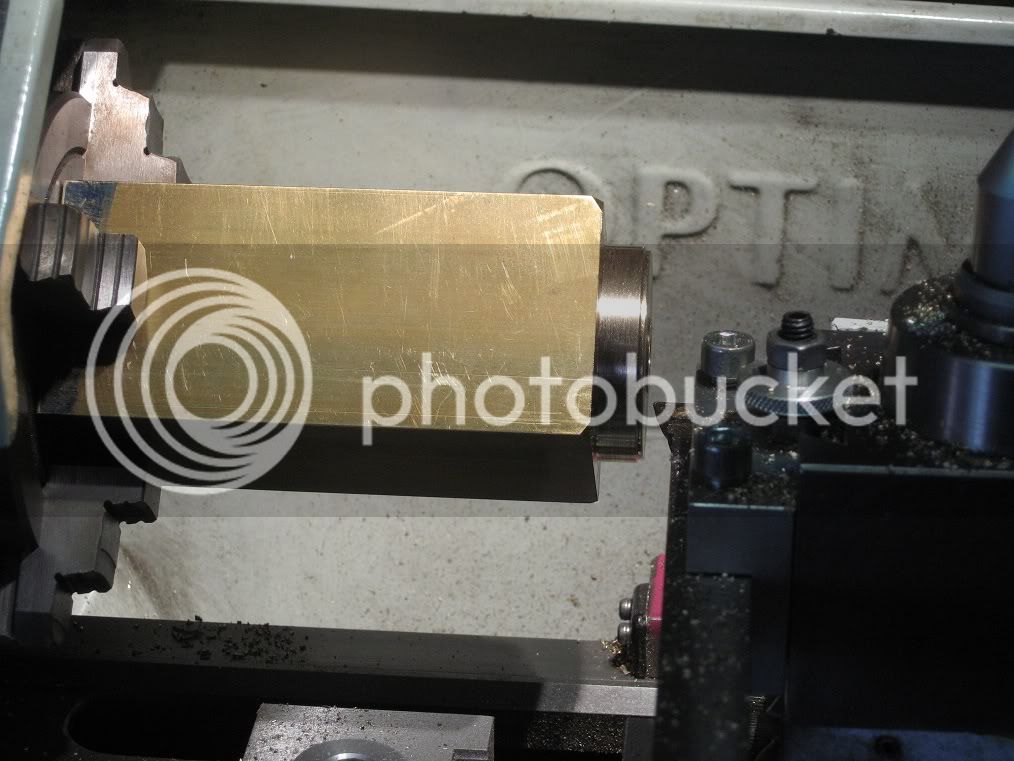

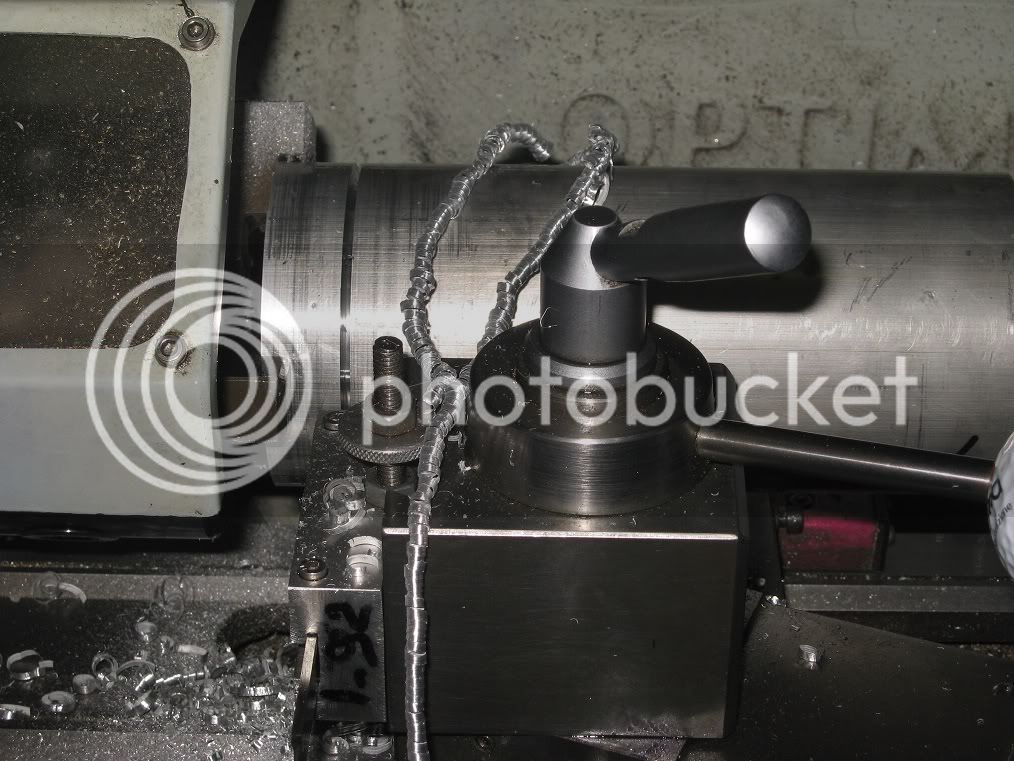

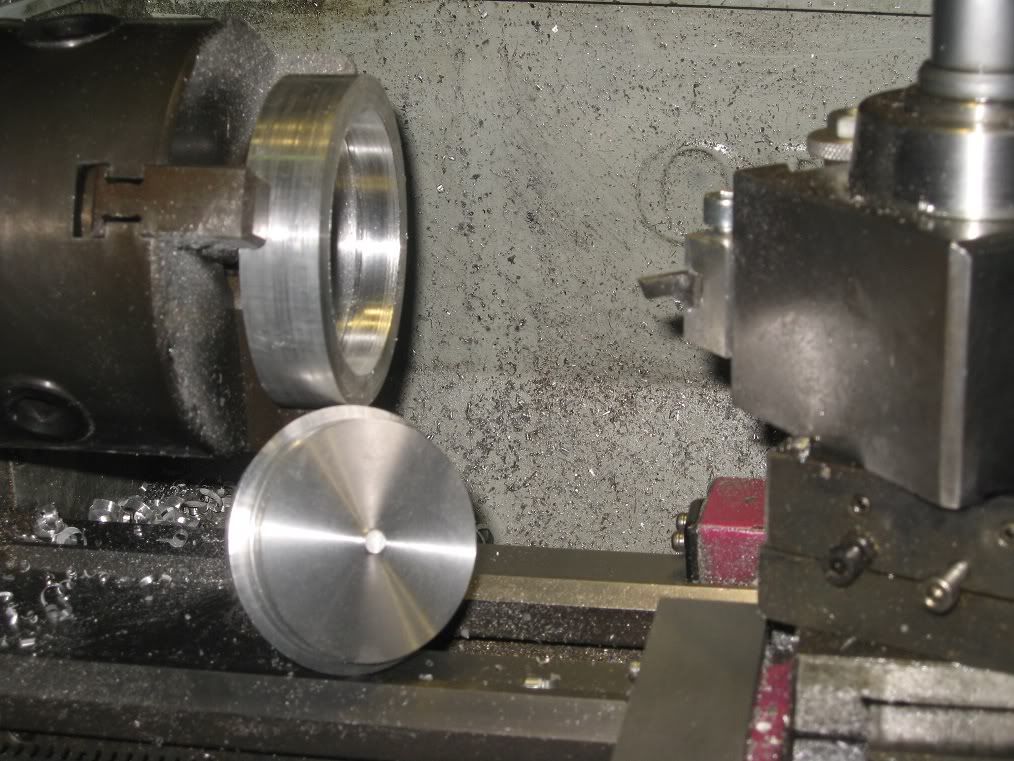

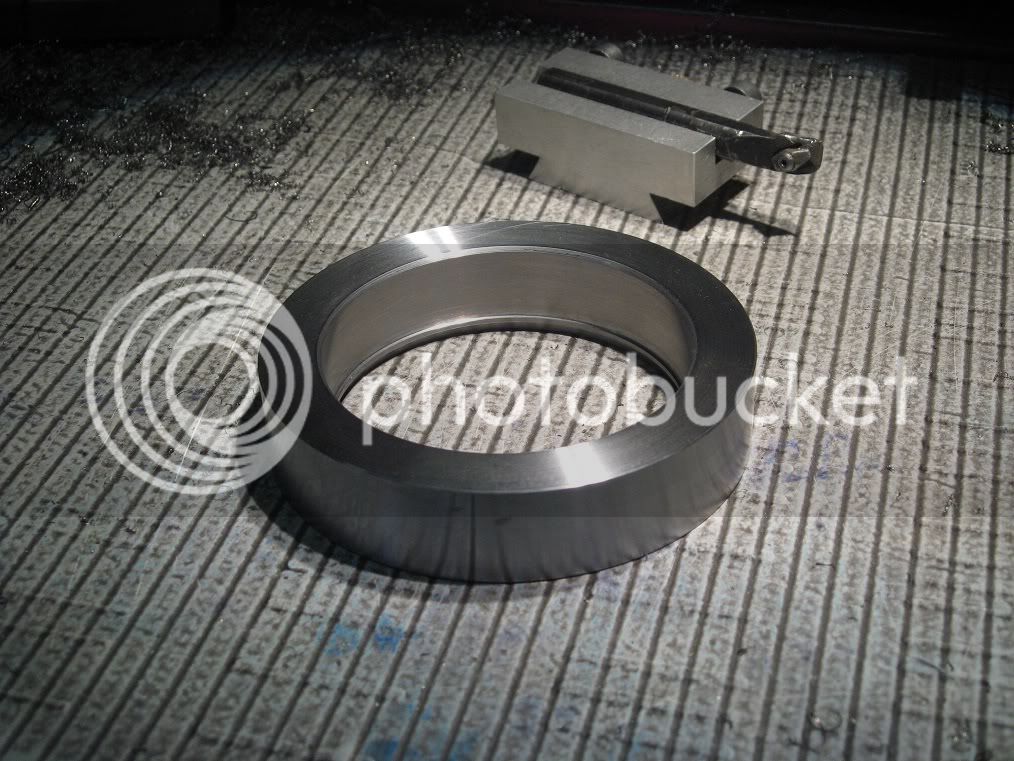

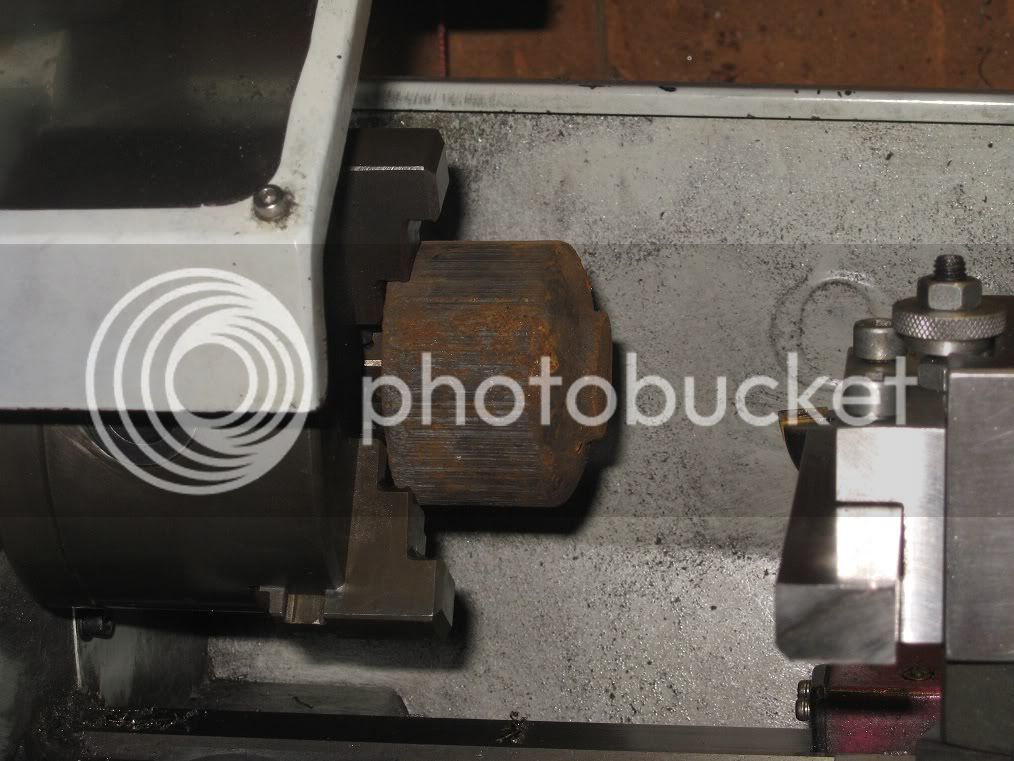

Parting stock for the ring. I rarely get swarfs like those while parting: I suppose the tool happened to be dead square on this occasion.

End of parting. Had to increase the tool overhang three times to get it done. The final 5 or 6mm portion was hacksawed.

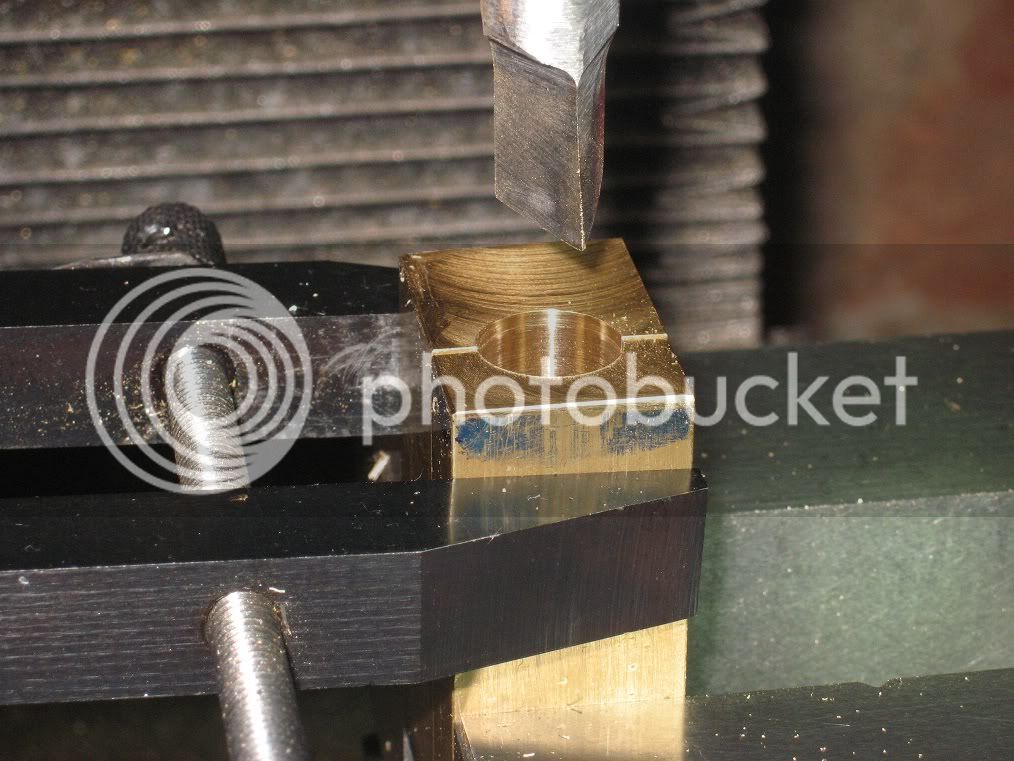

Trepanning the ring..

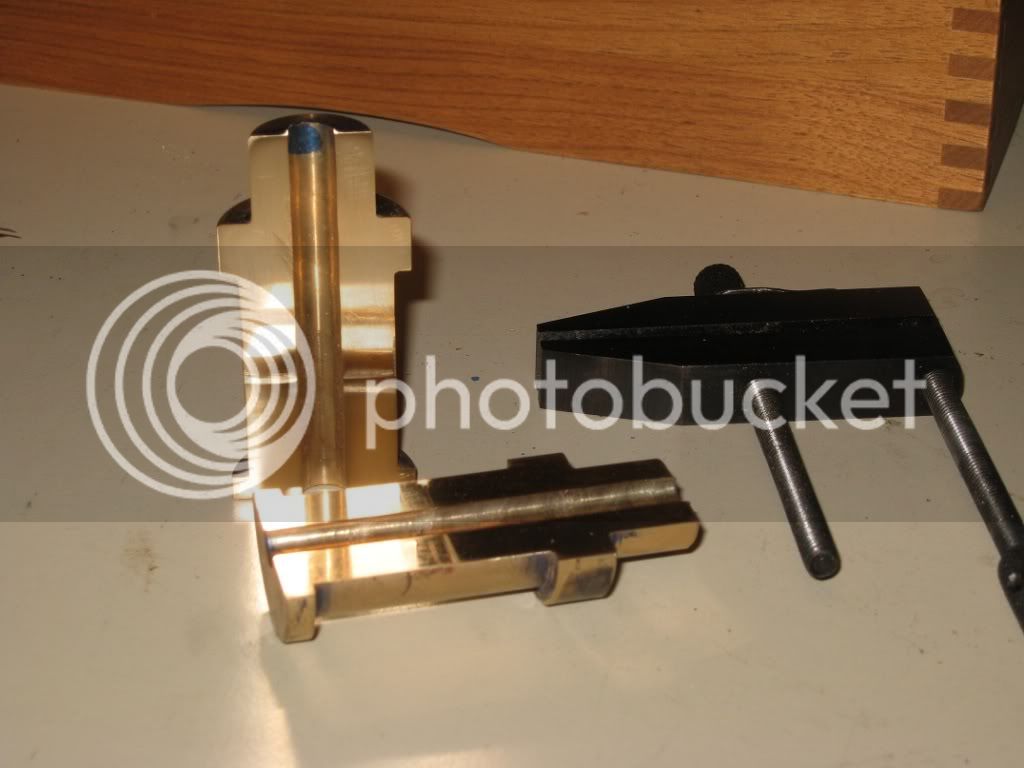

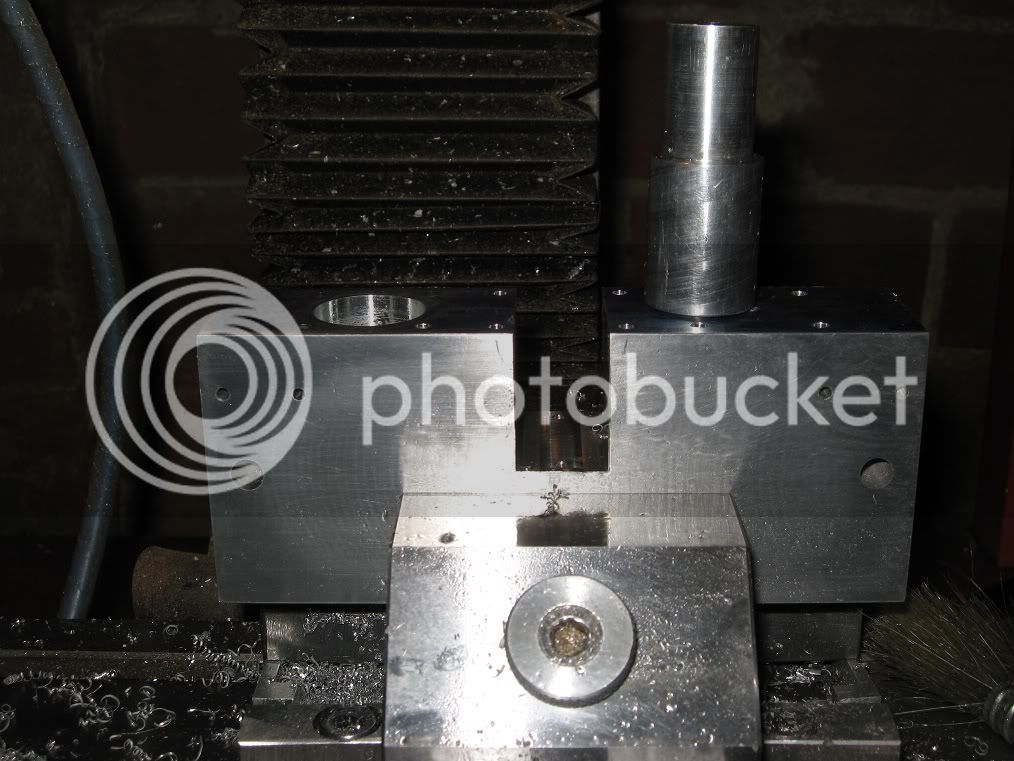

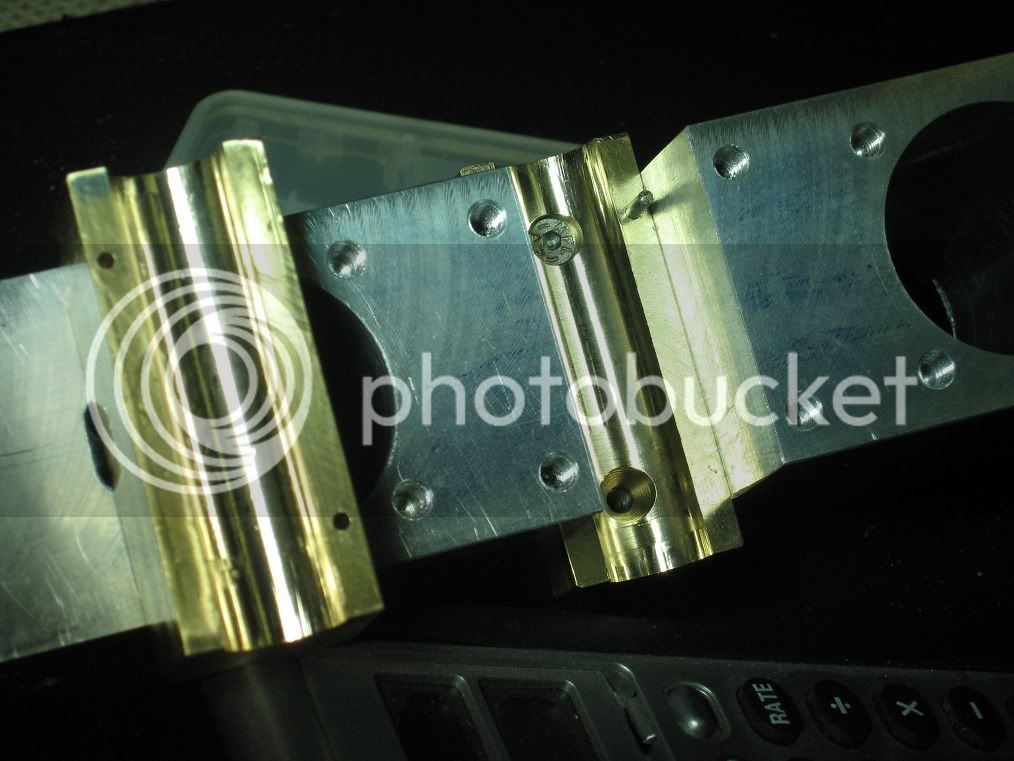

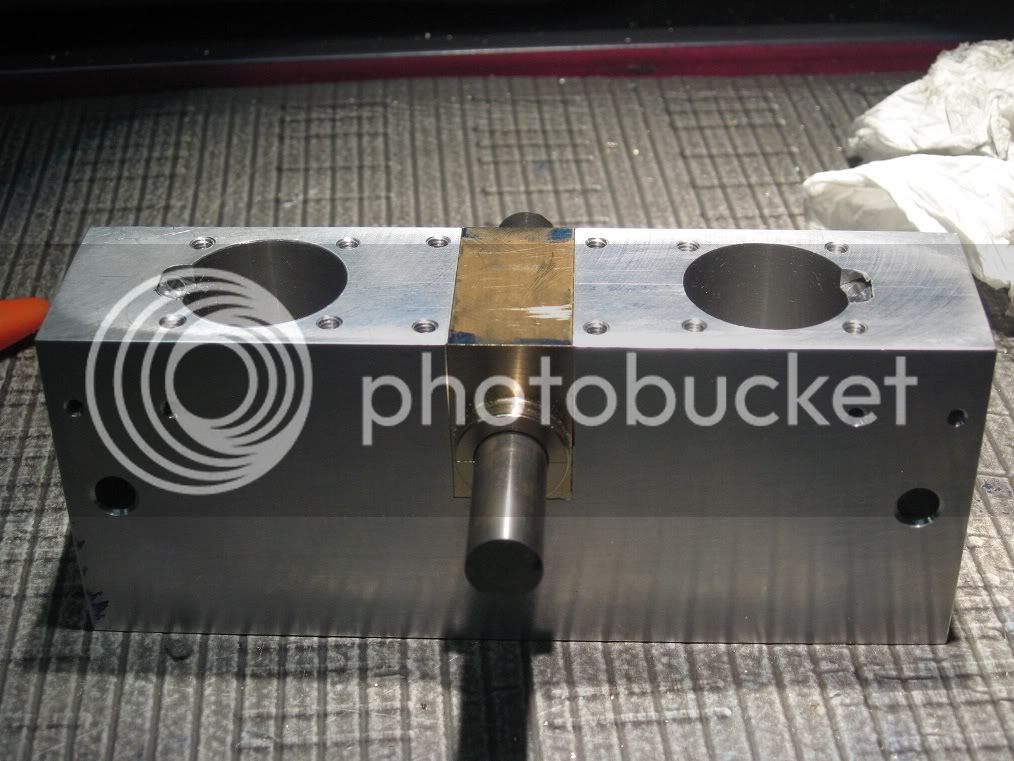

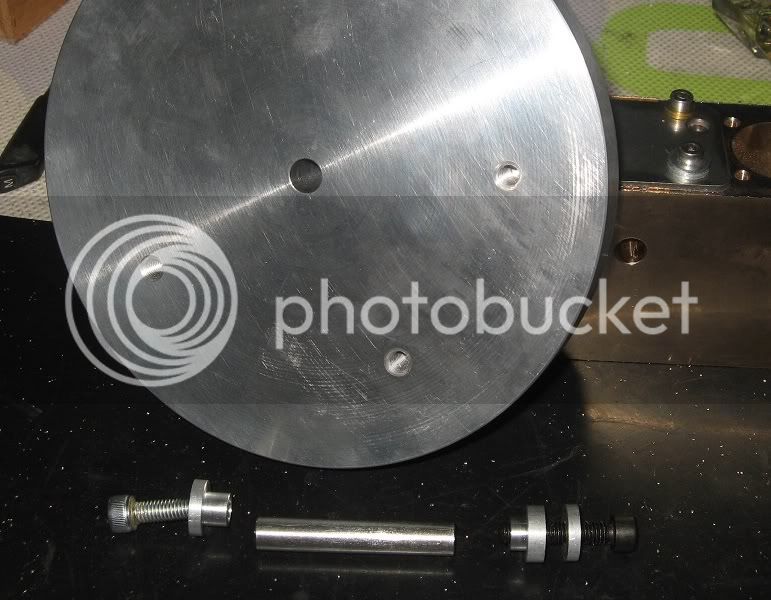

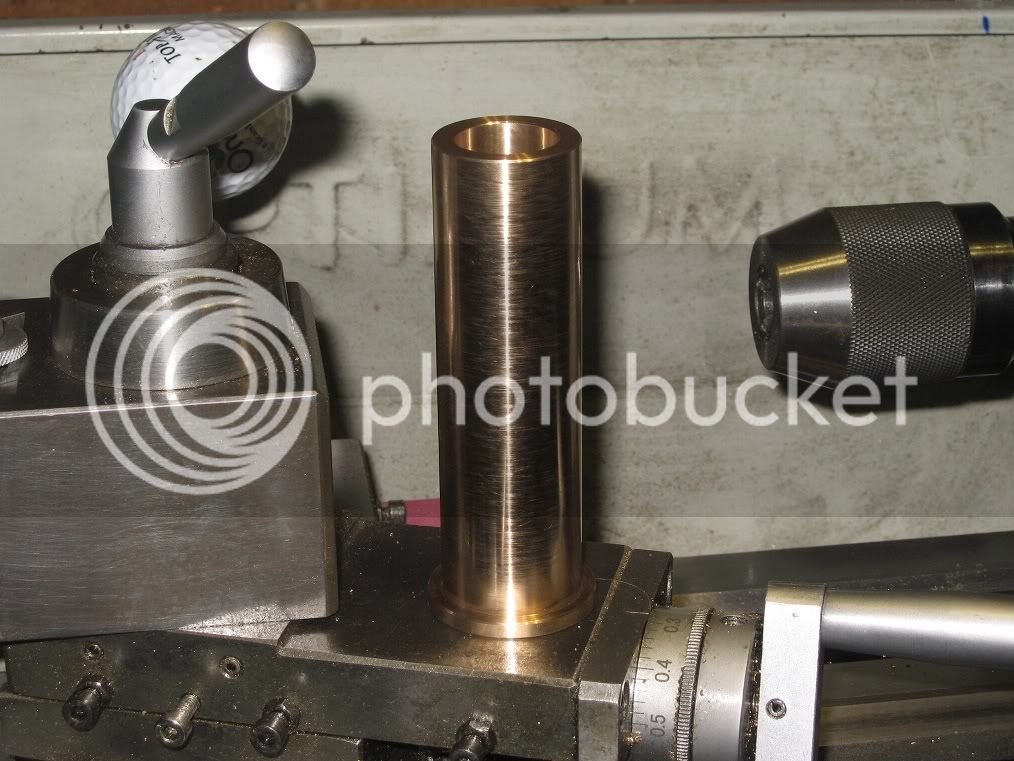

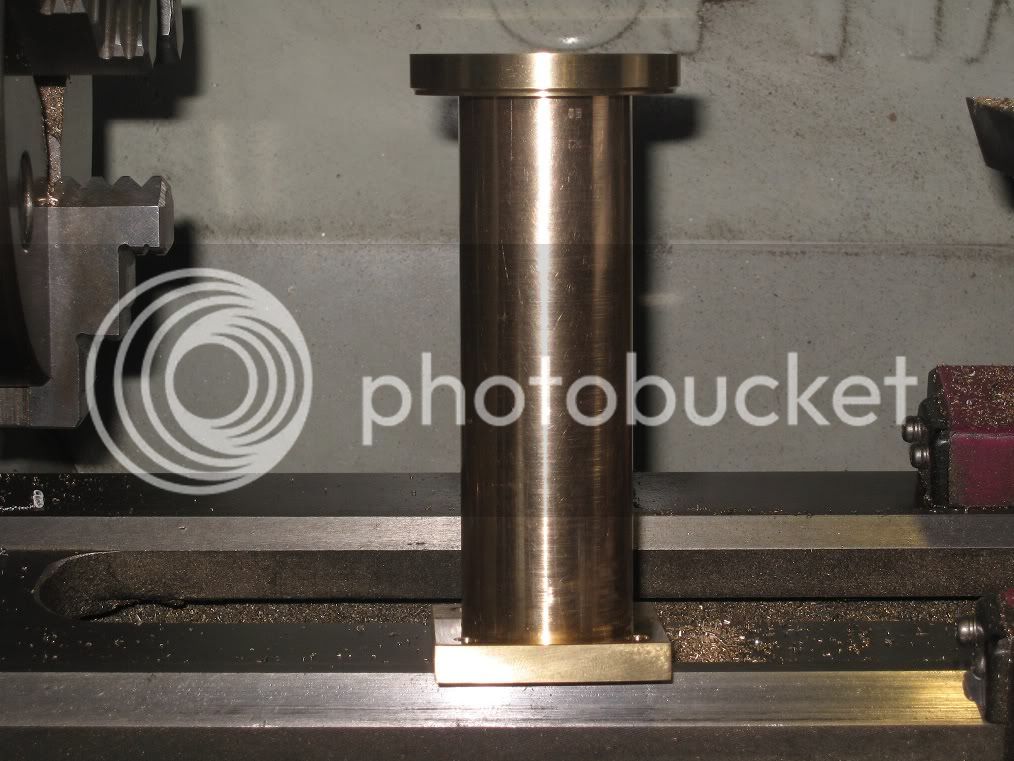

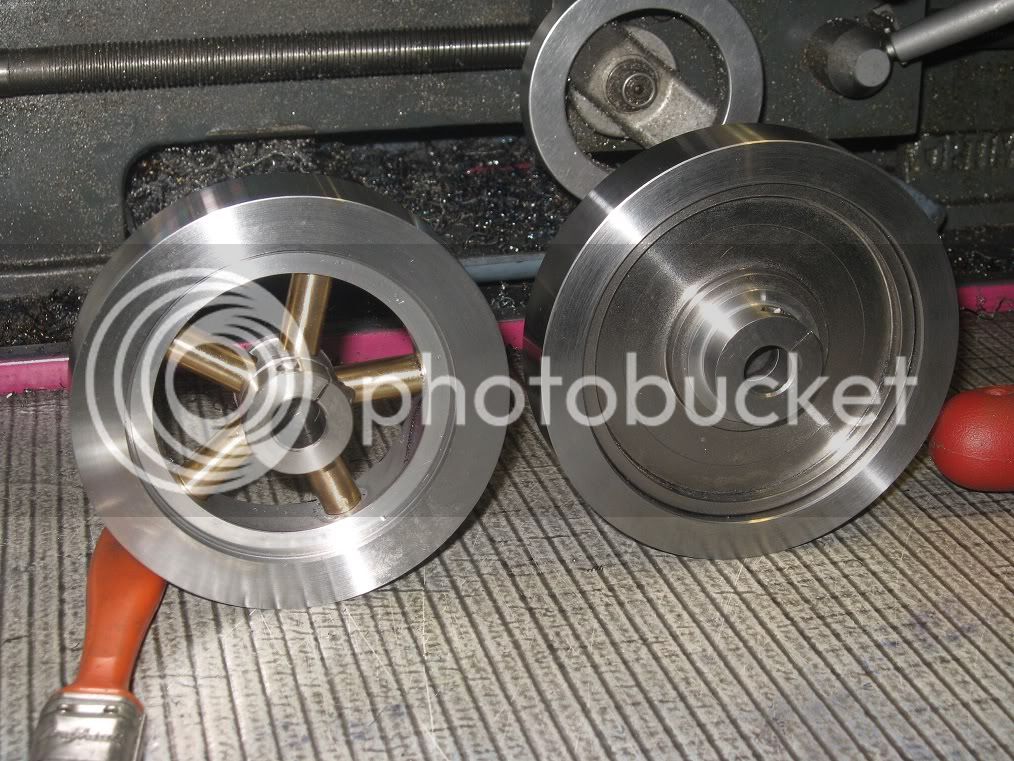

The still unfinished hub, ring, and an aluminum sleeve I made to fit the hub.

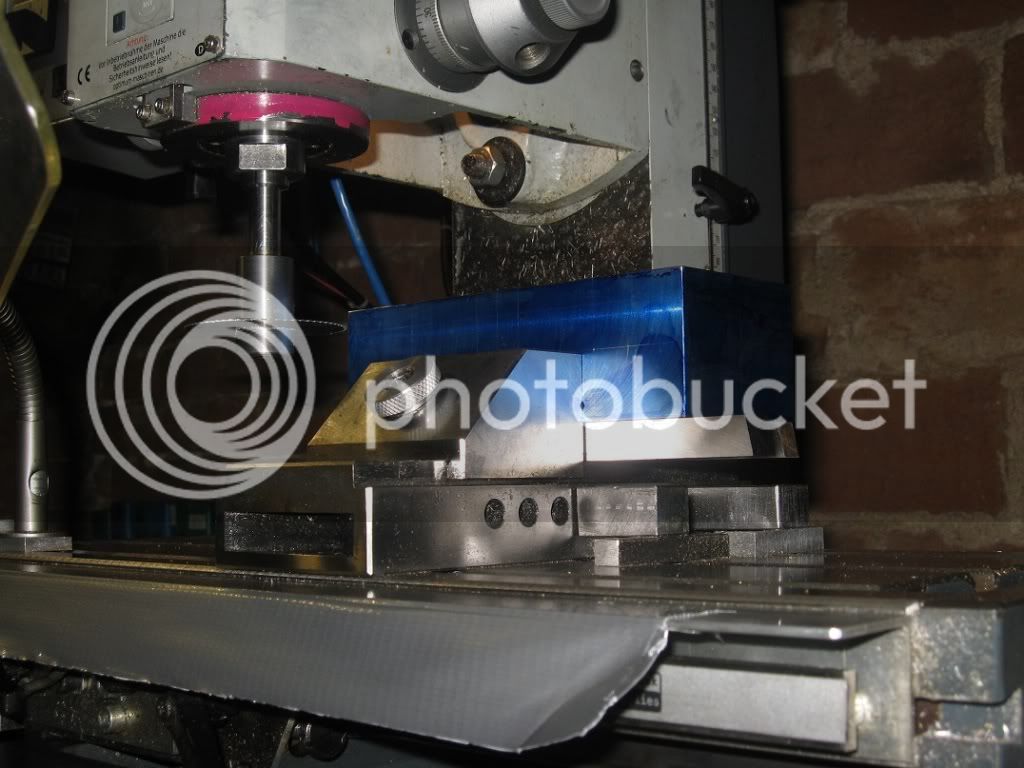

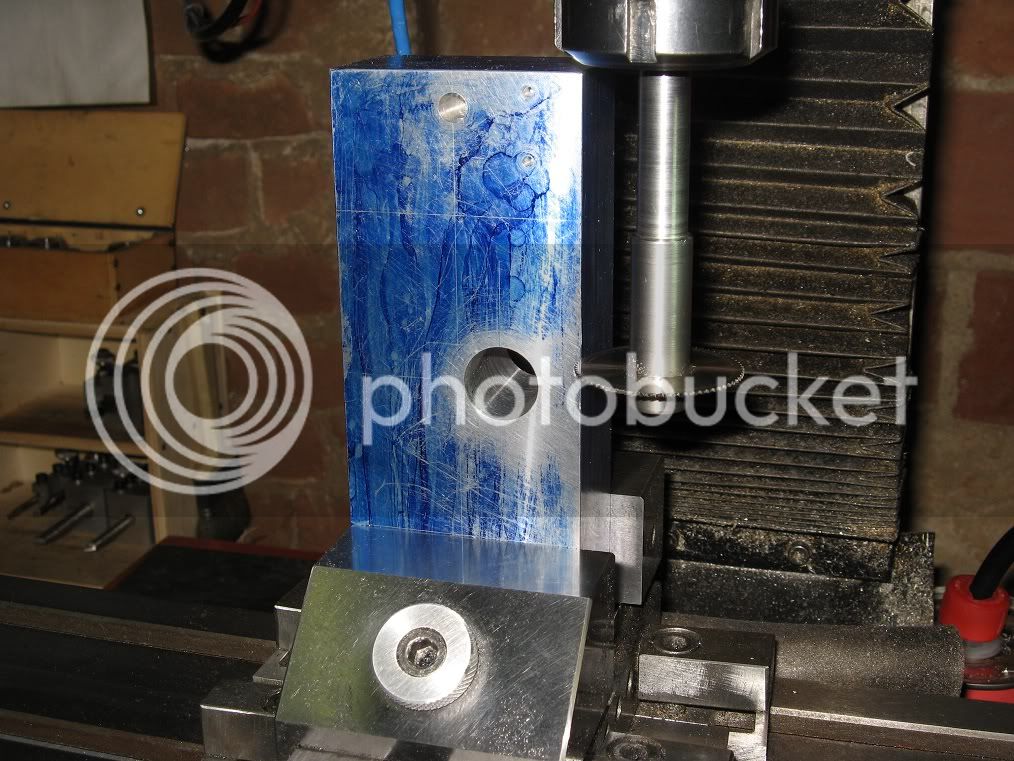

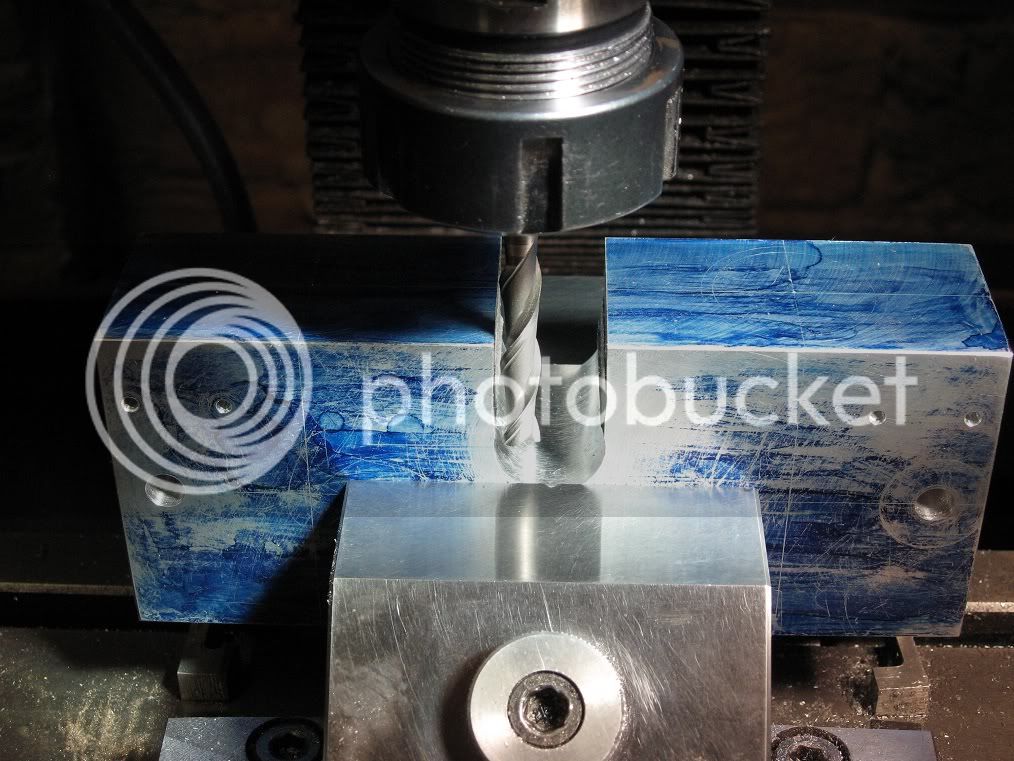

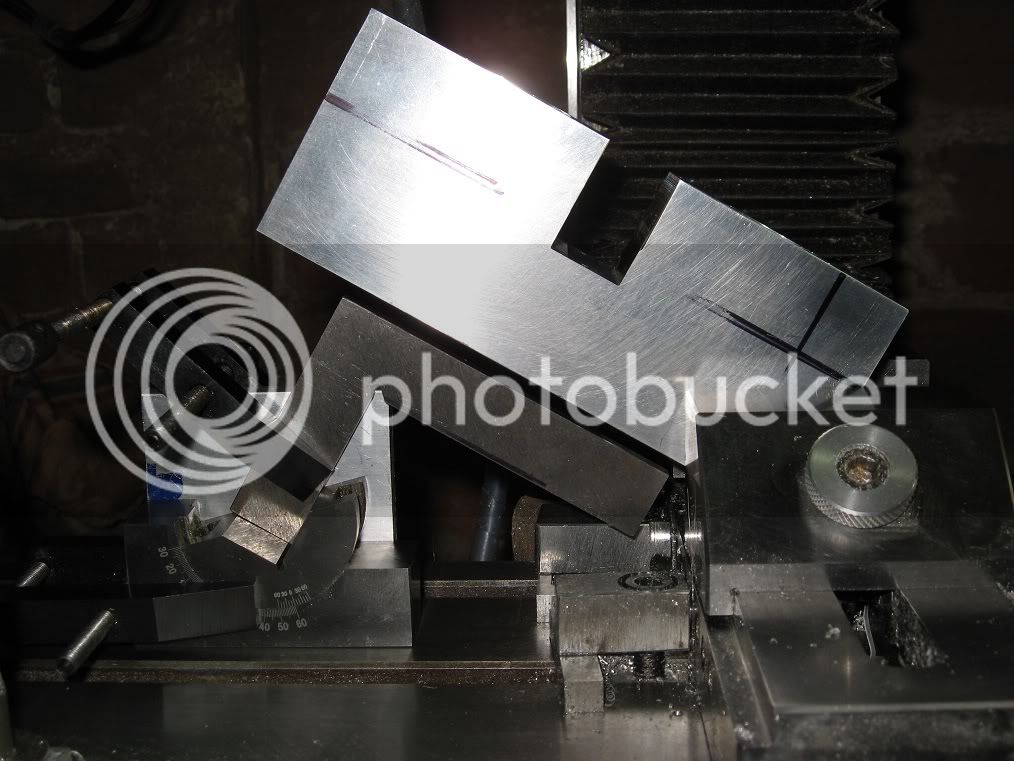

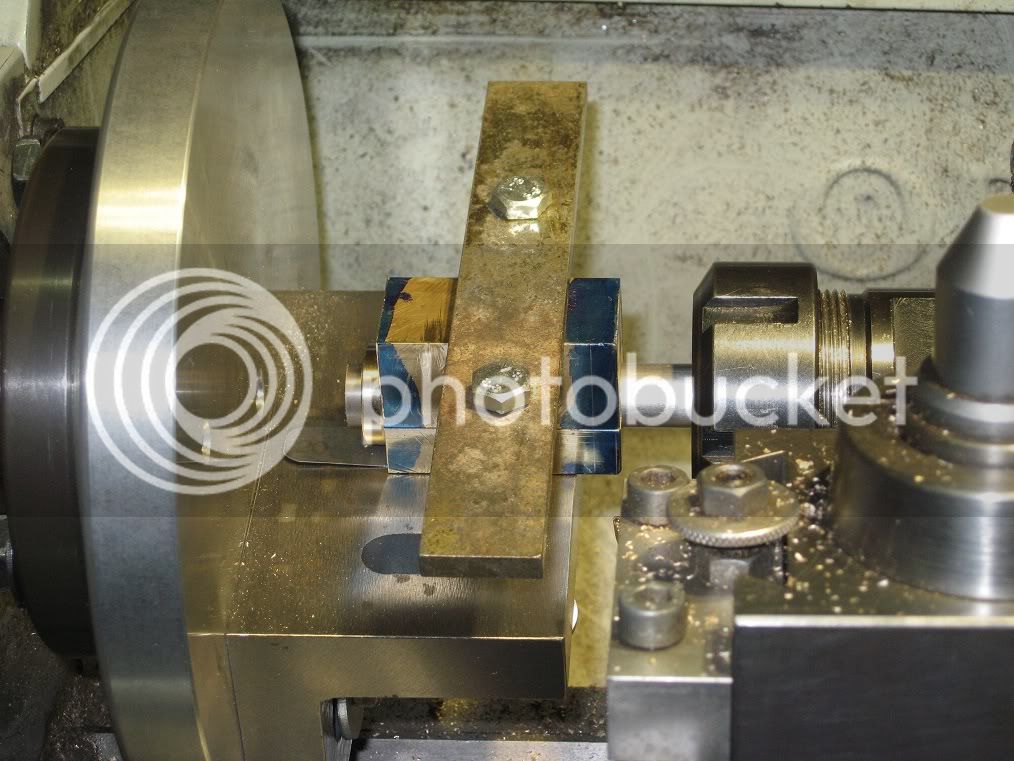

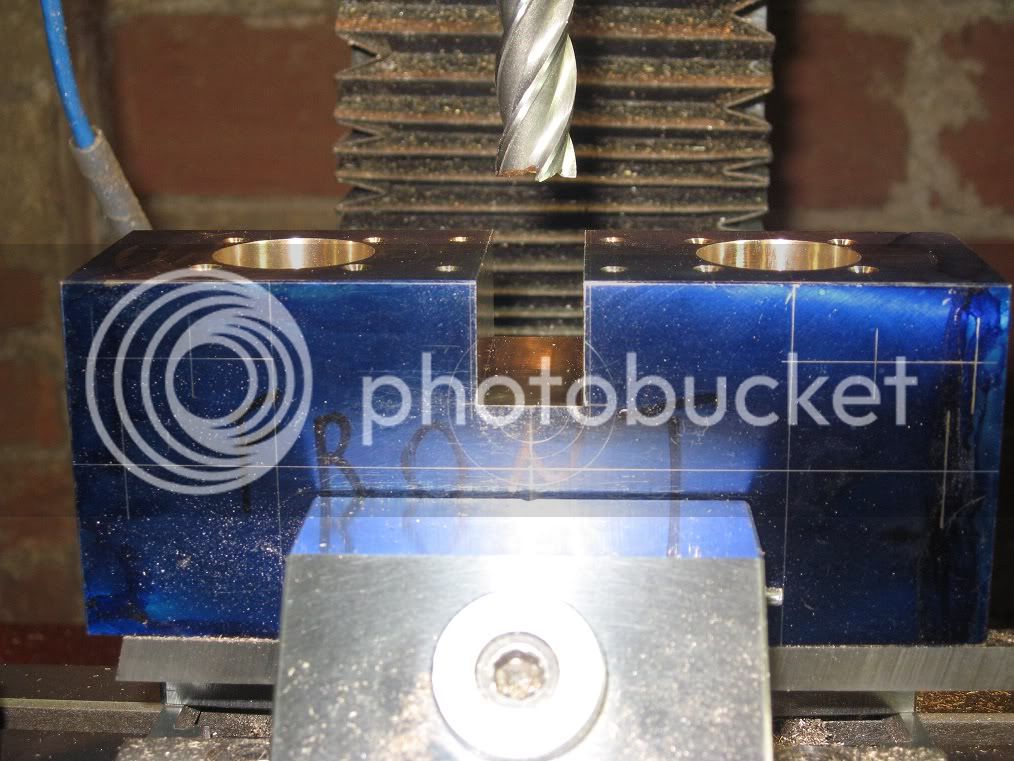

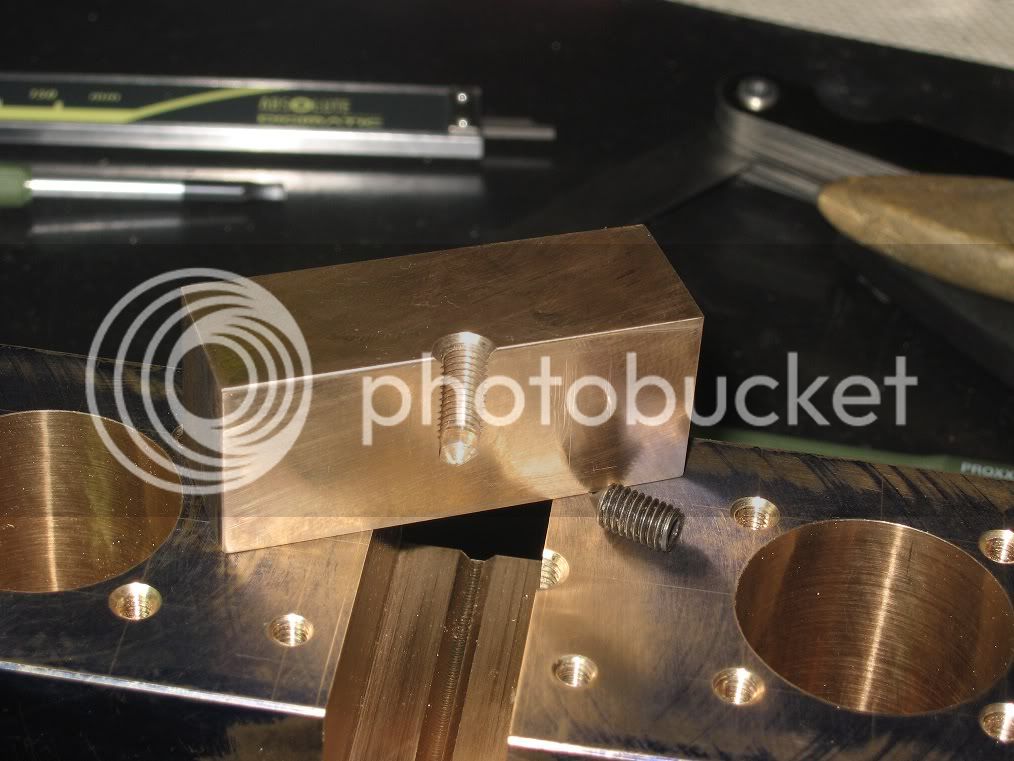

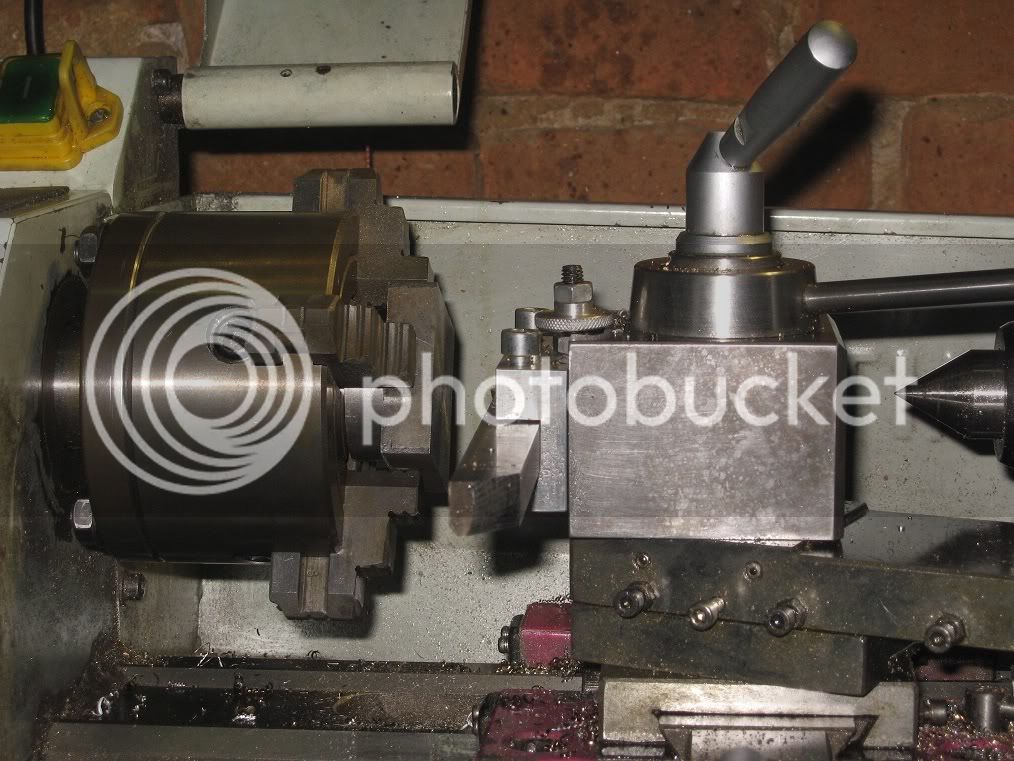

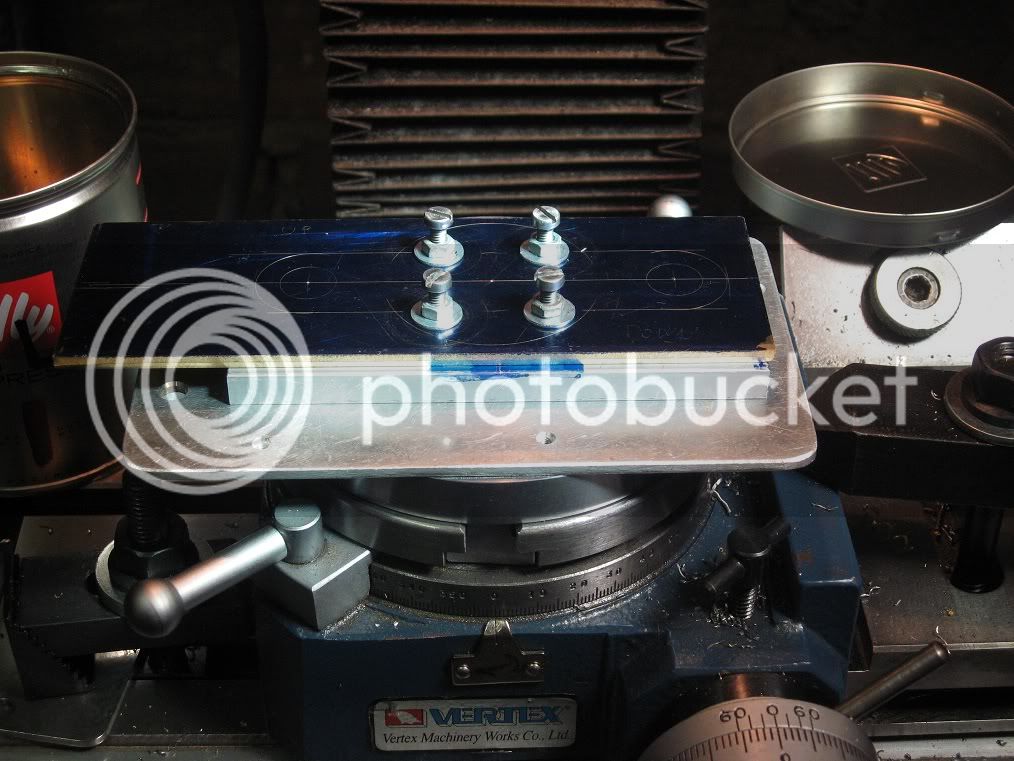

Slitting the hub. The RT was really not a must for this job, but was handy for holding the workpiece and will be ready for the next operations.

..of milling the flats for the columns and drilling the holes for the studs.

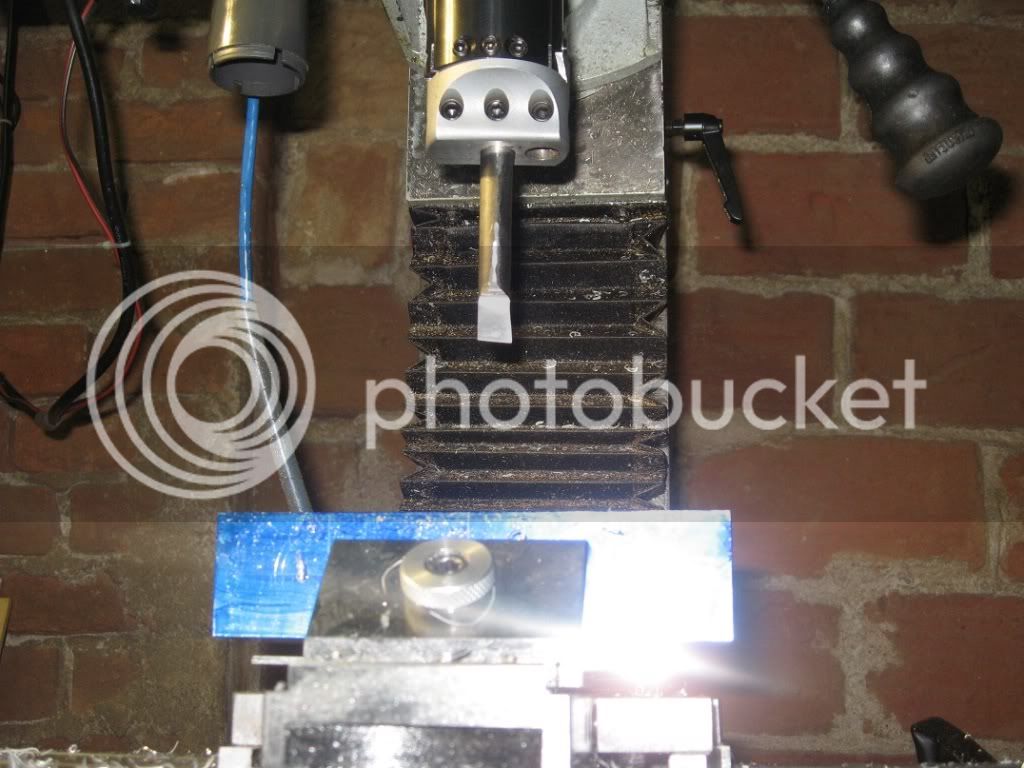

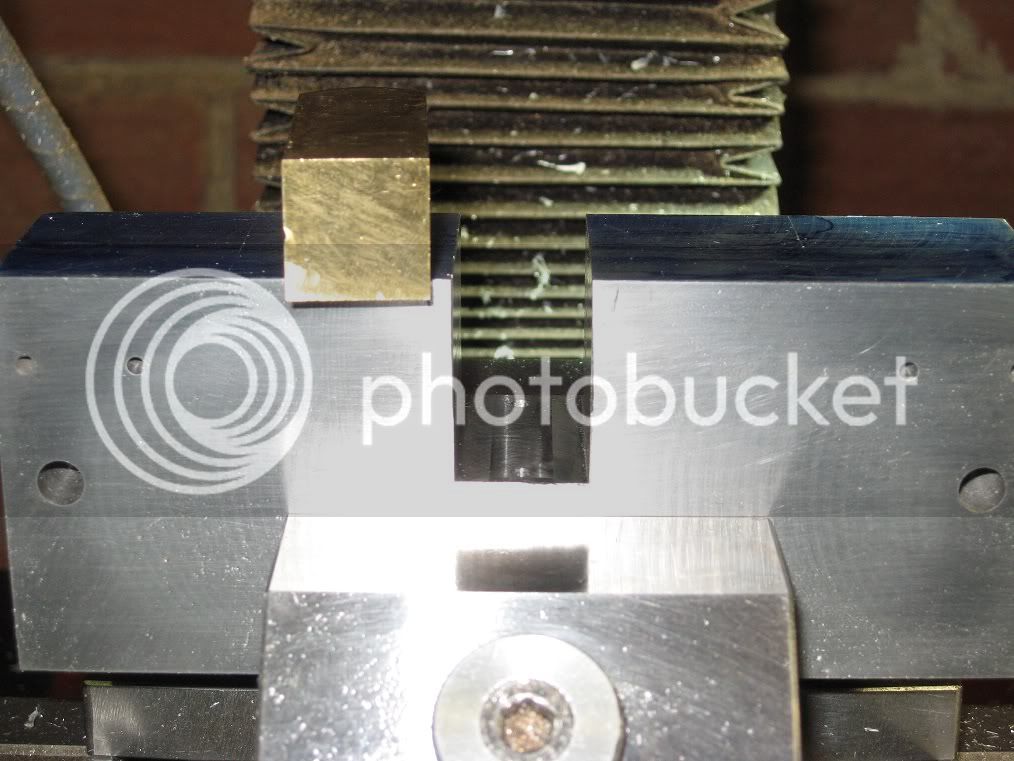

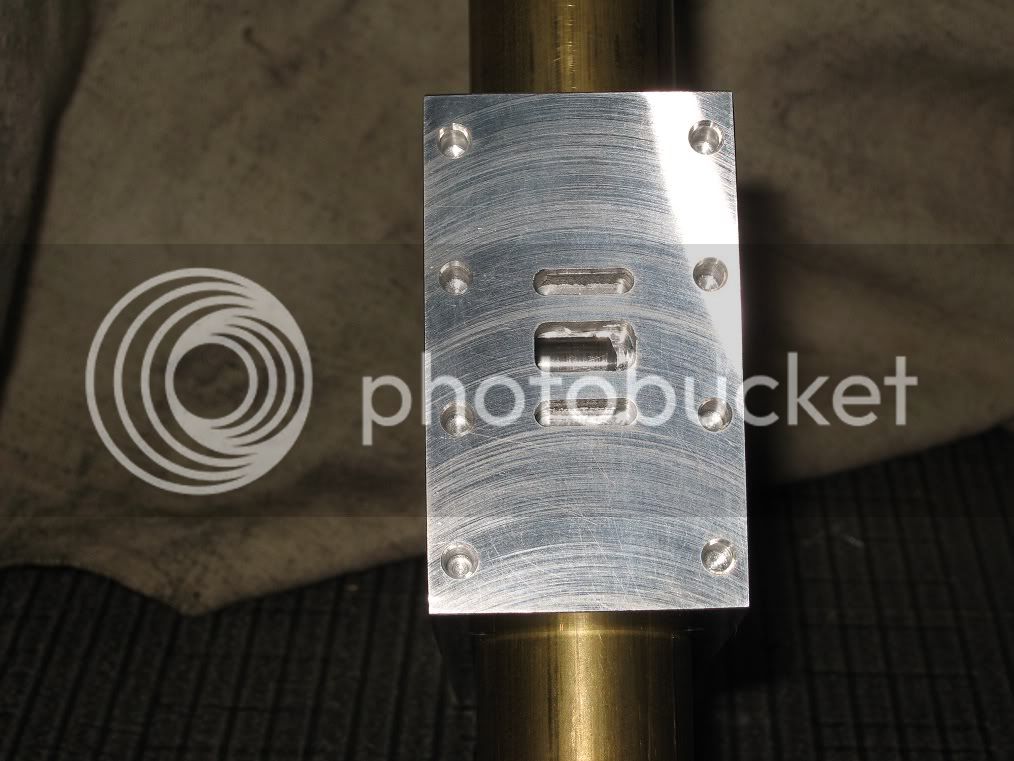

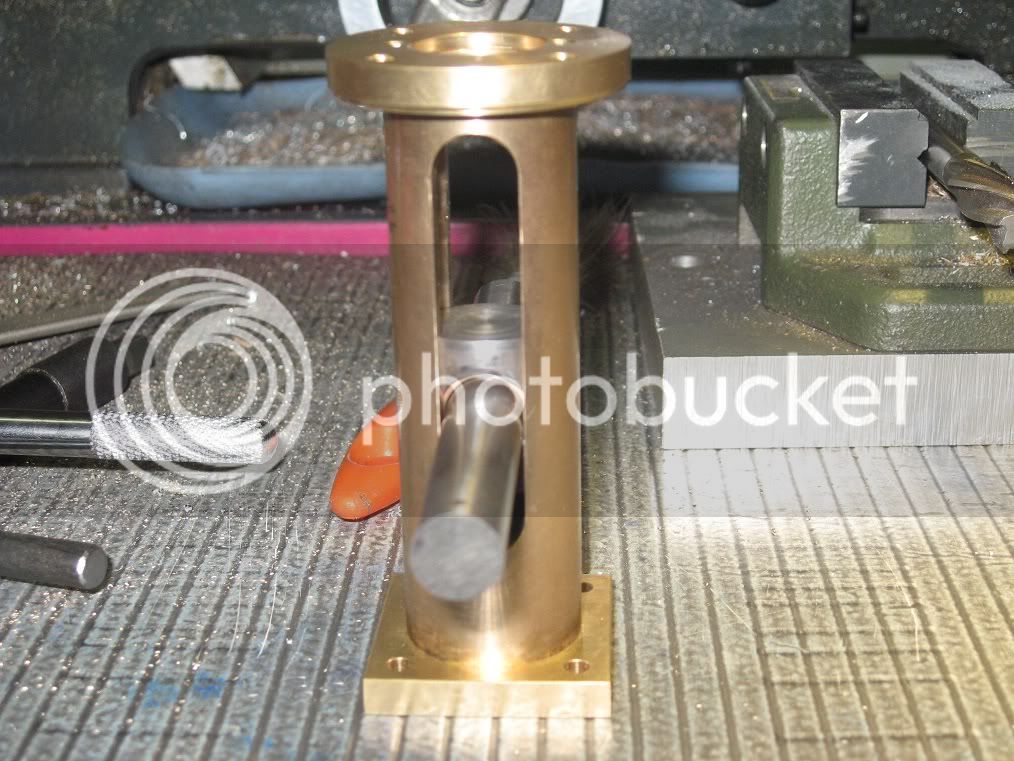

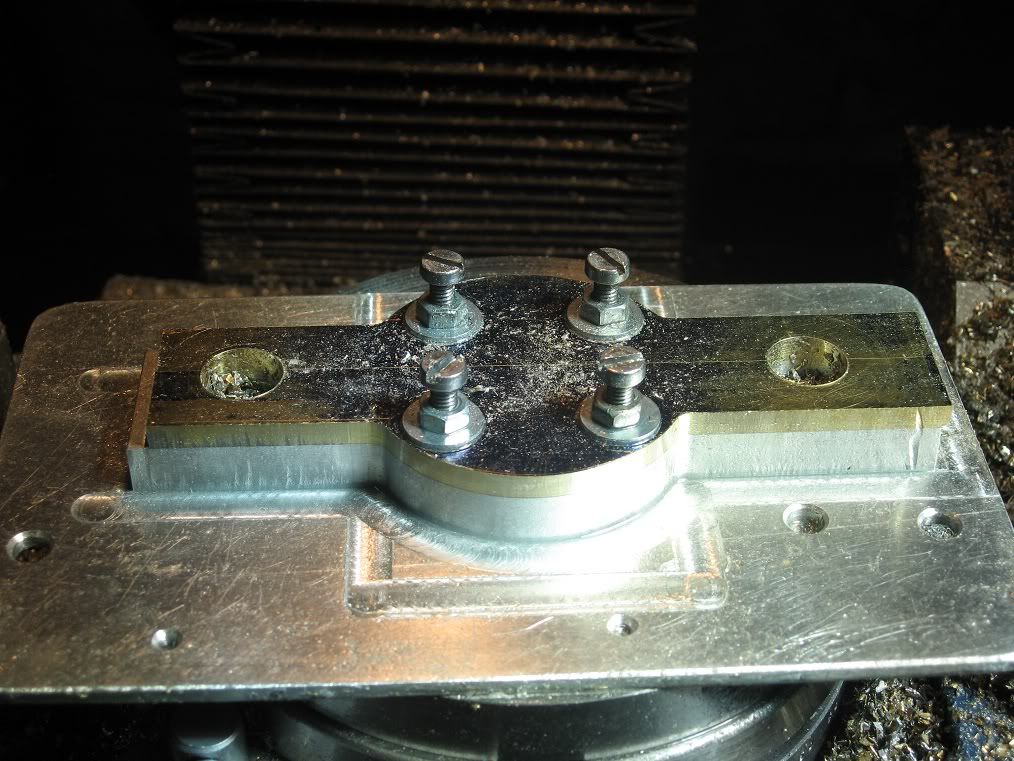

In the meanwhile I had drilled and tapped the hole for the locking screw, milled the pocket for the head and pressed the sleeve to hide the halfway cut as Chuck had explained into this thread

<

http://www.homemodelenginemachinist.com/index.php?topic=11471.0 >

Thanks again, Chuck!

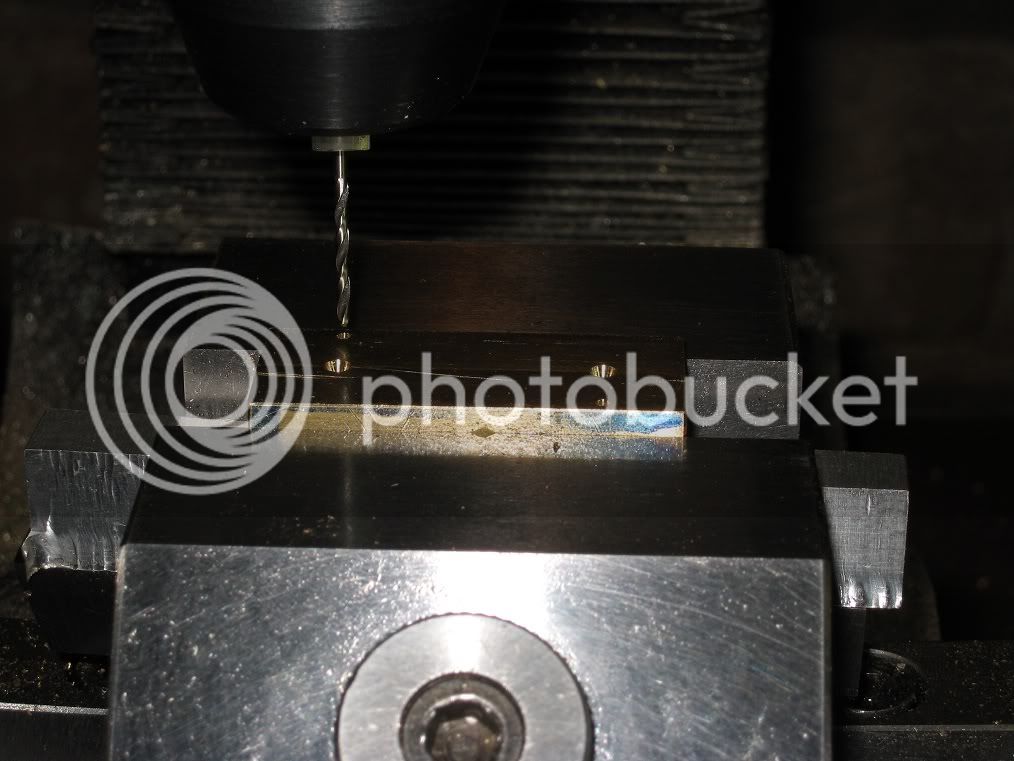

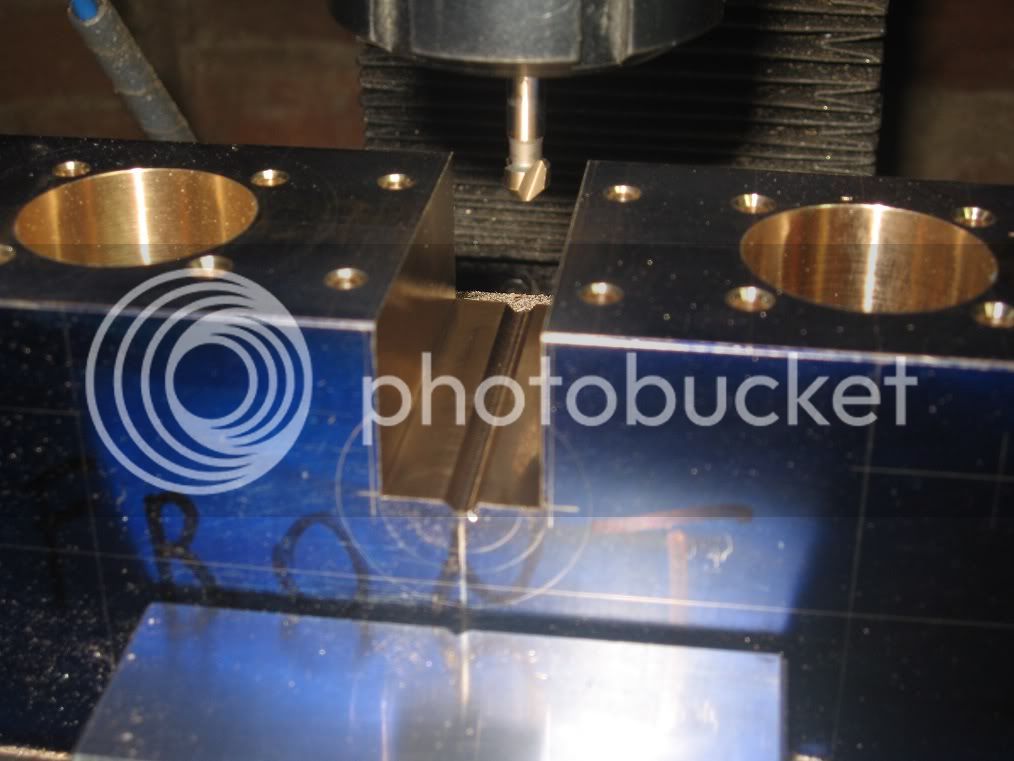

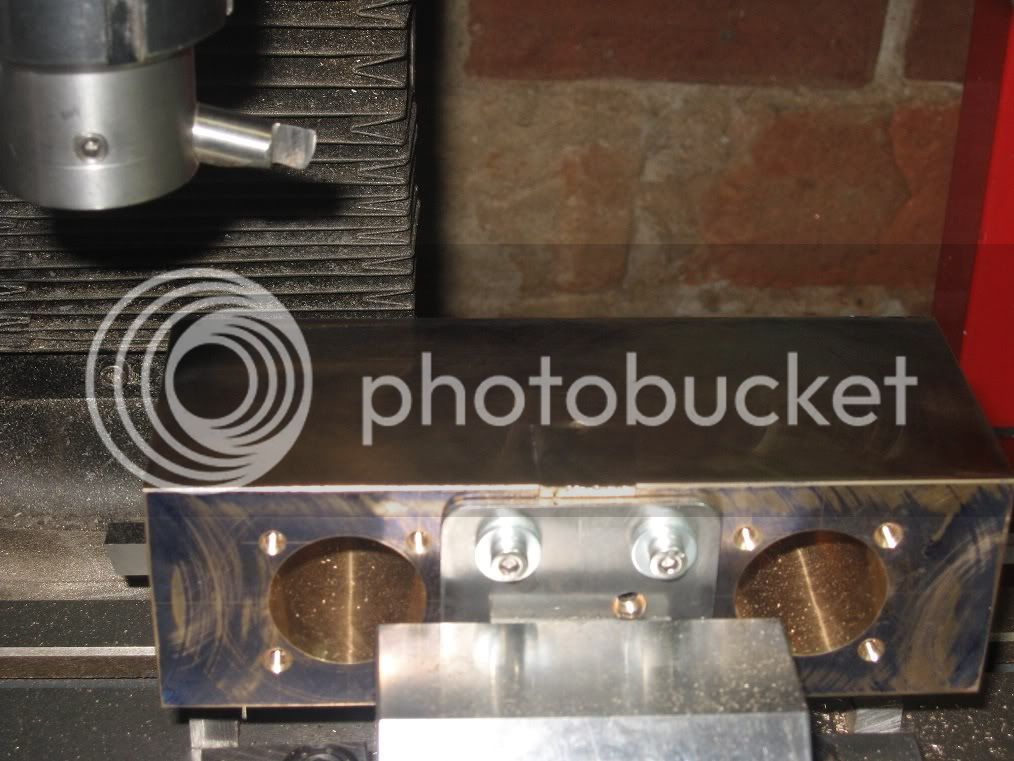

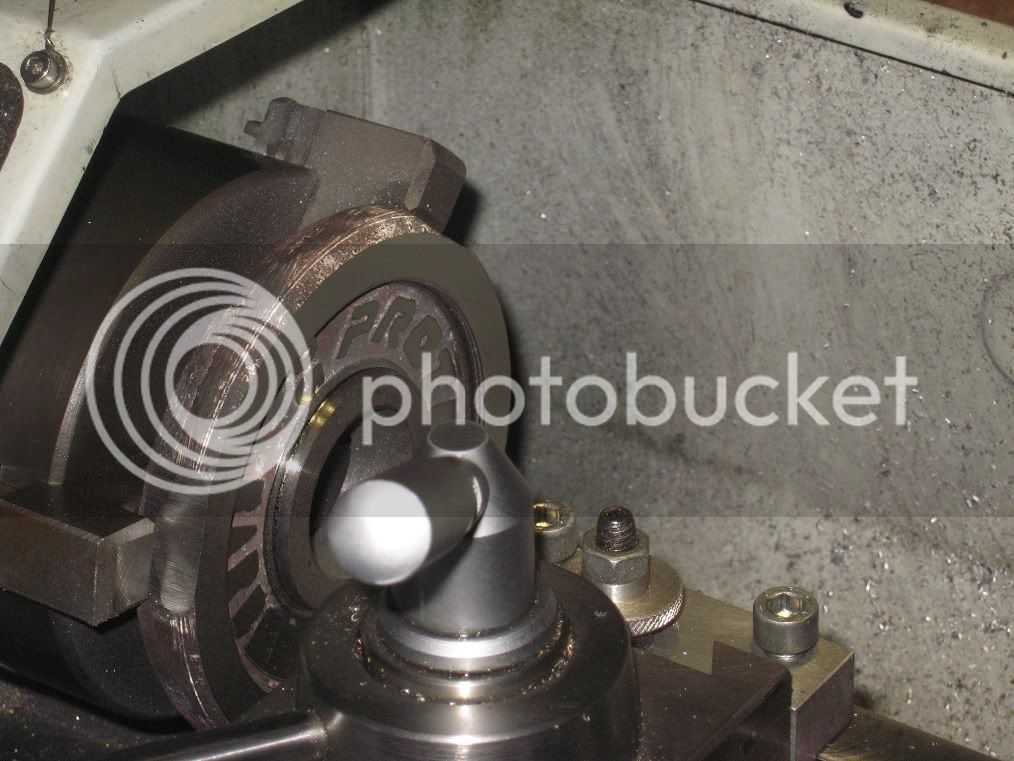

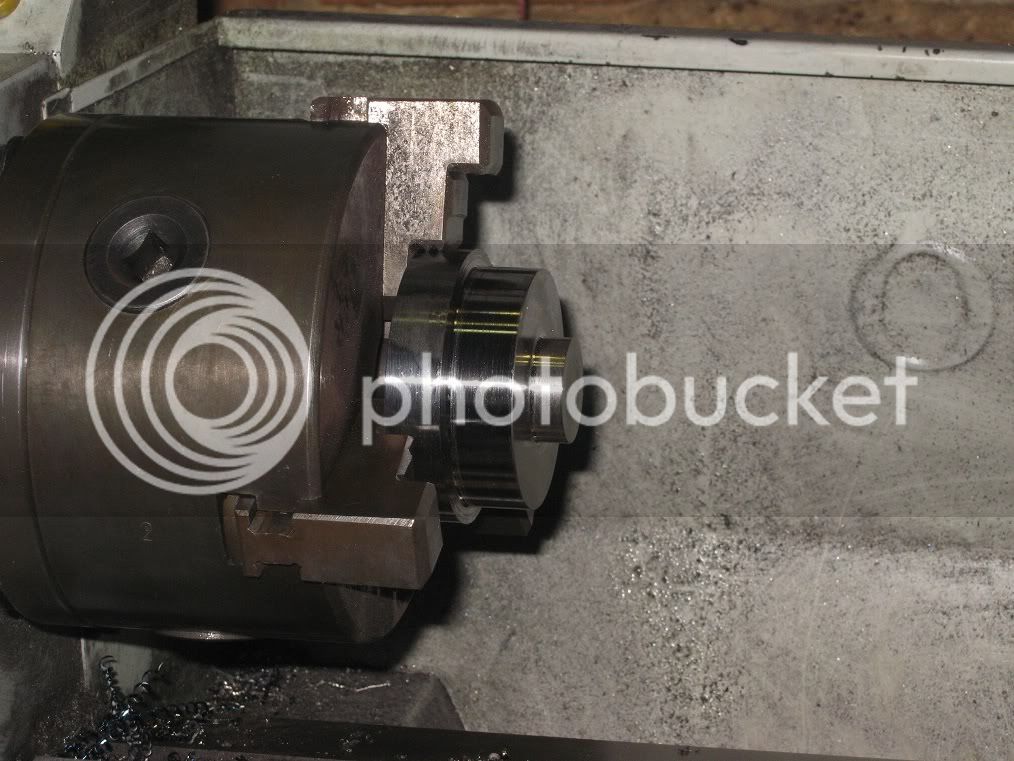

Still on the RT, to drill and countersinking the matching holes on the ring. Thats a 68mm Proxxon chuck I have mounted on a 20mm steel arbor to fit the largest collet of the ER32 series.

Having the five brass spokes turned, drilled and tapped M3, I cut portions of five of the ugliest M3 screws I had and used them as studs, with a bit of loctite to prevent unwanted unscrewing during the

next operation.

of turning them to a nice fit into the rim.

Again a bit of loctite on five cs screws and the rim is ready for the final truing on the lathe.

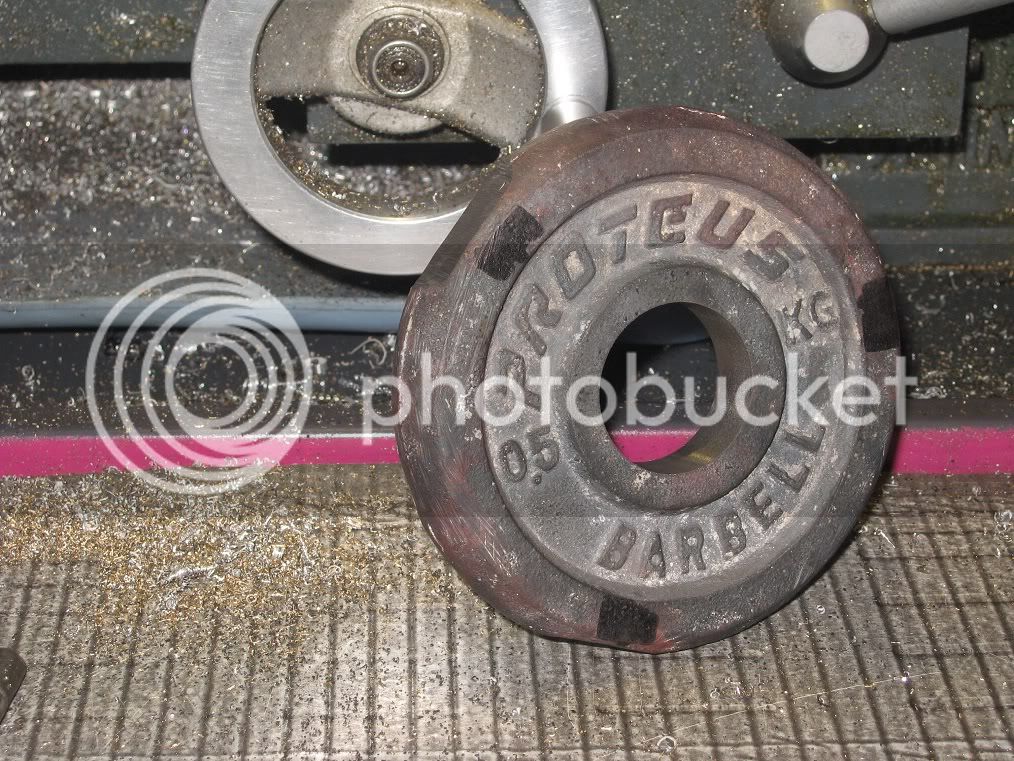

This barbell weight had resisted any previous attempt of machining: it simply ate the HSS bits like they were butter, and chewed the edges of the carbide tipped ones.

Now Ive got some insert holders to try it with.

First of all, I ground three notches on the circumference, for a better fit into the chuck: I really do not want the thing to chase me through the shop.

Guess what? They are working!

First side done. The material is really poor, rather rips instead of cutting. And some blow holes are appearing

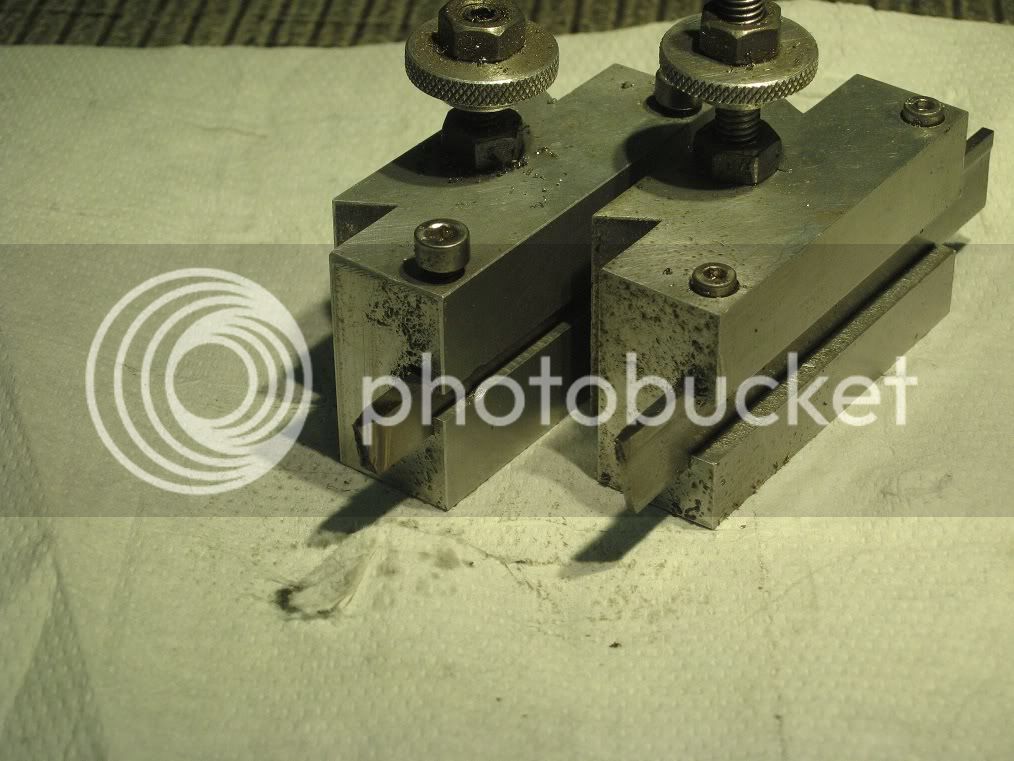

An old picture of them tools, the lower two shown before I milled out the shank in excess.

The hub, Chucks design again. (If it were not for cutting the half way slit 90deg wrong, :- ( - It still works, anyway - )

And the sleeve, before press fitting.

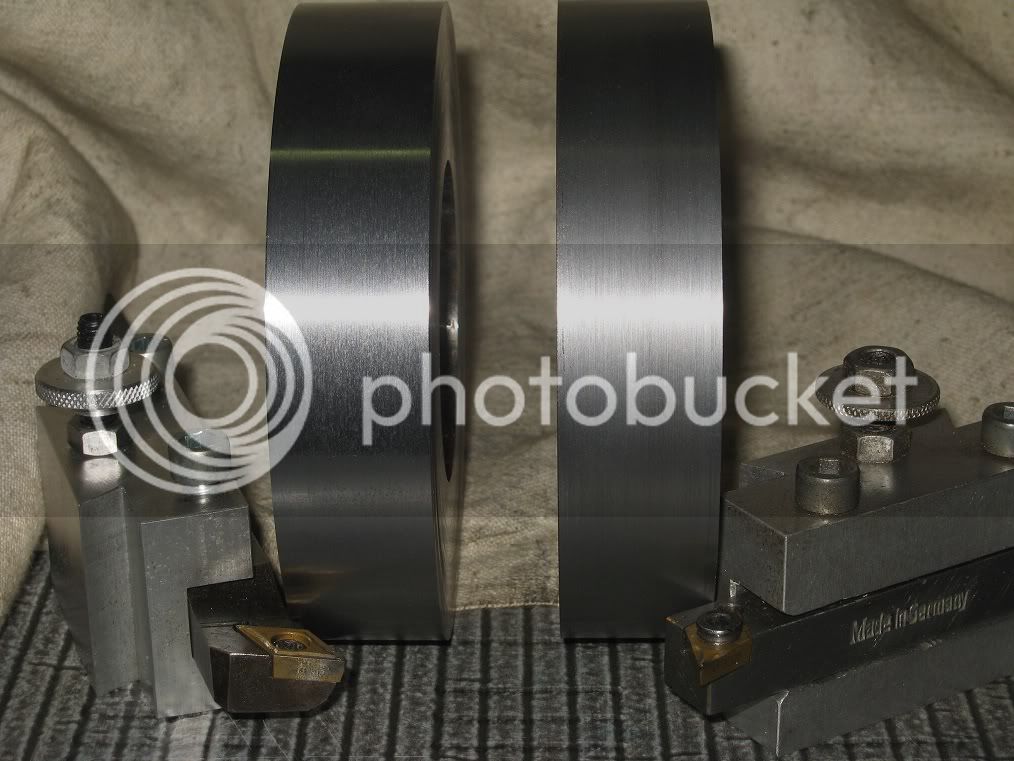

The two, yet unfinished flywheels, waiting patiently for their tyres.

The tyre problems

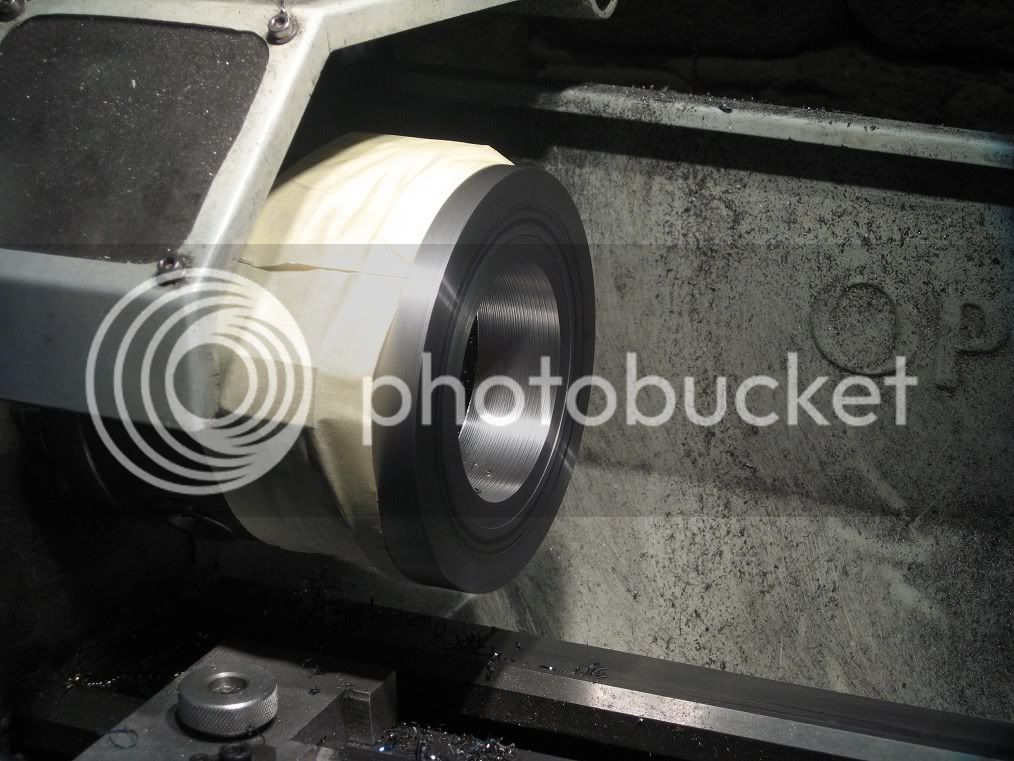

When the external jaw #3 dropped on the lathe bed, I knew for sure I could not hold a 105mm ring into my 100mm chuck. Not a 100mm ring, too: the limit being somewhere around 90, I discovered later.

Fonly I had some soft jaws!

The wiser option would have been fitting the thingy to the faceplate, for boring: but I really hate swapping workholding tools on the lathe, though it rarely takes more than a minute.

Went for some creative machining, instead.

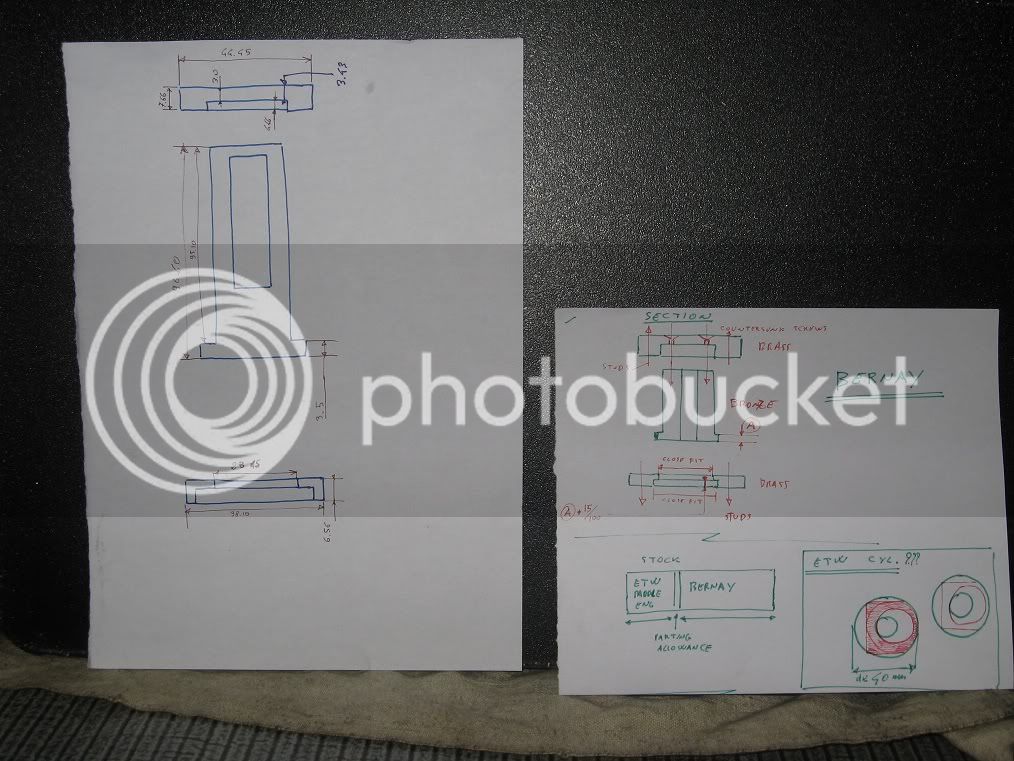

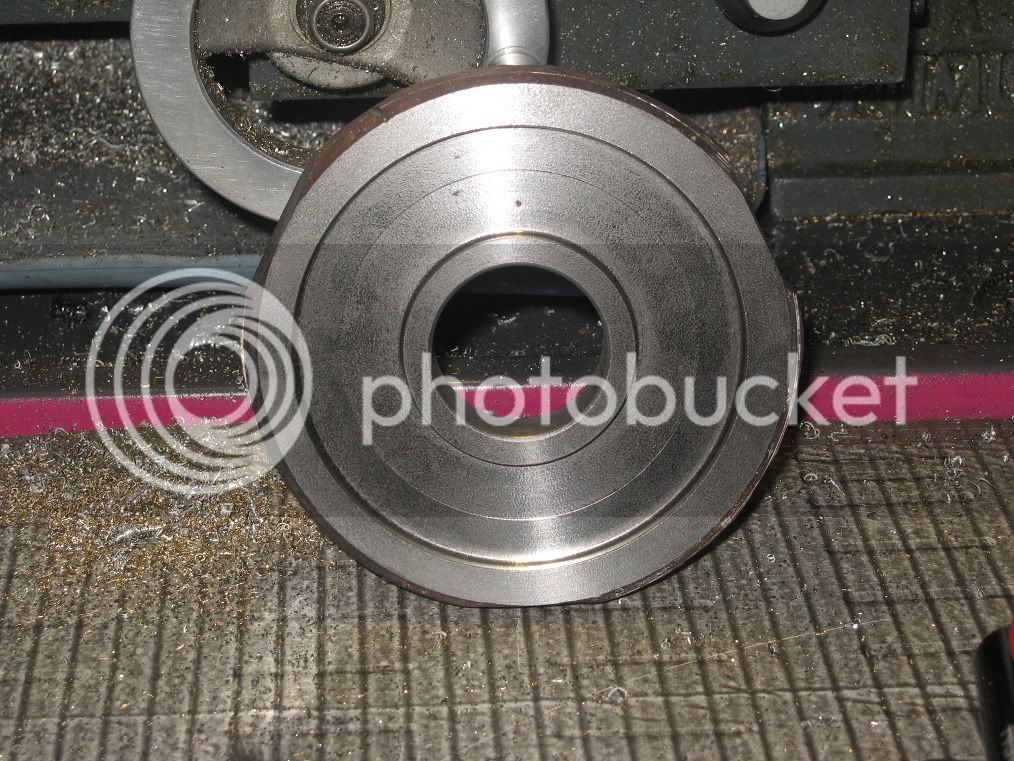

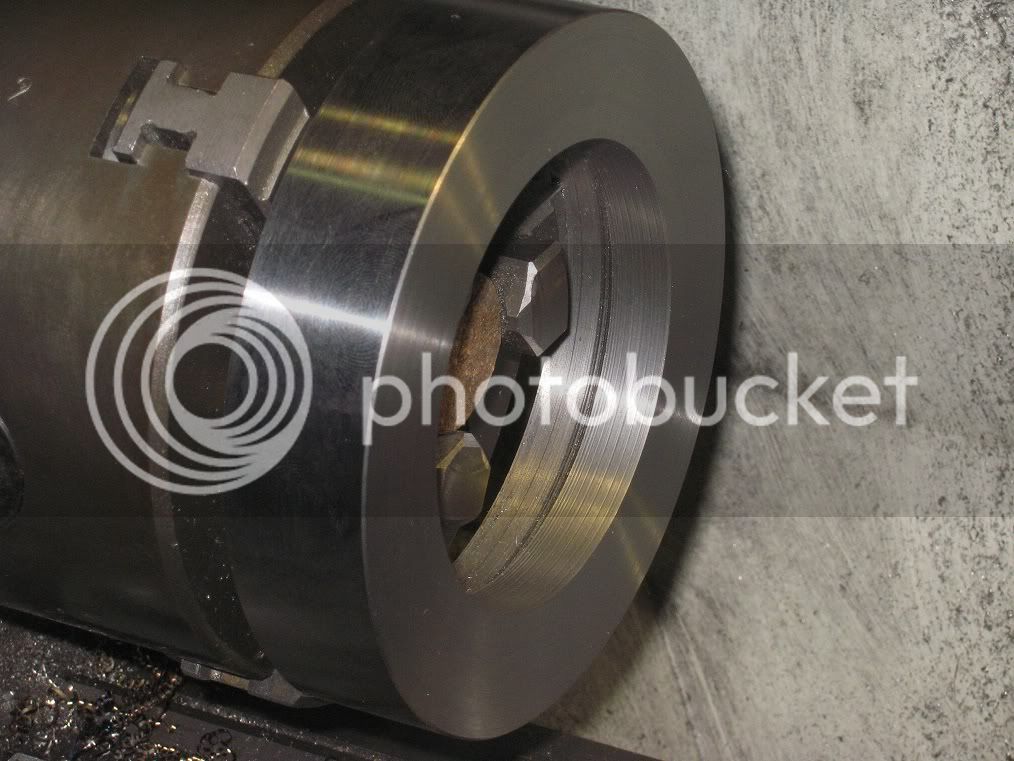

The ring was grabbed with the internal jaws and bored as deep as possible to a diameter 2mm shorter than the already completed part, with the exception of the initial 2.5mm that were enlarged to the

final diameter. Then it was reversed into the chuck, grabbed by the inside jaws on that step and to press fitting diameter, leaving about 1mm on the bottom to act as a stop for the press.

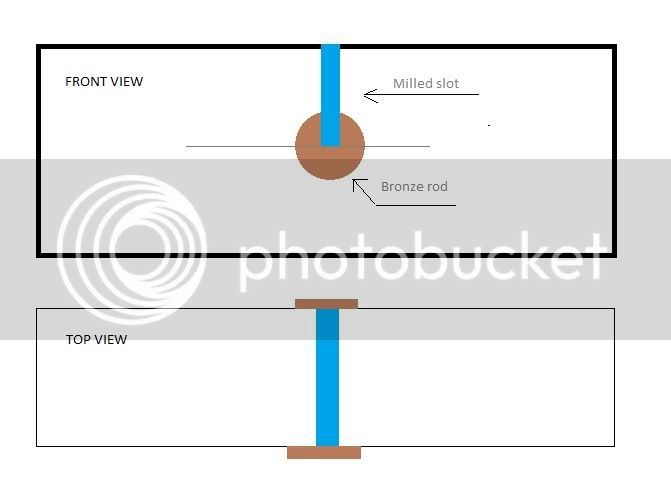

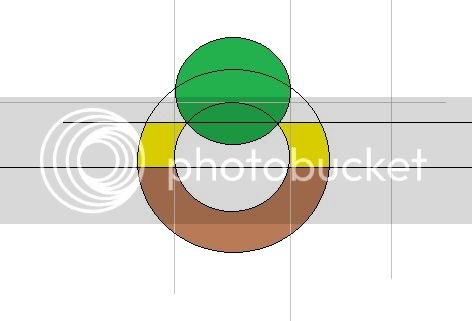

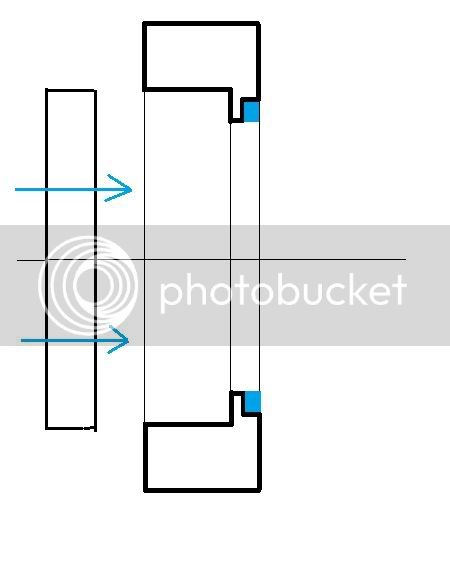

This might clarify the idea.

On the second tyre, I took a different approach: having the ring chucked by the internal jaws, I machined a small portion to about 90mm, with the tool at an angle so to have the inner diameter shorter

than the outer: that should ensure it wont escape from the jaws.

A bit of paper tape stopped short chips from being thrown directly at me through the space amont chuck and workpiece.

Heres the two flywheels: when I mounted them on a mandrel for the final truing, I could get mirror finish on the external surface and the ugliest chatter when cutting on the sides, though the mandrel I

used was rather stiff (a 12mm HSS bar)

I suppose they will go on the faceplate, someday. ;D

Marcello