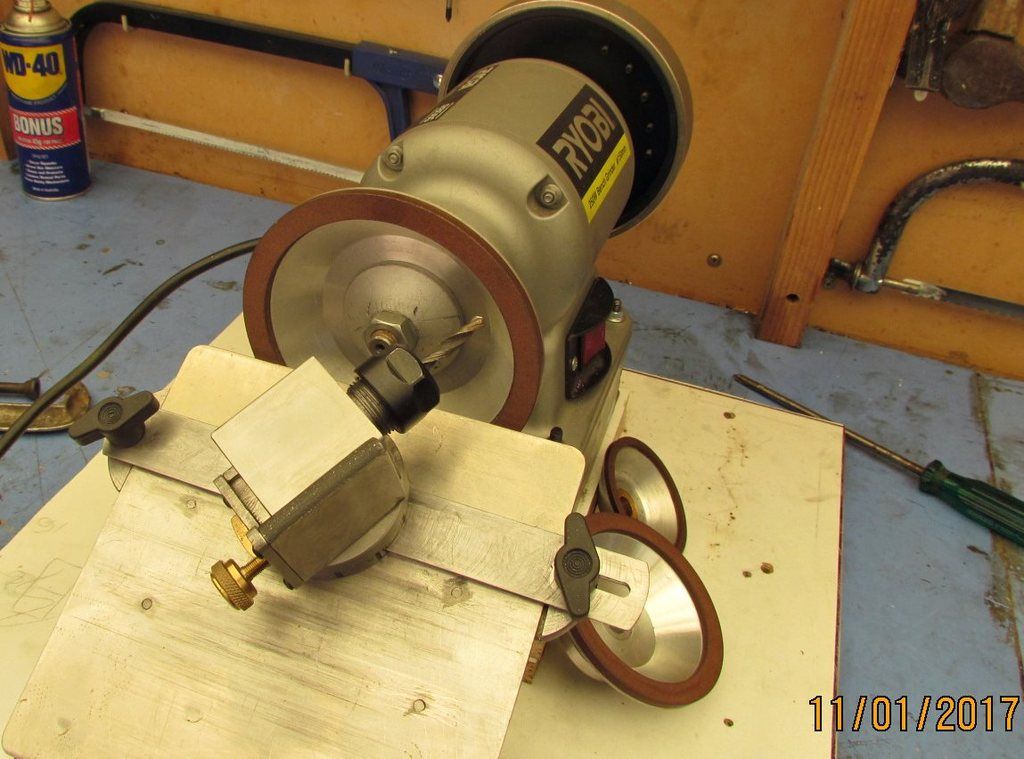

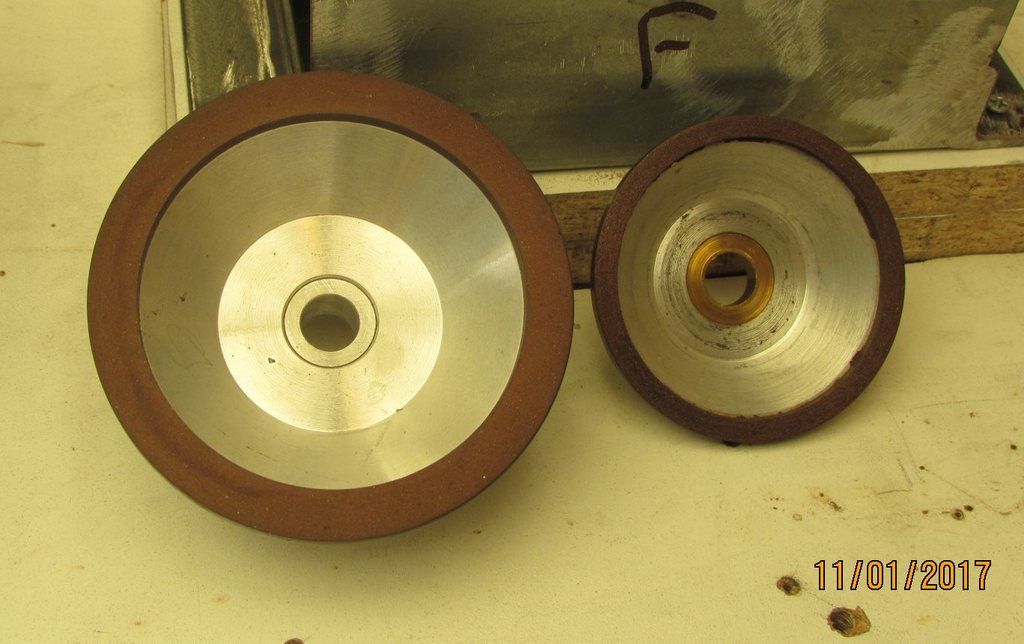

Some shops consider diamond wheel for HSS bad taste.

I learned toolgrinding from a guy who spent his entire carreer grinding tools in a woodworking factory . You know , the kind of guy with a grey dust coat , a butt of cigarette in his mouth , and a cup of coffee on the corner of the bench .

He thought me how to sharpen carbide sawblades , drill bits , endmills , wood cutters , knives .... And it all seemed so friggin easy when he demonstrated it

Back on topic :

This man told me never to use diamond wheels for carbon steel or hss .

Supposedly the carbon in the steel would do something to the diamond , wich is also carbon , and destroy it in no time .

I've always listened to his advice and use the diamond wheels exclusivly for carbide .

btw he also said never to breathe the carbide/diamond grinding dust .

Would be very dangerous . Don't know if it's true or not , but once again I carefully listened to his advice . Extraction unit ON , alway's !

Pat