- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

Just started my next project.I like the look of the acute system and with

information gleaned from Utube etc have sufficient info to make my version

However to play fair with Eccentric Engineering I have bought a set of drgs

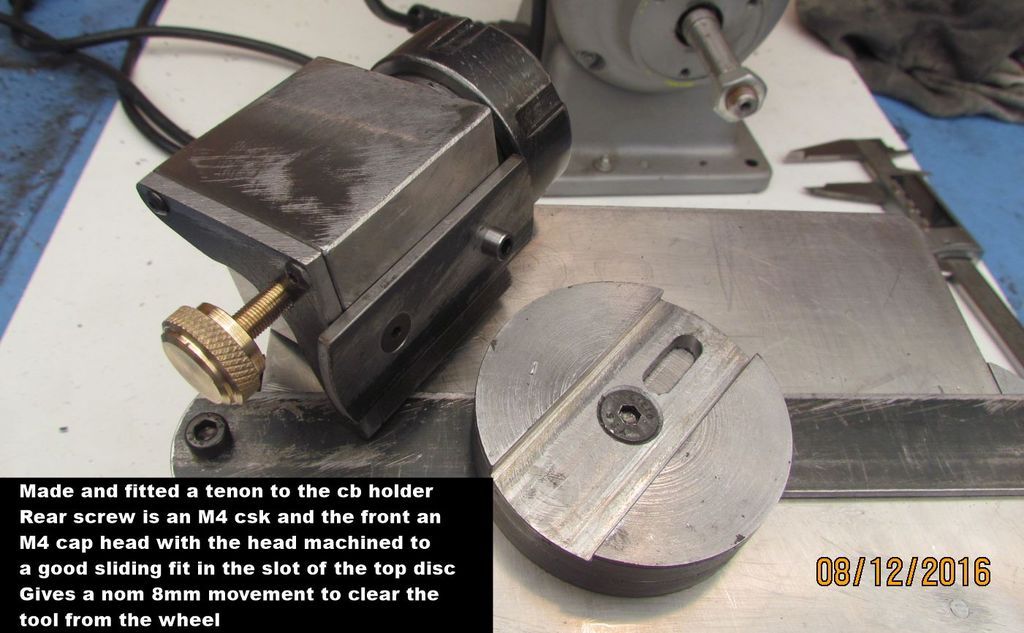

for $35.Have made a start with the table as drgs have not yet arrived

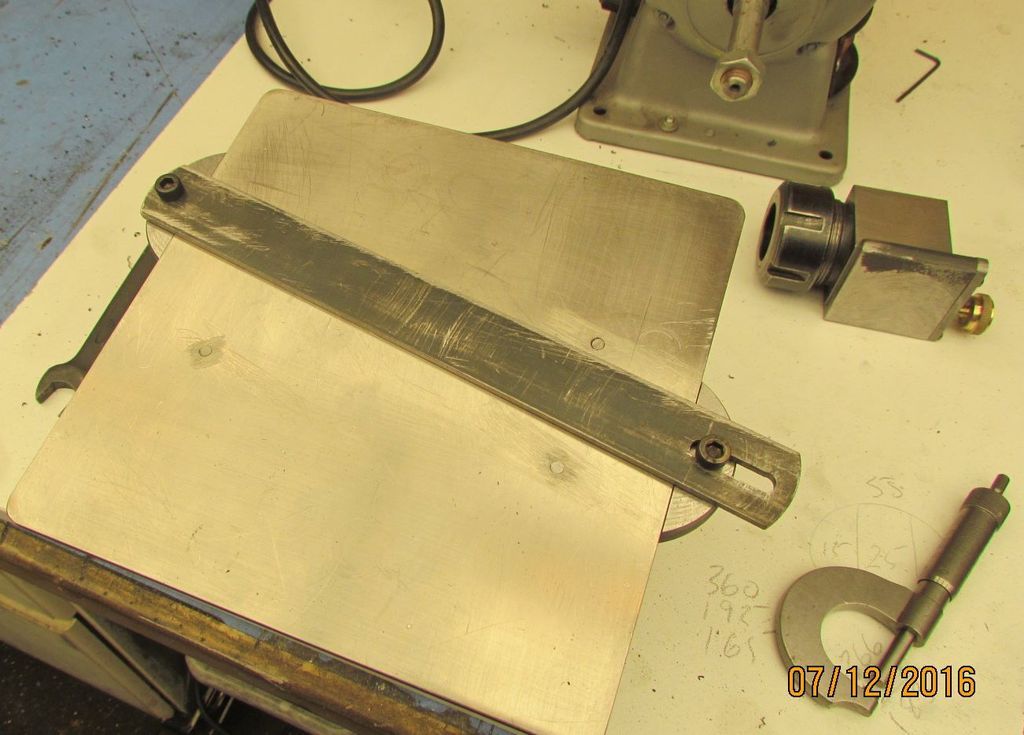

Table calls for 150mm sq x 4mm m/s so I used 165mm sq x 5 thk S/S

4 brkts were fabbed from 25x3 angle and 3mm plt,Spacers 25dia alum

M6 allthread S/S screws and although I have ordered a few knobs and clamps

from China I also made 2 ms lever arm screws.Table works well.Now waiting for the drgs before deciding how far to go with the pantograph arm etc and what

changes if any to make.As usual flying by the seat of my pants

pants

information gleaned from Utube etc have sufficient info to make my version

However to play fair with Eccentric Engineering I have bought a set of drgs

for $35.Have made a start with the table as drgs have not yet arrived

Table calls for 150mm sq x 4mm m/s so I used 165mm sq x 5 thk S/S

4 brkts were fabbed from 25x3 angle and 3mm plt,Spacers 25dia alum

M6 allthread S/S screws and although I have ordered a few knobs and clamps

from China I also made 2 ms lever arm screws.Table works well.Now waiting for the drgs before deciding how far to go with the pantograph arm etc and what

changes if any to make.As usual flying by the seat of my

pants

pants