- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

Having just posted the above and reading a thread on the pros and cons of slide valves and piston valves,i will post this short post

Many years ago I was in the process of making a 3.5 g 3 cylinder pacific loco

Heilan Lassie.The two outside cylinders had slide valves.They were mounted

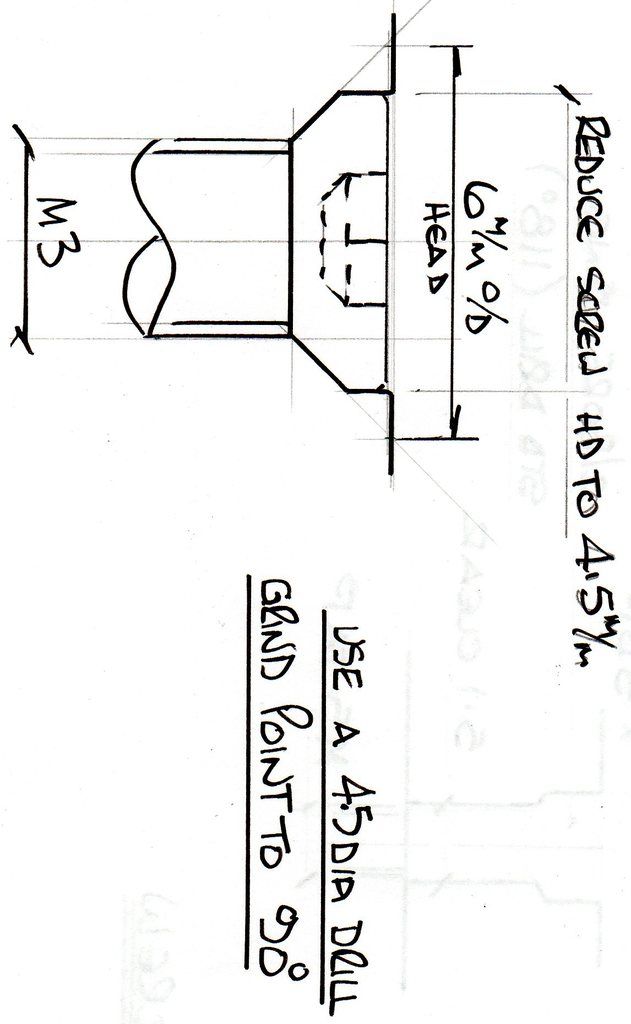

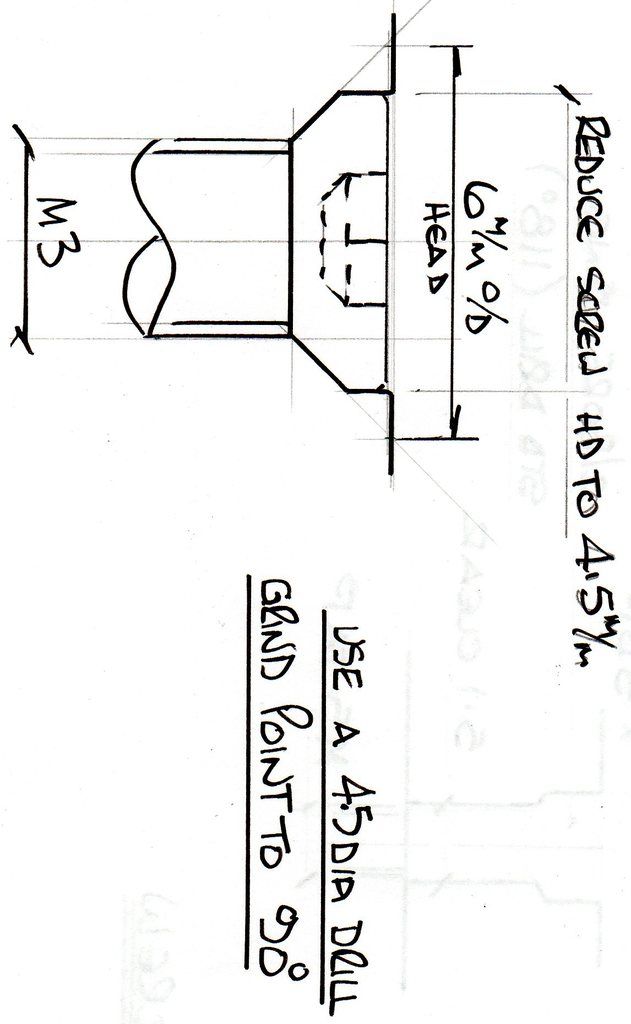

thru the cover plt and body and fixed to the cylinders with 12 7ba slotted hd CSK screws.Im not a lover of slt csk so went for M3 hx sock.Problem with them is the large head being out of proportion,so I turned the hds down to 4.4mm

in a simple fixture in the collet ,lathe.I ground the point pf a 4.5mm drill to 90o

and using the above procedure.All fixings lined up perfectly and looked good/proportional to the model.Most of the fixings were 5 and 7Ba which are

near enough M3 and M4.Still used a lot of hex hds for details but they have reduced hds and are difficult and expensive to source.As a note I have kept a set of drills sized and ground for a no of small fasteners both metric and imperial and I don't own any counterbores

Many years ago I was in the process of making a 3.5 g 3 cylinder pacific loco

Heilan Lassie.The two outside cylinders had slide valves.They were mounted

thru the cover plt and body and fixed to the cylinders with 12 7ba slotted hd CSK screws.Im not a lover of slt csk so went for M3 hx sock.Problem with them is the large head being out of proportion,so I turned the hds down to 4.4mm

in a simple fixture in the collet ,lathe.I ground the point pf a 4.5mm drill to 90o

and using the above procedure.All fixings lined up perfectly and looked good/proportional to the model.Most of the fixings were 5 and 7Ba which are

near enough M3 and M4.Still used a lot of hex hds for details but they have reduced hds and are difficult and expensive to source.As a note I have kept a set of drills sized and ground for a no of small fasteners both metric and imperial and I don't own any counterbores