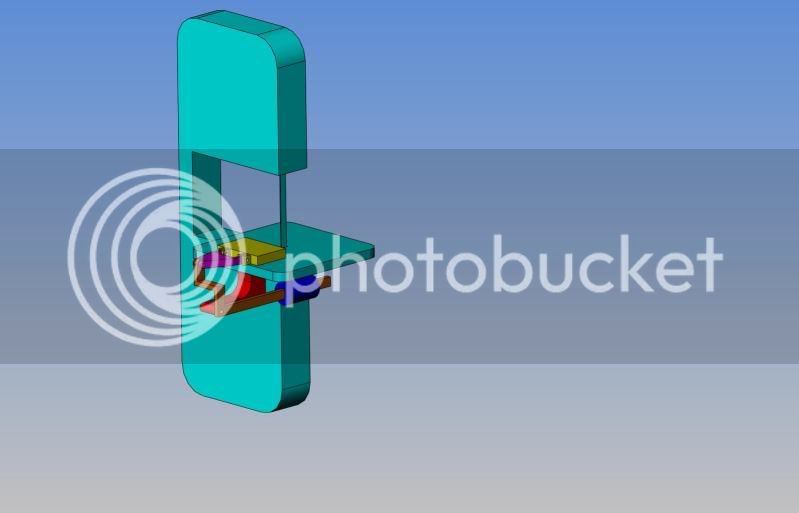

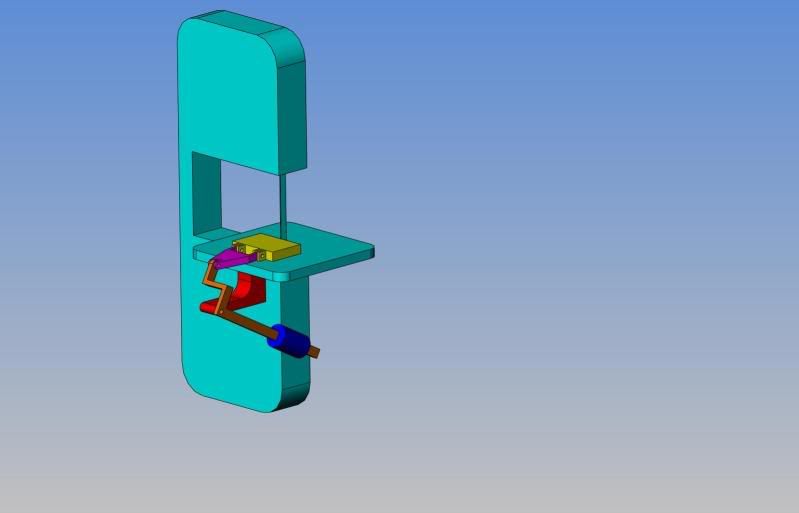

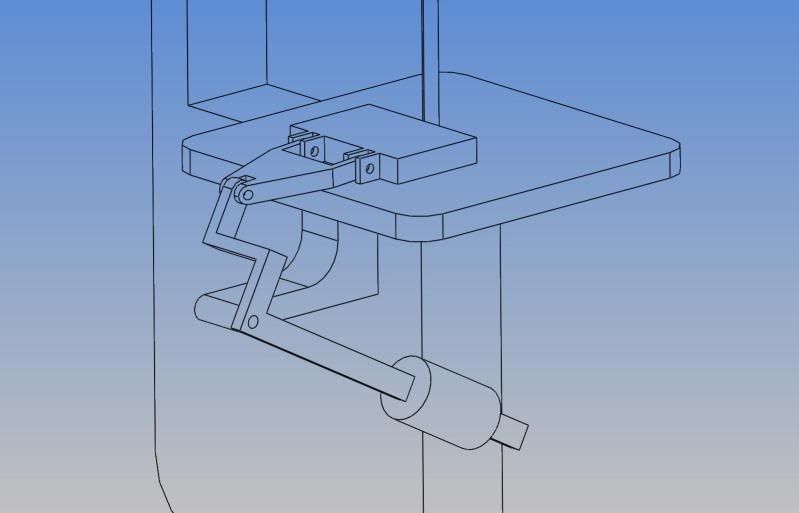

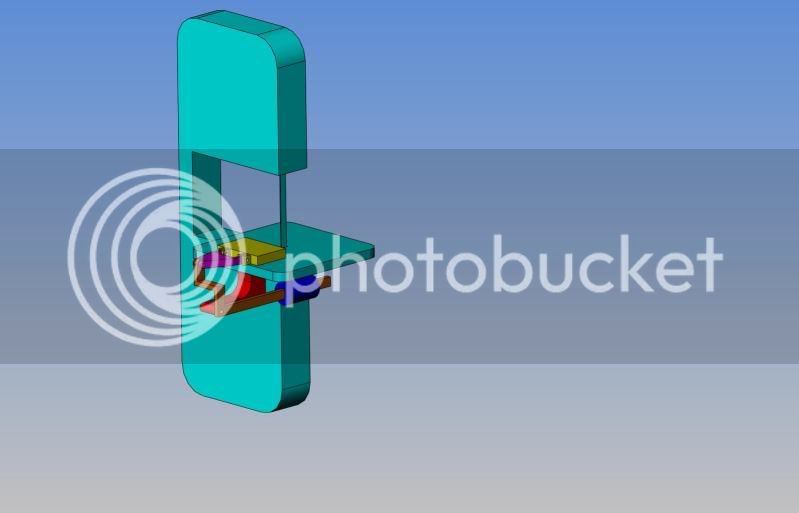

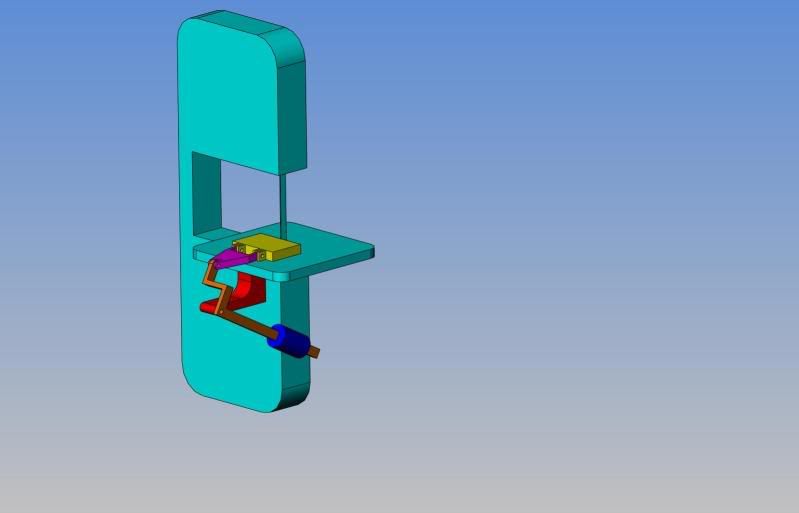

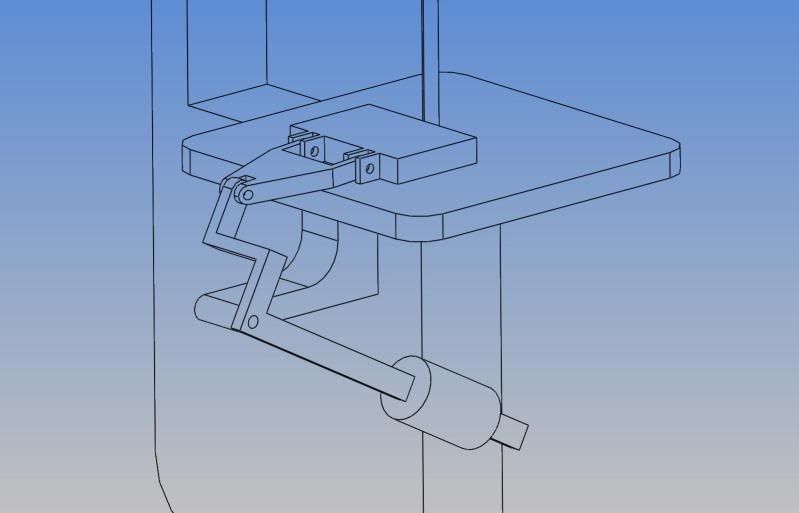

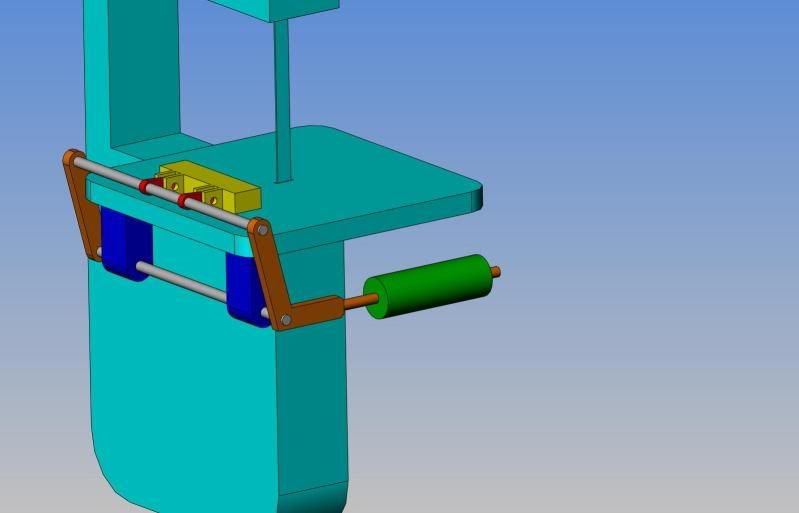

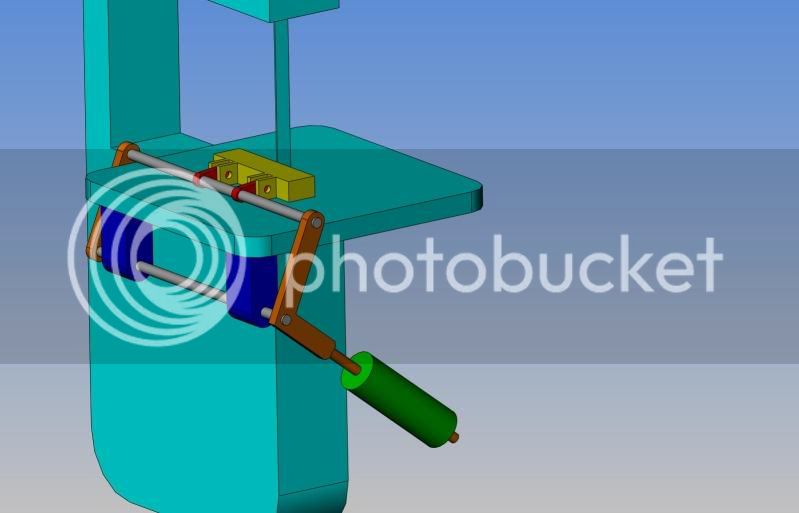

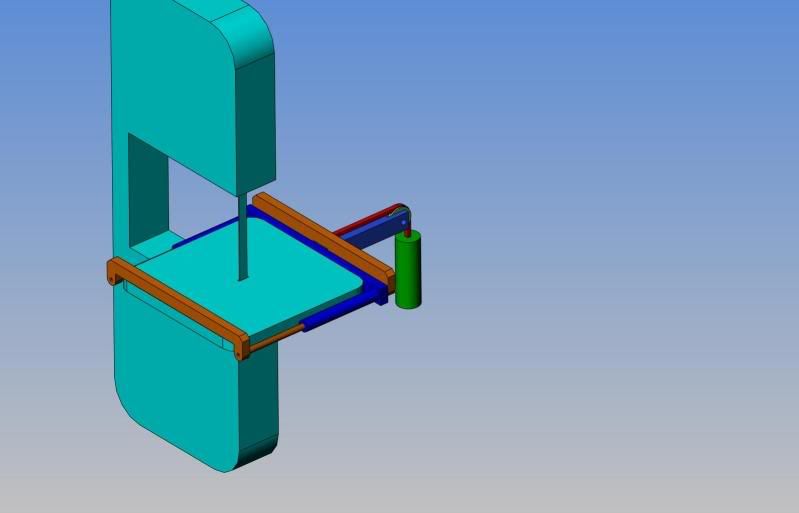

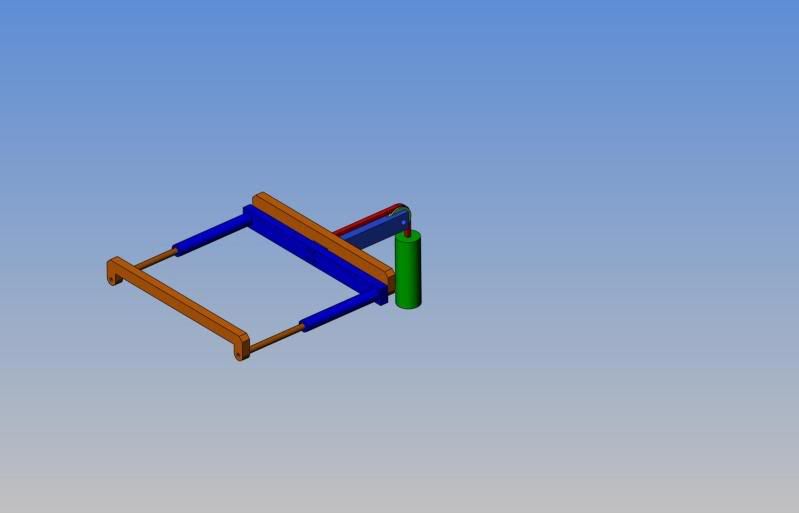

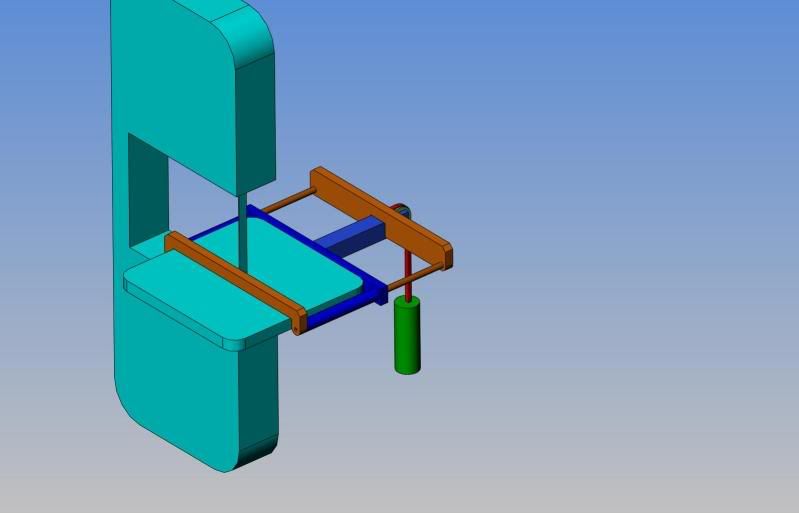

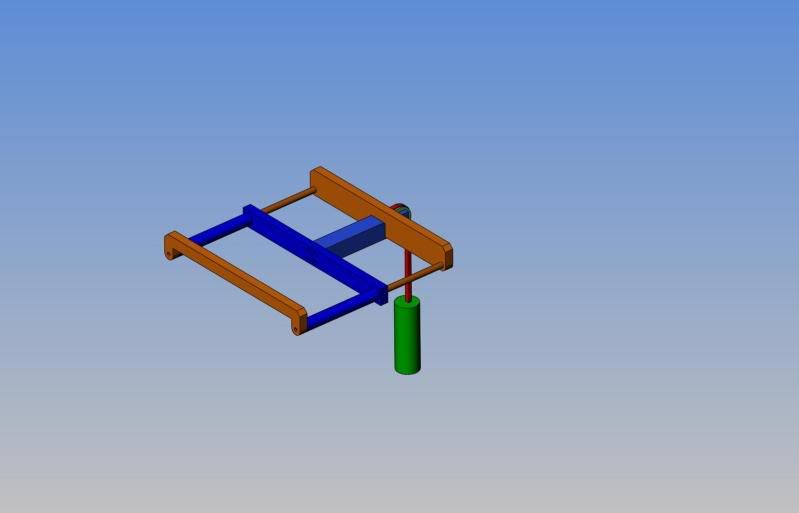

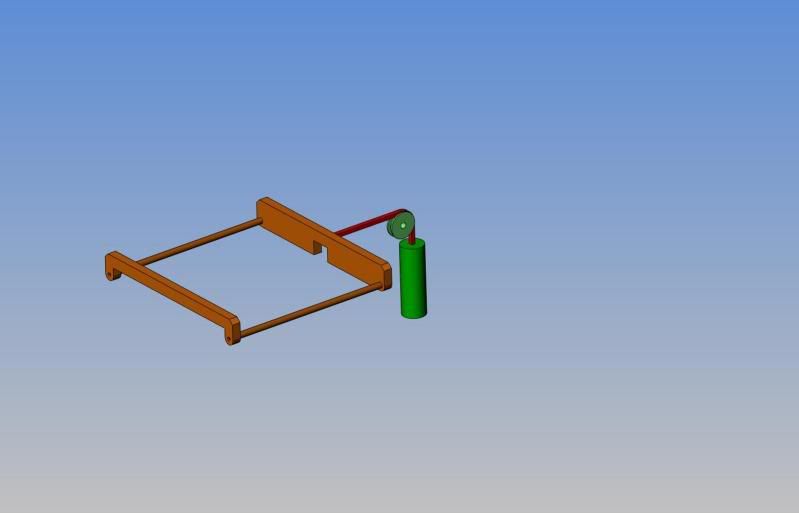

Last week when I was cutting some stock on my vertical bandsaw, I was thinking---"Gee---I wish I could just leave this and come back when its finished cutting, like I can my power hacksaw!!!"----This got me thinking---How hard would it be to rig a bandsaw autofeed. Hey--I do this kind of stuff for a living!!! So---Last night as I lay in bed, struggling with my insomnia. this is what I dreamed up. Very simple, but rather elegant. An arm, an adjustable position weight, and a couple of pivot points, I've shown a 1" thick x 3" wide x 6" long plate as the "Pusher" plate. One hardstop would be factored in to keep the pusher plate from cutting itself in half on the saw blade.---Brian