bezalel2000

Well-Known Member

- Joined

- May 8, 2011

- Messages

- 316

- Reaction score

- 7

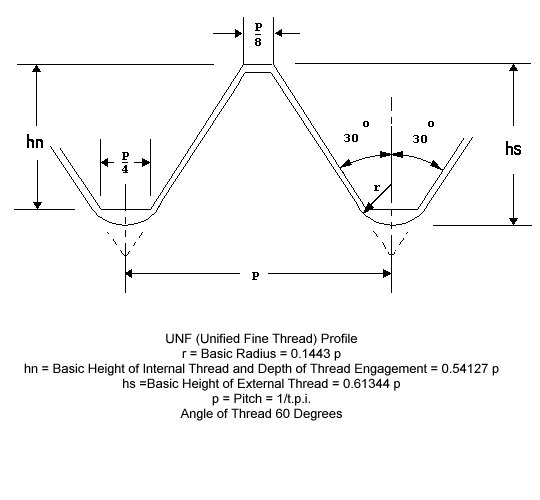

mklotz said:If you look at a thread diagram, you'll see that the depth of thread (sharp crest to flat root), is given geometrically by:

D = [[3/8]/tan(30)] / n = K / n

where:

n = thread pitch in tpi

and the thread angle is assumed to be 60 degrees (as it is for American and metric threads).

Doing the math , K evaluates to 0.649519

Simple Question

What is the general formula for thread depth? :shrug:

Now I know, thanks to Merv's and Rick, that for 60o threads thread depth per pitch can be calculated from a constant k = 0.65

I can also extrapolate from major/minor diameter charts that for;

Whitworth k = 0.64 and for,

BA k = 0.60

So how do I calculate it. ???

I know I could look up the chart, but with advancing years an A4 sheet is just big enough to accommodate the formula where I might previously tabulated the whole chart. ;D

Thanks

Bez