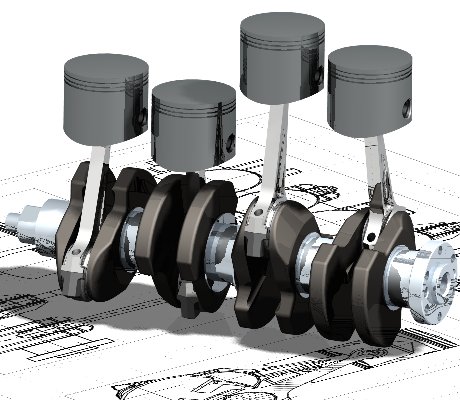

So has anyone experimented with diffrent firing orders in multicylinder engines?

Im not talking about which pair or set of pistons fire but for example having pistons fire at diffrent times. For example a 4 cylinder engine instead of having a pair fire every 180° have one cylinder fire every 90°. Similar to how the audi 5 cylinder fires a single cylinder every 78°

Im not talking about which pair or set of pistons fire but for example having pistons fire at diffrent times. For example a 4 cylinder engine instead of having a pair fire every 180° have one cylinder fire every 90°. Similar to how the audi 5 cylinder fires a single cylinder every 78°