playerofpawns

Member

- Joined

- Mar 16, 2011

- Messages

- 6

- Reaction score

- 0

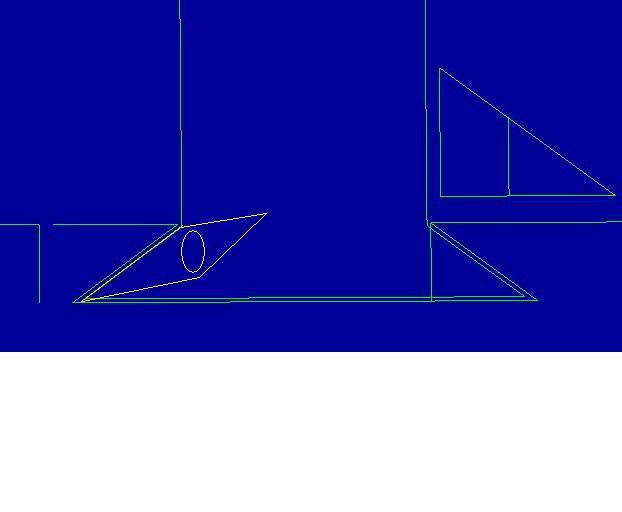

I have been wanting to make a 45 degree dovetail cutter/holder.

the only possible cutter that would work is a diamond cutter. however, the closest angle I can find is a 35-50 degrees, no 45 degree diamonds to be found.

anyone have any idea how to get this 45 degree angle out of an indexable cutter?

this is the cheepest place I can find the cutter needed to machine the dovetail for the boaring head project. as cutter width is 5/16 instead of the more common 1/4, and cutter diameter is 3/4 so it will fit into the, "less than an inch" opening for the dovetail.

http://www.shars.com/products/view/3057

View attachment boringhead[1].pdf

the only possible cutter that would work is a diamond cutter. however, the closest angle I can find is a 35-50 degrees, no 45 degree diamonds to be found.

anyone have any idea how to get this 45 degree angle out of an indexable cutter?

this is the cheepest place I can find the cutter needed to machine the dovetail for the boaring head project. as cutter width is 5/16 instead of the more common 1/4, and cutter diameter is 3/4 so it will fit into the, "less than an inch" opening for the dovetail.

http://www.shars.com/products/view/3057

View attachment boringhead[1].pdf