deere_x475guy

Well-Known Member

I have had this face mill since I bought my first mill (Rung Fu 31) in 2004. I have never gotten a decent finish with it and finally put it away last year. I don't have a fly cutter and never got around to making one (I know they are cheap but I like to make my own tools when I can). Anyway yesterday I needed to clean up the surfaces of the flat plate parts for my Webster and got the face mill out and thought I would try to change the geometry on the bits that came with it again. After looking at it and then going through my stash of lathe bits I found these. I got them about 4 years ago in bulk for cheap and use them on the lathe from time to time and they seemed to hold up well. You can see the original bits for the face mill in the back ground.

The front relief on these are 30degrees and I left that as is. I put a 4 degree top rake in them with the surface grinder and the took them over to the tool grinder and grinded in a 10degree front cutting edge angle and by hand created a slight nose radius. After this I used a fine stone to polish up the cutting point I know this picture my not show it very well and I can take more pictures if need be.

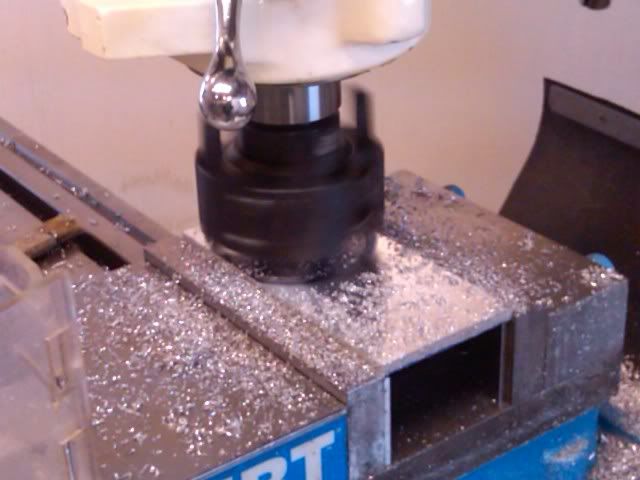

I started by taking a .005 first pass:

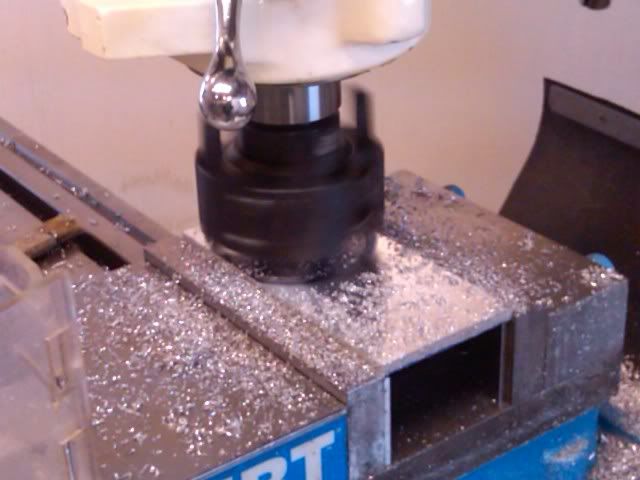

And then finished with a very slow feed rate and .001 DOC and this is the finish I ended up with. I am now very pleased with this tool.

I used Marv's speed calcuator and it called for 255 to 382 rpm. I tried the 255 and the 382 and the 255 gave the best finish.

The front relief on these are 30degrees and I left that as is. I put a 4 degree top rake in them with the surface grinder and the took them over to the tool grinder and grinded in a 10degree front cutting edge angle and by hand created a slight nose radius. After this I used a fine stone to polish up the cutting point I know this picture my not show it very well and I can take more pictures if need be.

I started by taking a .005 first pass:

And then finished with a very slow feed rate and .001 DOC and this is the finish I ended up with. I am now very pleased with this tool.

I used Marv's speed calcuator and it called for 255 to 382 rpm. I tried the 255 and the 382 and the 255 gave the best finish.