Lakc

Well-Known Member

With coils like that you dont need to hook the scope leads up to anything, just lay them nearby and set the scope voltage gain. The early GM HEI ignition used a tin can formed to the top of the coil as an inductive pickup.

Resistor plugs are not going to help, its the coil primary kick at around 400v mixxing with the secondary kick thats putting voltage across every wire within 3 feet. You have a classic RFI problem here, time to put on your electrical engineer thinking cap.

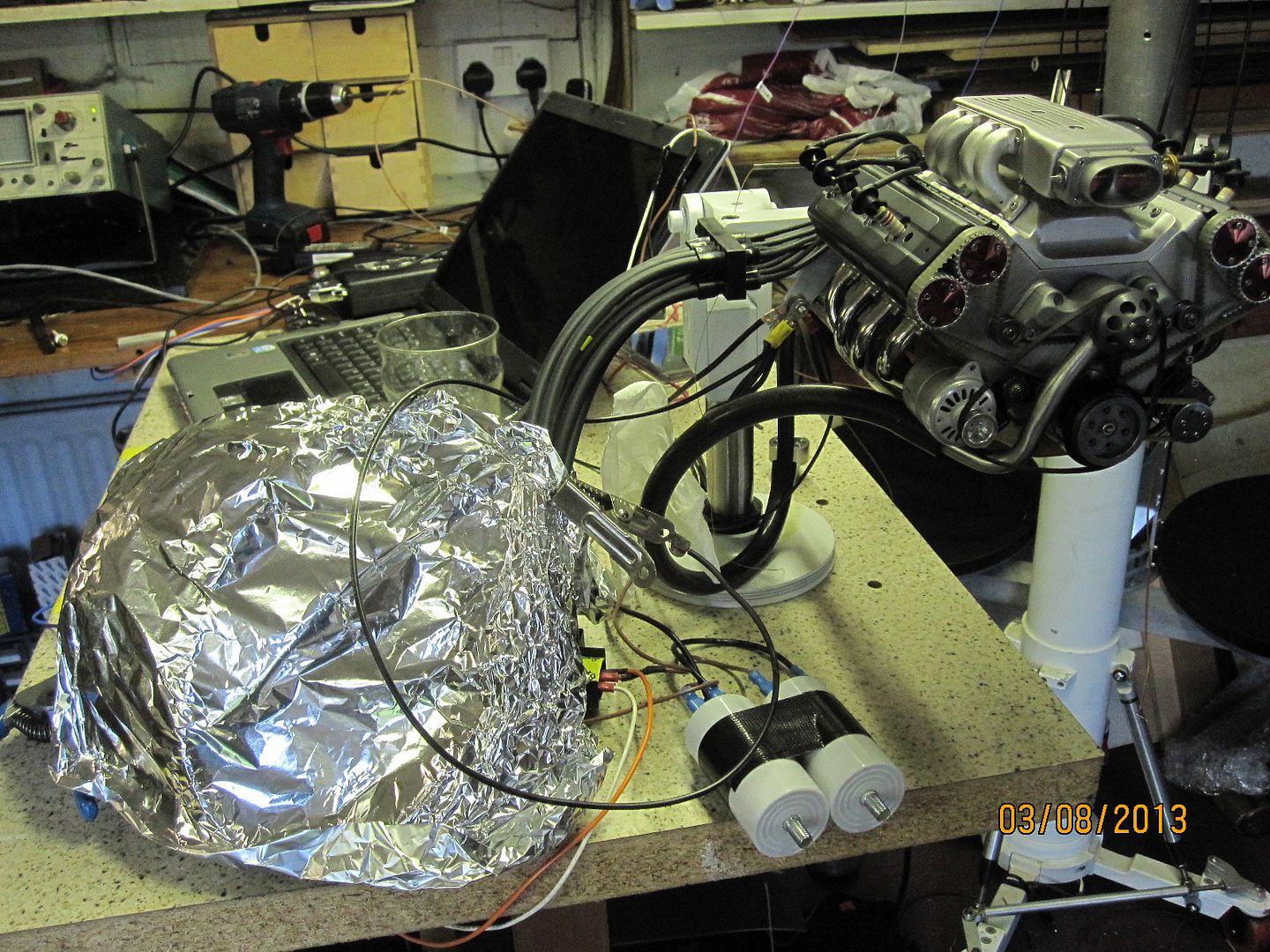

The insulation on the plug wires looks good, grab some metal (brass preferably) screen and wrap the coils up with the plug wires sticking out the top. Ground the screen. Same with the coil drivers (CDI coils?). What your making is called a Faraday cage.

Fit all the powers and grounds to the ignition with several different sized small capacitors, 1nf, .01uf, etc. Dont bother ordering a bunch, scrap them from that old VCR your never going to use again.

Make sure your grounds all go to a good mains ground. Use a 12v lead acid battery instead of any mains transformer or voltage supply. Batteries can suck up RFI really well if given a chance.

Next, get some ferrite beads from anywhere (like aforementioned VCR) and wrap the cable to the laptop in them. You can also wrap some grounded screen around the cable as well, it might help.

If it still doesnt work, dont fret, they can be tricky but solvable, with more ingenuity then coin. Know any ham radio operators in your area? They can be a great source of help if they have ever fought the "RF in the shack" battle.

Resistor plugs are not going to help, its the coil primary kick at around 400v mixxing with the secondary kick thats putting voltage across every wire within 3 feet. You have a classic RFI problem here, time to put on your electrical engineer thinking cap.

The insulation on the plug wires looks good, grab some metal (brass preferably) screen and wrap the coils up with the plug wires sticking out the top. Ground the screen. Same with the coil drivers (CDI coils?). What your making is called a Faraday cage.

Fit all the powers and grounds to the ignition with several different sized small capacitors, 1nf, .01uf, etc. Dont bother ordering a bunch, scrap them from that old VCR your never going to use again.

Make sure your grounds all go to a good mains ground. Use a 12v lead acid battery instead of any mains transformer or voltage supply. Batteries can suck up RFI really well if given a chance.

Next, get some ferrite beads from anywhere (like aforementioned VCR) and wrap the cable to the laptop in them. You can also wrap some grounded screen around the cable as well, it might help.

If it still doesnt work, dont fret, they can be tricky but solvable, with more ingenuity then coin. Know any ham radio operators in your area? They can be a great source of help if they have ever fought the "RF in the shack" battle.