- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

Hi everyone,

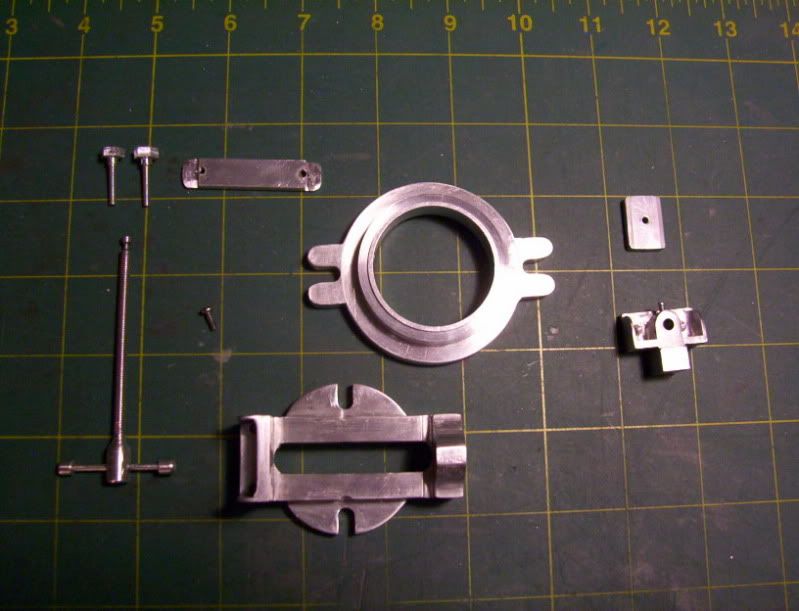

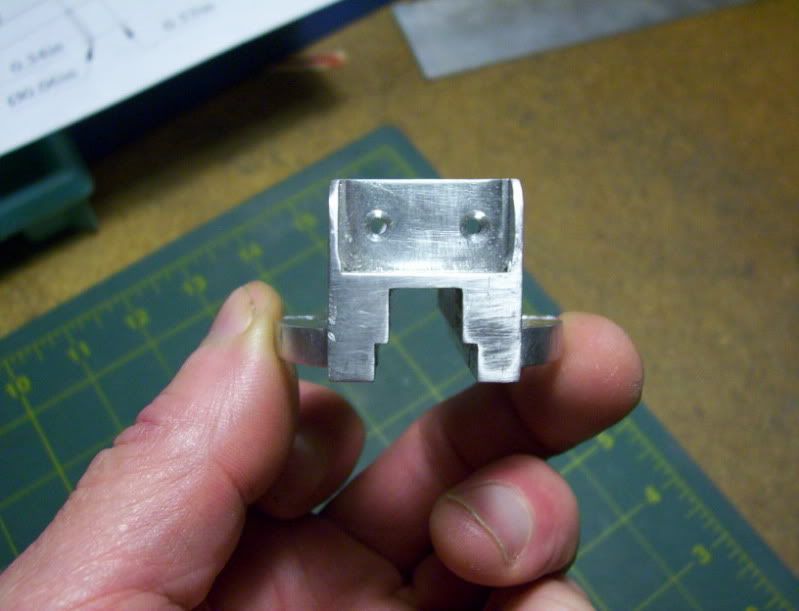

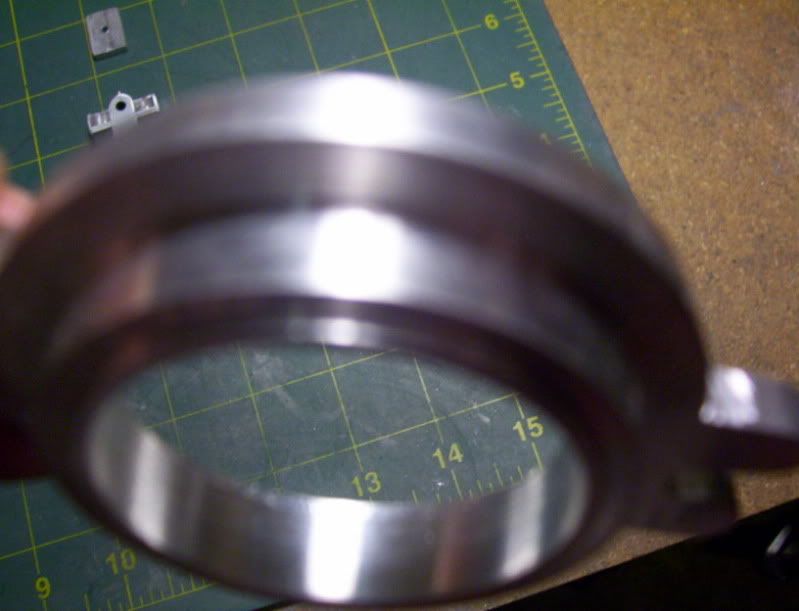

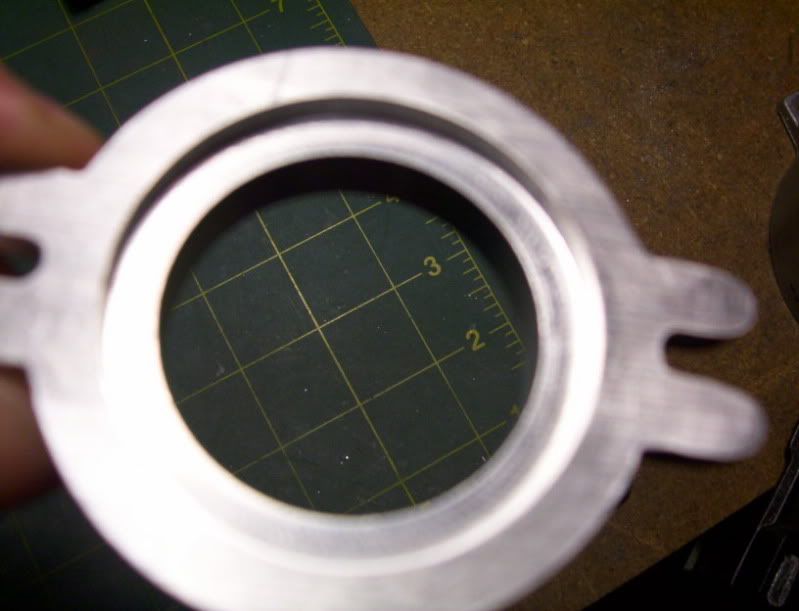

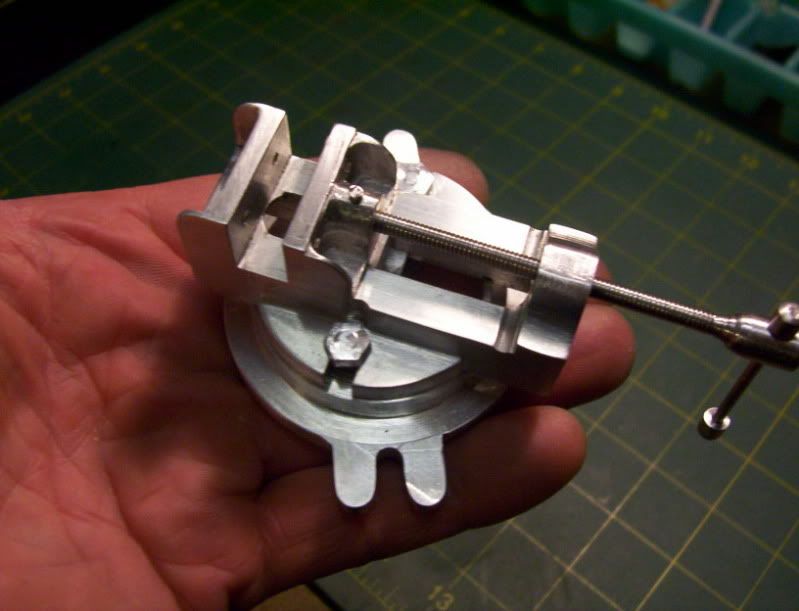

Like to share some pic's of my latest project, I just finished up on it tonight.

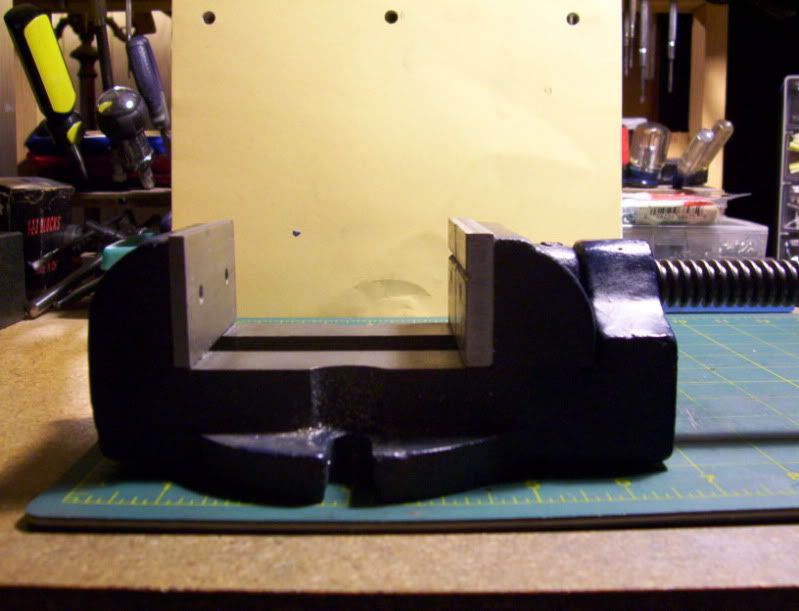

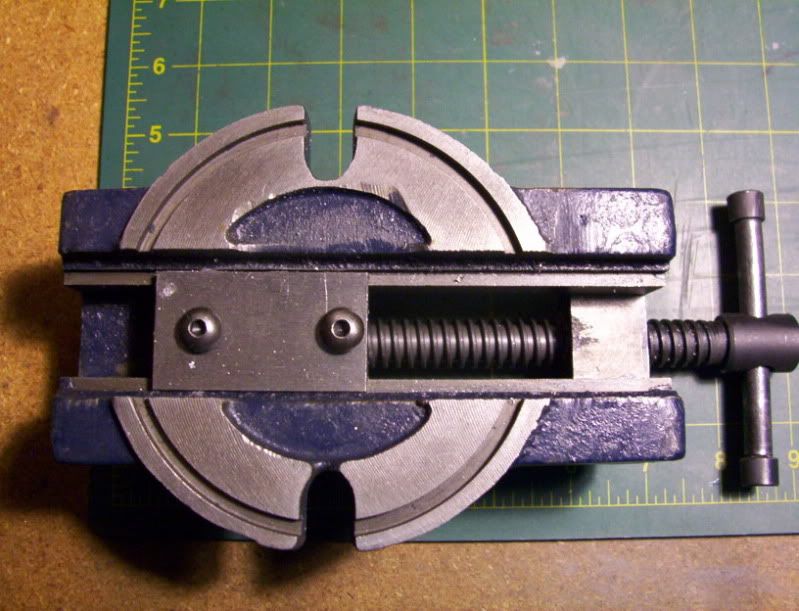

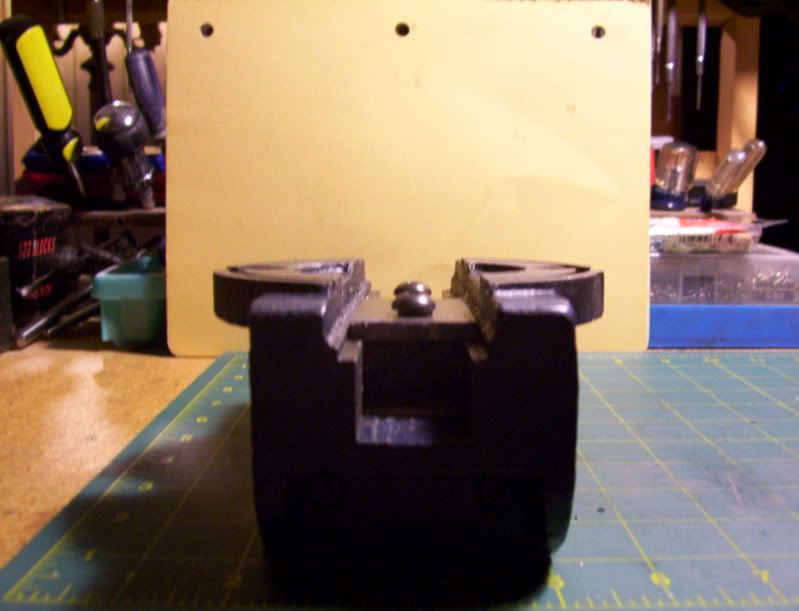

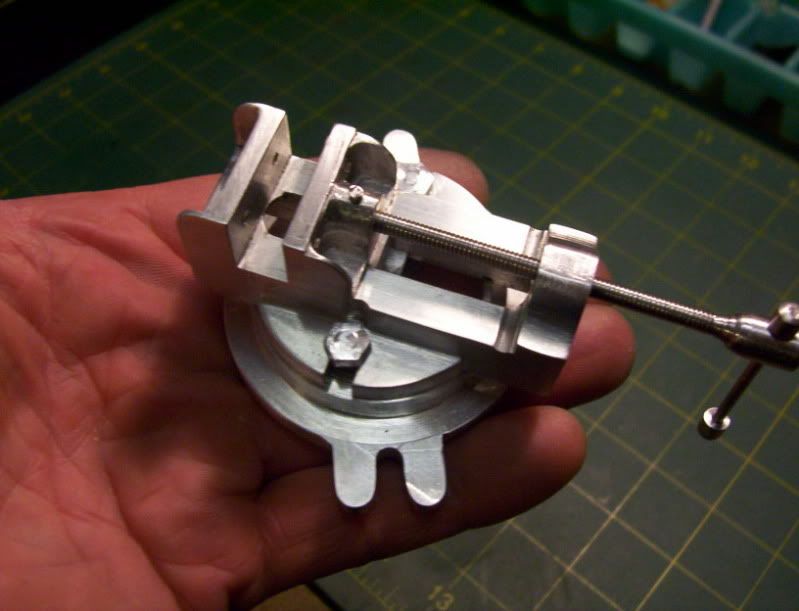

It's a scale model of my swivel vice.

I wanted to make it half scale as my other model vice, however the stock I have on hand is only 1" thick, and I needed 1-1/8" to make it around 1/2 scale, so rearanging the equations, I ended up with a scale model between 1/2 and 1/3 scale.

This project took a long time, because I was doing a lot of woodworking outside in my shed workshop, while I had real nice warm weather, but since it is getting real cold out now, I can start playing around in my hobby machine shop inside.

That's why I just now finished this project about 2 months later.

Have a great day...

Like to share some pic's of my latest project, I just finished up on it tonight.

It's a scale model of my swivel vice.

I wanted to make it half scale as my other model vice, however the stock I have on hand is only 1" thick, and I needed 1-1/8" to make it around 1/2 scale, so rearanging the equations, I ended up with a scale model between 1/2 and 1/3 scale.

This project took a long time, because I was doing a lot of woodworking outside in my shed workshop, while I had real nice warm weather, but since it is getting real cold out now, I can start playing around in my hobby machine shop inside.

That's why I just now finished this project about 2 months later.

Have a great day...