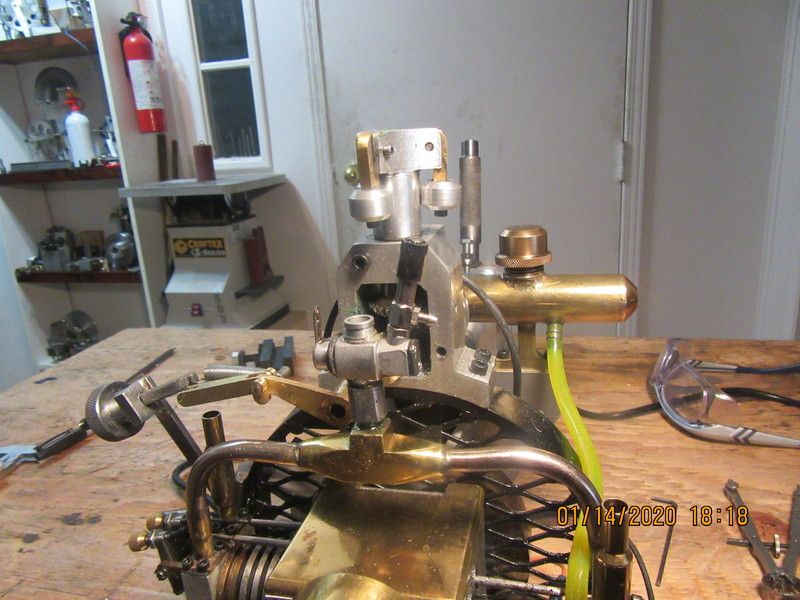

An update---I have hit the wall on this engine, for the moment. I have replaced gaskets, set and reset valve and ignition timing, replaced rings, replaced carburetors, and tested every individual part. Every member of the choir sings perfectly, but I can not get them to sing in harmony. This doesn't happen to me very often. I can't even get it to run with all of the self throttling apparatus disconnected. I haven't been able to identify anything specifically wrong with the engine, other than the fact that one valve adjuster was out by a fair bit, but even with that valve clearance readjusted, it refuses to run. When I turn the engine over by hand with the cylinder heads removed, it will put a good suction on my thumb which doesn't fade away, and gives a distinct "pop" when my thumb is removed. The gas lines are clear, and fuel will run from the hose when I remove it from the carburetor. The vent hole in the gas cap is clear. I have adequate spark at both plugs. engine spins freely with heads removed--no hard spots. Only thing left to do is remove the ignition points, starter hub, and brass gear cover so I can have a good look at the timing gears. Thank you for your patience.---Brian