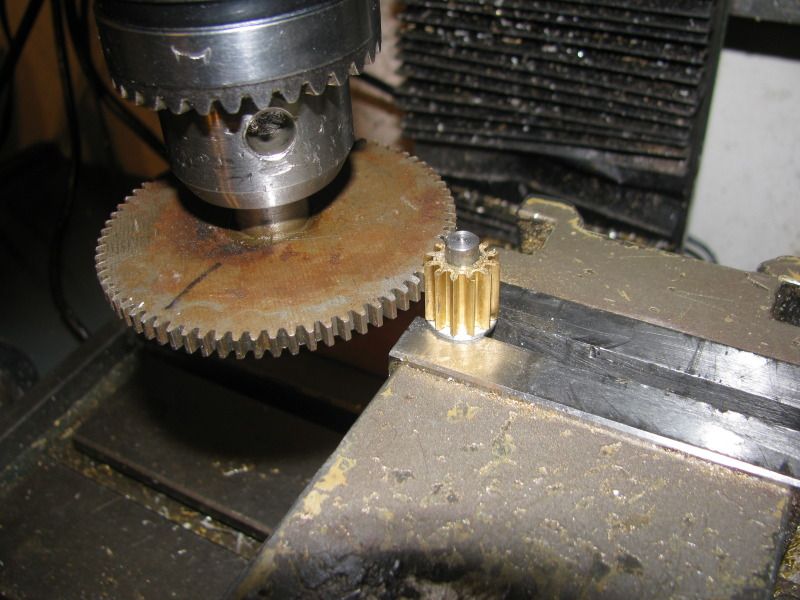

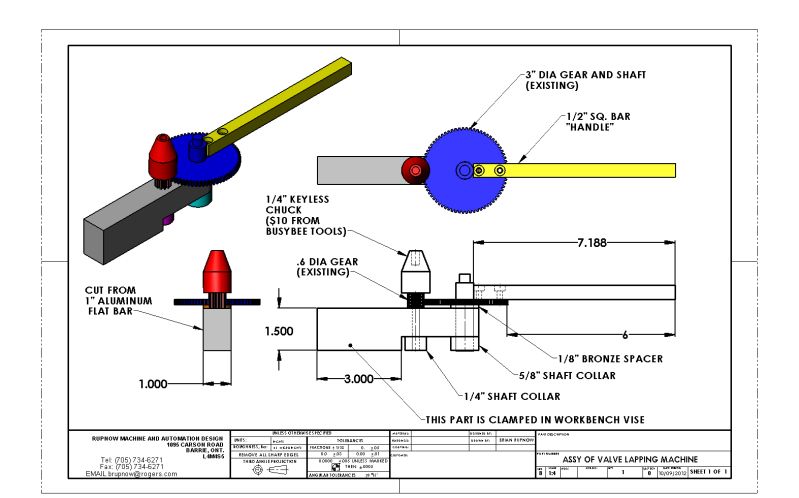

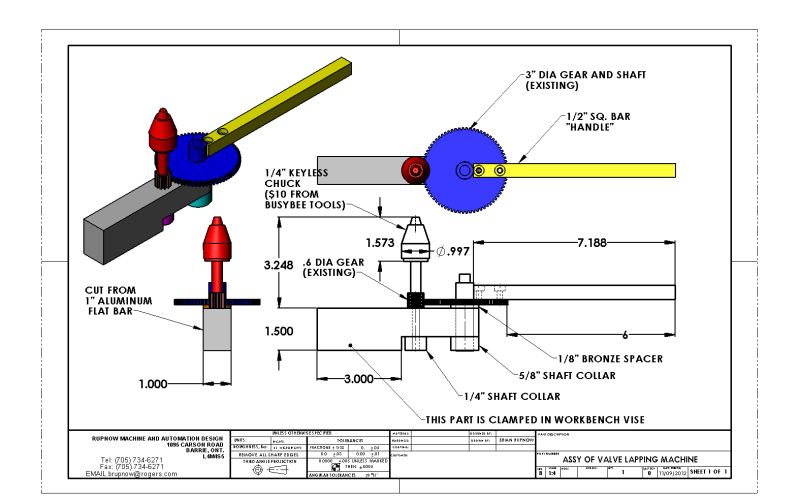

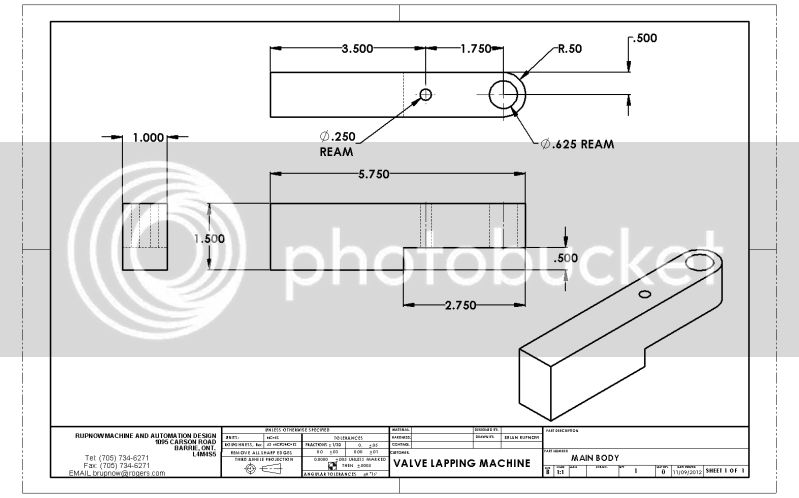

Last night, my old friend insomnia sat on the edge of my bed all night and kept me company.--Probably had something to do with many futile attempts to get my Atkinson engine started and not fully succeeding. I am going to pull the head off and lap the valves again. I find that the arthritis in my hands makes it somewhat difficult to rotate the valves back and forth with the lapping compound as I normally do. Not only do you have to rotate the valve back and forth against the seat, but you also have to apply a certain ammount of pressure between the valve face and the seat while doing the rotating, and every so often you have to lift the valve away from the seat to recharge the lapping compound, as it all gets squeezed out of the interface during the lapping procedure. I was taught long ago to never use a power tool such as an electric drill to do this, as it will quickly damage the valve and the seat. The rotating must be back and forth--at least 360 degrees one direction, then 360 degrees the other direction, repeated many times. Last night, I thought of a machine which would do exactly what is needed, that is hand powered, very simple to build, and best of all, I have all the material to build it right here---as in "Don't have to buy anything". It is a very simple machine, and I will post drawings, models, and pictures as I proceed with it. this will not be a long term build, but I THINK its a good idea.

Last edited: