- Joined

- Dec 31, 2010

- Messages

- 783

- Reaction score

- 195

Mosey:

No problem here. I didn't interpret it as a "smatypants" remark.

If you mean he should bite the bullet and buy a new coil, as I understand it these coils are hard to find and the design of the engine (so far) requires this type of coil. I was wondering if maybe he could get someone who stocks the coils interested in what's he's doing enough to borrow a known good coil to try.

It's pretty simple like it is. I hope he can get it working.

Not sure if you're coming into this late but the engine is a little different arrangement than most. Ignore below if you know what's going on.

For the benefit of others:

Correct me if I'm wrong Steve:

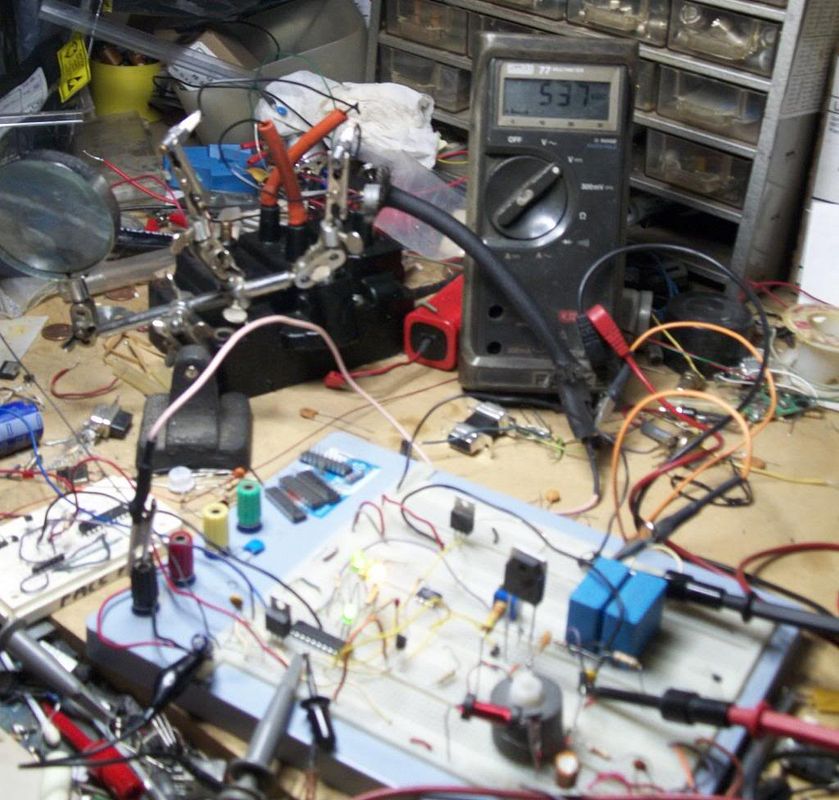

The engine has no distributor (shaft or otherwise) - only a container that looks like one. Inside there is the circuit to drive the coil. The coil is a bit different in that it can fire both cylinders at once. The coil drive circuit is fired by a hall sensor and magnets. In order to use a conventional coil he'd have to add a distributor and drive shaft from the camshaft or use two coils and two circuits.

Sage

No problem here. I didn't interpret it as a "smatypants" remark.

If you mean he should bite the bullet and buy a new coil, as I understand it these coils are hard to find and the design of the engine (so far) requires this type of coil. I was wondering if maybe he could get someone who stocks the coils interested in what's he's doing enough to borrow a known good coil to try.

It's pretty simple like it is. I hope he can get it working.

Not sure if you're coming into this late but the engine is a little different arrangement than most. Ignore below if you know what's going on.

For the benefit of others:

Correct me if I'm wrong Steve:

The engine has no distributor (shaft or otherwise) - only a container that looks like one. Inside there is the circuit to drive the coil. The coil is a bit different in that it can fire both cylinders at once. The coil drive circuit is fired by a hall sensor and magnets. In order to use a conventional coil he'd have to add a distributor and drive shaft from the camshaft or use two coils and two circuits.

Sage