You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

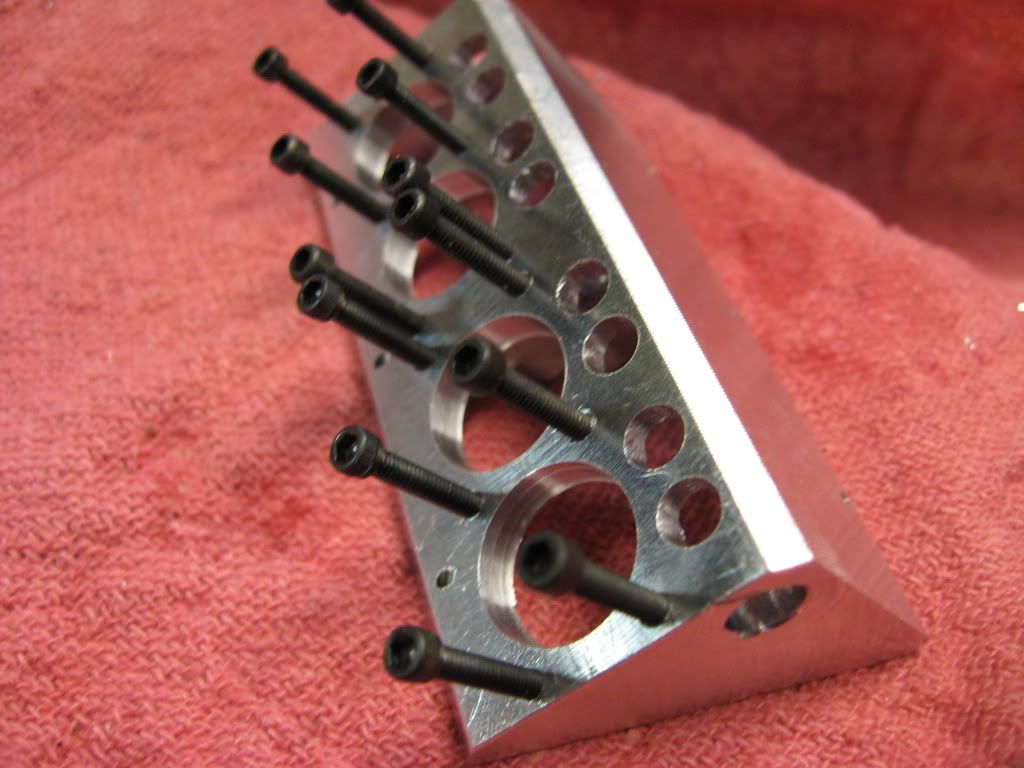

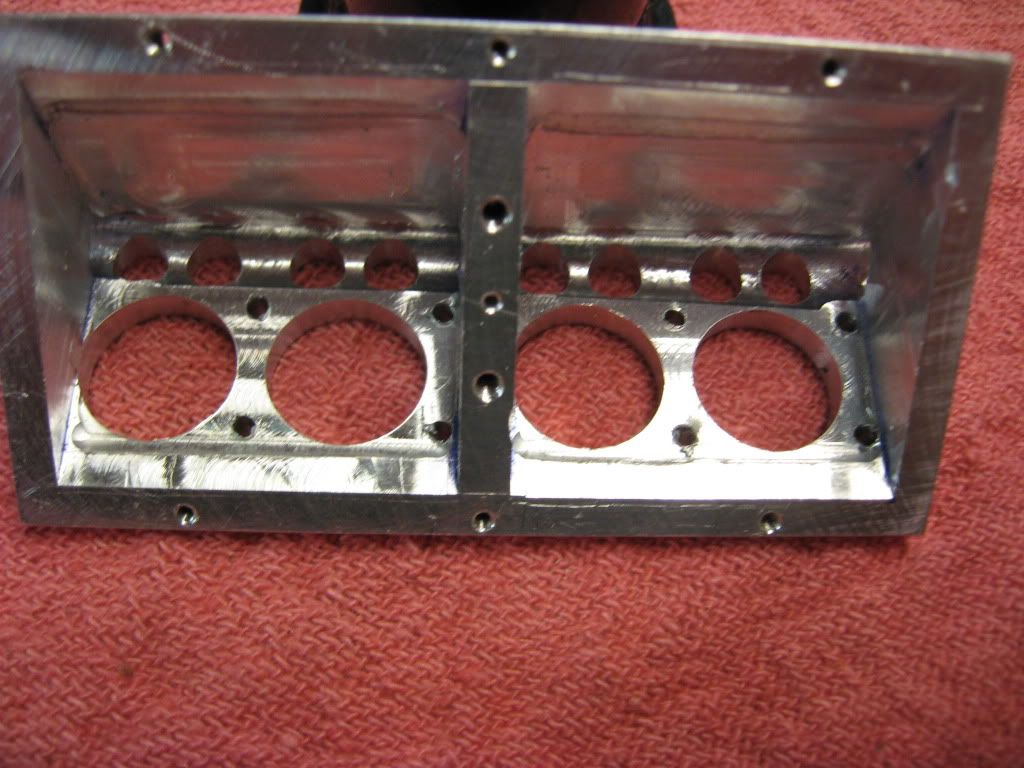

Whittle Aero V8 WIP

- Thread starter cobra428

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Deanofid said:Aren't those bitsy holes fun?

Dean

You bet Dean,

Now, I have to tap all the head bolts 2-56. I'll have to keep you guy's on line, this way if I break a tap. I can send my dyeing words

Rof} Rof} Rof}

Tony

Gail,

This A/C had the engine that EW modeled his after. The Airdisco

Look at the prop.... CCW Rotation from the pilots seat

http://en.wikipedia.org/wiki/File:DH51.JPG

Tony

This A/C had the engine that EW modeled his after. The Airdisco

Look at the prop.... CCW Rotation from the pilots seat

http://en.wikipedia.org/wiki/File:DH51.JPG

Tony

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Very nice Tony.

I have another photo of the same AC and engine from a different view. Shows the same prop rotation of course. Maybe EW just bolted on a RH prop for the photo of his engine. I am not going to worry about it any. When (if) I ever get as far as the cam then I will. I think I would be inclined to build it to the British CCW standard from rear as I think you are planning to do. LH props are easy to come by.

Gail in NM

I have another photo of the same AC and engine from a different view. Shows the same prop rotation of course. Maybe EW just bolted on a RH prop for the photo of his engine. I am not going to worry about it any. When (if) I ever get as far as the cam then I will. I think I would be inclined to build it to the British CCW standard from rear as I think you are planning to do. LH props are easy to come by.

Gail in NM

Well, I'll be making another upper crankcase. After all that work I discover I have a camshaft hole on an angle. I don't know how to get a hole that long to come out the other side dead on target.

I made sure that all was square (with squares). But to no avail, I'm .020 off side to side.010 off in the vertical. I'm wondering, should I drill the hole then put a rod in it and do my setups from the rod. Or indicate the verticals and adj x and shim y (y is table to column I place top to y in vise).

How do you get a 3" long .218d to hit the target on the other side?

Someone HELP!

Tony

I made sure that all was square (with squares). But to no avail, I'm .020 off side to side.010 off in the vertical. I'm wondering, should I drill the hole then put a rod in it and do my setups from the rod. Or indicate the verticals and adj x and shim y (y is table to column I place top to y in vise).

How do you get a 3" long .218d to hit the target on the other side?

Someone HELP!

Tony

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

Before starting over it would pay to try a repair. Can you drill/bore the end holes oversize, loctite in a plug, and redrill each from its end? I'm assuming that the holes need to be large enough for the cam lobes to pass through.

- Joined

- Jul 16, 2007

- Messages

- 2,987

- Reaction score

- 1,056

Tony, I find this to be one of the hardest jobs when building an engine. When drilling a deep hole I start out with a center drill and drill it just a bit deeper than than the diameter of the drill you're going to use. This will give you an accurate chamfer for the drill to start in. Next, with a new drill, I drill the hole undersize. A resharpened drill, no matter how well it's sharpened, will sometimes wander as it drills. Now a take an end mill that has been reground just a little under nominal and counterbore the hole before starting my next drill. The last thing I do is run a reamer through the hole. You have to realize that if all the prep work isn't done well that the reamer will just follow whatever hole you have in there. I don't mean this to be condescending, and maybe you did all these preliminary steps, but I have had the same problems and this is the only way I could find to cure it. Now on to your dilemma. First off, what size are we talking about? If it's a standard inch or metric diameter this is what I would try to do. Get a long or extra long 4 flute end mill. Grind all of the flutes under size by .005-.008 except for the first .25 (cutting end). Now set up your piece, indicate it as square as you can get it and cut it with your modified end mill. Run the spindle at about 4-500 rpm. There should be enough rigidity in the end mill to cut the hole true. If you can't get a long enough end mill then you might want to consider making a cutter out of drill rod. After forming the cutting flutes on the rod just harden that area. This way the bar won't warp. What you're after is a rigid boring bar. If you can't get all the way through with the end mill, go as deep as you can then pick up and layout the the good center on the unmachined end. Set the job back up using the same surfaces as you did for the first cut, wiggle you layout lines and recut. This should get you darn close. What you suggested is viable, drilling and reaming first and then working from that hole to do the rest of the work but it's a pain in the butt.

George

George

kvom,

Thanks for the thought but this engine spins at 8000~9000 rpm locktite scares me in that situation. And there isn't that much room to wiggle

George,

Thanks, I'm going to print that out and study it. Hole ends up a .218 ream

Thanks all

Tony

Thanks for the thought but this engine spins at 8000~9000 rpm locktite scares me in that situation. And there isn't that much room to wiggle

George,

Thanks, I'm going to print that out and study it. Hole ends up a .218 ream

Thanks all

Tony

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

Ugh, sorry to hear about your trouble.

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Tony,

Sorry about you drill run out.

The only alternative to Georges excellent suggestion I can offer is a guide bush and clock gauge to keep the drill on track at the centre web. A long series centre drill may also assist in control on the centre web.

Best Regards

Bob

Sorry about you drill run out.

The only alternative to Georges excellent suggestion I can offer is a guide bush and clock gauge to keep the drill on track at the centre web. A long series centre drill may also assist in control on the centre web.

Best Regards

Bob

Tony,

Have you seen the original drawings for the totally fabricated version of the Whittle V8? The block is fabricated from bar stock. This has always been a very interesting project to me. Now there are drawings to machine it from solid - very interesting - and a V8 too!

Bill C.

BTW: I'm enthusiastic about finding this forum so pardon some of the giddy - the rest is normal....But the down fall is that I'm sitting in front of a computer right now pecking on a keyboard!!

Have you seen the original drawings for the totally fabricated version of the Whittle V8? The block is fabricated from bar stock. This has always been a very interesting project to me. Now there are drawings to machine it from solid - very interesting - and a V8 too!

Bill C.

BTW: I'm enthusiastic about finding this forum so pardon some of the giddy - the rest is normal....But the down fall is that I'm sitting in front of a computer right now pecking on a keyboard!!

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Sorry Tony,

Just remember we build engines because we like to machine and because it is FUN.

I don't remember how I did mine. Typically on deep holes I peck drill with factory sharpened drill bit. About 1/2 a hole diameter on each peck and cutting fluid every time. Goes slow.

Gail in NM

Just remember we build engines because we like to machine and because it is FUN.

I don't remember how I did mine. Typically on deep holes I peck drill with factory sharpened drill bit. About 1/2 a hole diameter on each peck and cutting fluid every time. Goes slow.

Gail in NM

Thanks Guys for the condolences

Maryak I was thinking about that or Georges method. I was looking at end mills today at work (shhh) on the internet

was also going to experiment with a 135 deg drill and maybe a spiral ream :idea: :shrug:

BillC. Yes I have the plans from Hemmingway and a copy of EW's pub in ME and so far it's a good thing it's bar stock. What you are seeing is made from bar stock (would have spent a fortune in castings)

Gail, Yes, I do like machining and the $4 worth of Alum ah, the 30hrs of work ah. I'm learning, that the fun too. And I do have some chunks for the smaller parts out of the boo-boo's. Once I get past the cases the rest looks fairly easy to me (except the cam but I'll get through that to) Each one I get a little better at and hopfully a little smarter. scratch.gif

I'm going to relax and clean the shop. I'm knee deep in alum chips. I spent last night cleaning the mill and indicating the vise. I have to make a note to check it once a month just for fun. 2 years since the last check! It was off by .003 over the 6". Which wouldn't affect the way I made the block. And which wasn't the way it was a while ago. Maybe all the fly cutting moved it a bit. I do have a vise that swivels (I seen the posts on that and I probably should axe the swivel). Tonight I'm going to check my vertical with the DI

Don't worry, I don't give up easy or without a fight! Thm:

Tony

Maryak I was thinking about that or Georges method. I was looking at end mills today at work (shhh) on the internet

was also going to experiment with a 135 deg drill and maybe a spiral ream :idea: :shrug:

BillC. Yes I have the plans from Hemmingway and a copy of EW's pub in ME and so far it's a good thing it's bar stock. What you are seeing is made from bar stock (would have spent a fortune in castings)

Gail, Yes, I do like machining and the $4 worth of Alum ah, the 30hrs of work ah. I'm learning, that the fun too. And I do have some chunks for the smaller parts out of the boo-boo's. Once I get past the cases the rest looks fairly easy to me (except the cam but I'll get through that to) Each one I get a little better at and hopfully a little smarter. scratch.gif

I'm going to relax and clean the shop. I'm knee deep in alum chips. I spent last night cleaning the mill and indicating the vise. I have to make a note to check it once a month just for fun. 2 years since the last check! It was off by .003 over the 6". Which wouldn't affect the way I made the block. And which wasn't the way it was a while ago. Maybe all the fly cutting moved it a bit. I do have a vise that swivels (I seen the posts on that and I probably should axe the swivel). Tonight I'm going to check my vertical with the DI

Don't worry, I don't give up easy or without a fight! Thm:

Tony

cobra428 said:Don't worry, I don't give up easy or without a fight! Thm:

You've already proven that without a shadow of a doubt!

Most respectfully :bow: :bow:

Bill C.

Latest posts

-

-

For Sale 1/3 Scale Galloway Hit and Miss Casting Kit

- Latest: hopperwhistle

-

-

-

For Sale Coles American LaFrance Steam Fire Pumper Project

- Latest: hopperwhistle

-

For Sale Perkins Vertical Side Shaft Casting kit

- Latest: hopperwhistle

-

-

For Sale Coles Models Horizontal Gas Engine Casting Kit

- Latest: hopperwhistle

-

For Sale Murdoch & Aitkin Steeple Steam Engine

- Latest: hopperwhistle