You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Whittle Aero V8 WIP

- Thread starter cobra428

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

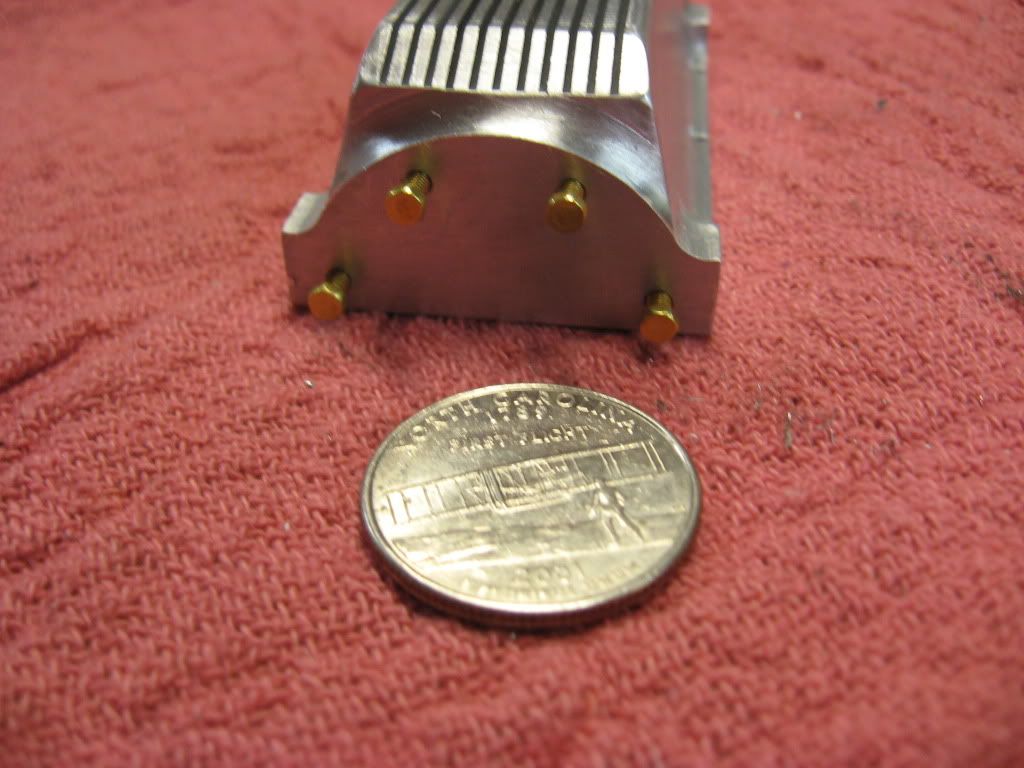

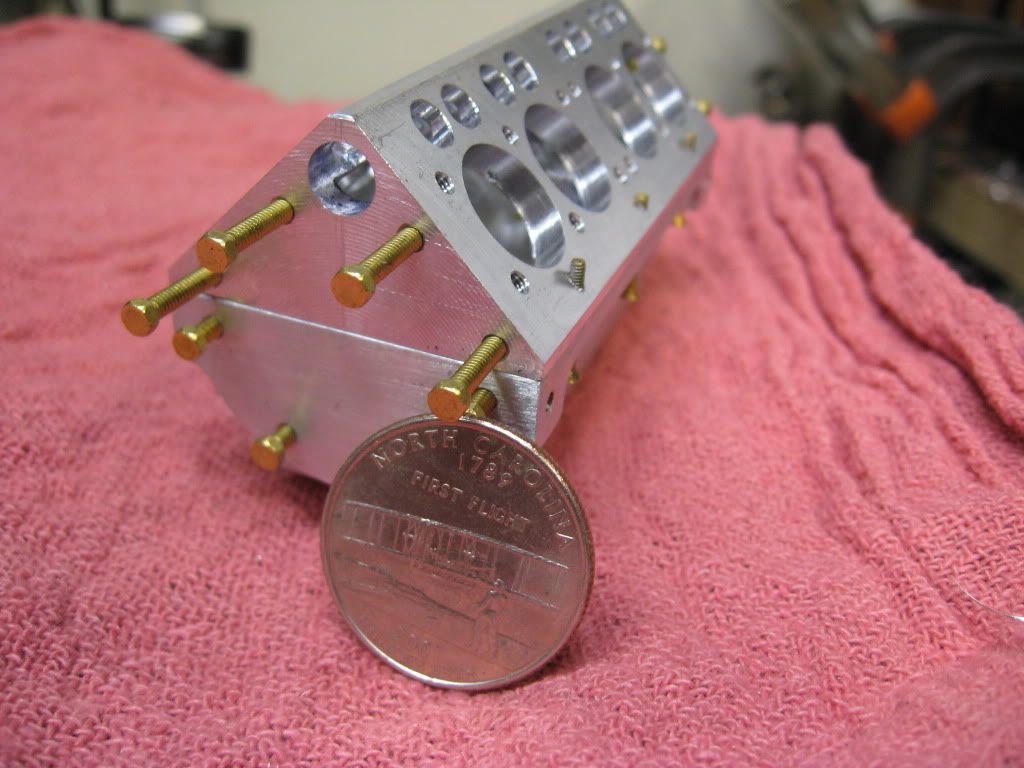

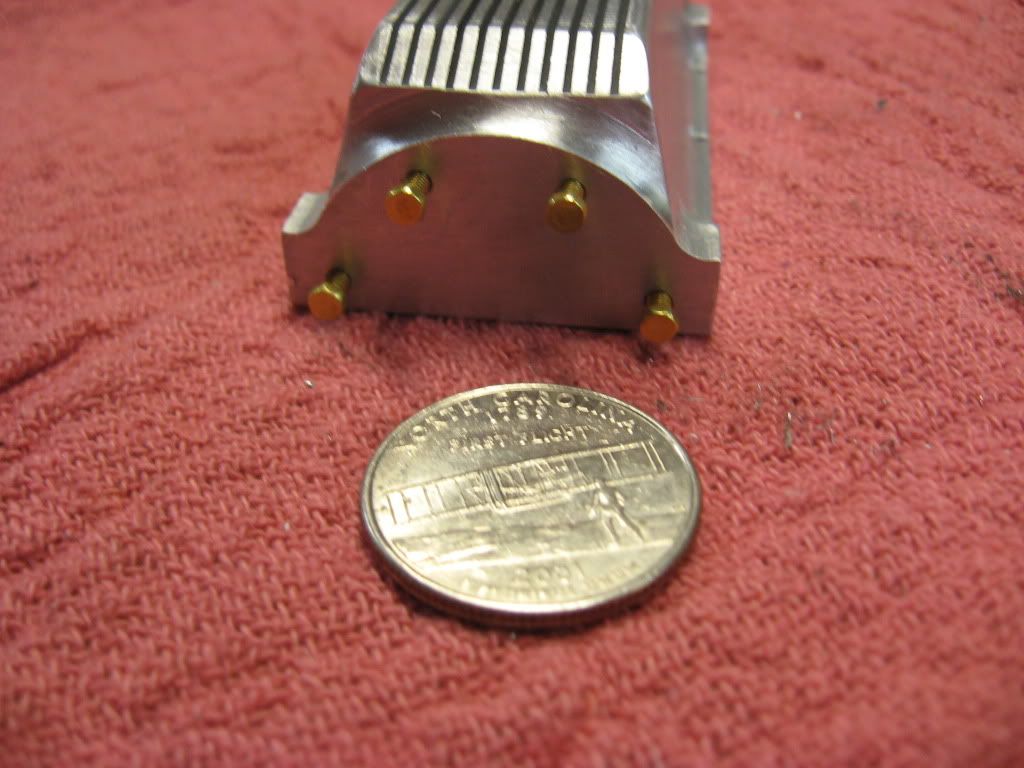

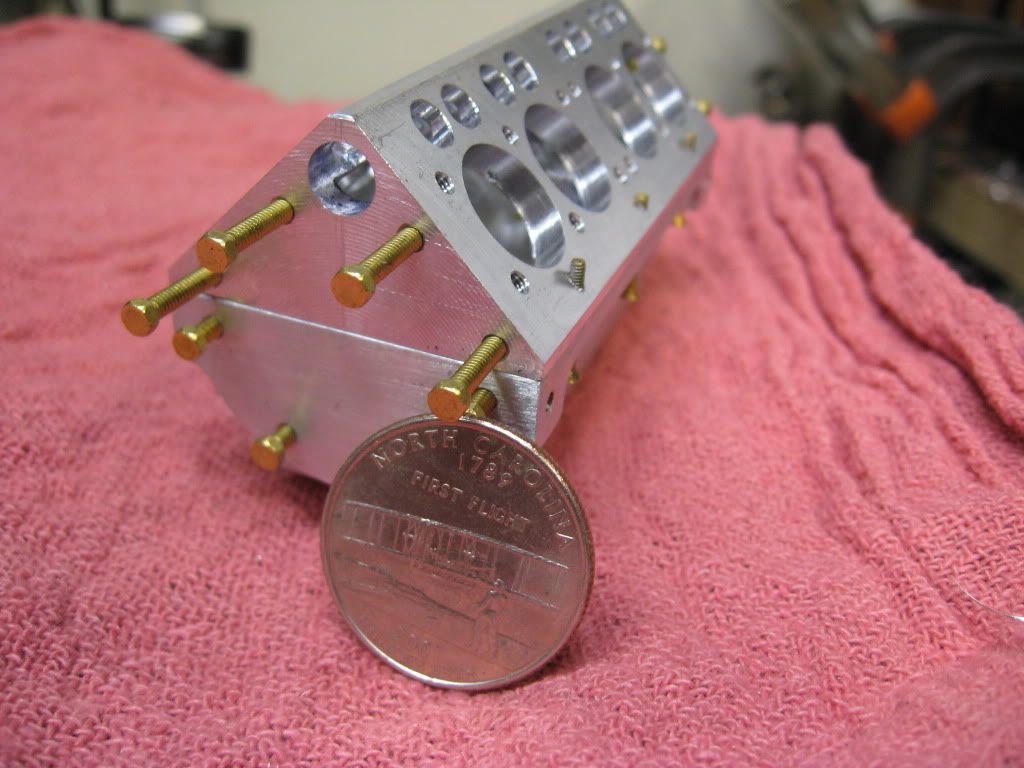

Wow. I knew it was small. But it's always such a shock.

What a project.

I wish I had that patience and skill.

Or at least the skill.

What a project.

I wish I had that patience and skill.

Or at least the skill.

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

Waiting anxiously. ;D

Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

Tony

I've quietly followed this thread and have marveled at your work. However, until you placed the quarter in the photo I'd never really gotten the scale of things. I can tell you my head almost exploded....LOL. You're working way down at George Luhr levels of tiny, there!!! I'll be watching as you progress, much more closely as things move ahead. Amazing!!

Steve

I've quietly followed this thread and have marveled at your work. However, until you placed the quarter in the photo I'd never really gotten the scale of things. I can tell you my head almost exploded....LOL. You're working way down at George Luhr levels of tiny, there!!! I'll be watching as you progress, much more closely as things move ahead. Amazing!!

Steve

Vernon, Wait no more....I figured I go up against Leno and or Conan :big:

Steve, That would be a Dime instead of a quarter on Luhrs engines!

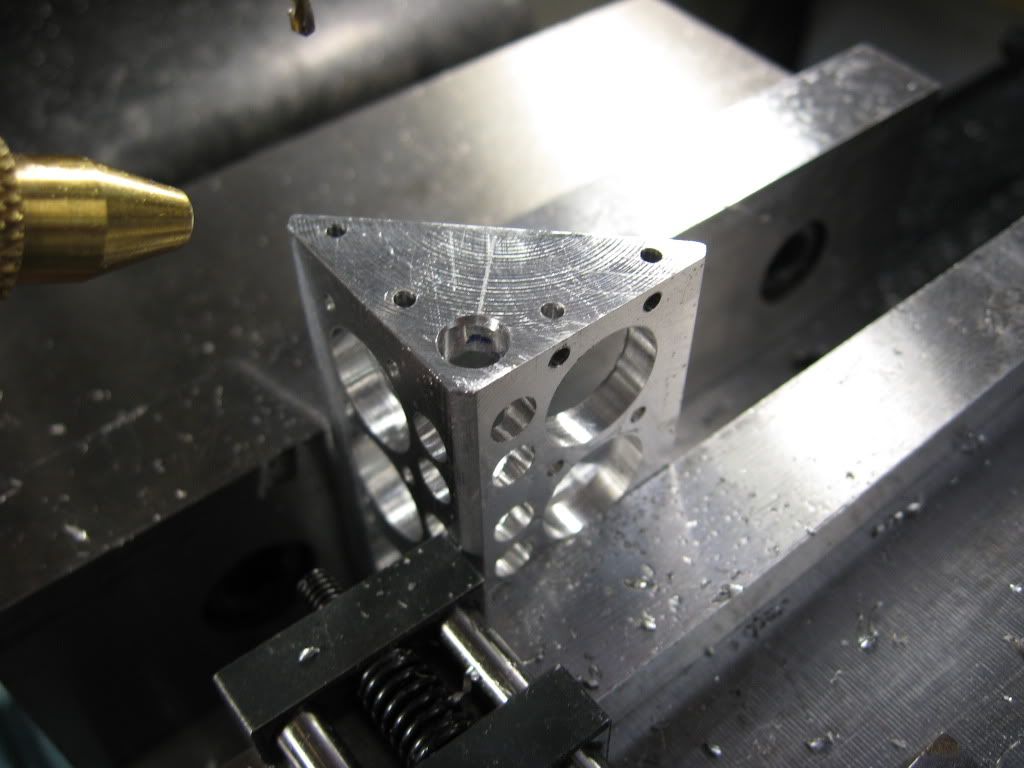

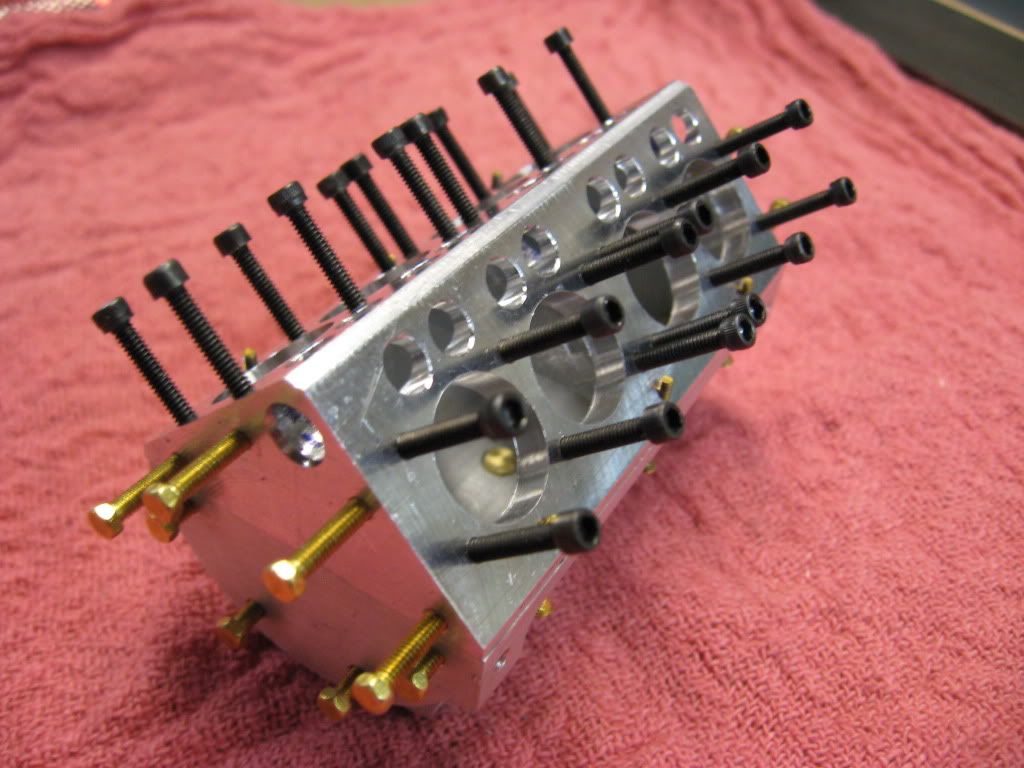

So anyway, Hole-ly smokes Tony is all taped out tonight because he spent the hole night screwing around... :big:

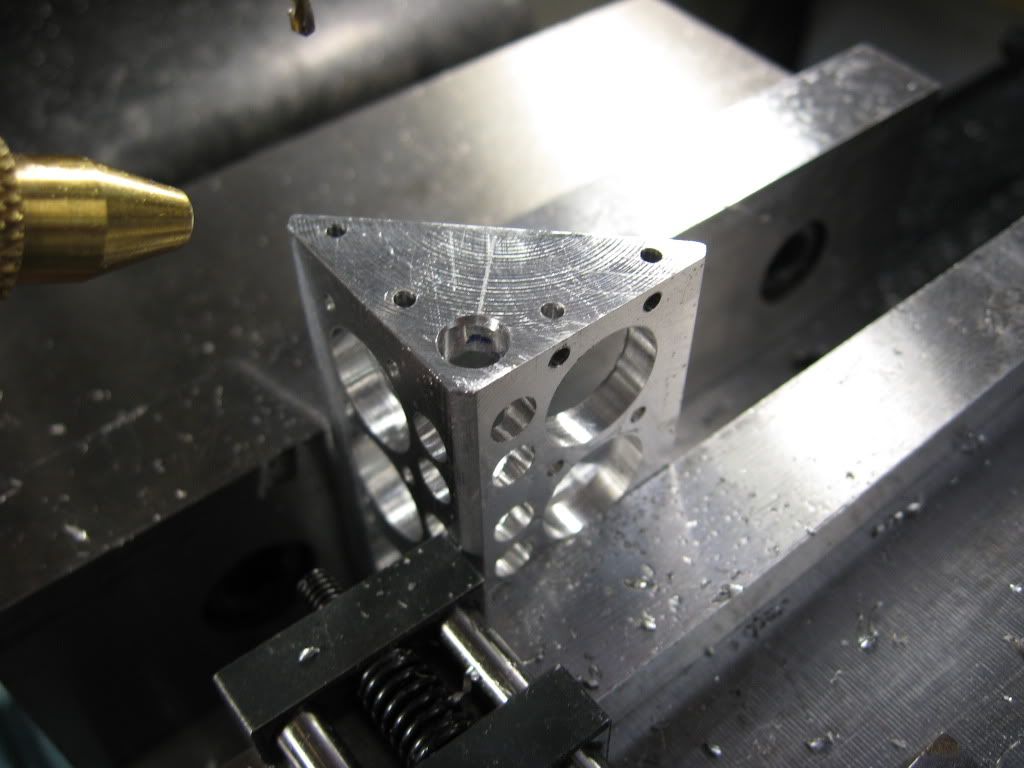

Did a little CAD work EW had 7 and 1/16 holes in the circle so I drew up the circle for the lower case in ACAD at 7 bolts.....well I lost .007 of the .135 he has you start at but the good news is it works for my DRO now.

Just use for the lower crankcase angle will depend on how you have your DRO set up and if anyone interested I will datum dim for you if you don't have bolt circle capability on DRO or doing it manual.

See Attached Below

So far so good!

Tony

View attachment Whittle_LOWER CASE CIRCLE.pdf

Steve, That would be a Dime instead of a quarter on Luhrs engines!

So anyway, Hole-ly smokes Tony is all taped out tonight because he spent the hole night screwing around... :big:

Did a little CAD work EW had 7 and 1/16 holes in the circle so I drew up the circle for the lower case in ACAD at 7 bolts.....well I lost .007 of the .135 he has you start at but the good news is it works for my DRO now.

Just use for the lower crankcase angle will depend on how you have your DRO set up and if anyone interested I will datum dim for you if you don't have bolt circle capability on DRO or doing it manual.

See Attached Below

So far so good!

Tony

View attachment Whittle_LOWER CASE CIRCLE.pdf

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

cobra428 said:So far so good!

Tony

WOW!

I'll second that thought!

I'm at a total loss for words here...

Looking great Tony! :bow: :bow: :bow:

Rick

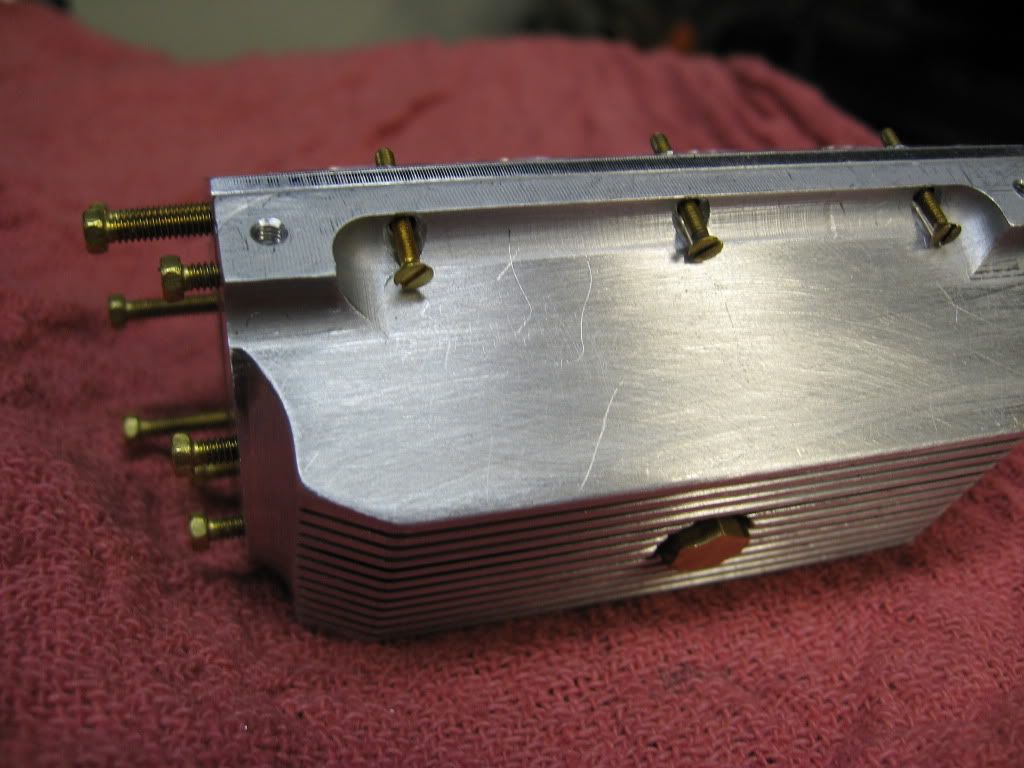

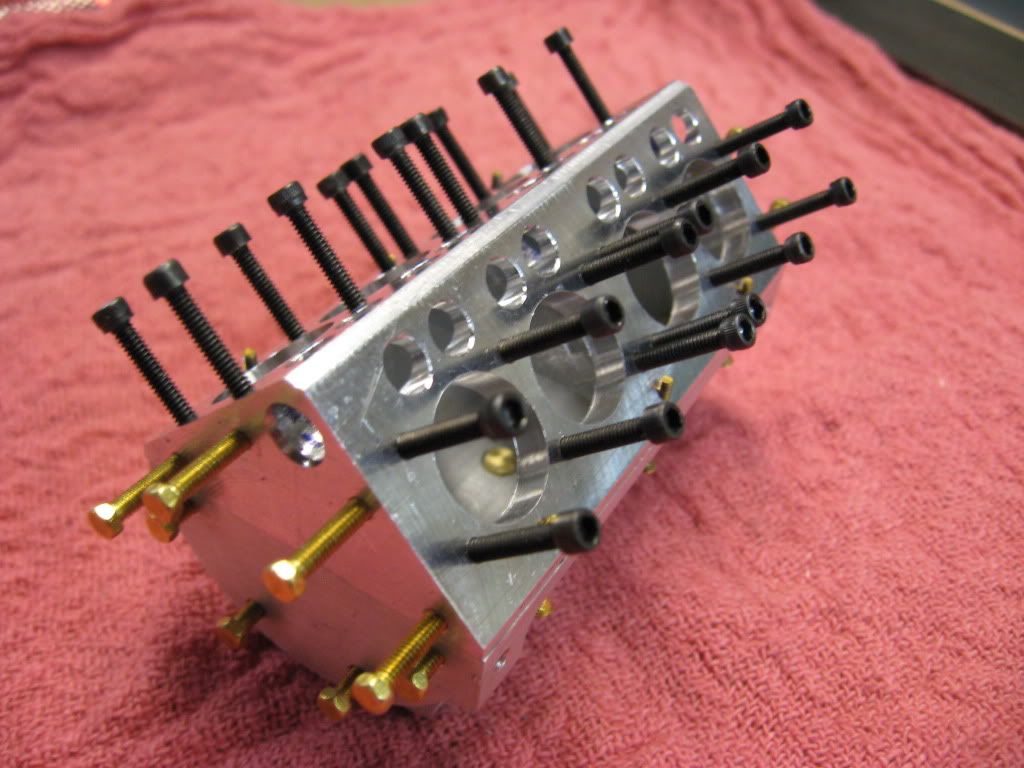

Oh man, Tony... You're gonna have carpel tunnel so bad. Not to mention the nervous breakdown.

If you're too busy for the breakdown, I'll do it for you. I owe you a favor.

That's a lot of tiny tapped holes!

Glad you got them done.

Dean

If you're too busy for the breakdown, I'll do it for you. I owe you a favor.

That's a lot of tiny tapped holes!

Glad you got them done.

Dean

joe d, Dean may be right...having a hard time pushing the mouse around at work.

ozzie46, Don't know if I'm going to get through it all. I think I'm pushing the top end of my limits! I will keep pushing on till there's no hope. Then I'll push on some more.

Tony

ozzie46, Don't know if I'm going to get through it all. I think I'm pushing the top end of my limits! I will keep pushing on till there's no hope. Then I'll push on some more.

Tony

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

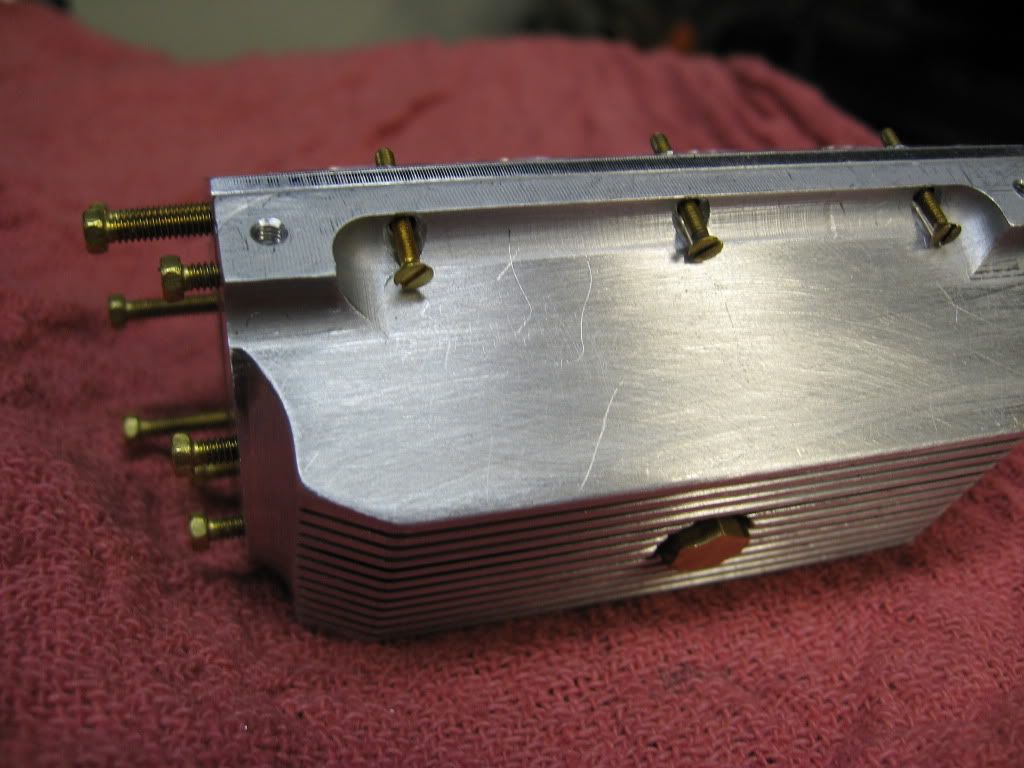

Tony,

Looks good.

You sure are getting close to having a finished crankcase. I presume you will have in in your pocket for Cabin Fever.

You will have a lot of fun there. Be sure to take about three times more photos than you think you want. Then allow about 3 days to rest up after you get back.

Cabin Fever will be a well deserved break. After the Crankcase is finished up are you going to make some easy parts for a while to break the tension?

Enjoy,

Gail in NM

Looks good.

You sure are getting close to having a finished crankcase. I presume you will have in in your pocket for Cabin Fever.

You will have a lot of fun there. Be sure to take about three times more photos than you think you want. Then allow about 3 days to rest up after you get back.

Cabin Fever will be a well deserved break. After the Crankcase is finished up are you going to make some easy parts for a while to break the tension?

Enjoy,

Gail in NM

Hi Gail,

I was thinking of jumping to the cylinders next. It will get me off the mill for a while and do some lathe stuff (the lathe hasn't been on for a month and no taping req.). This way I'll have a nice look at the engine and be even more inspired. I'll do the outside to spec. and leave the bore .005 short to finish later. I'll black oxide to stop any rust while they wait for the rest of the parts.

I don't know if my pockets are big enough to hold that :big:

Planing on many, many pics for those that can't make it. I'm thinking of leaving the credit cards home and only taking enough money to get there and back. I do have a tendency to buy at these type of affairs. Na, I'll bring the cards!

Are you planning to make NAMES, I'm going to give it my best shot.

Quick question (or maybe not). I was looking at the head drawings and wondering why EW put the plugs so close to the intake valve and cut the plug? Seems to me that it would be better at the center of the cyl so the cold intake air won't cool the plug element and no plug mod.

Tony

I was thinking of jumping to the cylinders next. It will get me off the mill for a while and do some lathe stuff (the lathe hasn't been on for a month and no taping req.). This way I'll have a nice look at the engine and be even more inspired. I'll do the outside to spec. and leave the bore .005 short to finish later. I'll black oxide to stop any rust while they wait for the rest of the parts.

I don't know if my pockets are big enough to hold that :big:

Planing on many, many pics for those that can't make it. I'm thinking of leaving the credit cards home and only taking enough money to get there and back. I do have a tendency to buy at these type of affairs. Na, I'll bring the cards!

Are you planning to make NAMES, I'm going to give it my best shot.

Quick question (or maybe not). I was looking at the head drawings and wondering why EW put the plugs so close to the intake valve and cut the plug? Seems to me that it would be better at the center of the cyl so the cold intake air won't cool the plug element and no plug mod.

Tony