You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which vise?

- Thread starter nsfr1206

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Lew Hartswick

Well-Known Member

- Joined

- Sep 20, 2007

- Messages

- 505

- Reaction score

- 10

If you can afford it a Kurt 6" or one of the clones would be the only thing I'd consider.

The ones Bridgeport made (we have 2 with them) are OK but take up a lot of realestate

and the jaws dont take a "clamp on" stop.

...lew...

The ones Bridgeport made (we have 2 with them) are OK but take up a lot of realestate

and the jaws dont take a "clamp on" stop.

...lew...

ninefinger

Well-Known Member

The vises from Glacern Machine Tools have received some pretty good reviews that I've read. They are clones of the Kurt, Then there is also Shars (also on ebay as discount_machine) who sell clones as well. I haven't heard any reviews of the "premium" Shars vises.

Good luck deciding.

Mike

Good luck deciding.

Mike

Too large a vise can be as much of a pain as one too small. It can restrict the Y travel and be in the way of the Y handwheel. All small mills have restricted space between the table and spindle so stay with a low vise and avoid the rotating base that take up a lot of headroom.

I think the OP has a Bridgeport, but I totally agree with ditching the rotating base. I've picked up 3 Kurts over the years (eBay & such are your friend-- used Kurts can be had for close to new import prices) and the bases are gathering dust under a pile of junk. As for height, the "CNC" vises are a little taller than the D-60/675/688 typeStan said:Too large a vise can be as much of a pain as one too small. It can restrict the Y travel and be in the way of the Y handwheel. All small mills have restricted space between the table and spindle so stay with a low vise and avoid the rotating base that take up a lot of headroom.

- Joined

- Oct 20, 2010

- Messages

- 913

- Reaction score

- 132

I have a 6" Japanese Kurt clone likely 30 years old and still tight, takes Kurt size jaws as well handy for replacing or specials. I've heard of chinese vises that broke in 2 on a hard crank, but since so much of the chi stuff has no branding it often all gets lumped in the trash catagory.

Used Kurts are in the $250-300, used chinese I've not seen ??? that may mean something. Wilton sells vises made in Taiwan, I have a new 4" which I purchased thinking I needed one, made nice, for test I put a block of steel in the corner of the jaws, and reefed down on the handle, it stayed together, not much of a test but it made that ok. They also make 6", maybe look at those at least there is a name on it.

Used Kurts are in the $250-300, used chinese I've not seen ??? that may mean something. Wilton sells vises made in Taiwan, I have a new 4" which I purchased thinking I needed one, made nice, for test I put a block of steel in the corner of the jaws, and reefed down on the handle, it stayed together, not much of a test but it made that ok. They also make 6", maybe look at those at least there is a name on it.

Sshire

Well-Known Member

- Joined

- Jun 29, 2011

- Messages

- 936

- Reaction score

- 259

If you ask 8 people you'll get 9 opinions.

I did a lot of research when I got my mill (BF20). The consensus was that the 6" was too large for that mill.

I was considering a Kurt but the 4" cost more than the 6". I assume a supply demand issue.

Long story short, I bought the Glacern 4" and love it. Beautifully finished, smooth as silk and no jaw lift at all.

The 6" would have been too big.

So with your BP, a 6" is probably right. Look at the Glacern. Good value. My 2 cents.

Best

Stan

I did a lot of research when I got my mill (BF20). The consensus was that the 6" was too large for that mill.

I was considering a Kurt but the 4" cost more than the 6". I assume a supply demand issue.

Long story short, I bought the Glacern 4" and love it. Beautifully finished, smooth as silk and no jaw lift at all.

The 6" would have been too big.

So with your BP, a 6" is probably right. Look at the Glacern. Good value. My 2 cents.

Best

Stan

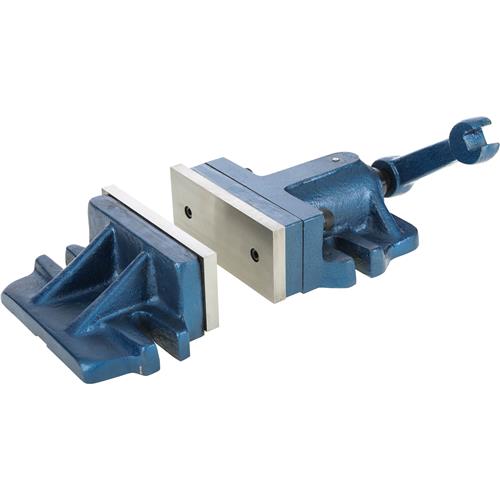

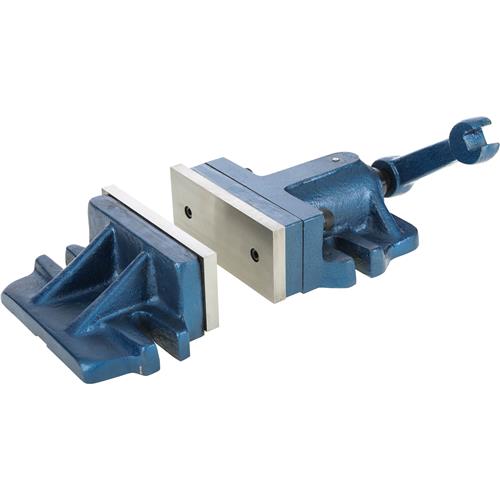

I purchased a Grizzly H2992 2 pc vice last year. I needed it for a special job and thought I would never use it again. It's become the most used vice sense then and lives on the mill 99% of the time. Because it has no bottom I just bolt the non moving face to the table using a precision square. Doing this carefully gets it within .001 so I almost never spend any time with a dial indicator zeroing in that face. The other moving face is pushed up to the work and bolted down to the table. It's also an inexpensive vice so even if you buy a traditional swivelling vice for milling angles the 2 pc vice is still a nice addition for the mill. The only thing I would advise is attaching a Walnut or other very hard wood to the moving face which prevents movement of the work when taking heavy cuts. I do this on all my other milling vices too so this is not mandatory due to the design of this vice.

http://www.grizzly.com/products/2-pc-Milling-Vise-6-/H2992

http://www.grizzly.com/products/2-pc-Milling-Vise-6-/H2992

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

I have several Kurts, all purchased used, and am very satisfied with them.

GWRdriver

Senior Member

- Joined

- Jan 22, 2009

- Messages

- 721

- Reaction score

- 109

David,

Normally I've always tried to buy first quality tooling, if I can afford it (and sometimes when I can't), and Kurt vises would fall into that category. But a few years ago, on the recommendation of my long-time mentor (Jim) I bought a 4" Kurt-clone from Travers Tool Co. (IIRC) Despite being bought years apart both of these were still made in Taiwan, not China. (I can provide a product number if you wish.) Jim was one of the most meticulous model engineers and machinists I ever knew and he said it more than exceeded his expectations and needs for far less than the cost of the same size Kurt. It is heavy and very well made and finished and I was more than pleased with what I got for the money. Likewise it more than matches my needs and machine capabilities and I am almost as meticulous as Jim was.

Normally I've always tried to buy first quality tooling, if I can afford it (and sometimes when I can't), and Kurt vises would fall into that category. But a few years ago, on the recommendation of my long-time mentor (Jim) I bought a 4" Kurt-clone from Travers Tool Co. (IIRC) Despite being bought years apart both of these were still made in Taiwan, not China. (I can provide a product number if you wish.) Jim was one of the most meticulous model engineers and machinists I ever knew and he said it more than exceeded his expectations and needs for far less than the cost of the same size Kurt. It is heavy and very well made and finished and I was more than pleased with what I got for the money. Likewise it more than matches my needs and machine capabilities and I am almost as meticulous as Jim was.

One more voice to the chorus - for BP use, a 6" Kurt is just so hard to beat. Everything about them is superb. And there are gobs of accessories for them.

Example of what a good Kurt can do - it can take an 8" long irregular stock and using proper procedure, create a machined rectangle that off of my mill is within 0.0003" or less end to end. They are just well made, square, and accurate, and when you put keys on them, the fixed jaw is within 0.000,2" of parallel on my mill. I haven't used a DTI on my vise jaw in years.

Clones and other brands can sometimes do as well, but the hard part is, are you SURE you've got a good clone? Hard to know until you put it to work.

I've got a THREE inch Kurt vise I found on eBay... cute little thing. I've never seen another. Kurt apparently didn't make very many of them.

Example of what a good Kurt can do - it can take an 8" long irregular stock and using proper procedure, create a machined rectangle that off of my mill is within 0.0003" or less end to end. They are just well made, square, and accurate, and when you put keys on them, the fixed jaw is within 0.000,2" of parallel on my mill. I haven't used a DTI on my vise jaw in years.

Clones and other brands can sometimes do as well, but the hard part is, are you SURE you've got a good clone? Hard to know until you put it to work.

I've got a THREE inch Kurt vise I found on eBay... cute little thing. I've never seen another. Kurt apparently didn't make very many of them.

FWIW, When I was looking for vises for my 8x36 Millrite, I was complaining about the 4" Kurts being more expensive than the 6's to a pro machinist friend of mine. His response was "go for the biggest vise that will fit, you'll want the extra mass". Along the way I've acquired a 5" Kurt (not made anymore either, but a great size for the mini-Bridgeports) and an import 4", but the original 6" is the one that stays on the table. It's a tad big, but just plain works and works well.

GWRdriver

Senior Member

- Joined

- Jan 22, 2009

- Messages

- 721

- Reaction score

- 109

My vise is TTC Vise Model LY-4 - current catalogue Item #61-204-206. (Old catalogue #61-204-204) On occasion I ask it to hold .0005" and it always exceeds my needs. The nameplate reads Bemato or Benato, Taiwan, however time flies and it's now been 10 years since I bought mine and frankly I would doubt these are still made in Taiwan, but they might. It also comes with a swivel base, which I never use.

There's zero doubt Asian tools have hugely improved over the last 20 years, but I'll probably always be a bit gun shy.

An early Kurt clone was so bad that when mounted flat, no swivel base, the vise bed varied by .005" from flat. It was horrible... a boat anchor for sure. I still have it. Can't throw it out, I'll never sell it, as that would be cruel, and it's too heavy for casual drill press work.

An early Kurt clone was so bad that when mounted flat, no swivel base, the vise bed varied by .005" from flat. It was horrible... a boat anchor for sure. I still have it. Can't throw it out, I'll never sell it, as that would be cruel, and it's too heavy for casual drill press work.

Similar threads

- Replies

- 14

- Views

- 1K