Is there a general rule or ratio between displacement and valve size in model IC engines? I have the cylinder and crankcase casting from an old air compressor that I'd like to turn into an IC engine. Throttled carb, dual OHC's, & pressure lube are what I'd like, but maybe I'm aiming too high. I'm definitely running out of space to fit everything. I don't know how you guys manage to build engines so small!

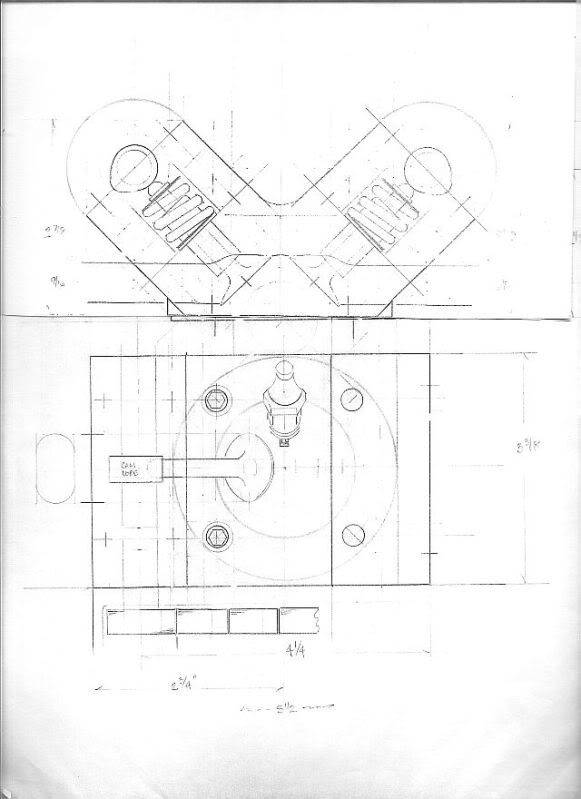

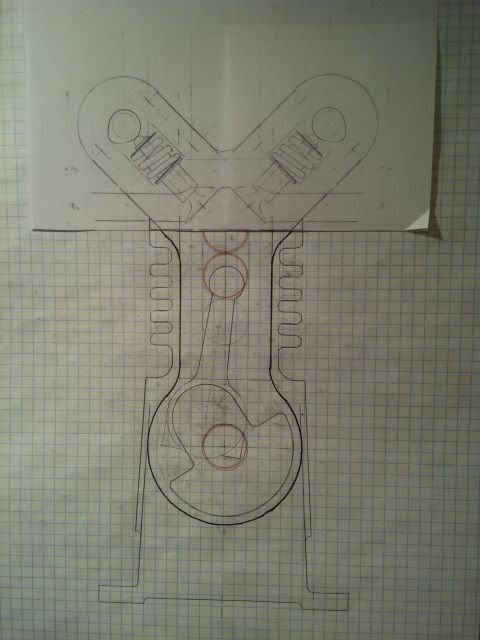

The pump body has a 2" bore and the original crank had a 1.5" stroke, so 4.7124-CuIn's is what I calculate for displacement. I can put a hemispherical combustion chamber in the head to give more room for larger valves, but the biggest is a pair of 1-inchers. That's probably much more than necessary, and it's hard to squeeze those in there among head studs, intake/exhaust ports, bolt holes, etc. A pair of 3/4-inchers make life easier, but 1/2-inchers seem proportionally too small. I'm currently drawing a 45-degree angle between the cam banks but if I narrow that it will make more room for the ports. I'd like to keep it at 45-degrees if I can, just because it looks like a little Offenhauser head.

Are there any rough design guidelines to help me make everything fit without having to find out later the hard way that the valves I ended up with won't work?

Thanks,

Bob

The Victim:

The pump body has a 2" bore and the original crank had a 1.5" stroke, so 4.7124-CuIn's is what I calculate for displacement. I can put a hemispherical combustion chamber in the head to give more room for larger valves, but the biggest is a pair of 1-inchers. That's probably much more than necessary, and it's hard to squeeze those in there among head studs, intake/exhaust ports, bolt holes, etc. A pair of 3/4-inchers make life easier, but 1/2-inchers seem proportionally too small. I'm currently drawing a 45-degree angle between the cam banks but if I narrow that it will make more room for the ports. I'd like to keep it at 45-degrees if I can, just because it looks like a little Offenhauser head.

Are there any rough design guidelines to help me make everything fit without having to find out later the hard way that the valves I ended up with won't work?

Thanks,

Bob

The Victim: