So here is the latest update on my Fowler build, did not get much done in Nov & Dec but things are back on track now.

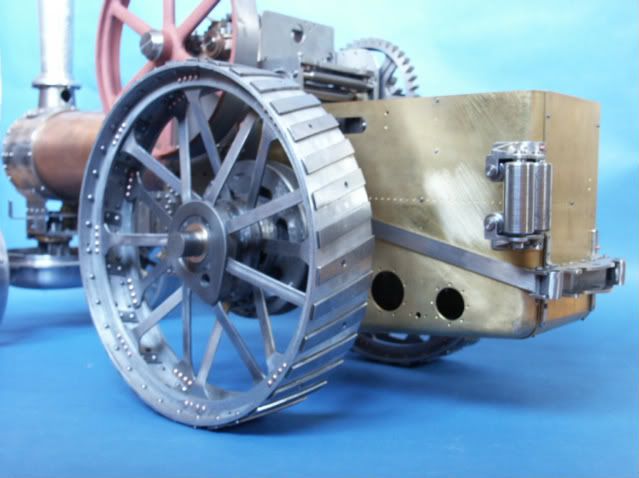

The dummy tie plates were fitted to the rear rims with alloy rivits so the filed down CSK ends would not show, I then did the strakes with steel snapheads. Drilling the rims vertically on the X3 pushed it to its limits I just got the rim under the spindle to drill the holes using the collet chuck and an 1/8" stub drill.

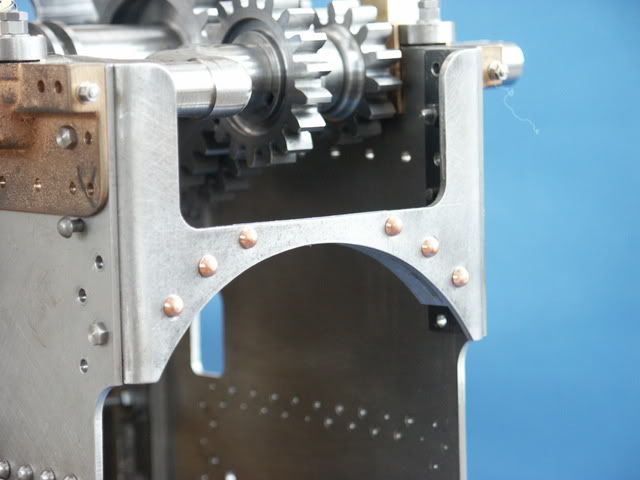

I then tackled the spectacle plates, these were bent over a former 10thou or so oversize and then milled to size so as not to distort the hornplates.

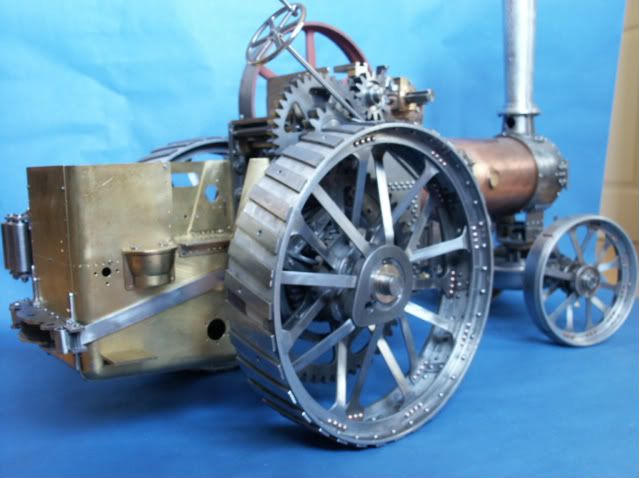

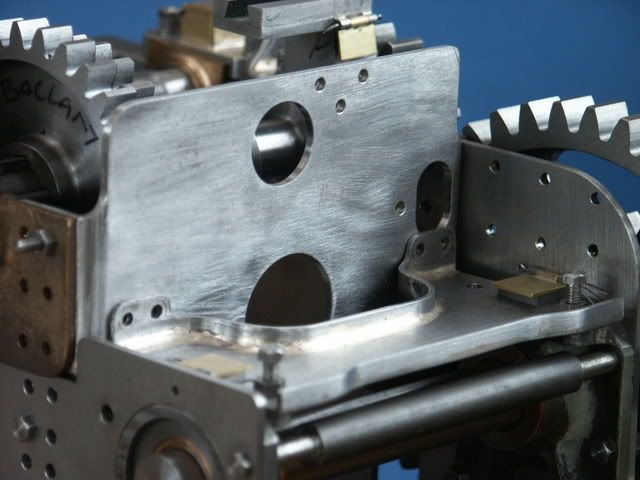

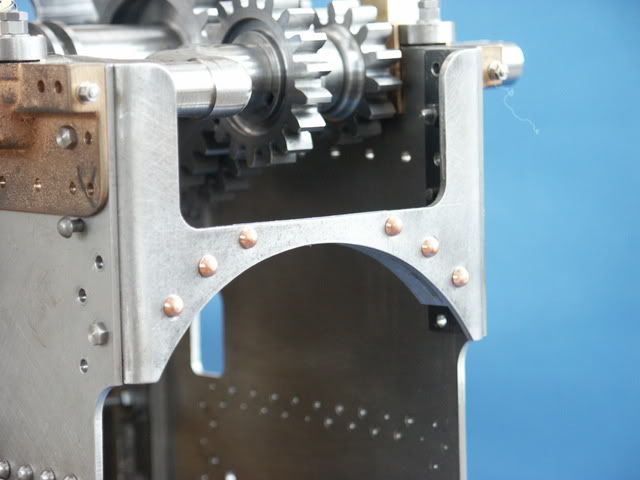

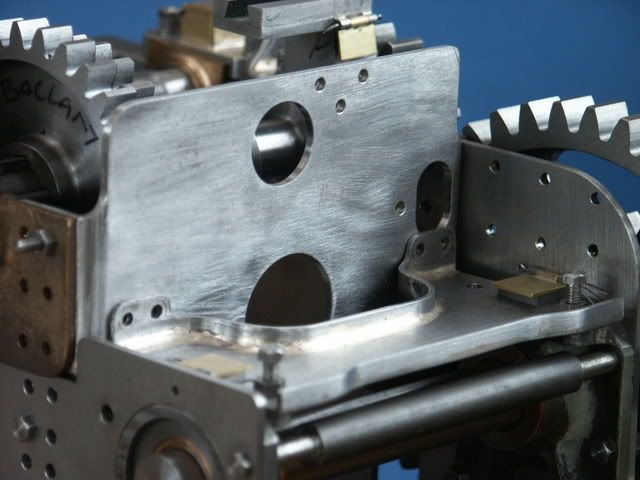

I had dropped off my machined gear blanks with MJ at Amberley and picked them up just before xmas, at the same time I borrowed the steel former for the tender sides. All the gears mesh nicely and line up well

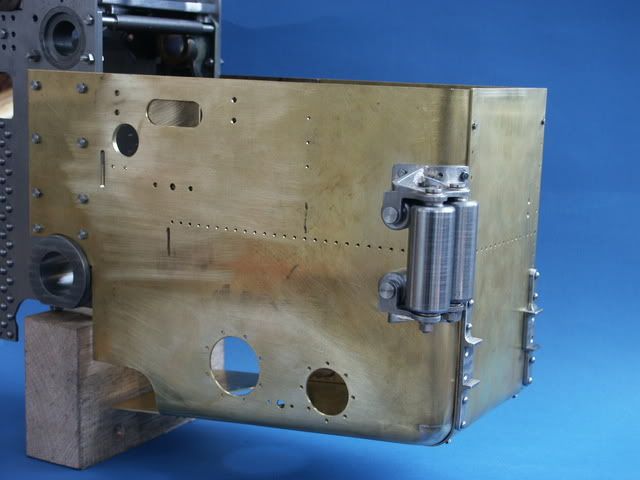

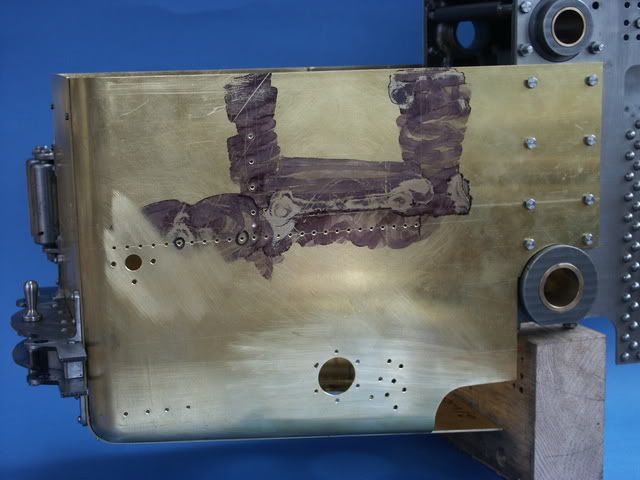

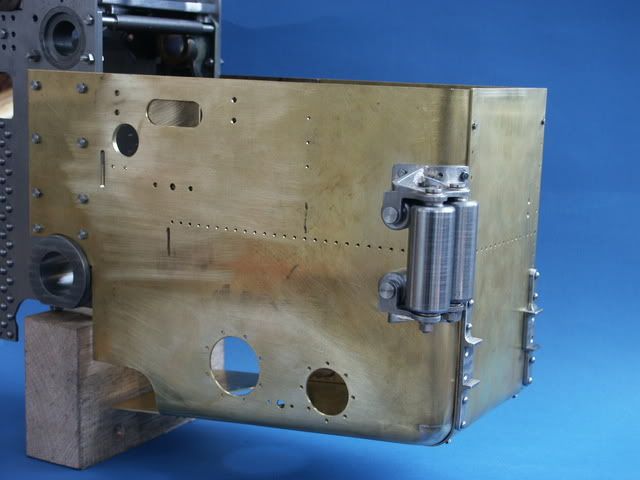

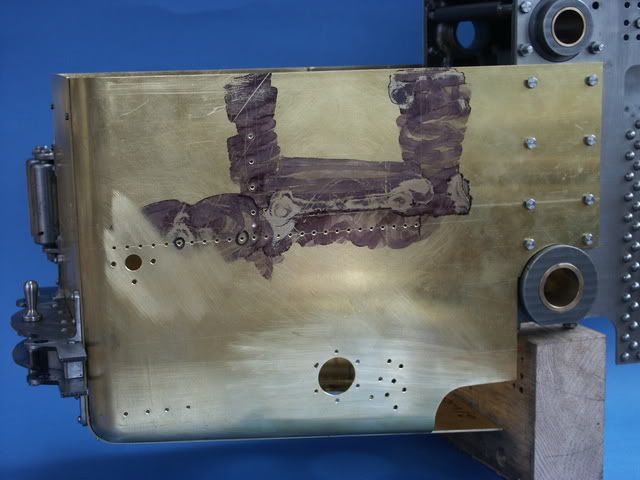

First job over the xmas holidays was to flange the tender sides, on the 3rd annealing I managed to buckle the plate and could not get it straight, so had to get another one. For the other plate and the replacement rather than try to flange the corner I opted to silver solder in a small fillet which worked out far easier. The sides were then drilled for all the various bits and the back/botton bent and rivit holes drilled.

While waiting to pick up the replacement tender side from Alan at Alley Pally I got on with the various bits that fit onto the tender, following advise here the tow bar was rivited with 1/8" rivits with the heads turned down to the size of 3/32nd ones.

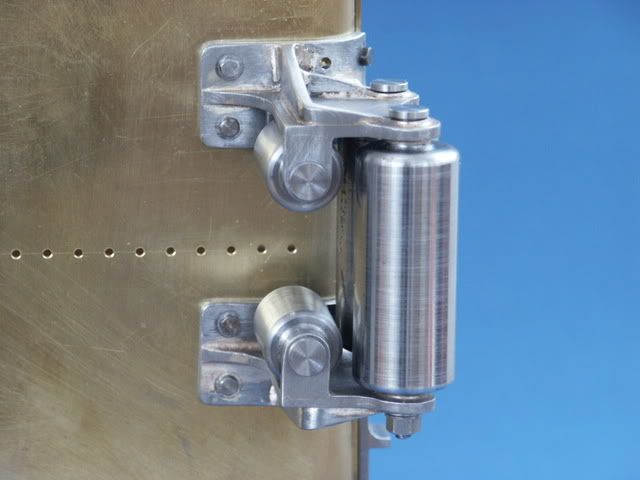

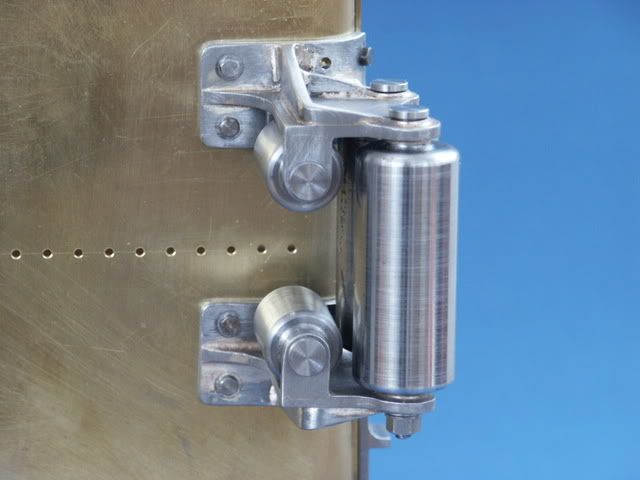

The most recent item was the fairlead/roller guide. On the fowler this is quite a complex fabrication, not just a couple of lengths of angle iron as on some engines. It took a while to get my head round the drawing and then try to work out how to keep all the bits in line and in position while it was silver soldered. I came up with the solution below which was to make as one and then cut in half, this worked well as it was all soldered in one go with just two clamps holding it together.

Well thats it for now, off to flange the tender floor.

Jason

The dummy tie plates were fitted to the rear rims with alloy rivits so the filed down CSK ends would not show, I then did the strakes with steel snapheads. Drilling the rims vertically on the X3 pushed it to its limits I just got the rim under the spindle to drill the holes using the collet chuck and an 1/8" stub drill.

I then tackled the spectacle plates, these were bent over a former 10thou or so oversize and then milled to size so as not to distort the hornplates.

I had dropped off my machined gear blanks with MJ at Amberley and picked them up just before xmas, at the same time I borrowed the steel former for the tender sides. All the gears mesh nicely and line up well

First job over the xmas holidays was to flange the tender sides, on the 3rd annealing I managed to buckle the plate and could not get it straight, so had to get another one. For the other plate and the replacement rather than try to flange the corner I opted to silver solder in a small fillet which worked out far easier. The sides were then drilled for all the various bits and the back/botton bent and rivit holes drilled.

While waiting to pick up the replacement tender side from Alan at Alley Pally I got on with the various bits that fit onto the tender, following advise here the tow bar was rivited with 1/8" rivits with the heads turned down to the size of 3/32nd ones.

The most recent item was the fairlead/roller guide. On the fowler this is quite a complex fabrication, not just a couple of lengths of angle iron as on some engines. It took a while to get my head round the drawing and then try to work out how to keep all the bits in line and in position while it was silver soldered. I came up with the solution below which was to make as one and then cut in half, this worked well as it was all soldered in one go with just two clamps holding it together.

Well thats it for now, off to flange the tender floor.

Jason