Okay people, help me out here please. I would like to build a twin cylinder horizontal engine in which the cylinders are double acting, probably two 4" diameter flywheels, and possibly a set of crosshead guides if I need them. I want the engine to have either sliding valves similar to the famous "beam engine at double scale" or else poppet valves ala Chuck fellows. I want to build it from bar stock, and I want to offset the crank journals at 90 degrees so it self starts. I don't want to pay for any plans. ---Surely thats not asking too much, is it??? I've been looking at the cylinder, valve, and piston on the "beam engine at double scale" and thinking---"Why couldn't I take a larger single block of brass, and bore a cylinder and valve hole on each side of it, and mount the block so the cylinders are horizontal and"---"This would of course require two seperate eccentrics, and a single built up crank and---" Yes, Ive nearly got it designed in my head. Any thoughts or comments on this flight of fancy?---Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Two cylinder, double acting, horizontal engine???

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Twinsquirrel

Well-Known Member

- Joined

- Jun 8, 2008

- Messages

- 227

- Reaction score

- 0

No input as usual from my end but the image I have in my head of it is bl**dy gorgeous!!

Brian Rupnow said:Yes, Ive nearly got it designed in my head. Any thoughts or comments on this flight of fancy?---Brian

Thoughts... Go for it! That's my thought. ;D

So for some other thoughts; The beauty of designing your own engine is you can utilize different componets and ideas from other design as you see fit. Based on what you describe, I don't at all see why it wouldn't be a successful project. Build it in the computer first, and you will save yourself some grief!

Are there some details to be worked out? Oh yeah, but all of these engines have been at that stage at one point or another. You can do it!

Well, I think the cylinder block would look something like this---right now its set up at 3" center to center of the cylinders, however as the design progresses, that can be easily altered with my software. You can see that I have rotated the air inlet ports so that they will be pointed up---thats so I can join them with a common manifold.

The cylinder heads would probably look like this. Since there will be a lot of side forces acting on the piston rod, I have bumped the diameter up to 1/4" fom the original 1/8", so have enlarged the holes where the rods come out though the heads. I have also moved the valve bores 1/8" farther away from the cylinder bores to give me a bit more room.

max corrigan

Well-Known Member

- Joined

- Aug 24, 2008

- Messages

- 156

- Reaction score

- 4

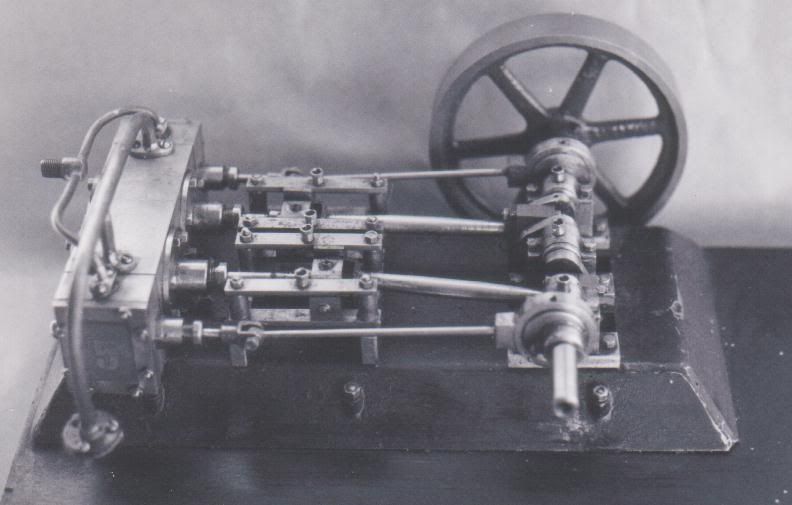

Brian i don't know if this would help but if you look at my first effert (notice the spelling) which i posted, it is a stuart S50 double acting horizontal engine with the slide type valve which you can just see in one picture, the cover is removed, i would think you could double it up and add the crank shaft you were refering to without to much trouble' it is a nice looking engine and runs well, and would look great as a twin! and being you are not useing castings it would not look like the Stuart "Score" which is pretty much the same as a S50 but with twin cylinders and a single flywheel either way it might give you an idea!

Regards Max.............

Regards Max.............

Brian Rupnow said:I don't want to pay for any plans.

Tight

In my case I think plans would be a necessity, given your background I suspect you can design it as you can go along, the idea's so far seem good ........... tell me though (as I'm sure there is a good reason ............. it just seems to escape me at present

CC

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Brian,

Attached is a PDF of a simple twin, reversing engine which I had a fiddle with a few years ago to help me learn 2D CAD. It's based on a Paddle Steamer Engine hence the gear on one side. I designed it with a view to using bar stock.

Just a thought ???

Best Regards

Bob

View attachment QuickCAD.pdf

Attached is a PDF of a simple twin, reversing engine which I had a fiddle with a few years ago to help me learn 2D CAD. It's based on a Paddle Steamer Engine hence the gear on one side. I designed it with a view to using bar stock.

Just a thought ???

Best Regards

Bob

View attachment QuickCAD.pdf

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Brian,

Attached video of my little donkey engine that I built about 10 or 12 years ago. It is much smaller than you like, but I MAY still have the CAD drawings on the computer somewhere and they could be doubled as a starting point if you like the engine. It could easily be adapted to your single cylinder block. Maybe give you some ideas of at least one approach anyway.

Gail in NM,USA

[ame]http://www.youtube.com/watch?v=ZpwFdimoCsU[/ame]

Attached video of my little donkey engine that I built about 10 or 12 years ago. It is much smaller than you like, but I MAY still have the CAD drawings on the computer somewhere and they could be doubled as a starting point if you like the engine. It could easily be adapted to your single cylinder block. Maybe give you some ideas of at least one approach anyway.

Gail in NM,USA

[ame]http://www.youtube.com/watch?v=ZpwFdimoCsU[/ame]

Gentlemen--Thank you so much. Outstanding engine, Gail, and nice plan Maryak. Crewcab--The cylinders are that far apart as a "starting point" only.--I won't know untill I get deeper into the design how far apart they really need to be. I have designed the cylinder block in such a manner that one keystroke will change that center distance to what it needs to be, when I get that far. I know the shape of the cylinder block in all other respects except for that center to center distance, and those dimensions are "locked".----thats one of the nice things about 3D cad. I will probably finish this design over the next 2 or 3 days, and will post it as I develop it.--Brian

And here we are with piston and rod assemblies. The pistons are the same as the piston in the "Beam action at double scale", except they are threaded for a 1/4"-20 rod instead of the previous 5-40 thread. The rod is the same length as the beam engines, but bumped up to 1/4" diameter to compensate for the side loading that will result from having an additional link between the end of the piston rod and the crankshaft throw. The end opposite the piston has been bumped up to 3/8" wide to accomodate the 1/4" piston rod.

chuck foster

Well-Known Member

- Joined

- Jul 11, 2007

- Messages

- 704

- Reaction score

- 2

hey brian................do you have wood working machines in your shop?????

cause at the rate you are going you are going to need a big display case for all your models ;D :big:

;D :big:

chuck

cause at the rate you are going you are going to need a big display case for all your models

chuck

max corrigan

Well-Known Member

- Joined

- Aug 24, 2008

- Messages

- 156

- Reaction score

- 4

Gail that is a beautiful one hell of a little engine does it run ok on steam? messy i know but it gives that something that these designs were meant to be! or maybe i'm wrong we have easily electrically or whatever, pumped air nowadays, so in them steam days,had they known, i think they would have gone along on these lines also, and would have come up with some great adaptions and inventions without the use of cads and such! food for thought!! but! where would they get pumped air from? what was that song theres a hole in the bucket dear liza dear liza

Good luck Max.............

Good luck Max.............

Well there! That enough foolishness for one day. Now that I know how much space I have between the connecting rods, I was able to shrink the center distance between cylinders from 3" down to 1 5/8". I had to design the connecting rods and attach them to the piston rods, then leave enough room between them for a crankshaft center bearing. thats what determines the center to center of cylinders.

Jeez---Once I get started with this stuff, I can't leave it alone!!! I have modelled a built up crankshaft with the "throws" at 90 degrees to each other so the engine should self start. I just went through some rather amazing math to get the piston stroke exactly centered between the valve ports in the cylinder, when the crank is at its 2 extremes of rotation. now I really gotta quit!! Its past my bed time..

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Looking good Brian. Lots of us watching to see how this evolves.

Max: The engine runs better on steam than or air. As with all small diameter cylinders on steam, it is necessary to keep the steam dry by keeping the plumbing short. If I was going to run it on steam regularly, I would replace the aluminum cylinder mounts with an insulating material to keep the rest of the works cooler.

Gail in NM,USA

Max: The engine runs better on steam than or air. As with all small diameter cylinders on steam, it is necessary to keep the steam dry by keeping the plumbing short. If I was going to run it on steam regularly, I would replace the aluminum cylinder mounts with an insulating material to keep the rest of the works cooler.

Gail in NM,USA

Brian, I see a fatal flaw in the design... It will never run with a green crankshaft. It would be fine with an orange or blue crankshaft, but the green one just isn't going to hold up. ;D :big:

Seriously, the design is looking great. I think you are well on your way to a cool project! Keep us updated as you progress.

BTW I feel your pain when you can't shut the old noodle down once it gets going. I have that problem myself. Especially at night when I need to be going to sleep! :

Seriously, the design is looking great. I think you are well on your way to a cool project! Keep us updated as you progress.

BTW I feel your pain when you can't shut the old noodle down once it gets going. I have that problem myself. Especially at night when I need to be going to sleep! :

Tel--Thats a nice one. I've been wondering about crosshead guides. I see how you solved the problem. do you think they were really necessary?---Brian

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 44

- Views

- 8K

- Replies

- 21

- Views

- 4K