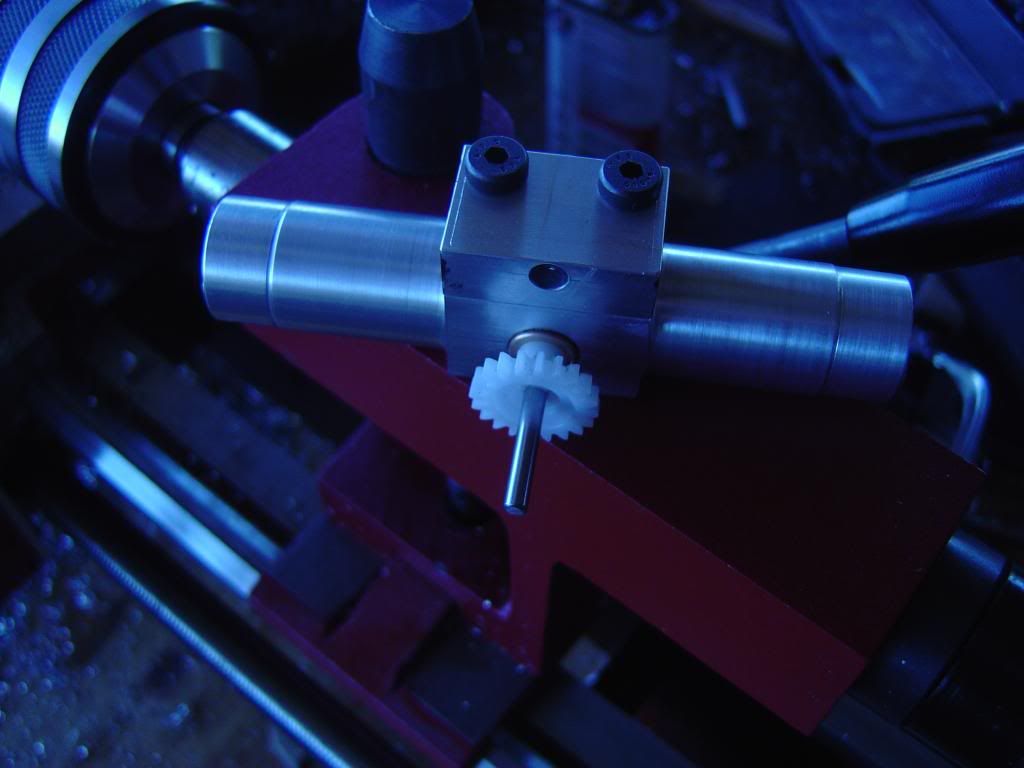

here is a 2 cylinder engine i designed. it is almost complete. i just need to build the valve system and a flywheel.

it started out as a 3 inch long piece of 3/4 inch square aluminum block. the cylinders and crankcase are all one piece. the bore is .375 inch and the stroke is 0.500. the valve will be a rotary tube type driven by the gear.

i started it 2 days ago and hopefully it will get its first run in a day or two.

it measures 3.9 inches across the whole engine.

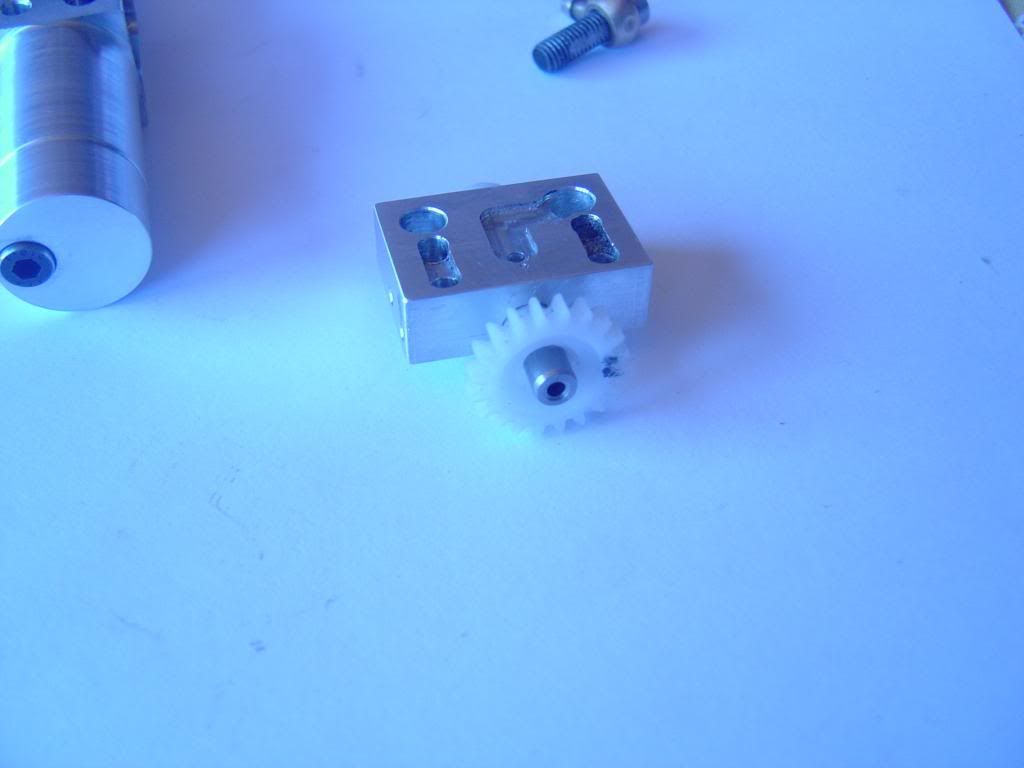

and the tiny crankshaft.

it started out as a 3 inch long piece of 3/4 inch square aluminum block. the cylinders and crankcase are all one piece. the bore is .375 inch and the stroke is 0.500. the valve will be a rotary tube type driven by the gear.

i started it 2 days ago and hopefully it will get its first run in a day or two.

it measures 3.9 inches across the whole engine.

and the tiny crankshaft.