- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

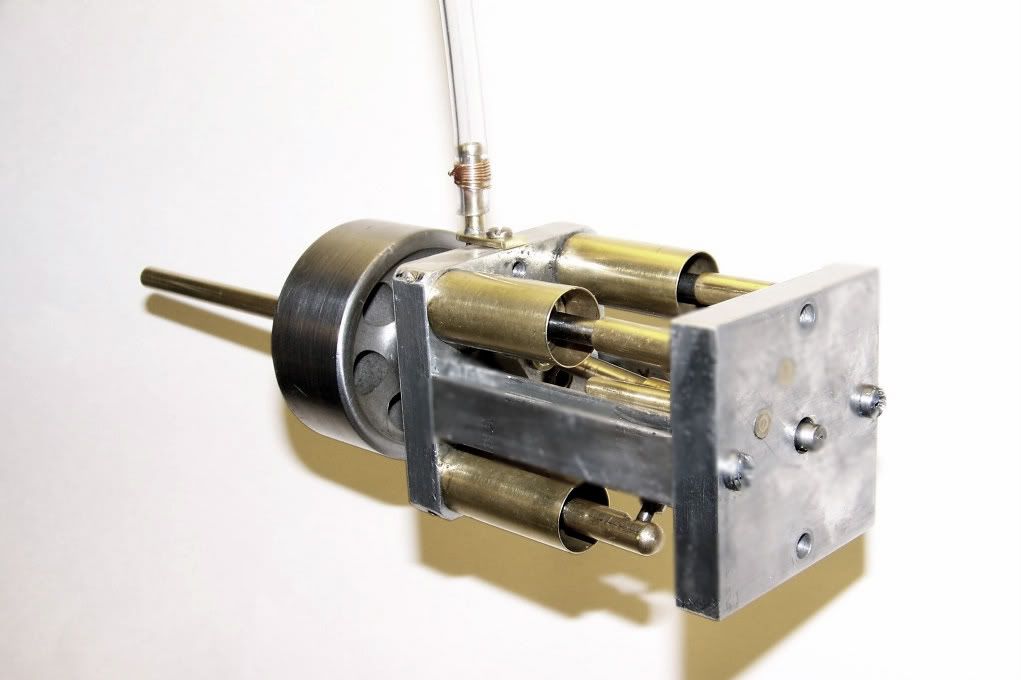

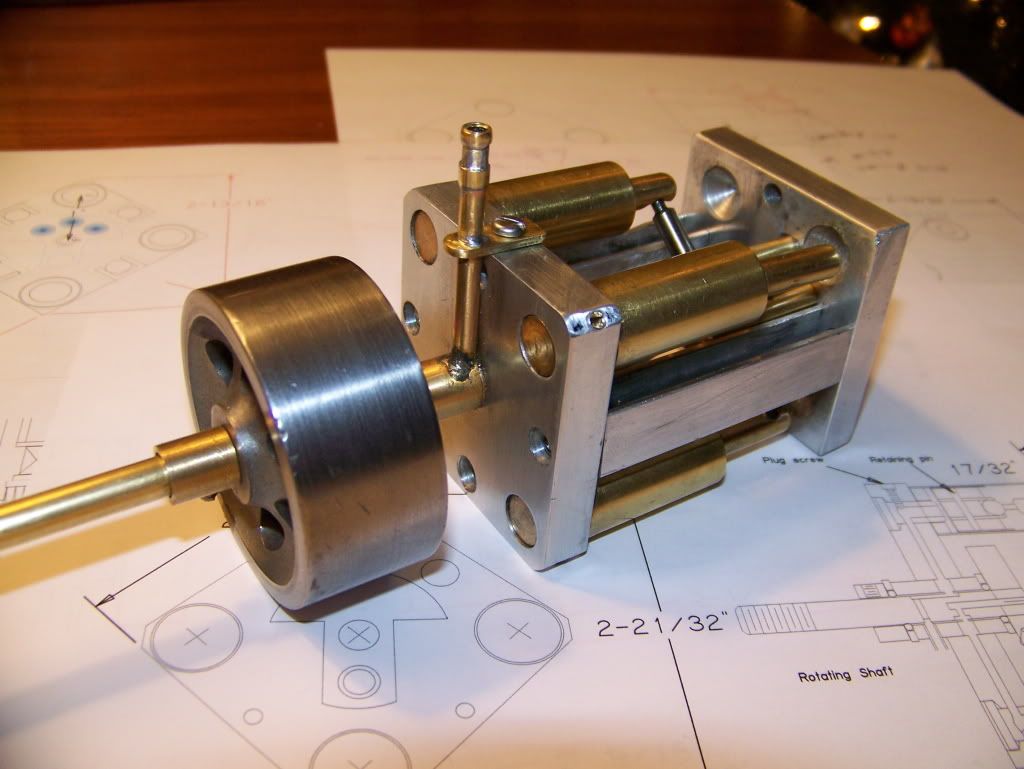

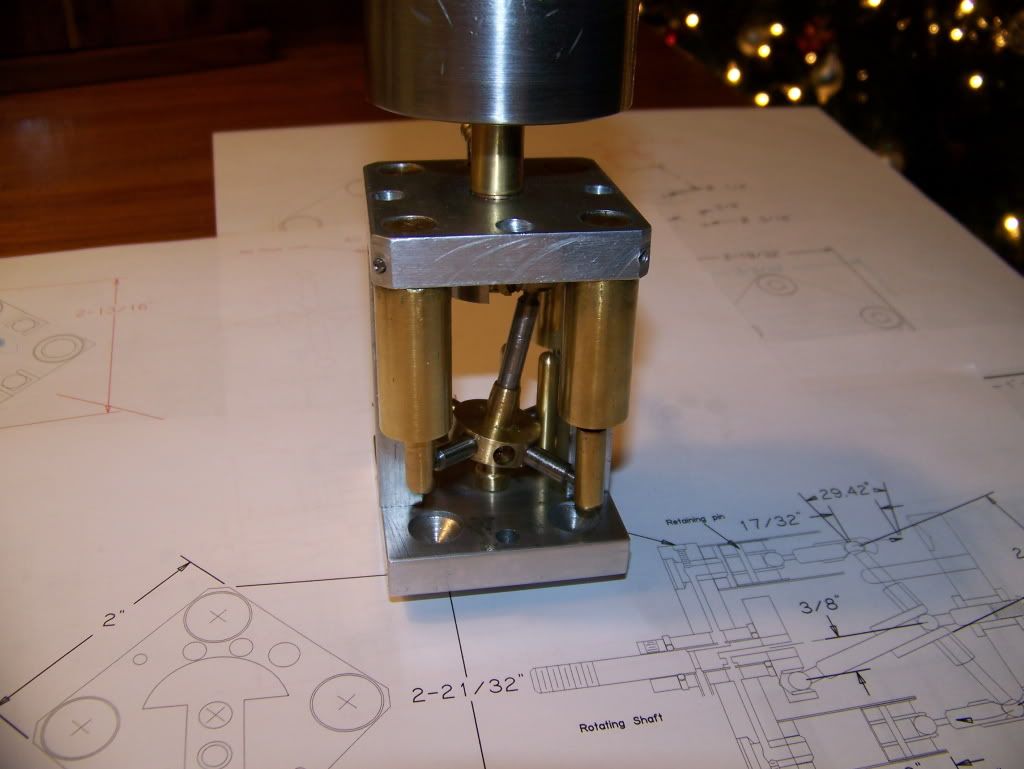

Here is a new engine that I am working on. It is almost complete but since there are mods that I will add, I'll call it a work in progress. This is a four cylinder, wobble plate engine of my own design but leans heavily on all previous designs for this type of engine. There are some innovations that I have not seen elsewhere but that doesn't mean that it hasn't been done before. This engine is more of a demonstration of principle than anything.

I don't have the skills or equipment to produce accurate scale models of historic engines so I just build little machines. One of the things that I wanted to achieve was a clean and uncluttered appearance so routing the air passages through the head plate was critical. I didn't want a lot of copper tubes with visible solder joints to distract from the simplicity of the design.

I am drawn to this type of engine due to the simple but slightly exotic mechanism. They belong to a class of engines called axial engines or barrel engines and they are similar but quite different from swash plate engines. They offer some challenges but are easily within the reach of an beginner. For the concepts involved and for some historic predecessors here is a link to check out.

http://www.dself.dsl.pipex.com/MUSEUM/POWER/unusualICeng/axial-ICeng/axial-IC.htm#smb

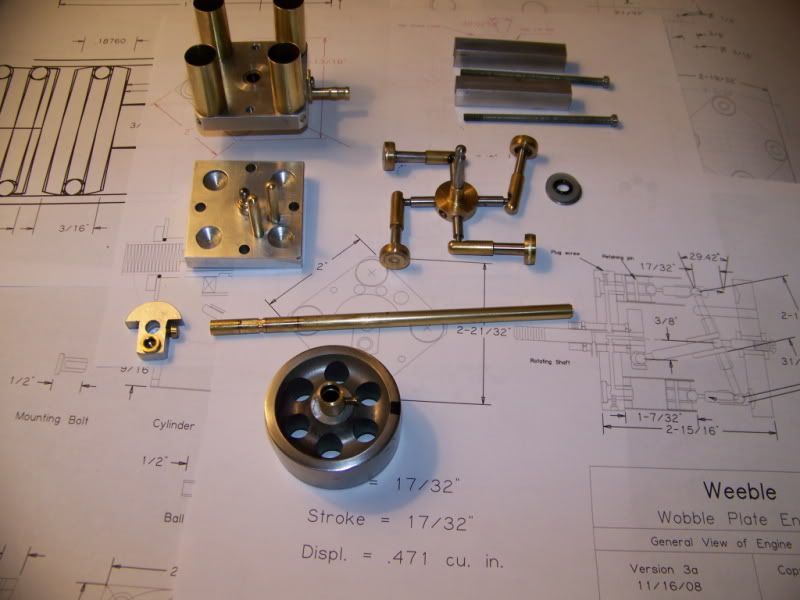

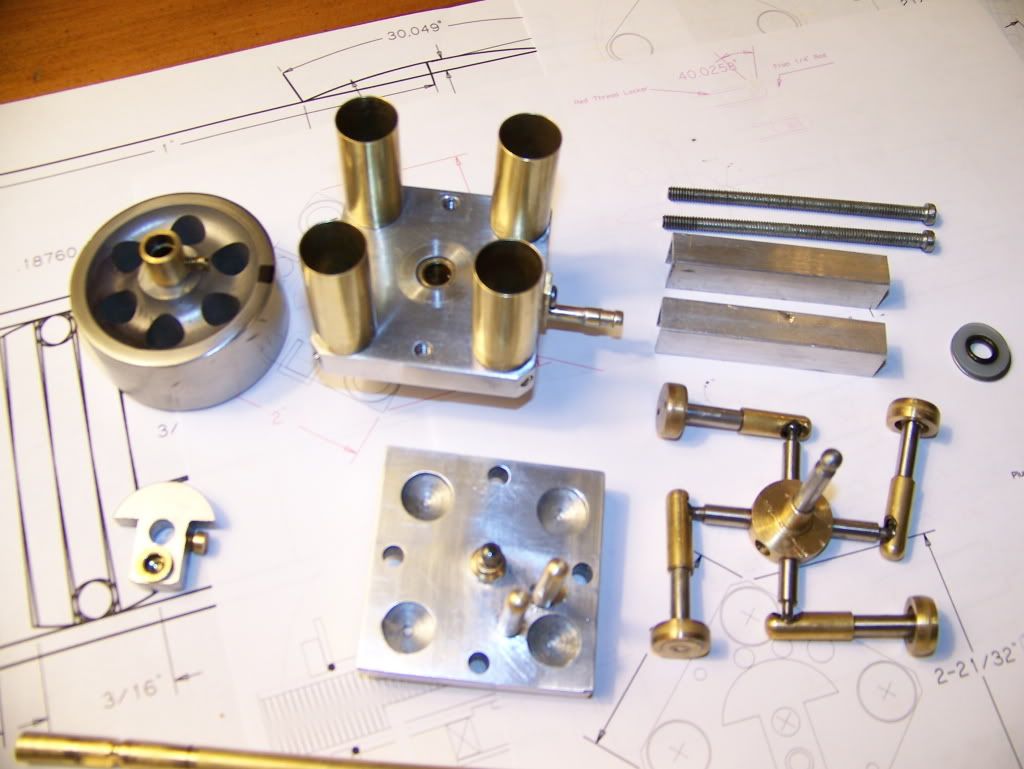

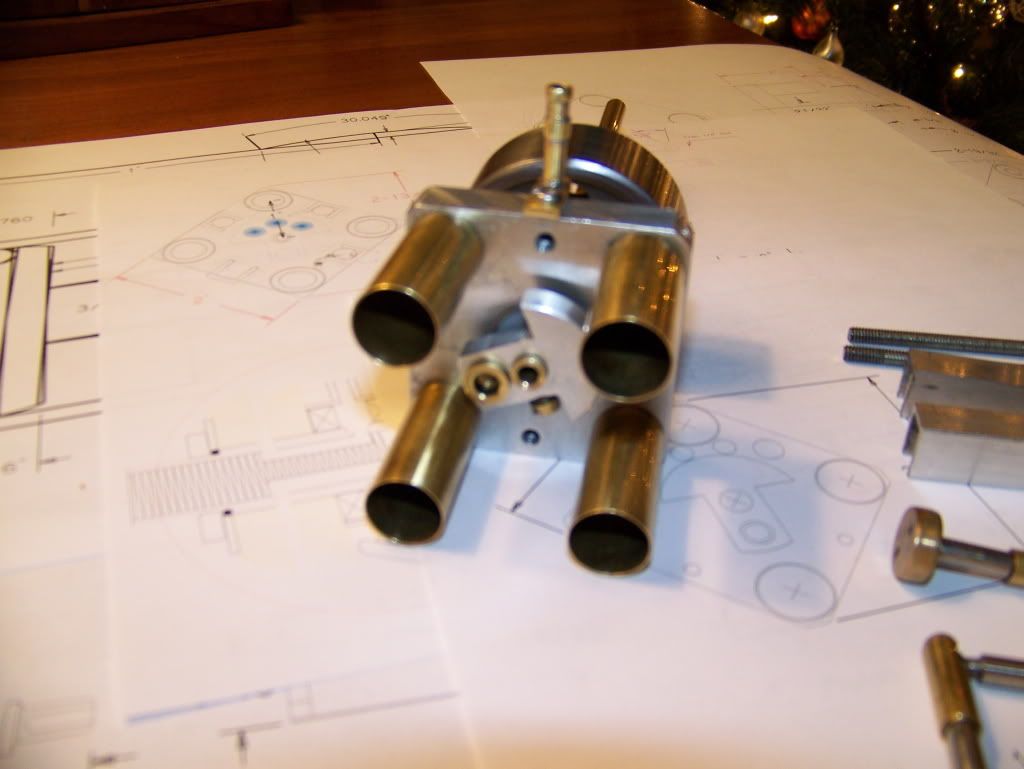

here are some pics of the parts before final assembly:

The engine is assembled and ready for testing but its too late in the evening to run the compressor so if I get some shop time tomorrow we will give it a go and I'll shoot some video.

Regards to all

Jerry