Hey all, ive got a work in progress going, at the moment its only in the computer, but within the next week or two i need to get to cutting!

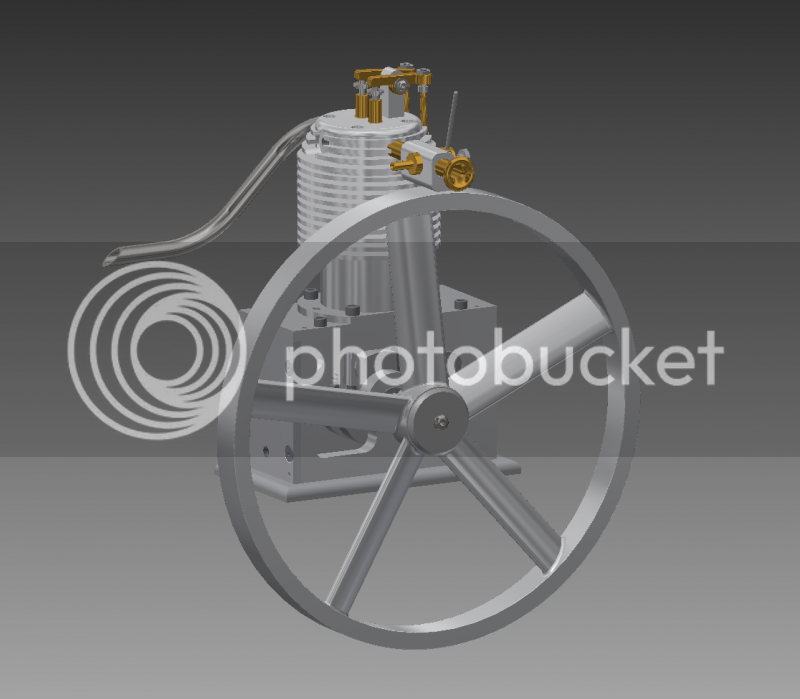

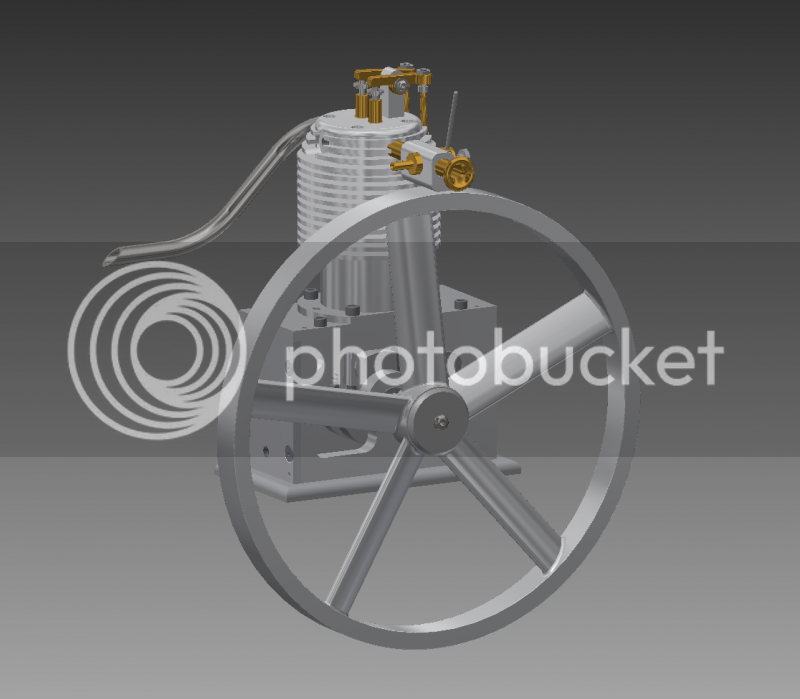

Heres a picture of the engine in Inventor

its been modified somewhat from the original plans, but primarily in style

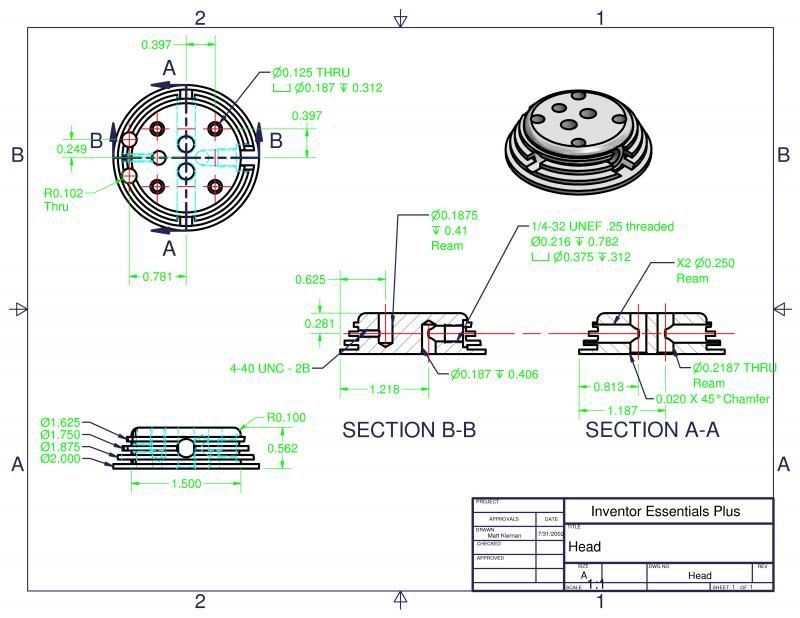

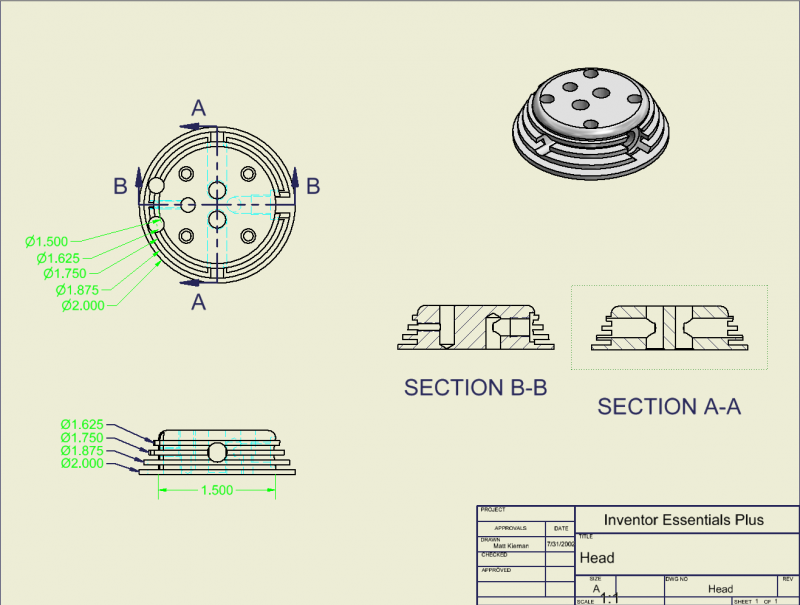

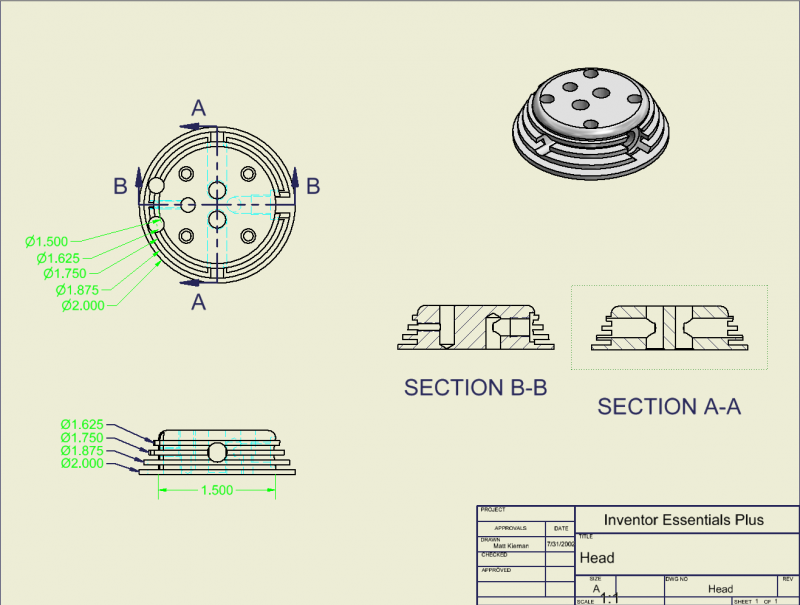

my starting question for you guys is about machining the head.

obviously the drawing isnt done here, but my question to you guys is how to go about doing the fins. my current plan is to stick a piece of 2" round in the vice on the mill and cut a square in the perimeter so that it can be flipped and held in the vice at 90s.

now heres where im not sure, should i drill all of the holes and features before i do the fins? or vice versa. my concern with the first method is the interrupted cutting may mess things up. But im thinking much less so than trying to drill and tap through the fins.

Thanks in advance,

ill try to keep this thread updated, though im painfully bad at keeping these things up to date.

Matt

Heres a picture of the engine in Inventor

its been modified somewhat from the original plans, but primarily in style

my starting question for you guys is about machining the head.

obviously the drawing isnt done here, but my question to you guys is how to go about doing the fins. my current plan is to stick a piece of 2" round in the vice on the mill and cut a square in the perimeter so that it can be flipped and held in the vice at 90s.

now heres where im not sure, should i drill all of the holes and features before i do the fins? or vice versa. my concern with the first method is the interrupted cutting may mess things up. But im thinking much less so than trying to drill and tap through the fins.

Thanks in advance,

ill try to keep this thread updated, though im painfully bad at keeping these things up to date.

Matt