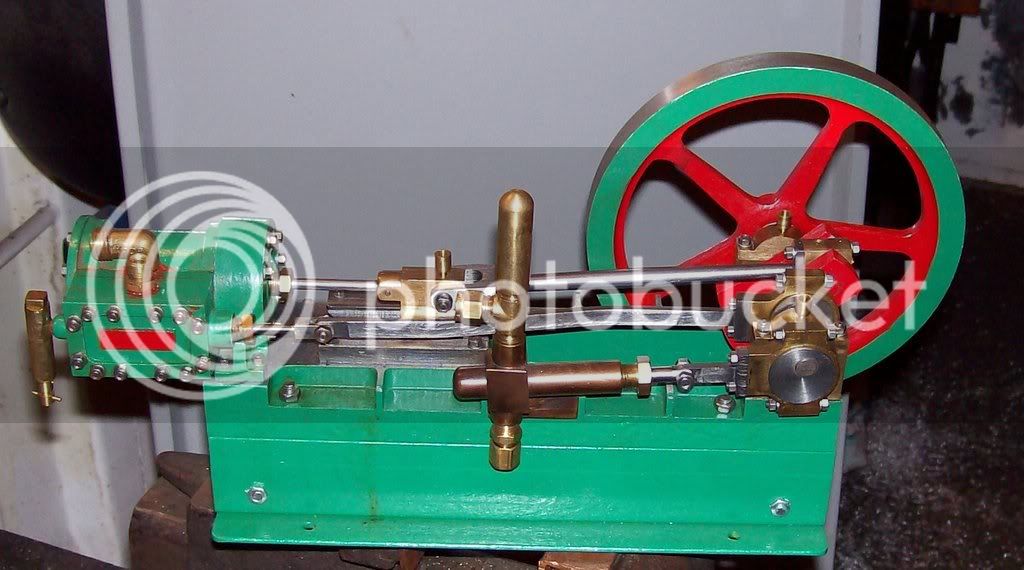

Hi all. I'm a Sr. at a small high school in southeast Ks. 5 or so years ago my dad got a ~16x54 leath and a ~49x16 mill. In the past few years or so I have gotten back into air/steam engines. about a year ago I turned out my first osolateing (I'm a terable speller I'm sorry) engine in about 6 hrs from plains in the 3 book set of Rudy Kouhoupt's. After that I "tryed" to buld a vertical engine with a spool valve out of the same plains.. to small so I scaled up 2x and this one really runs good. I had been workin on this one for probly 6mo... got out of the mood with the 100* temps and no A/C in the shop. Next I would like to buld a BIG walking Beam of my own desin. Growing up in the oil field you know how to make things work(mostly why I am going to PSU for Eng. tec.)

Back to the walking beam...

I cant deside what type of Valve I want to use. Valve's are the only thing that scare me about engines. I'm ok with the spool but the one I have in my 2x vertical is allready starting to leak bad and has less than 2 hrs on it. I know I didnt get a very good finish on the valve body and that it is just running its self in but I would still like to know more options.

The sliding chest type valves seam to be a pain to buld. IMO

So I guess I'm just asking every ones opinon on different ways to go..

Some spects on the beamer.. as of now.

bore : 3"

stroke: 3"

fly wheel:12" (thinkin about usin a shive off of the gear box on a pumpjack)

will probly stand 3' tall

base will probly be 18"x 36"

I would like to buld a small duplex water pump for it after this is all said and done.

buld should start 2 weekends from now and hoping to have it done befor Xmass.

I'm loving this site I have been creepin for the past 3 days and have spent probly 10 hrs on here.

Thank you all!

GJ

Back to the walking beam...

I cant deside what type of Valve I want to use. Valve's are the only thing that scare me about engines. I'm ok with the spool but the one I have in my 2x vertical is allready starting to leak bad and has less than 2 hrs on it. I know I didnt get a very good finish on the valve body and that it is just running its self in but I would still like to know more options.

The sliding chest type valves seam to be a pain to buld. IMO

So I guess I'm just asking every ones opinon on different ways to go..

Some spects on the beamer.. as of now.

bore : 3"

stroke: 3"

fly wheel:12" (thinkin about usin a shive off of the gear box on a pumpjack)

will probly stand 3' tall

base will probly be 18"x 36"

I would like to buld a small duplex water pump for it after this is all said and done.

buld should start 2 weekends from now and hoping to have it done befor Xmass.

I'm loving this site I have been creepin for the past 3 days and have spent probly 10 hrs on here.

Thank you all!

GJ