Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

About 12 months ago now I bought a pallet of returned tools from Axminster tools (UK). The idea was to get what I wanted (powered hacksaw and a few other bits) and sell the other items to get my tools free. The purchase was non returnable so it was a risk. However when the pallet arrived it turned out to be two! I lost count of the circular saws, routers etc. Anyway to cut a long story short, the damage to most equipment was minor and easily sorted out. They were then put back on eBay and away they went. Financially it worked well and I covered the initial costs. I only have a slide circular saw left. Amongst the many tools that I got there were only two items that were not repairable (at a sensible cost). One was a Jet tool sharpener (I haven't given up on this one though) and a wood powered mortice.

The electric motor is fine and I use that for 'other' things. However i have decided to turn the base and cast iron head as a tapping fixture. Today I started to size the job up and hope to improve on using the mill for my tapping now. The real prompt to start the project now is I want to tap my Fowler Traction engine boiler for attaching the hornplates to. As its a big boiler using the prospective tapping stand makes sense and should lead to a better job. It should also see a lot of use in other projects. We are always tapping aren't we.

Well I have bought a small chuck with a J2 taper and will cut an internal taper to match (or attempt to). I will include bearings but I am thinking of a tight fit in nylon bushes to let the tap push down. Any thoughts appreciated.

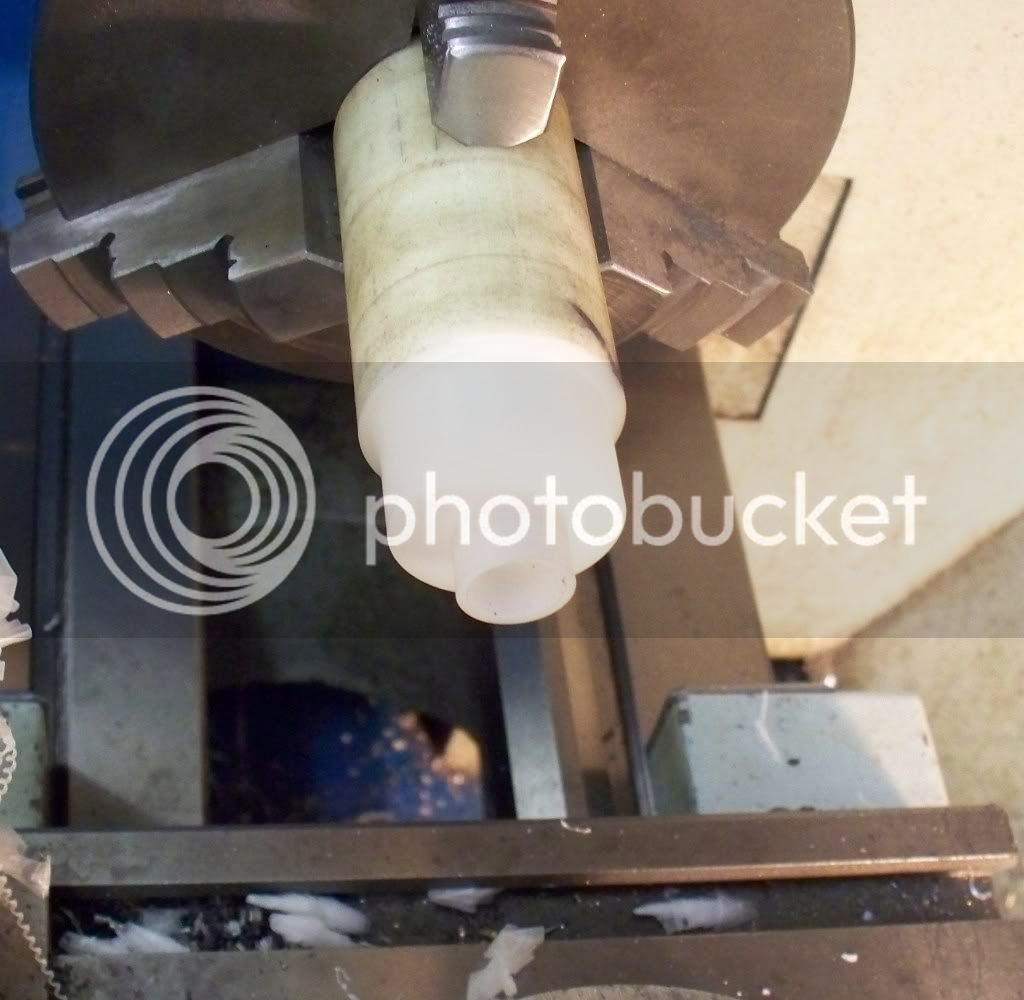

This is the cast iron head. I will put a bearing in the bottom and a new top including another bearing....

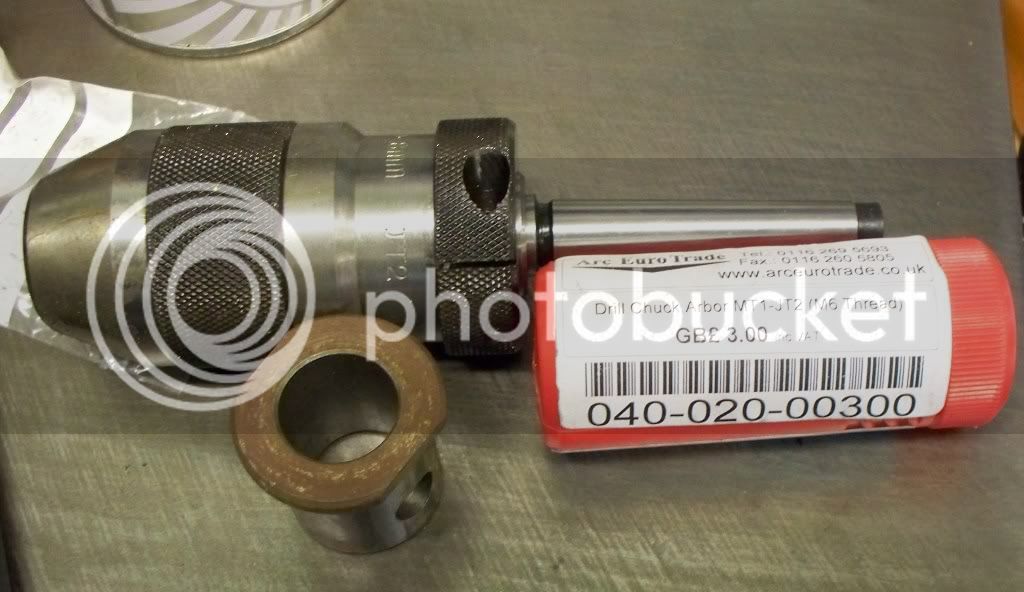

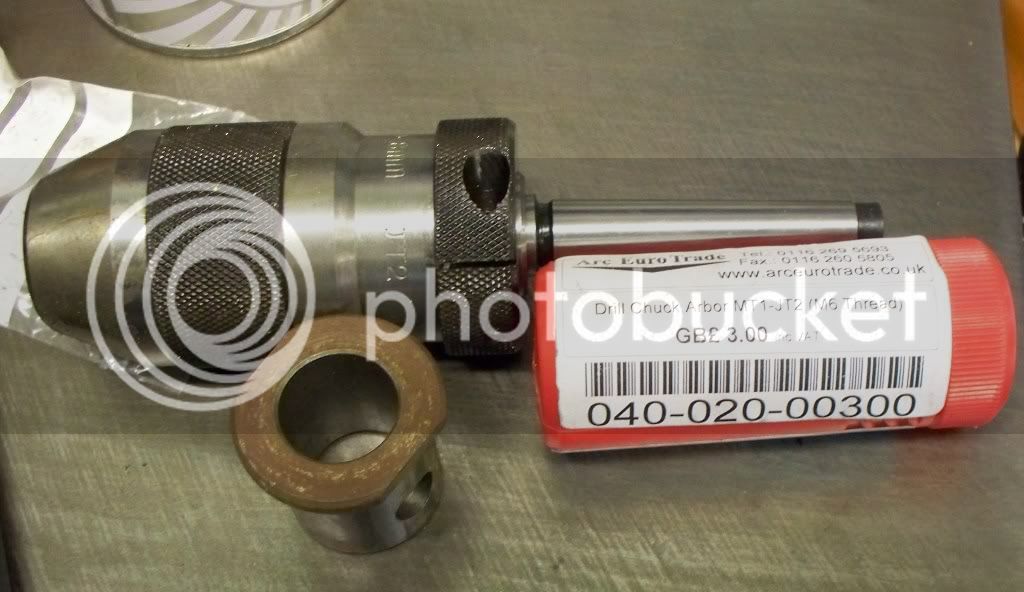

The keyless chuck and J2 taper.............

The electric motor is fine and I use that for 'other' things. However i have decided to turn the base and cast iron head as a tapping fixture. Today I started to size the job up and hope to improve on using the mill for my tapping now. The real prompt to start the project now is I want to tap my Fowler Traction engine boiler for attaching the hornplates to. As its a big boiler using the prospective tapping stand makes sense and should lead to a better job. It should also see a lot of use in other projects. We are always tapping aren't we.

Well I have bought a small chuck with a J2 taper and will cut an internal taper to match (or attempt to). I will include bearings but I am thinking of a tight fit in nylon bushes to let the tap push down. Any thoughts appreciated.

This is the cast iron head. I will put a bearing in the bottom and a new top including another bearing....

The keyless chuck and J2 taper.............