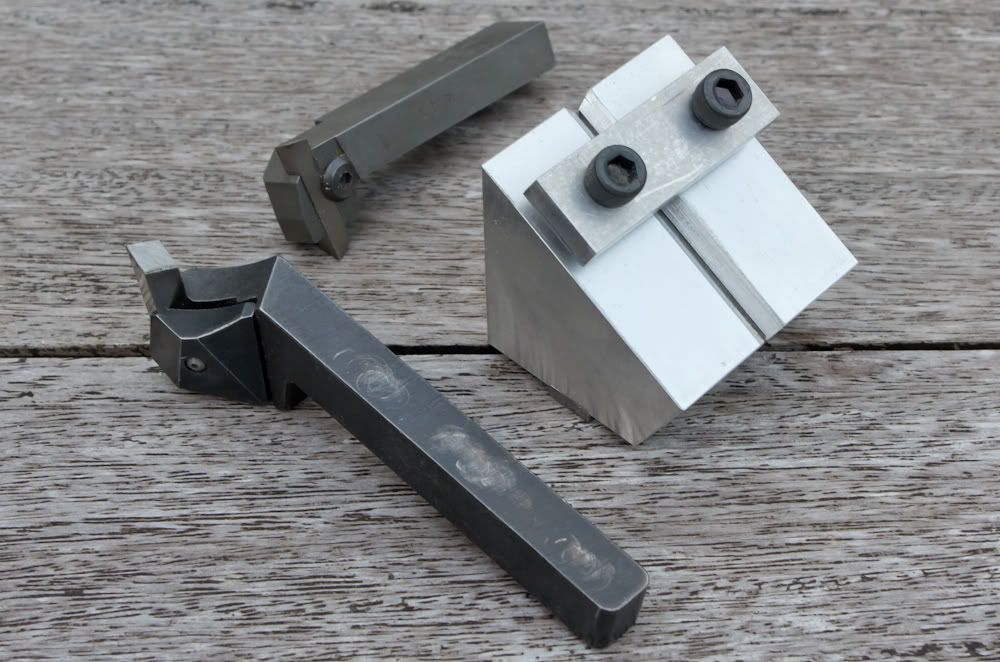

There have been a few posts about these, this is my collection. Three home made and one commercial.

The bought one is the black one with a round bit. I need to make a right hand version at some point!

This is the most used one.

Sharpening jig.

Height setting gauge.

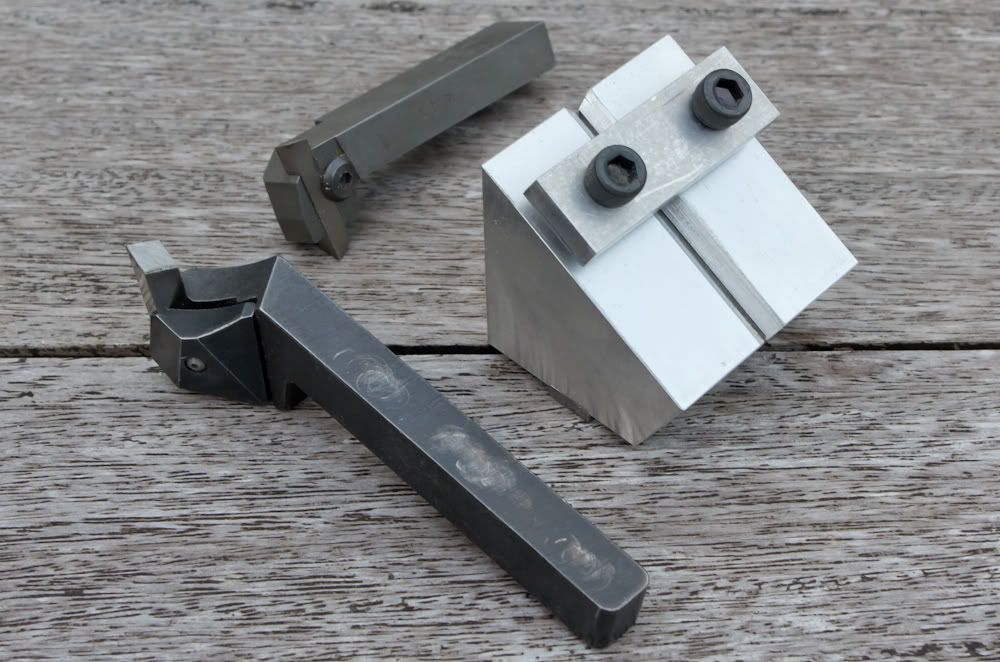

The bought one is the black one with a round bit. I need to make a right hand version at some point!

This is the most used one.

Sharpening jig.

Height setting gauge.