Dan Rowe

Well-Known Member

- Joined

- Feb 12, 2010

- Messages

- 594

- Reaction score

- 18

Robin,

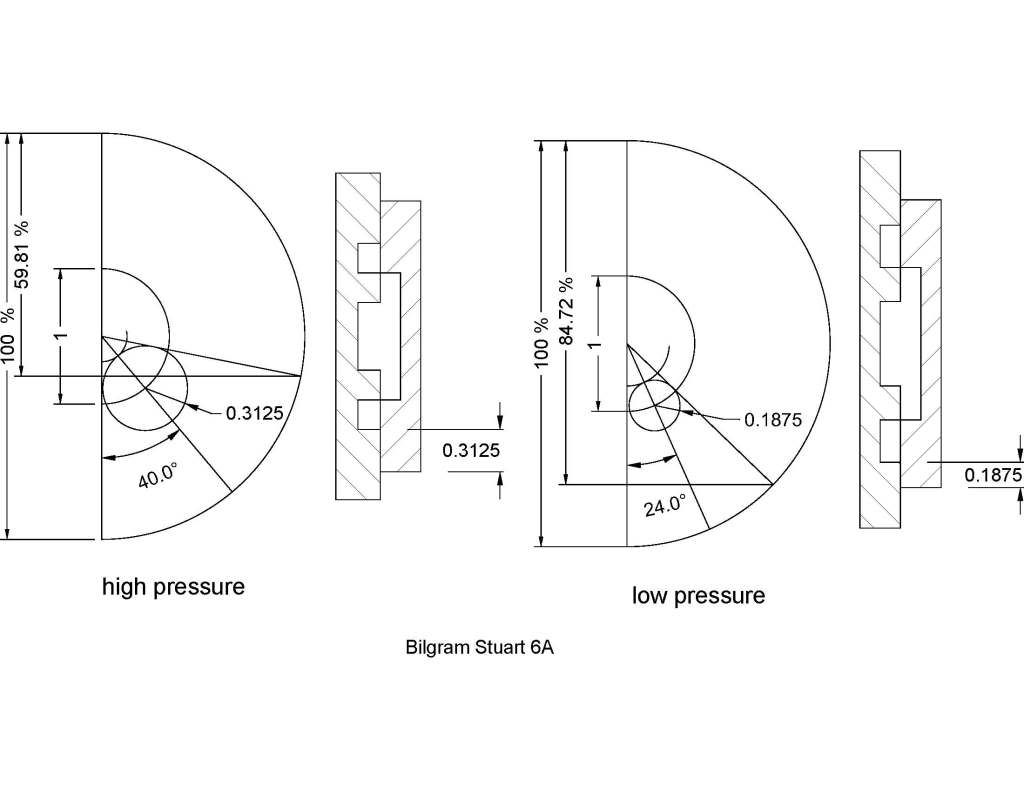

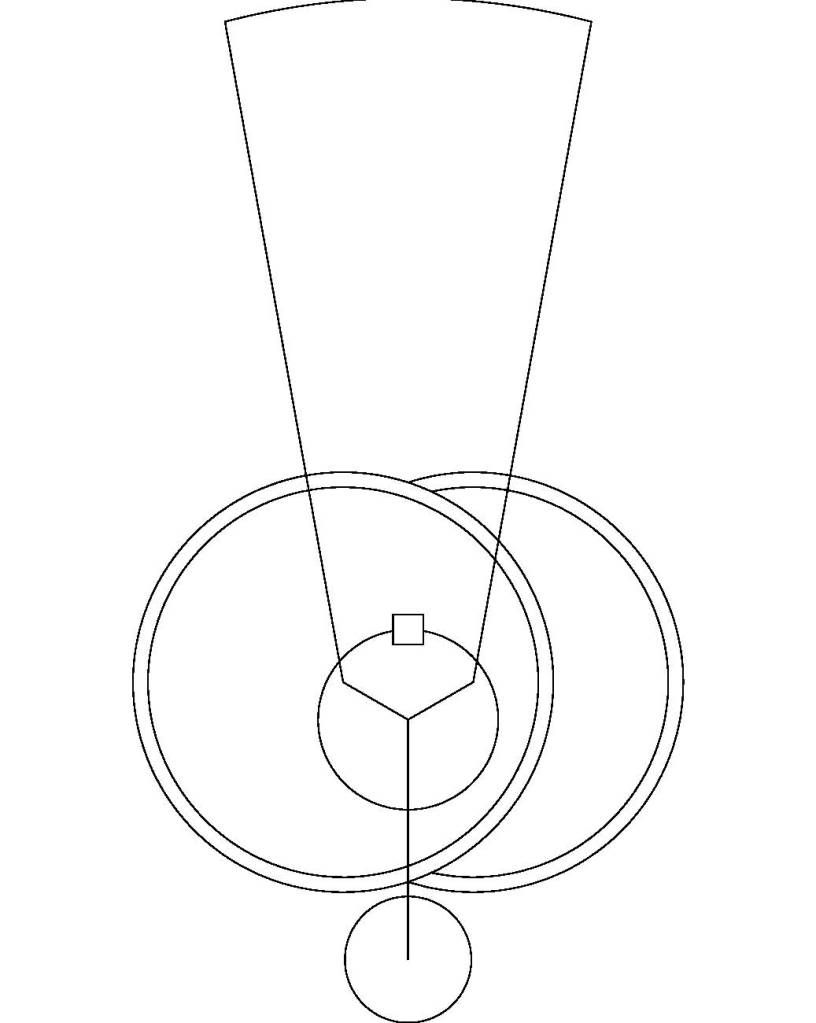

I do not have the Stuart triple but I do have a set of 6A castings and drawings. I will try my advise about the angle of advance on the 6A and report back. It looks like I was wrong as the Hp has a greater angle than the LP on the 6A so I should see more lap on the HP than the LP.

I also see that it looks like a D slide valve for all the cylinders. That is very important as the eccentrics would flip 180 degrees for piston valves.

As for the eccentrics being reversed the photo tells the story. Lets just say that the photo shows the engine set for ahead operation. Now looking at the LP cylinder the ahead rod is closer to the bed plate and bearing. Now if we look at the HP cylinder we can see that it is the astern rod that is close to the bed plate. With a Shay the last part would be reversed. So yes the eccentrics are handed but they are handed the same way so my concern was not justified.

Dan

I do not have the Stuart triple but I do have a set of 6A castings and drawings. I will try my advise about the angle of advance on the 6A and report back. It looks like I was wrong as the Hp has a greater angle than the LP on the 6A so I should see more lap on the HP than the LP.

I also see that it looks like a D slide valve for all the cylinders. That is very important as the eccentrics would flip 180 degrees for piston valves.

As for the eccentrics being reversed the photo tells the story. Lets just say that the photo shows the engine set for ahead operation. Now looking at the LP cylinder the ahead rod is closer to the bed plate and bearing. Now if we look at the HP cylinder we can see that it is the astern rod that is close to the bed plate. With a Shay the last part would be reversed. So yes the eccentrics are handed but they are handed the same way so my concern was not justified.

Dan