thezetecman

Active Member

- Joined

- Apr 30, 2008

- Messages

- 37

- Reaction score

- 0

Hello

I bought a starrett edge finder at the week end.

It has 2 ends one cylinder end for finding the edge. I understand how to use this end. It works very well.

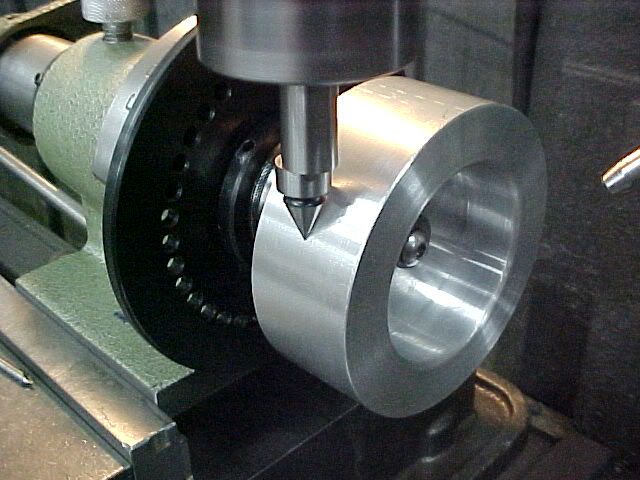

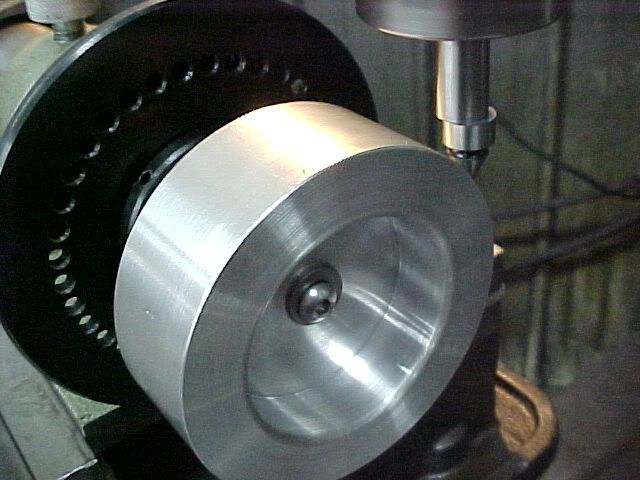

How do you use the pointed end to find a hole centre?

Thanks for your help

Paul

I bought a starrett edge finder at the week end.

It has 2 ends one cylinder end for finding the edge. I understand how to use this end. It works very well.

How do you use the pointed end to find a hole centre?

Thanks for your help

Paul