Hello all, while attending the 1000 engine rally here in the UK I came across these castings for a small gas engine. The large parts had been machined and a few items were included with the castings. It is always a risk buying castings that have been machined as to whether they are correct or not, luckily these measure up fine to the drawings.

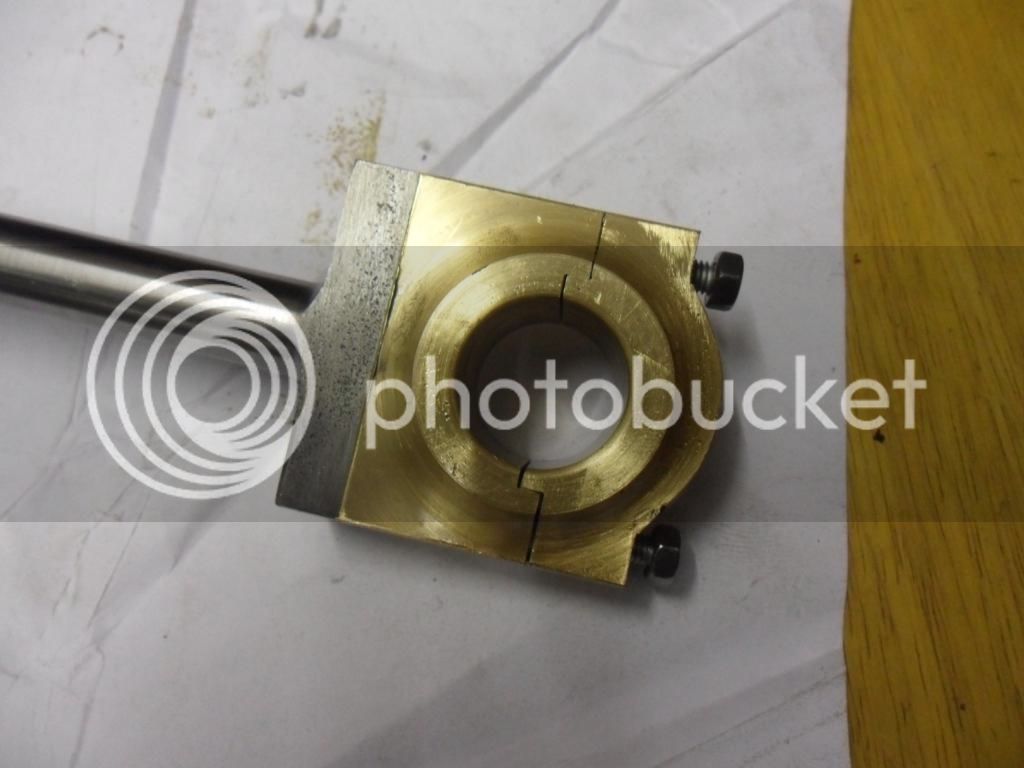

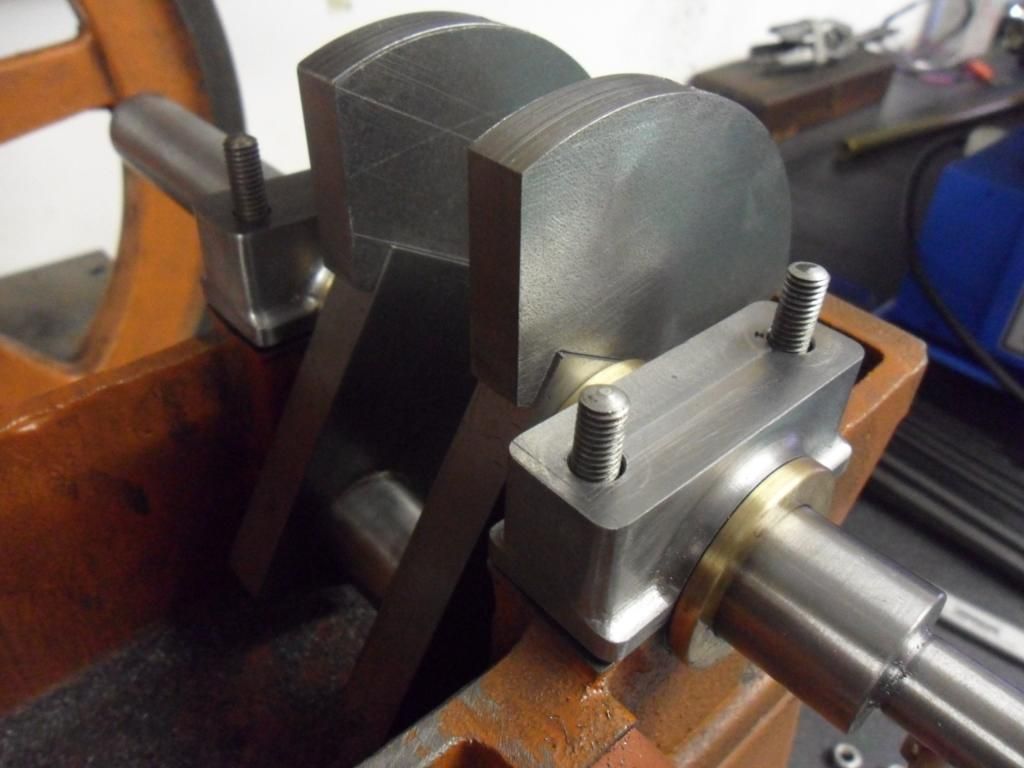

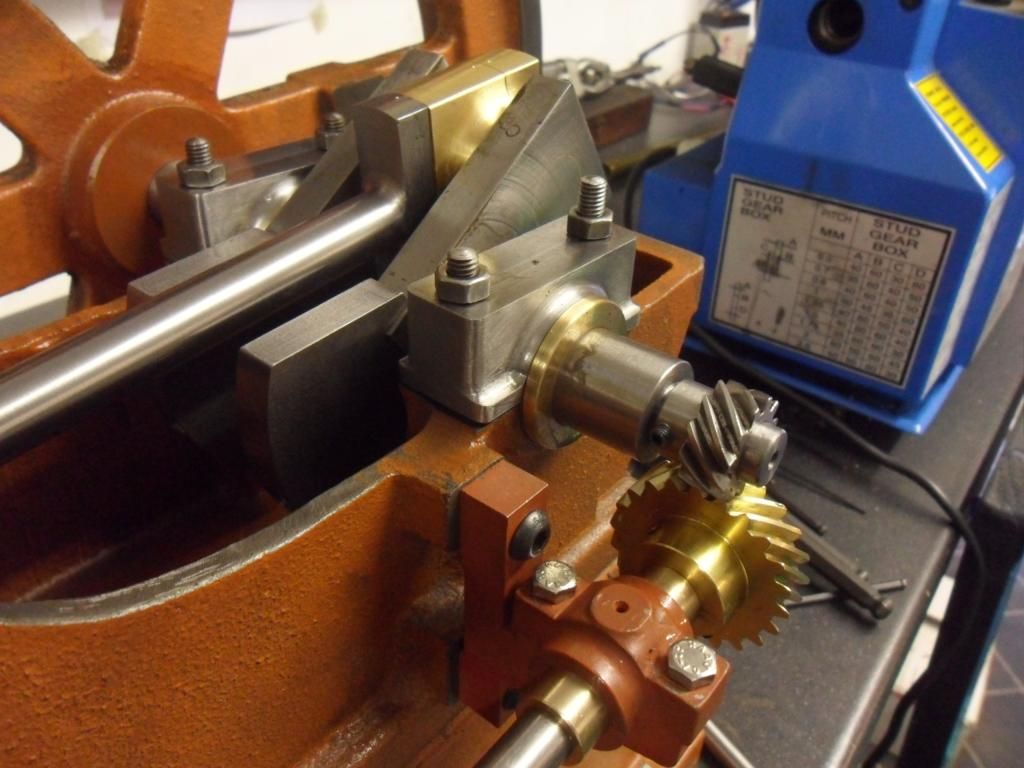

The engine is not a model but a full size engine. The bore is 61mm and the stroke is 80mm. The flywheel is around 14" in diameter and 2" across the face.

Although it is not a model, It is a Klein gas motor of German manufacture, I thought some of you would like to follow my trials and tribulations in a build log for it.

I will be ran on propane and have hot tube ignition, it has sideshaft driven cams that operate the valves. I may also fit a CDI ignition unit and spark plug so that the engine can be run outside if it is windy.

Let me know if you think a build log would be of use to anyone.

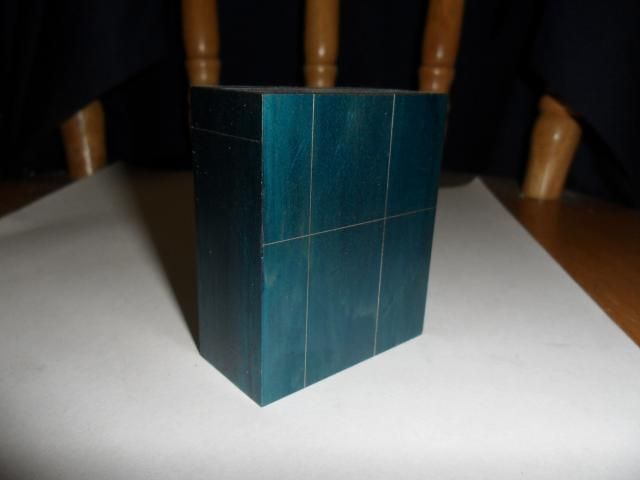

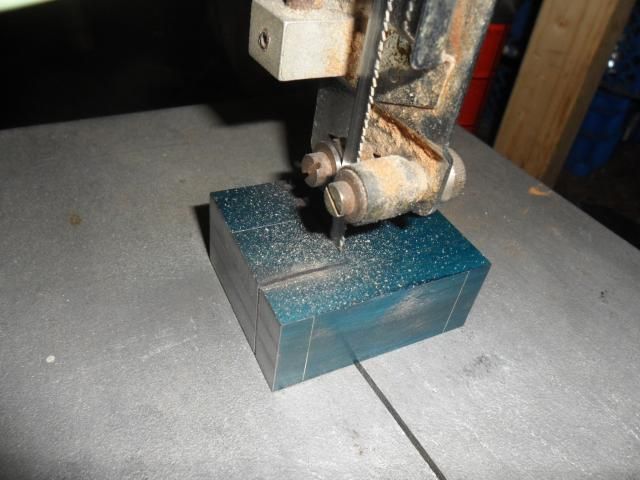

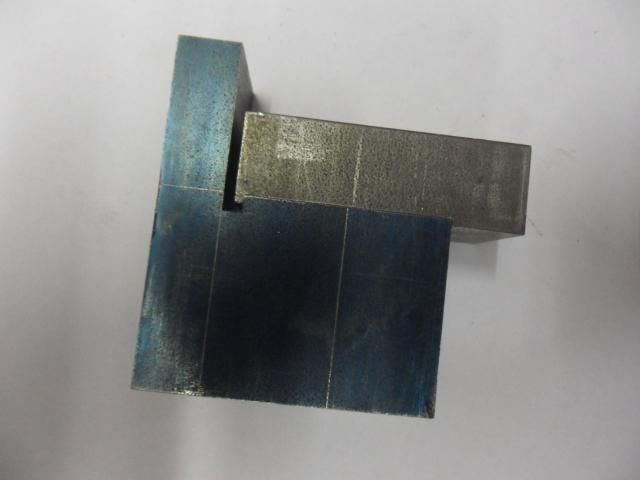

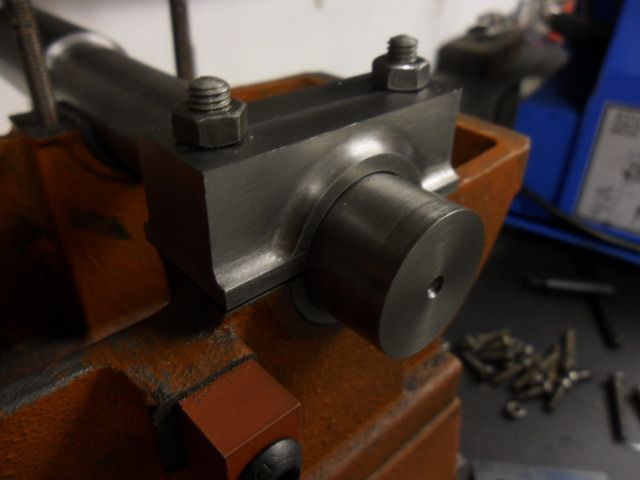

A few pics of the castings below, the vernier in front of them is 6" and should give some idea of the physical size of the engine.

Cheers,

MartinH

The engine is not a model but a full size engine. The bore is 61mm and the stroke is 80mm. The flywheel is around 14" in diameter and 2" across the face.

Although it is not a model, It is a Klein gas motor of German manufacture, I thought some of you would like to follow my trials and tribulations in a build log for it.

I will be ran on propane and have hot tube ignition, it has sideshaft driven cams that operate the valves. I may also fit a CDI ignition unit and spark plug so that the engine can be run outside if it is windy.

Let me know if you think a build log would be of use to anyone.

A few pics of the castings below, the vernier in front of them is 6" and should give some idea of the physical size of the engine.

Cheers,

MartinH