toolznthings

Project of the Month Winner

Hi All,

A few notes on using shoulder bolts to fixture parts for machining both on the manual mill, lathe or CNC. A good place to see all the types of shoulder bolts that are available is the McMaster Carr catalog.

The first consideration for standard shoulder bolts is the fact that they are under size for their given size. Picture of a .500 bolt showing almost .0035 under size.

It may or may not matter depending on the use, but good to know. Precision shoulder bolts are available with a tighter tolerance. Shoulder bolts are machinable if a modification is needed.

When used to fixture a part I use a washer smooth side down against the part if I have room to work around the bolt. Otherwise you need to file a radius under the head to remove the sharp edge that will make a heavy mark in your part when used without a washer.

Sharp edge ....

Edge rounded over ....

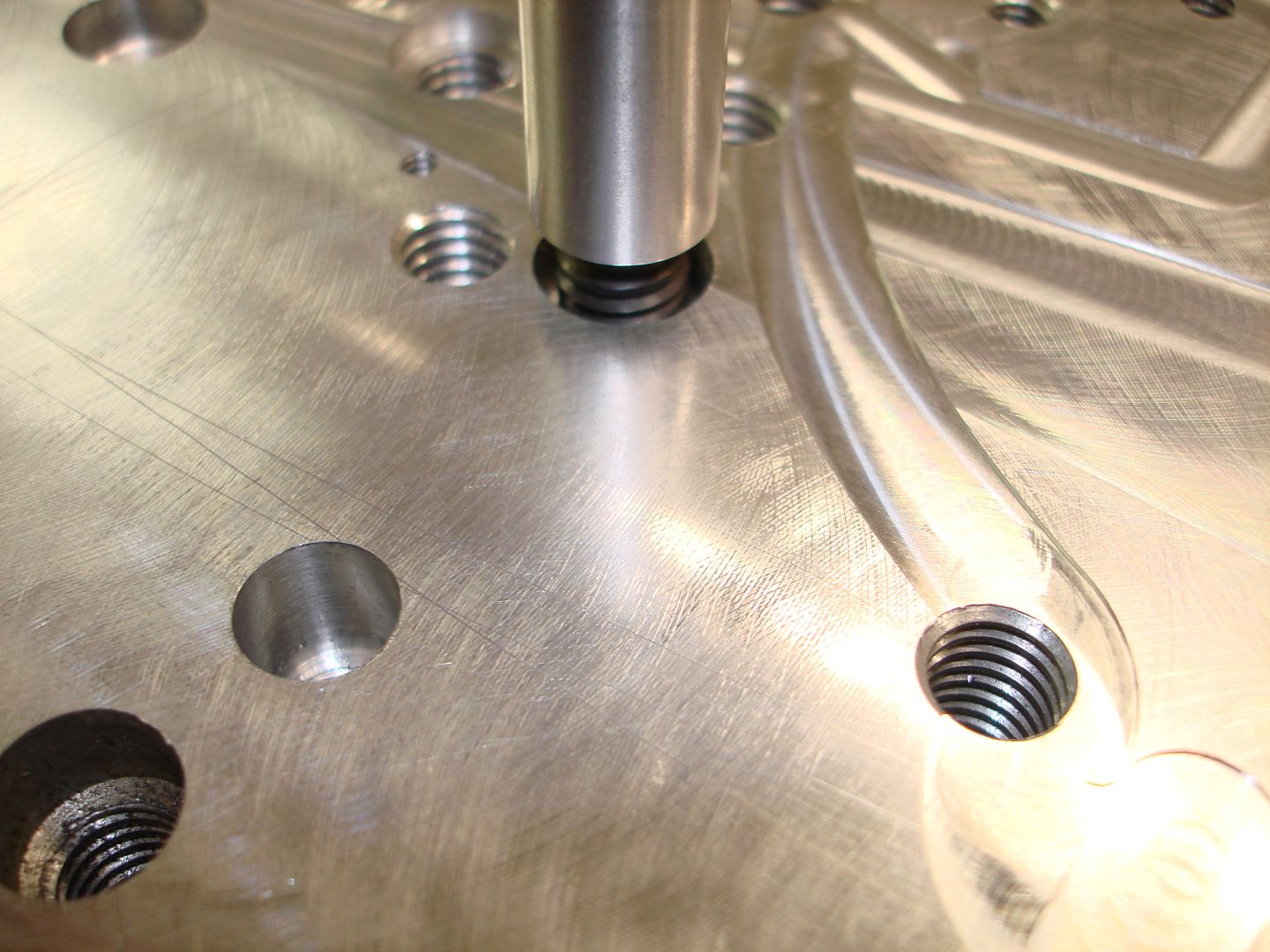

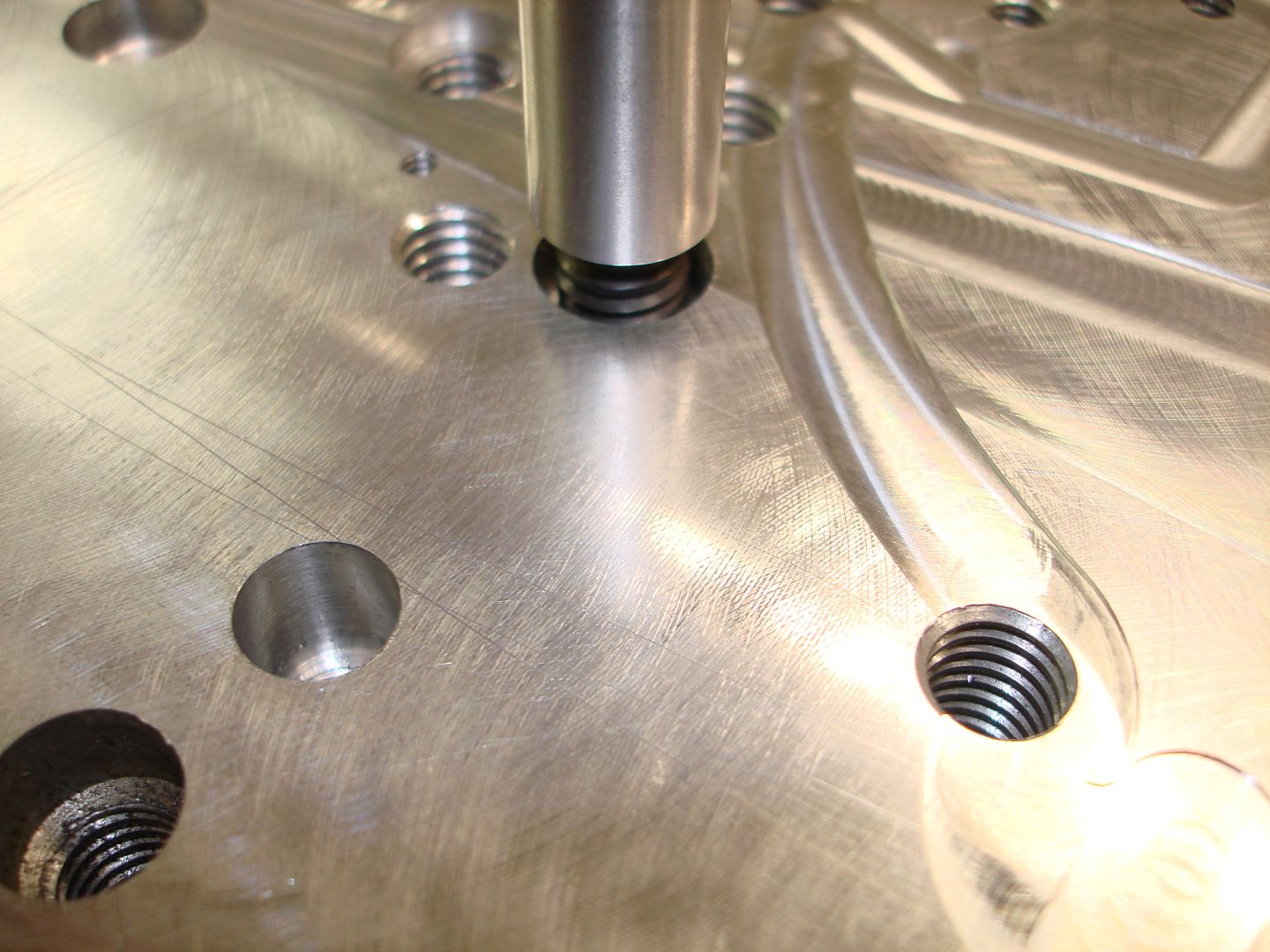

When making your fixture it is necessary to make a counter bore to accept the diameter of the bolt. The thread to bolt diameter will not be concentric enough to locate from. Typically any use of threads alone may not provide great accuracy. Exceptions of course.

Example of counter bore for 1/2" shoulder bolt ....

I've modified the heads and diameters on shoulder bolts to work in parts where standard sizes won't work. Very handy item in the shop.

A few notes on using shoulder bolts to fixture parts for machining both on the manual mill, lathe or CNC. A good place to see all the types of shoulder bolts that are available is the McMaster Carr catalog.

The first consideration for standard shoulder bolts is the fact that they are under size for their given size. Picture of a .500 bolt showing almost .0035 under size.

It may or may not matter depending on the use, but good to know. Precision shoulder bolts are available with a tighter tolerance. Shoulder bolts are machinable if a modification is needed.

When used to fixture a part I use a washer smooth side down against the part if I have room to work around the bolt. Otherwise you need to file a radius under the head to remove the sharp edge that will make a heavy mark in your part when used without a washer.

Sharp edge ....

Edge rounded over ....

When making your fixture it is necessary to make a counter bore to accept the diameter of the bolt. The thread to bolt diameter will not be concentric enough to locate from. Typically any use of threads alone may not provide great accuracy. Exceptions of course.

Example of counter bore for 1/2" shoulder bolt ....

I've modified the heads and diameters on shoulder bolts to work in parts where standard sizes won't work. Very handy item in the shop.