Hexbasher

Well-Known Member

- Joined

- Sep 24, 2007

- Messages

- 73

- Reaction score

- 1

Got this idea from over on PM aboot a month or two ago(From Tdkkart's Post in a the 'Electronic Edge Finders' thread), and I finally had 3 hours free last weekend (14 hours weekdays machining between work and school, and weekends doing well, the busman's holiday routine between overtime, harleys and toyotas)

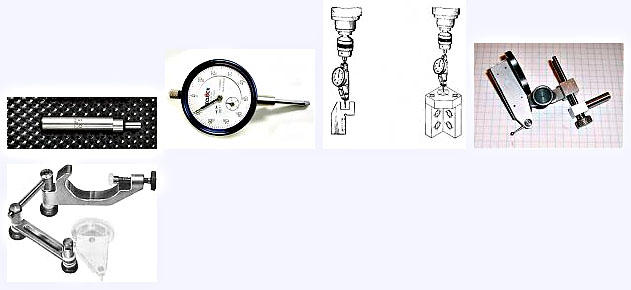

2" OAL 0.750 bearing, 0.500 chucking dia

3" OAL 0.750 bearing, 0.375/0.500 chucking dia

4" OAL 0.750 bearing, 0.375/0.500 chucking dia

6" OAL 22mm bearing, reduced neck, 0.375/0.500 chucking dia

the 6 inch one is the one i really wanted to make for bastard* CNC setups where i have raw stock over hang and only 0.25 of machined material sticking out of the vise to sweep a dial on, it has a 50 buck 22mm bearing on the end of it, i peeled the seals off, flushed the grease out with methl-hydrate so it spins (and stops) more freely

simple to use, chuck, run, slowly bring to edge, when the outer race stops spinning, you've found it. the bearings with the plastic seals on it (with brands and whatnot on it) are easier to see vs. ones with metal seals

making em:

my ER collet chuck for my Okuma LS had too much run out for my liking (0.0005 on the taper)...so i bored some softjaws and chucked a 5c collet chuck, still not good enough (0.0002 was the best i could get after hitting with a brass hammer for a bit)

i ended up using the collet chuck to rough, and i finished between centers, practically zero runout, which was my biggest concern with the 6 inch one. I used DNMG - 221 S/S grade inserts, but i've have no prob in the past with general purpose inserts, i wanted the s/s inserts because i took a light skim cut (0.0005) to 'true' up the 0.500 diameter for chucking (@ 2000 RPM 0.002 feed) I'd run it faster if i could but thats the fastest my manual lathe runs and it would take too long to program and set up on one of the CNC lathes. the 1 rad (1/64) TNR is great for undercutting fillets (which i always do on tooling)

these four were made from 1/2 inch O-1 drill rod, my favorite/most common side project material..bearings were pressed on. all of them (except for the 2inch stub) have turned 0.500 and 0.375 dia for chucking (my two most commonly used collets)

on a 5 month old Haas VF-1 the 6 inch had 0.0001 repeatability or better (after touching off the 1-2-3 block, i zeroed the operator page, backed off and found the edge again, the next ten or so times i found that edge the op page read +0.0001)...done at 1000 RPM

the three others have shitty bearings and i'll prob be replacing them in the future, but good enough for a manual mill with 0.0005 repeatability on a POS Dahlih mill

with the short ones on a manual mill, theres nothing to break, and if you go too far the table will go no where further (hand feed talkin here)

its a great design thats highly customizable and modifiable for whatever your needs are.

*Bastard - aka oddball aka awkward Op. 2 setups, awkward castings, SNAFU jobber type stuff

2" OAL 0.750 bearing, 0.500 chucking dia

3" OAL 0.750 bearing, 0.375/0.500 chucking dia

4" OAL 0.750 bearing, 0.375/0.500 chucking dia

6" OAL 22mm bearing, reduced neck, 0.375/0.500 chucking dia

the 6 inch one is the one i really wanted to make for bastard* CNC setups where i have raw stock over hang and only 0.25 of machined material sticking out of the vise to sweep a dial on, it has a 50 buck 22mm bearing on the end of it, i peeled the seals off, flushed the grease out with methl-hydrate so it spins (and stops) more freely

simple to use, chuck, run, slowly bring to edge, when the outer race stops spinning, you've found it. the bearings with the plastic seals on it (with brands and whatnot on it) are easier to see vs. ones with metal seals

making em:

my ER collet chuck for my Okuma LS had too much run out for my liking (0.0005 on the taper)...so i bored some softjaws and chucked a 5c collet chuck, still not good enough (0.0002 was the best i could get after hitting with a brass hammer for a bit)

i ended up using the collet chuck to rough, and i finished between centers, practically zero runout, which was my biggest concern with the 6 inch one. I used DNMG - 221 S/S grade inserts, but i've have no prob in the past with general purpose inserts, i wanted the s/s inserts because i took a light skim cut (0.0005) to 'true' up the 0.500 diameter for chucking (@ 2000 RPM 0.002 feed) I'd run it faster if i could but thats the fastest my manual lathe runs and it would take too long to program and set up on one of the CNC lathes. the 1 rad (1/64) TNR is great for undercutting fillets (which i always do on tooling)

these four were made from 1/2 inch O-1 drill rod, my favorite/most common side project material..bearings were pressed on. all of them (except for the 2inch stub) have turned 0.500 and 0.375 dia for chucking (my two most commonly used collets)

on a 5 month old Haas VF-1 the 6 inch had 0.0001 repeatability or better (after touching off the 1-2-3 block, i zeroed the operator page, backed off and found the edge again, the next ten or so times i found that edge the op page read +0.0001)...done at 1000 RPM

the three others have shitty bearings and i'll prob be replacing them in the future, but good enough for a manual mill with 0.0005 repeatability on a POS Dahlih mill

with the short ones on a manual mill, theres nothing to break, and if you go too far the table will go no where further (hand feed talkin here)

its a great design thats highly customizable and modifiable for whatever your needs are.

*Bastard - aka oddball aka awkward Op. 2 setups, awkward castings, SNAFU jobber type stuff