Divided He ad

Well-Known Member

- Joined

- Mar 21, 2008

- Messages

- 549

- Reaction score

- 2

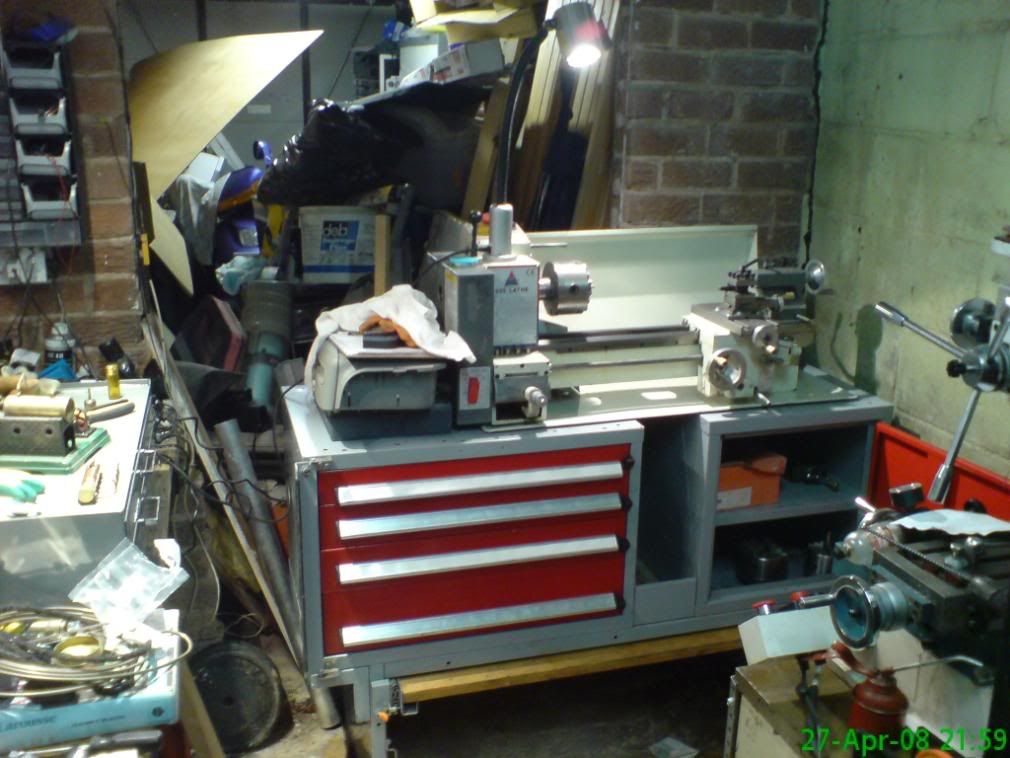

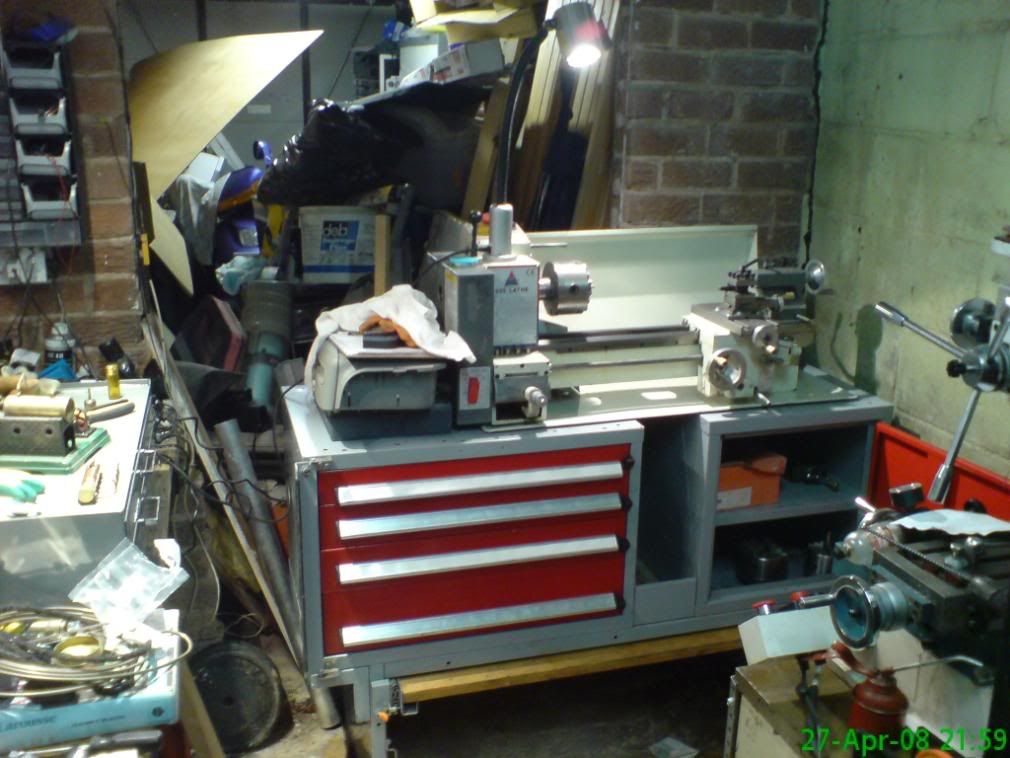

Well I finally decided to reorganise my little shop... Well I had to really since I just purchased a new bench for my lathe to sit on!

A couple of photo's... bear in mind I have no where near finished yet.... For a start I am going to go next door and find out what is causing all that damp up the wall by my mill!!

This is a bit through the days work. Mill on the floor (well heavy !!) and bench and lathe stacked with stuff to get it out of the way!

Mill in it's new home. Not plugged in yet but won't be long.

New bench in and lathe moved on to it ;D

Still lots to do... as you can see!! But I will get it done soon, Can't carry on working otherwise!

Ralph.

A couple of photo's... bear in mind I have no where near finished yet.... For a start I am going to go next door and find out what is causing all that damp up the wall by my mill!!

This is a bit through the days work. Mill on the floor (well heavy !!) and bench and lathe stacked with stuff to get it out of the way!

Mill in it's new home. Not plugged in yet but won't be long.

New bench in and lathe moved on to it ;D

Still lots to do... as you can see!! But I will get it done soon, Can't carry on working otherwise!

Ralph.