DICKEYBIRD

Well-Known Member

- Joined

- Sep 27, 2007

- Messages

- 653

- Reaction score

- 46

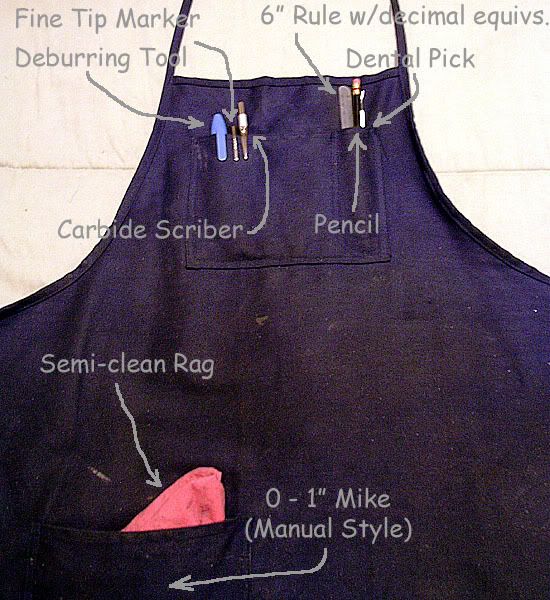

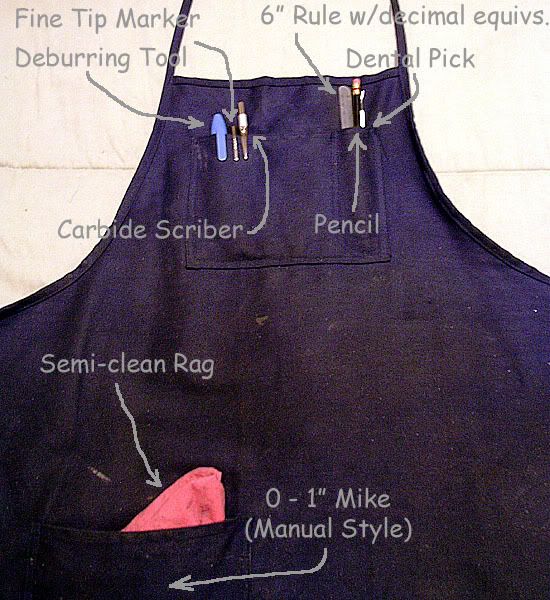

Here's a tip that is probably obvious to most of you but didn't occur to me until a few months ago.

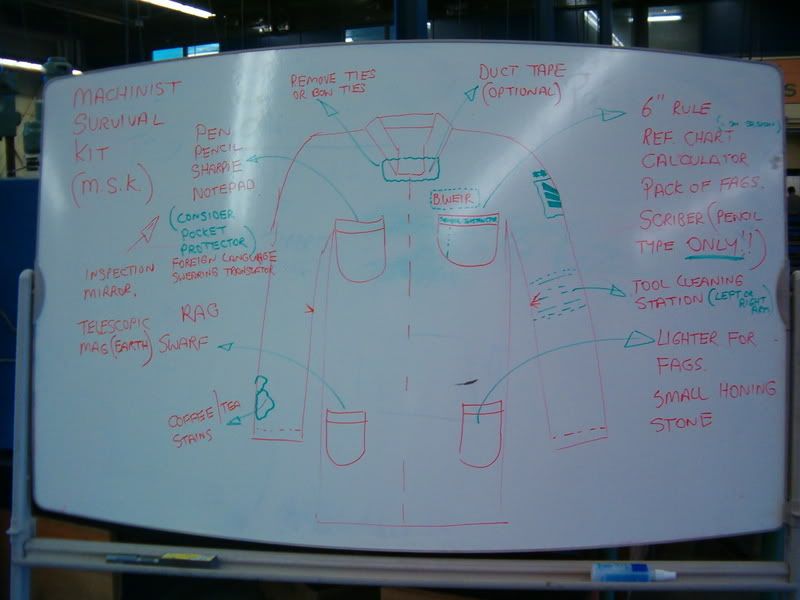

A shop apron is a great weapon to add to the workshop. I don't do a thing in my shop without 1st tying on an apron fitted with the basic accessories shown here. It performs the obvious role of keeping oil & debris off your shirt and britches but more importantly it stores the often-used gadgets close to hand. After a few hours of use, your hands will go right to that needed tool instantly. No wasting time fumbling around looking for it!

Oh yeah, almost forgot, right after the apron goes on, I put on a pair of thin, nitrile gloves. Keeps the hands clean & tidy for caressing your sweetie at a moment's notice but not strong enough to suck a hand into the spinning machinery.

A shop apron is a great weapon to add to the workshop. I don't do a thing in my shop without 1st tying on an apron fitted with the basic accessories shown here. It performs the obvious role of keeping oil & debris off your shirt and britches but more importantly it stores the often-used gadgets close to hand. After a few hours of use, your hands will go right to that needed tool instantly. No wasting time fumbling around looking for it!

Oh yeah, almost forgot, right after the apron goes on, I put on a pair of thin, nitrile gloves. Keeps the hands clean & tidy for caressing your sweetie at a moment's notice but not strong enough to suck a hand into the spinning machinery.