B

Bogstandard

Guest

On my usual troll thru u-tube I came across this little vid.

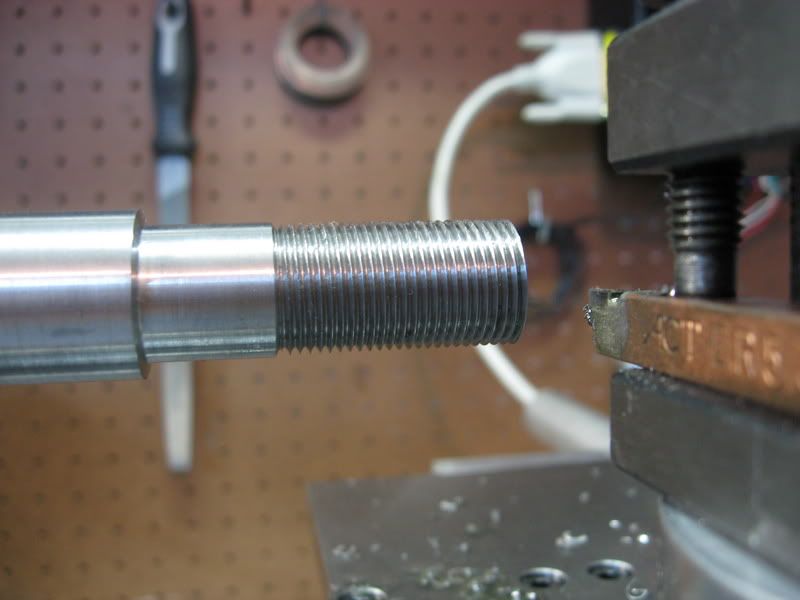

It is totally boring, but if you have never tried screwcutting (and we have talked about this before) this shows it is really not difficult to do, and saves a lot of time and money for those one offs that you would go out and buy a die for and only ever use the once.

[youtube=425,350]0q_q53wsyHU&rel[/youtube]

Plus everything is concentric, not always possible when using a die.

Maybe we can have a bit of follow up on this for those who haven't got this under their belt yet. It is definitely worth trying.

John

It is totally boring, but if you have never tried screwcutting (and we have talked about this before) this shows it is really not difficult to do, and saves a lot of time and money for those one offs that you would go out and buy a die for and only ever use the once.

[youtube=425,350]0q_q53wsyHU&rel[/youtube]

Plus everything is concentric, not always possible when using a die.

Maybe we can have a bit of follow up on this for those who haven't got this under their belt yet. It is definitely worth trying.

John