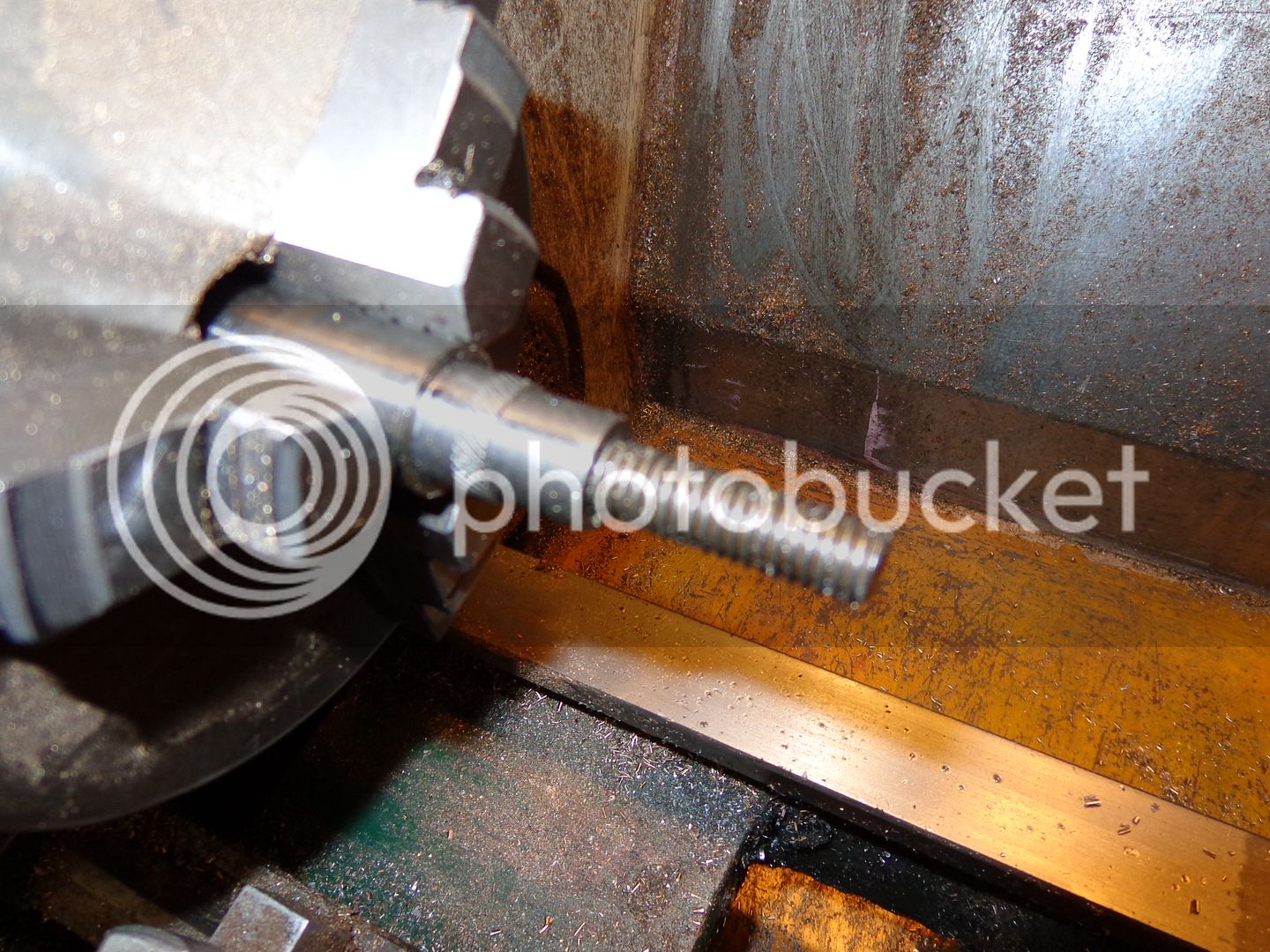

Here is the second part of the quill stop bolted into place. The reason I changed the bracket design was because the original one shrouded the reverse switch and start/stop button too much for my taste. The temporary 3/8" bolt I screwed into it was just to prove to myself that it does indeed miss the M5 bolts which will hold the final part to the side of the machine head, and it does---barely. A strange thing happened. When I removed the rectangular box which originally served as a mount for the plexiglass chip guard, there were two wires hanging out of the larger hole in the side of the milling machine head that were supposed to recognize whether or not the plexiglass guard was in place. That switch never worked from day one. I removed the switch and seperated the wires, and the machine wouldn't run. I twisted them together and the machine ran fine, so i soldered them together, taped them up, and shoved them up in the machine head to get them out of the way. (there are no moving parts inside the machine head casting). The strange thing is, that I took a picture of them, loaded the pictures onto Photobucket, and the damned picture dissapeared. Photobucket somehow deleted it off my camera but didn't save it either. I'm using the new Photobucket format, and find it rather "Hinky".