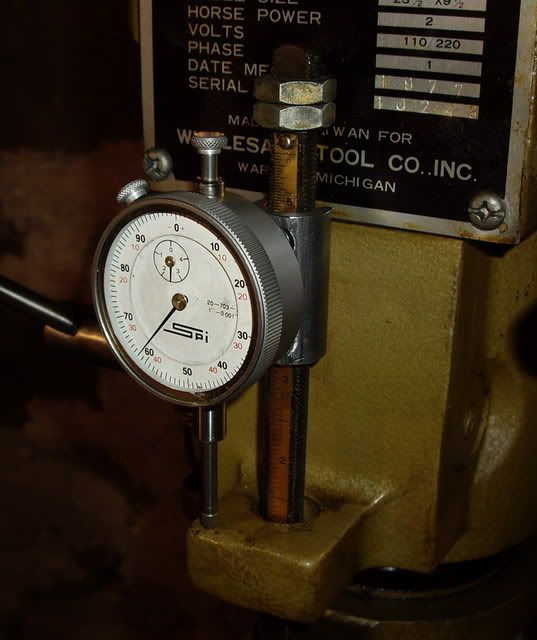

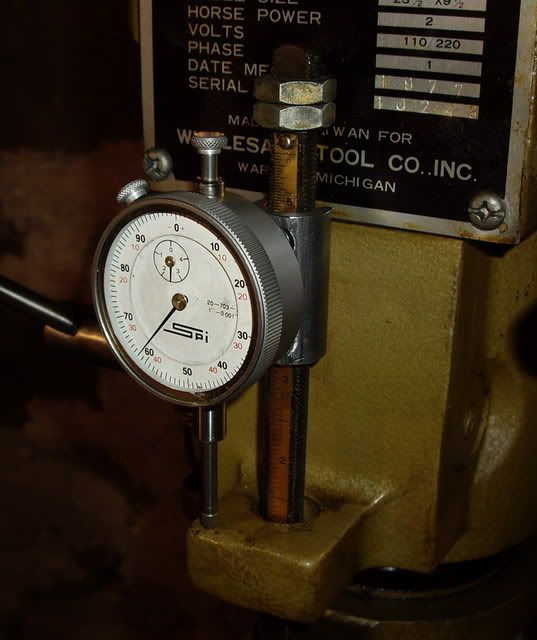

Hi all. One of my frustrations has been depth control on the mill, with no readout. I came up with this indicator holder. It slips on real easy, magnets hold it fairly secure. There's a flat on the thread rod for the magnets to locate on.

I started with a round piece 1" dia x 1-1/2" long. Drill / tap 1/2-20 for the scale on the quill. Mill out a slot so I can put it on from the front. I went about 3/8" deep on the cut. Inset a couple of rare earth magnets from the craft store. I cut 1/2" dia holes for 3/8 dia magnets, set in with epoxy so the magnets don't touch the indicator holder. A little slot on the side for the indicator lug and here it is. It's got a few shortfalls from the digi-cal readouts, but it seemed pretty quick and easy for me to do. Without the indicator, it also works as a quill stop for drilling, etc., not having to spin those #%&@ nuts down.

Hope someone finds this of use or can improve on it...

DB

I started with a round piece 1" dia x 1-1/2" long. Drill / tap 1/2-20 for the scale on the quill. Mill out a slot so I can put it on from the front. I went about 3/8" deep on the cut. Inset a couple of rare earth magnets from the craft store. I cut 1/2" dia holes for 3/8 dia magnets, set in with epoxy so the magnets don't touch the indicator holder. A little slot on the side for the indicator lug and here it is. It's got a few shortfalls from the digi-cal readouts, but it seemed pretty quick and easy for me to do. Without the indicator, it also works as a quill stop for drilling, etc., not having to spin those #%&@ nuts down.

Hope someone finds this of use or can improve on it...

DB