compound driver 2

Well-Known Member

- Joined

- Jan 3, 2008

- Messages

- 207

- Reaction score

- 1

Hi

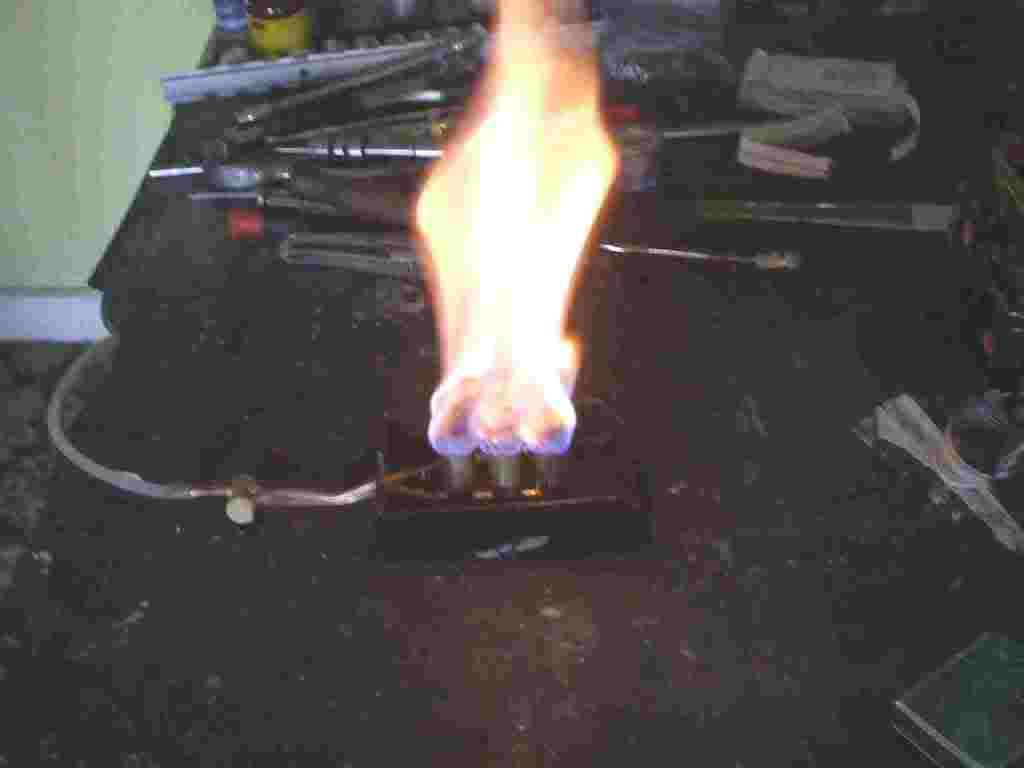

The following burner was made in desperation to overcome the lack of decent coal thats available at the moment. All i seem to be getting is Either Polish or Russian coal and both are little better than slate clinkering at the first sign of hard work and producing huge amounts of ash when not working. I was so fed up with not being able to get a decent fire in my small traction engine I cobbled together the following.

The burner its self is made from six 1.25 inch long 1/2 inch diameter brass tubes with a brass plug silver soldered into the bottom of each tube. The feed pipe for the meth is 5/32 thin wall copper passed through the bottoms of the brass tubes and then pierced after silver soldering in place. Keep the feed tubes as low in the wick tubes as you can.

I arranged the wick tubes in two lines of three with a balance pipe on the end two wick tubes. Along with a feed to both banks of wicks this allows a good feed of meth when running.

As can be seen the two feed pipes link into a manifold for the meth. All in all the burner took about half hour to make and infact it took longer sorting out the wick length.

these are great little burners for for small engines be it a gauge 1 loco or a small traction engine. The one big advantage over gas is that if you run out of steam in the boiler on a meth burner the flame will go out reducing the risk of damage to the boiler.

The only down side is you do still need to give the fire ad raft to get it going and the steam blower will have to be used to keep the fire going if the engine isnt running.

The burner could cope with some cleaning up and the pipes being arranged a bit better but atleast now and until some decent coal turns up i can steam the engine.

Worth remembering that good quality methalated spirit burns with an almost invisible flame so take care when your using the burner. I added a drop of paraffin to the meth to give the flame some colour for the picture.

cheers kevin

Cheers kevin

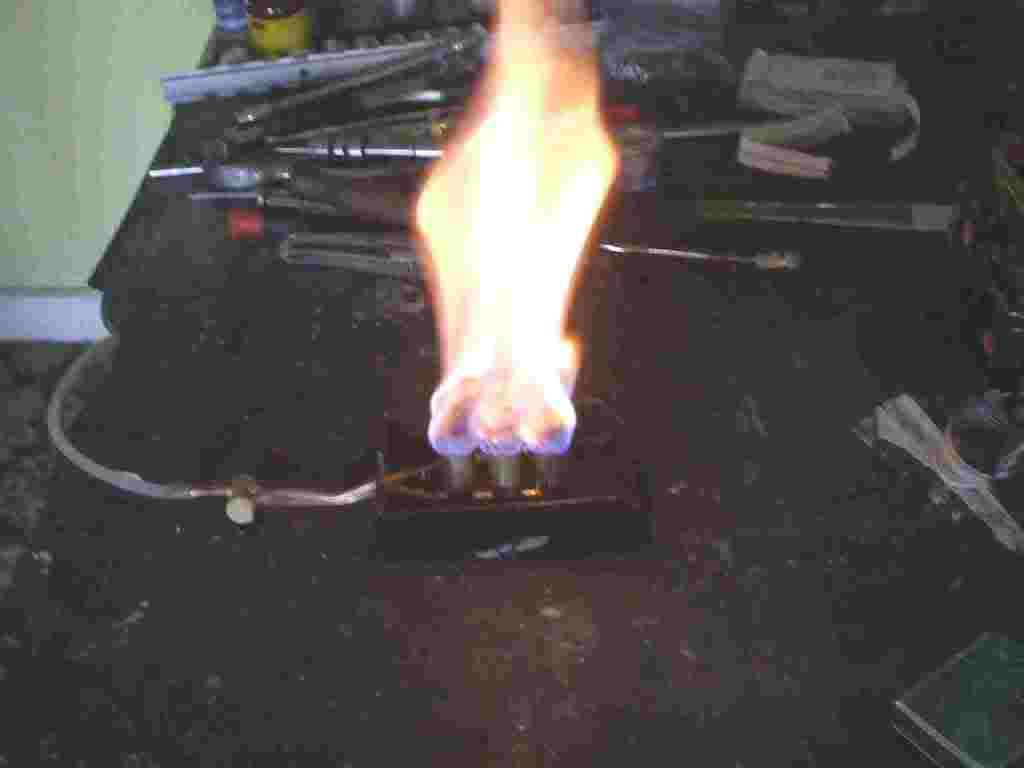

The following burner was made in desperation to overcome the lack of decent coal thats available at the moment. All i seem to be getting is Either Polish or Russian coal and both are little better than slate clinkering at the first sign of hard work and producing huge amounts of ash when not working. I was so fed up with not being able to get a decent fire in my small traction engine I cobbled together the following.

The burner its self is made from six 1.25 inch long 1/2 inch diameter brass tubes with a brass plug silver soldered into the bottom of each tube. The feed pipe for the meth is 5/32 thin wall copper passed through the bottoms of the brass tubes and then pierced after silver soldering in place. Keep the feed tubes as low in the wick tubes as you can.

I arranged the wick tubes in two lines of three with a balance pipe on the end two wick tubes. Along with a feed to both banks of wicks this allows a good feed of meth when running.

As can be seen the two feed pipes link into a manifold for the meth. All in all the burner took about half hour to make and infact it took longer sorting out the wick length.

these are great little burners for for small engines be it a gauge 1 loco or a small traction engine. The one big advantage over gas is that if you run out of steam in the boiler on a meth burner the flame will go out reducing the risk of damage to the boiler.

The only down side is you do still need to give the fire ad raft to get it going and the steam blower will have to be used to keep the fire going if the engine isnt running.

The burner could cope with some cleaning up and the pipes being arranged a bit better but atleast now and until some decent coal turns up i can steam the engine.

Worth remembering that good quality methalated spirit burns with an almost invisible flame so take care when your using the burner. I added a drop of paraffin to the meth to give the flame some colour for the picture.

cheers kevin

Cheers kevin