Can anyone tell me if there is a benefit or disadvantage of using PTFE packing over graphite yarn.

The reason I'm asking is I just received my gradfathers Stuart 10V he build in the 1980s but it is in need of an overhaul and I'm making a list of what I need to order at the moment.

Besides it being made by my grandfather this engine has another reason its special to me.

When I was 13 I spent 2 weeks with my grandfather in Sydney (I live in Perth about 4500km away) and he showed me his not long built Stuart. As I showed so much interest in it he found and gave me his old 'toy' steam engine.

It is because of this engine I took the interest in model engineering.

If I had never seen it I probably wouldn't have a workshop.

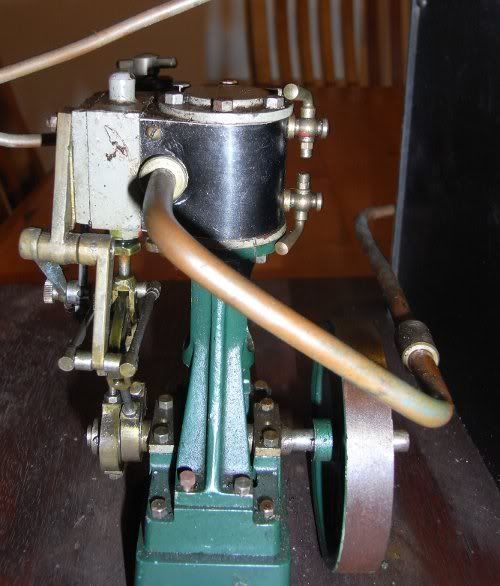

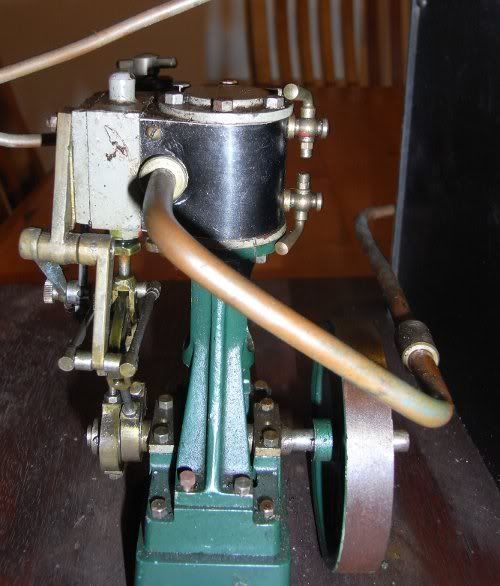

ANd now of course just a few photos and yes the Stuart 504 boiler came with it which is huge!

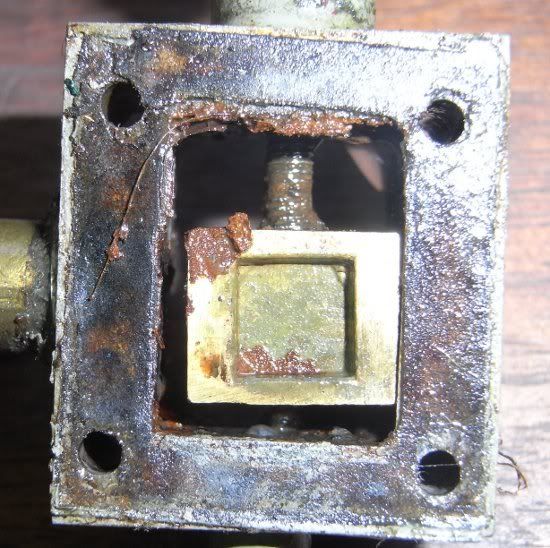

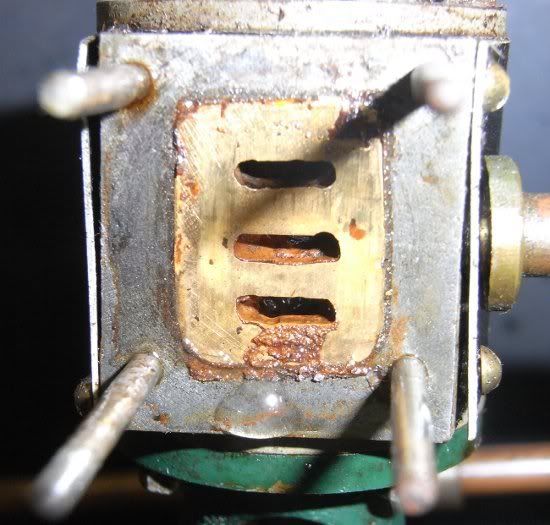

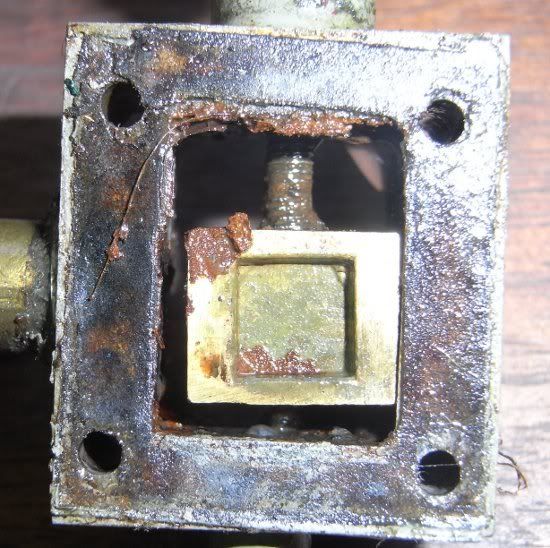

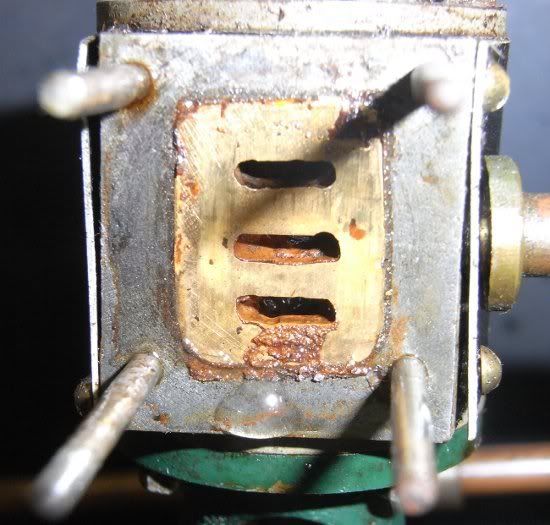

Here is why I'm stripping it down.

The reason I'm asking is I just received my gradfathers Stuart 10V he build in the 1980s but it is in need of an overhaul and I'm making a list of what I need to order at the moment.

Besides it being made by my grandfather this engine has another reason its special to me.

When I was 13 I spent 2 weeks with my grandfather in Sydney (I live in Perth about 4500km away) and he showed me his not long built Stuart. As I showed so much interest in it he found and gave me his old 'toy' steam engine.

It is because of this engine I took the interest in model engineering.

If I had never seen it I probably wouldn't have a workshop.

ANd now of course just a few photos and yes the Stuart 504 boiler came with it which is huge!

Here is why I'm stripping it down.