- Joined

- Mar 3, 2008

- Messages

- 243

- Reaction score

- 20

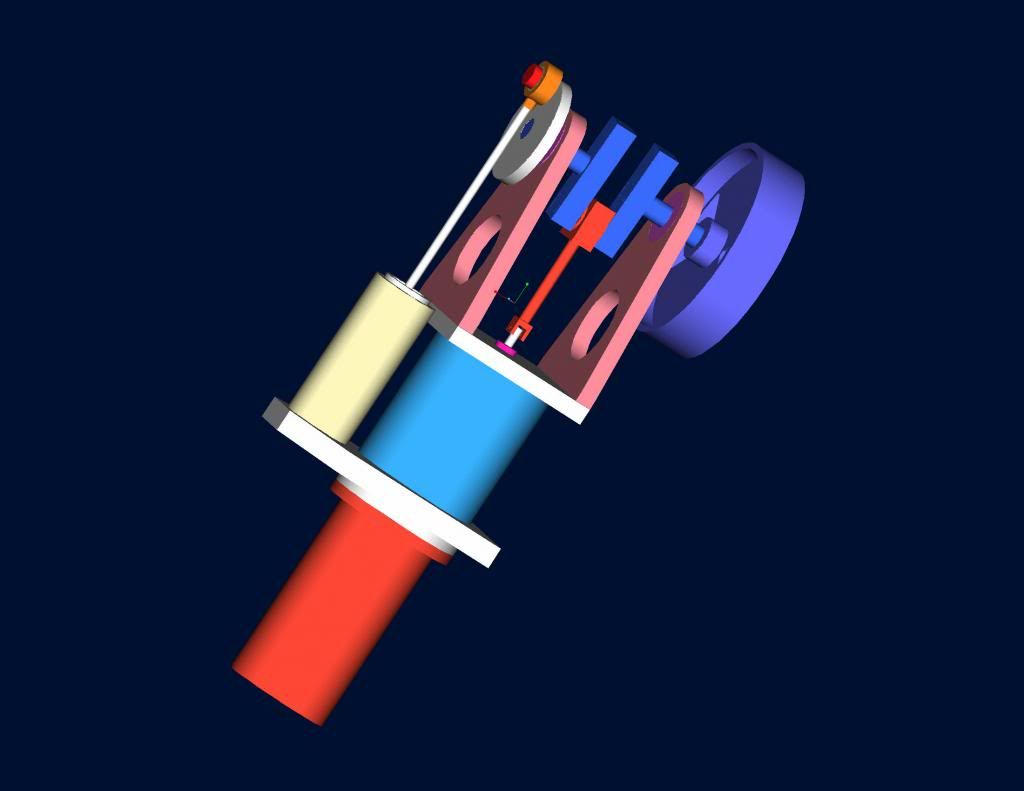

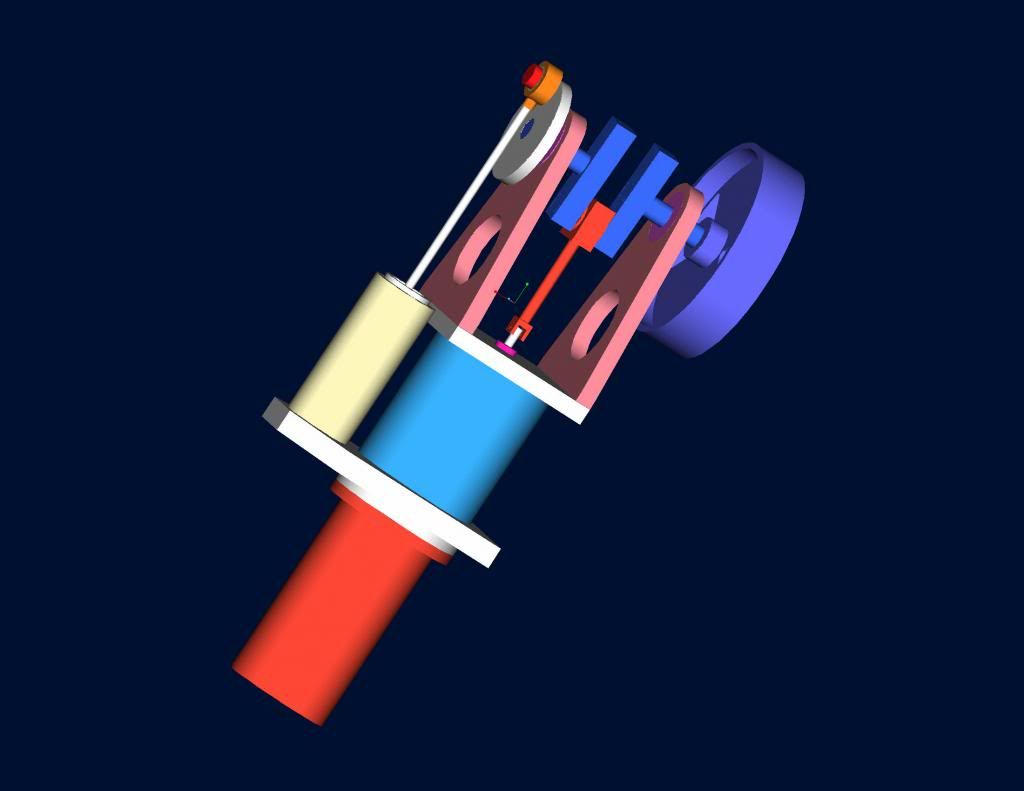

Well I woke up one day late last year yearning to build a whacky engine. You know the kind; Large, made from reclaimed parts, lots of pipes and spinning things and no bling. I started with the Moriya engine plans. I like this design because you can scale it up or down and it always works. Basically it is a 2X scale engine with water cooling. I modeled the engine in Pro/Engineer first to make sure everything worked and to work out all the dimensions.

I found this Made in Taiwan miniature pot-bellied stove at a local Antique/Junk store. I am sure it was meant to be purely ornamental, but with working dampers, grate, ash tray and provision for a chimney, it was perfect! I fabricated a chimney up out of some pipe and sheet metal and mounted the engine to the top. The engine will run at 400Rpm with a nice fire below.

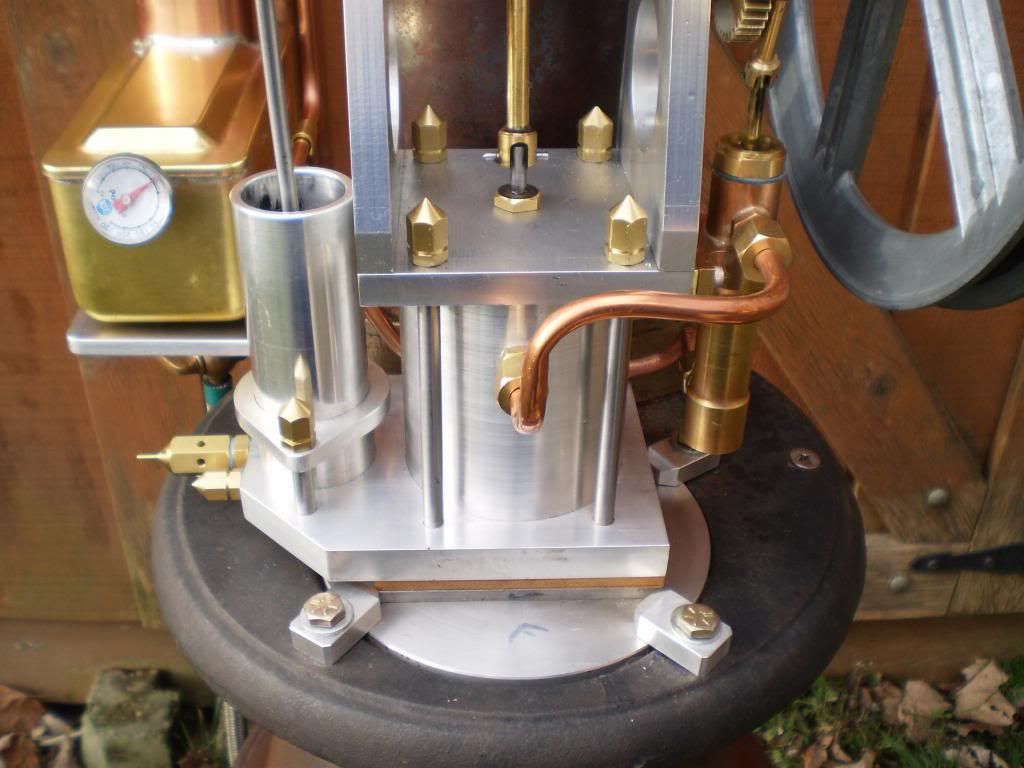

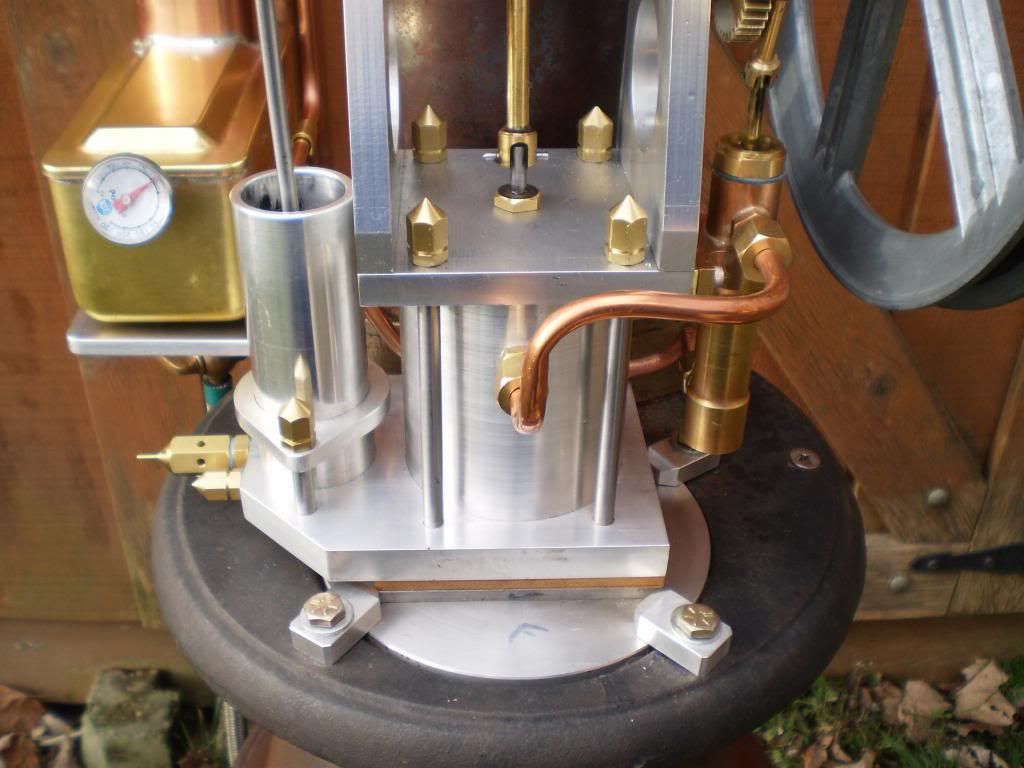

The cold cylinder was made from 2 pieces of aluminum tubing. I machined the inner tube so it would fit inside the outer tube, and then hogged out the inside of the outer tube. I then sandwiched them between two thick plates.

The power cylinder is mounted in what I call a flying Flangemethod and the piston inside is from graphite.

The pump is basically the same as the one used on the Ericson Hot Air Engine, with a few minor modifications.

The brass water reservoir is a part I found in the garbage at work, I think it is for a de-humidifier. It had a float attached to one end,which I cut out and soldered the copper pipe to. I also added a small Cookingthermometer so I can monitor the water temperature.

Although Hot Air Engines are inherently safe, I made apressure relief valve just in case. I figured that since this is water cooled,and there is only a gasket to seal it, If ever there was a leak of water into the hot cylinder, I would have a sealed Boiler! This would be very dangerous,so I made the valve to be on the safe side.

It ran the first time real good. It will run at 300RPM witha propane torch on full, but it will run forever at 100RPM on the smallest flame (¼) I can get on the torch. There may be some more power available to run a small generator,but first I am going to do a propane conversion so I can run it inside this winter.

And finally a Video. It was -4Deg C this morning when I made this.

IronHorse

I found this Made in Taiwan miniature pot-bellied stove at a local Antique/Junk store. I am sure it was meant to be purely ornamental, but with working dampers, grate, ash tray and provision for a chimney, it was perfect! I fabricated a chimney up out of some pipe and sheet metal and mounted the engine to the top. The engine will run at 400Rpm with a nice fire below.

The cold cylinder was made from 2 pieces of aluminum tubing. I machined the inner tube so it would fit inside the outer tube, and then hogged out the inside of the outer tube. I then sandwiched them between two thick plates.

The power cylinder is mounted in what I call a flying Flangemethod and the piston inside is from graphite.

The pump is basically the same as the one used on the Ericson Hot Air Engine, with a few minor modifications.

The brass water reservoir is a part I found in the garbage at work, I think it is for a de-humidifier. It had a float attached to one end,which I cut out and soldered the copper pipe to. I also added a small Cookingthermometer so I can monitor the water temperature.

Although Hot Air Engines are inherently safe, I made apressure relief valve just in case. I figured that since this is water cooled,and there is only a gasket to seal it, If ever there was a leak of water into the hot cylinder, I would have a sealed Boiler! This would be very dangerous,so I made the valve to be on the safe side.

It ran the first time real good. It will run at 300RPM witha propane torch on full, but it will run forever at 100RPM on the smallest flame (¼) I can get on the torch. There may be some more power available to run a small generator,but first I am going to do a propane conversion so I can run it inside this winter.

And finally a Video. It was -4Deg C this morning when I made this.

IronHorse